One-step completing method for chemical finishing of yarn cone before weaving

A chemical finishing and process technology, applied in textiles and papermaking, textile material treatment, textile material continuous treatment, etc., can solve problems such as large liquor ratio, uneven softness, environmental pollution, etc., and achieve non-destructive and volatile, surface Smooth and soft, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

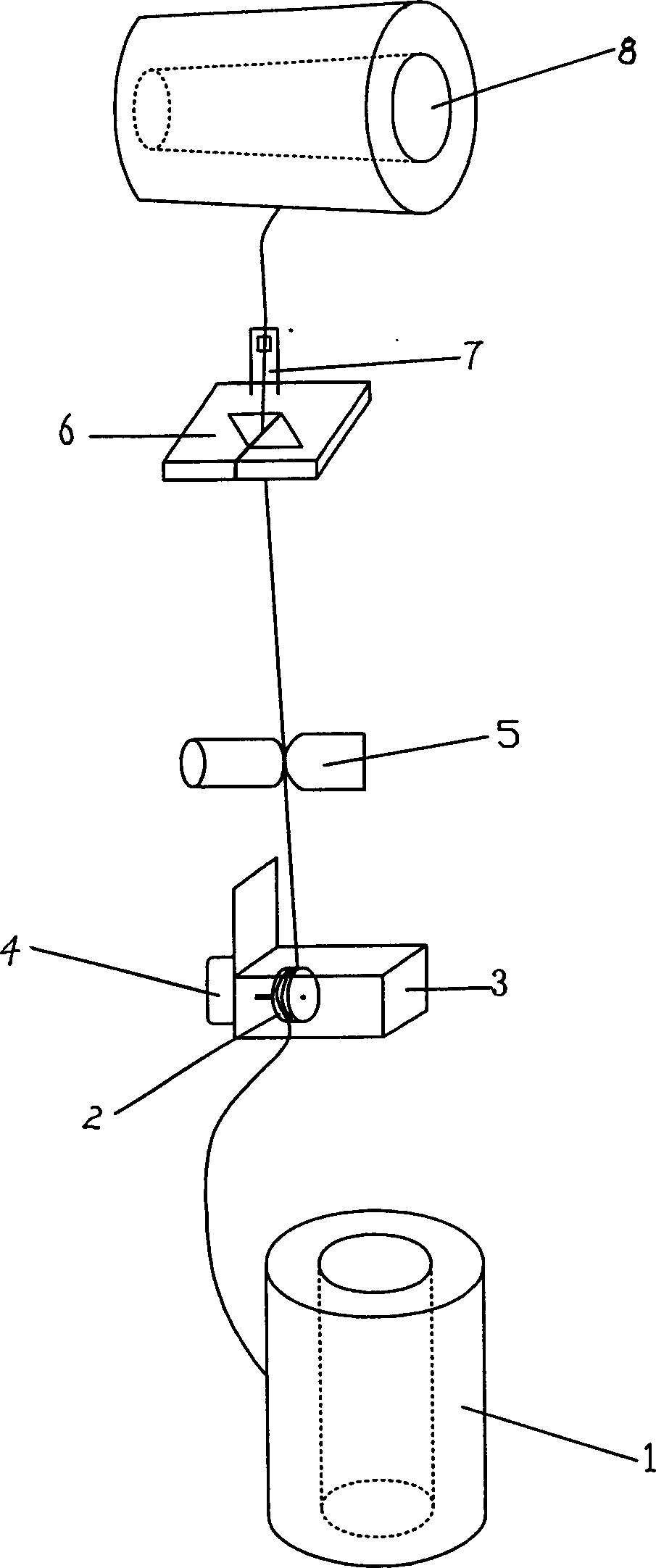

[0025] Such as figure 1 As shown, it is a one-step process flow chart of the yarn winding chemical finishing process before weaving. The yarn 1 is installed with an oil tank in front of the tension regulator 5 between the yarn guide to the yarn shaft 8, yarn clearing and winding. 3. A guide roller 2 with a motor 4 is installed in the oil tank 3, and a far-infrared drying device 7 is added behind the yarn breaking and clearing sensor 6.

[0026] The yarn is the yarn spun from natural cellulose fibers, and the chemical materials used in softening, sizing, waxing and smoothing chemical finishing process are composed of 20 parts of softening agent, 30 parts of sizing agent, 30 parts of textile wax, smoothing agent 5 parts, 15 parts of diluent. Add the weighed chemical materials into the oil tank 3 after compounding;

[0027] The softness, sizing, waxing and smoothing chemical finishing process of the yarn spun from natural cellulose fiber is completed in the winding process afte...

Embodiment 2

[0035] The yarn is chemical fiber filament, soft, antistatic, and smooth. The composition of chemical materials used in the chemical finishing process is: 25 parts of softening agent, 25 parts of antistatic agent, 5 parts of smoothing agent, and 45 parts of thinner.

[0036] The chemical fiber filament is soft, antistatic, and smooth. The line speed of the chemical finishing process is 15 m / s, the temperature is 20 ° C, and the relative humidity is 75%; the far-infrared drying device is closed in the process 1-6; other processes are the same as in Example 1 .

Embodiment 3

[0038] Yarns blended with natural cellulose fibers and chemical fibers, softening, sizing, waxing, antistatic chemical finishing process chemical materials used in percent by weight: 20 parts of softening agent, 25 parts of textile wax, 5 parts of smoothing agent, antistatic 7 parts of agent, 30 parts of sizing agent, 13 parts of thinner.

[0039] The yarn of natural cellulose fiber and chemical fiber blending, the line speed of softness, antistatic, waxing, sizing finishing is 10 m / s, temperature 20 ℃, relative humidity 70%, other processes are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com