Postage stamp gum tape automatic production line and method

An automatic production line and back tape technology, applied in the field of auto parts, can solve problems such as reducing work efficiency, easily damaging the back glue of fonts or patterns, increasing labor intensity, etc., and achieving cost-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

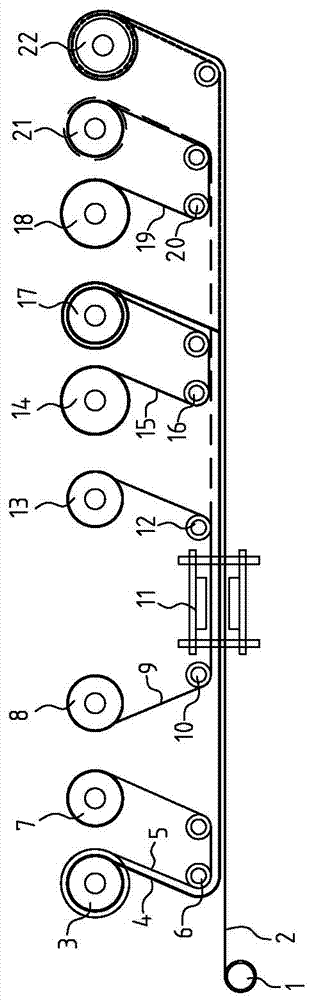

[0028] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0029] Such as figure 1 As shown, an automatic production line for back tape, which includes in sequence according to the processing sequence of materials: a release film replacement device for replacing the original release film of the original back tape, and a release film replacement device for applying the first release film on the other side of the sponge tape. A first peritoneal device for paper, a die-cutting device for die-cutting the first release paper and the sponge backing tape to form fonts or patterns, a first collection device for collecting the first release paper other than covering fonts or patterns, and Second collection unit for collecting waste adhesive. The automatic production line also includes an operation platform that runs through the release film replacement device, the first peritoneal device, the die-cutting device, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com