PP wave plate production line

A production line and corrugated board technology, which is applied in the field of PP sheet and board production equipment, can solve the problems of being unable to produce PP corrugated boards and meet the technological requirements of PP corrugated boards, and achieve the effect of meeting the production process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

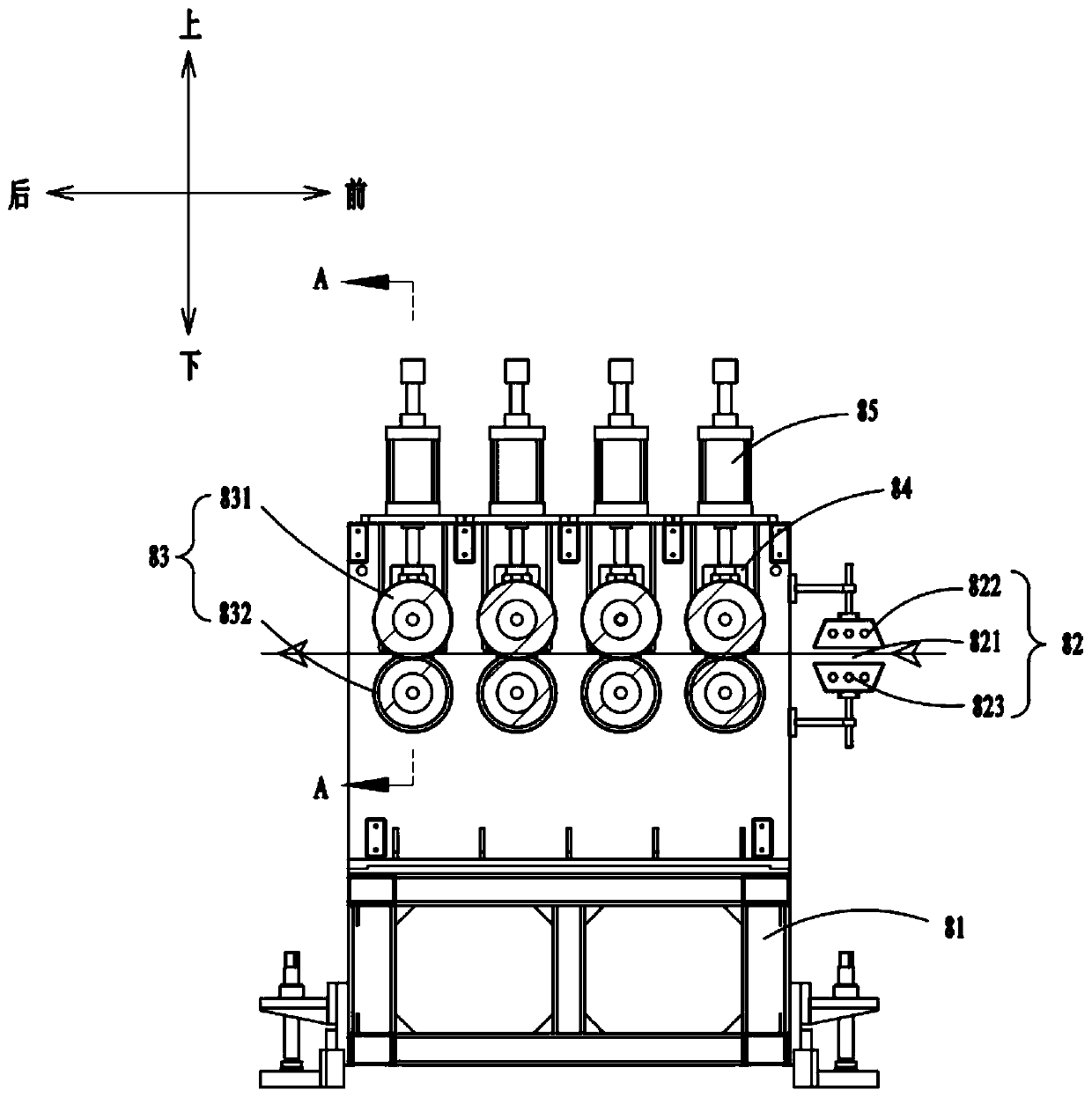

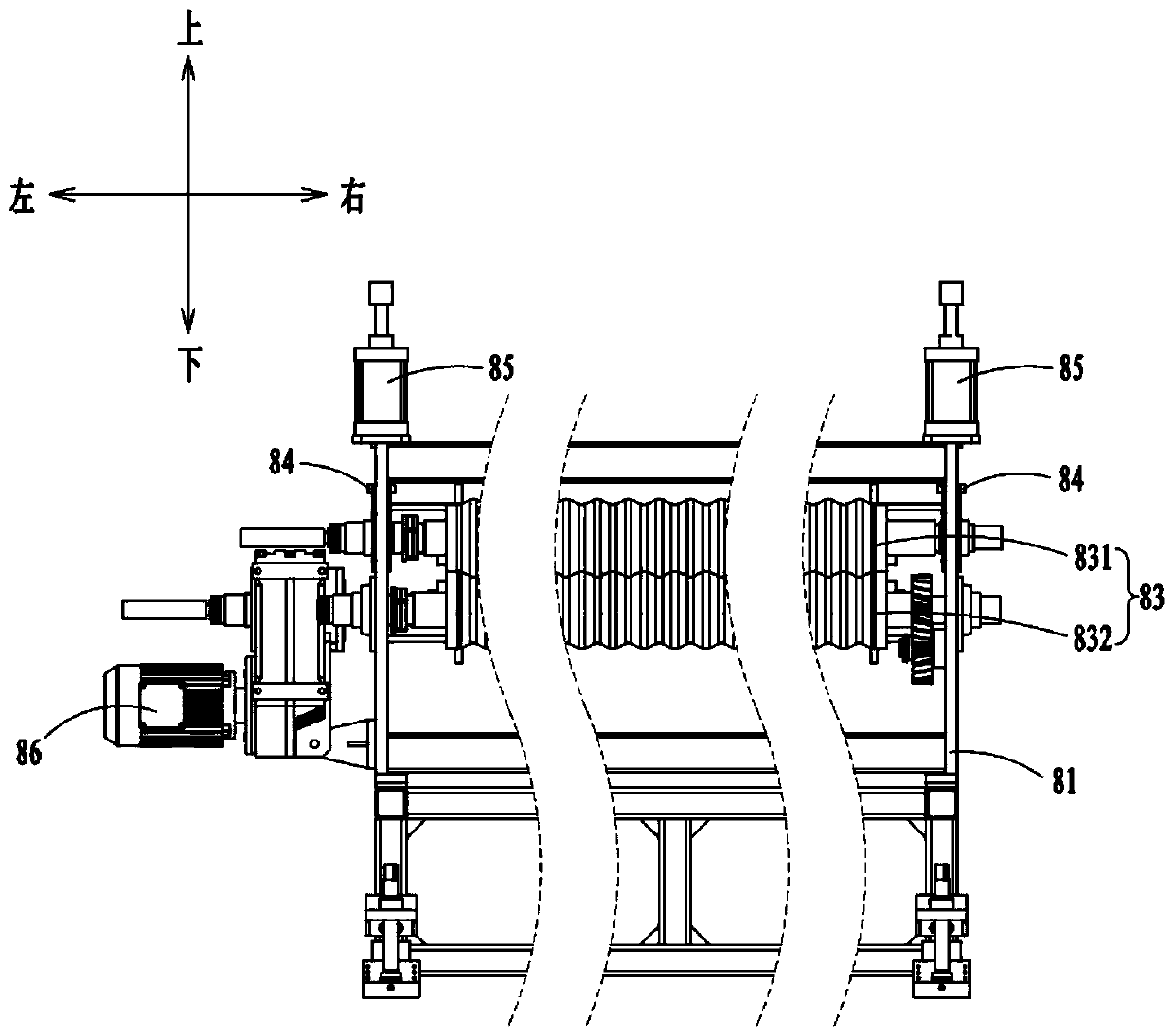

[0045] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. Among them, the upstream described in this embodiment refers to figure 1 In the direction of the side where the plastic extruder is located, the downstream refers to figure 1 The side direction of the stacker shown in , the above, up, down, left, right, front and back refer to Figure 2-Figure 4 in and Figure 7-Figure 8 Each positional relationship shown in corresponds to each other.

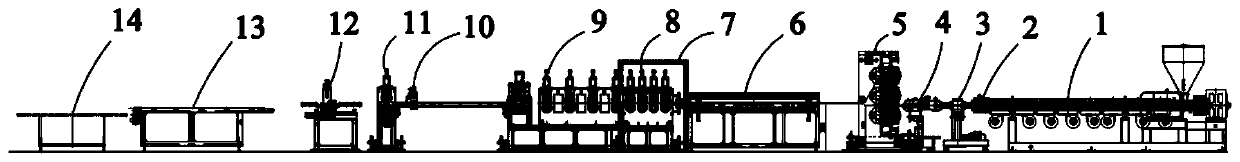

[0046] Such as figure 1As shown, according to the production process sequence of PP corrugated sheets, along the direction from upstream to downstream, the PP corrugated sheet production line includes plastic extruder 1, mold 4, three-roll calender 5, wave forming machine 8, wave setting machine 9, Edge trimming device 10 , tractor 11 , shearing machine 12 , conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com