Method for controlling content of biuret in compound fertilizers for melt granulation in prilling tower

A control method and technology for compound fertilizers, which are applied to urea compound fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of reducing urea, particle blockage, and limited cooling range, so as to reduce the generation of biuret, save production costs, and reduce The effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

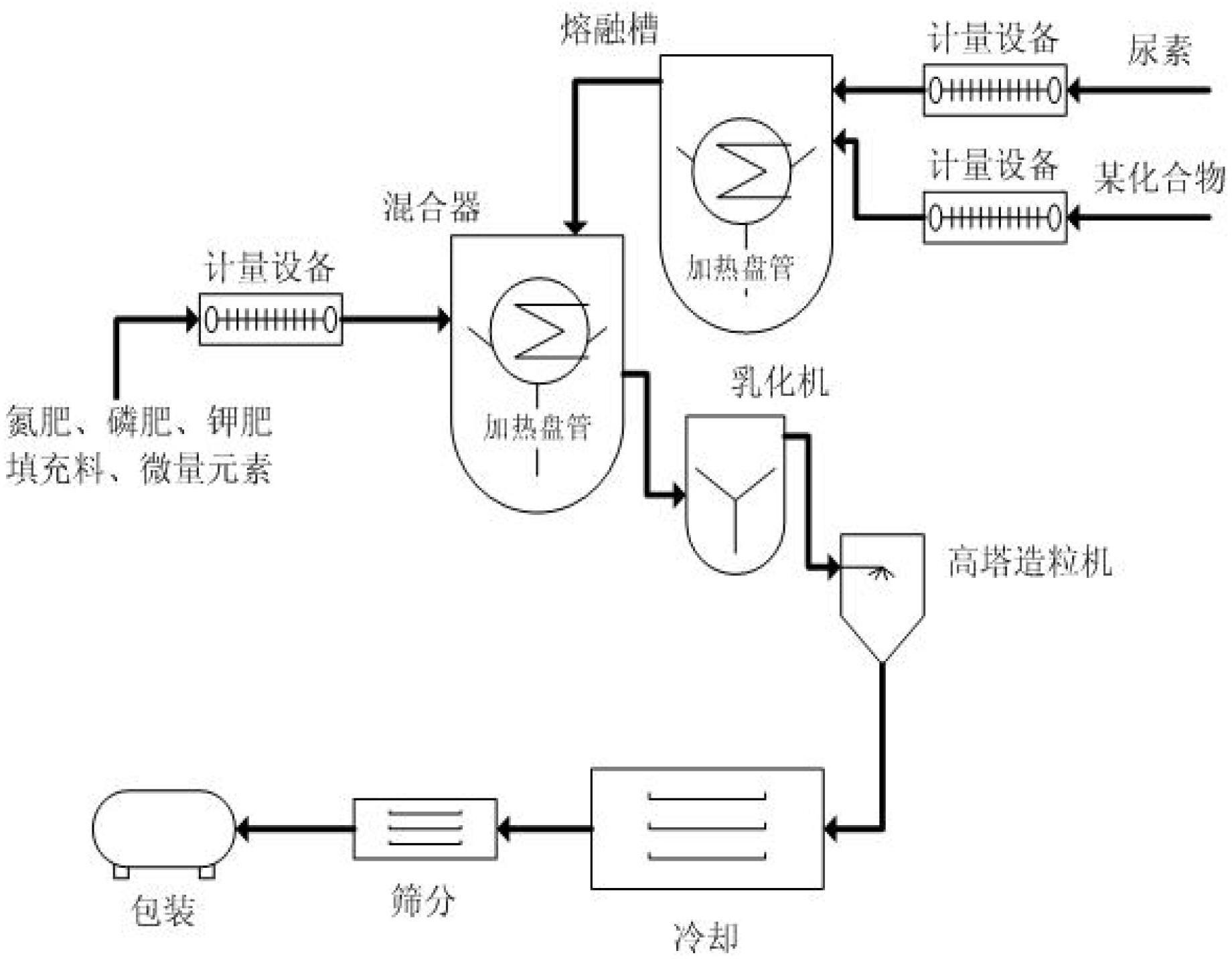

Method used

Image

Examples

Embodiment 1

[0039] a) Transport 35kg of urea to the melting tank through the conveying equipment, and add 3kg of potassium chloride and 1kg of ammonium nitrate to form a eutectic system, and the material forms molten urine at 114°C; the melting tank is equipped with an automatic overflow device, continuous Production feed, when the liquid level exceeds a certain level, the molten urine will automatically overflow to the mixer;

[0040] b) Overflow the molten urine to the mixer, and add 2kg of ammonium chloride, 12kg of potassium sulfate, 30kg of dolomite powder, 16kg of monoammonium phosphate, and 1kg of trace elements (zinc sulfate, manganese sulfate mixture) to make it in the mixer , Pre-mixing at 102°C; the mixer is equipped with an automatic overflow device for continuous production, and when the liquid level exceeds a certain level, the slurry will automatically overflow to the emulsifier;

[0041] c) Flow the pre-mixed mixture into a constant temperature slurry emulsifier for emulsi...

Embodiment 2

[0047] a) Transport 25kg of urea to the melting tank through the conveying equipment, and add 3kg of potassium chloride, 0.5kg of ammonium nitrate and 0.5kg of water to form a eutectic system, and the materials form molten urine at 110°C;

[0048] b) Overflow the molten urine to the mixer, and add 20kg of potassium chloride, 40kg of dolomite powder, 10kg of monoammonium phosphate, and 1kg of trace elements (ferrous sulfate, ammonium molybdate mixture), make it in the mixer, in the Pre-mixed at 108°C;

[0049] c) Flow the pre-mixed mixture into a constant temperature slurry emulsifier for emulsification to obtain emulsified slurry;

[0050] d) Pass the emulsified slurry into the high tower granulator for spray granulation;

[0051] e) Collecting, cooling and sieving the compound fertilizer particles obtained in step d to obtain compound fertilizer.

[0052] The obtained compound fertilizer is a high tower melt granulation compound fertilizer containing 12.55% (mass) of nitrogen...

Embodiment 3

[0055] a) Transport 45kg of urea to the melting tank through conveying equipment, and add 4kg of ammonium chloride, 2kg of potassium chloride and 1kg of water to form a eutectic system, and the materials form molten urine at 108°C;

[0056] b) Overflow the molten urine to the mixer, and add 25kg of ammonium chloride, 5kg of ammonium sulfate, 5kg of potassium chloride, 12kg of monoammonium phosphate, and 1kg of trace elements (mixture of ferrous sulfate, borax, and ammonium molybdate) to make It is premixed in a mixer at 105°C;

[0057] c) Flow the pre-mixed mixture into a constant temperature slurry emulsifier for emulsification to obtain an emulsified slurry; the emulsification temperature is 105°C;

[0058] d) Pass the emulsified slurry into the high tower granulator for spray granulation; the granulation temperature is 105°C;

[0059] e) Collecting, cooling and sieving the compound fertilizer particles obtained in step d to obtain compound fertilizer.

[0060] The obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com