Circulation evaporator

An evaporation device and evaporation liquid technology, applied in the field of evaporation system, can solve the problems of no obvious improvement in energy saving effect, large number of system equipment, complex control system, etc., to meet the needs of production process, control links and investment, The effect of low evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

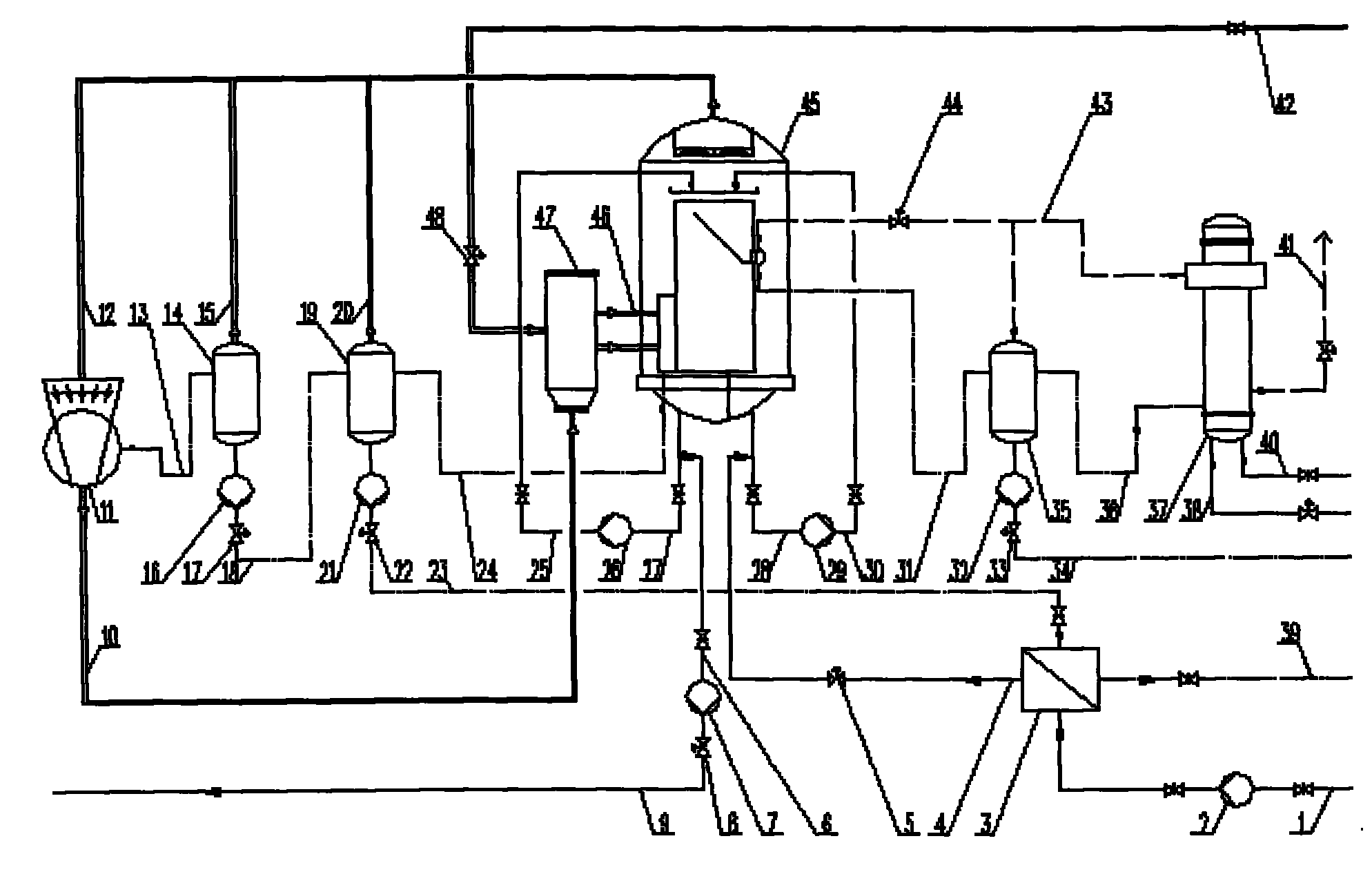

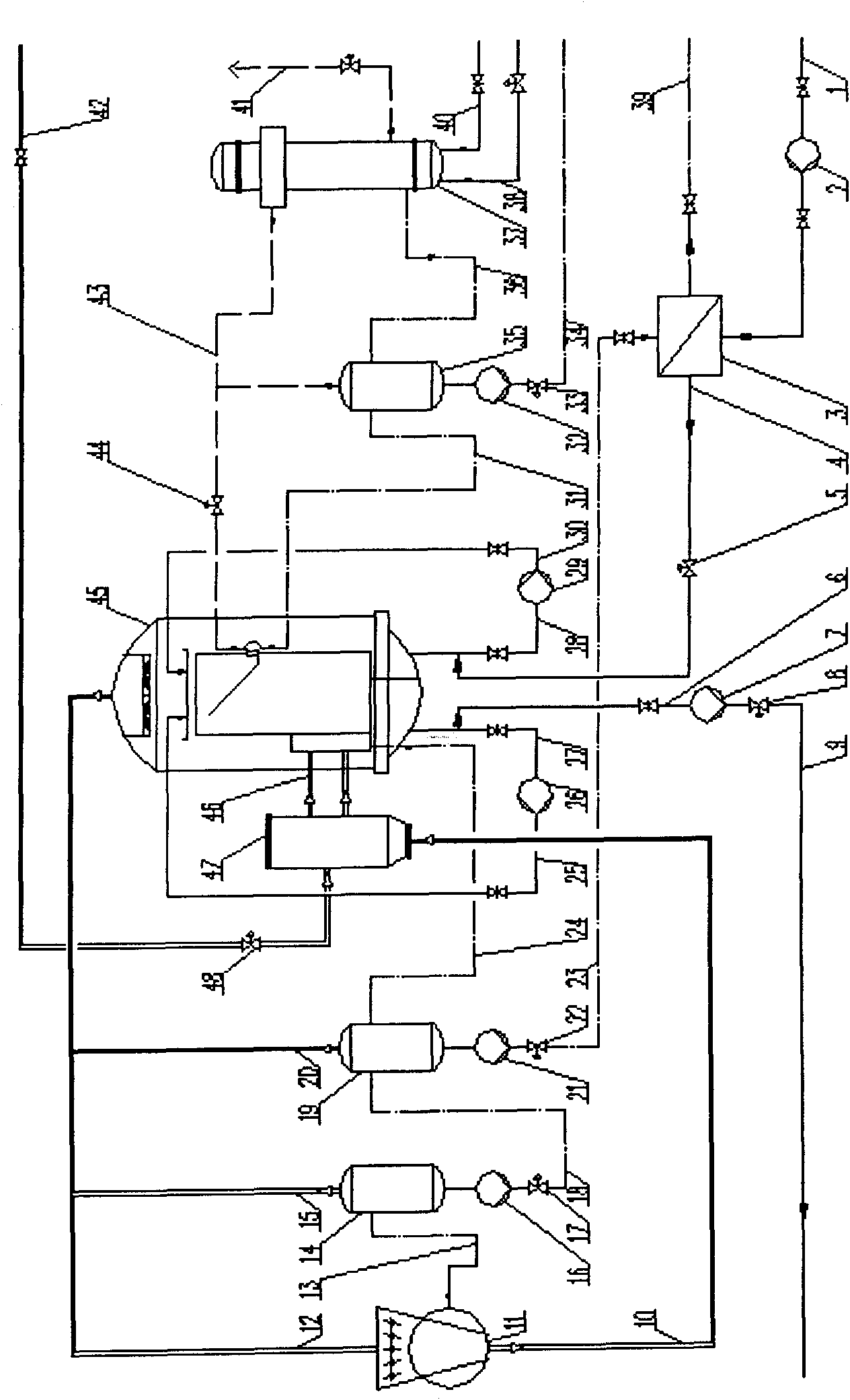

[0018] FIG. 1 is a schematic diagram of an embodiment of the device of the present invention, and FIG. 1 fully shows the composition of each component and the connection relationship with each other. A specific embodiment of the present invention is as follows: according to process requirements, first determine the specifications and technical parameters of main and auxiliary equipment such as falling film evaporator, heater, condenser, steam compressor, etc. Taking papermaking black liquor treatment as an example, if the total amount of dilute black liquor to be treated is 170M 3 / H, the initial temperature is 75°C, the solid content percentage concentration of the dilute black liquor is 1.5%, and the treated black liquor requires a solid content percentage concentration of 15%. By calculation, the area of the falling film evaporator is 9500M 2 , the shell side working temperature is 95℃, the plate (or tube) side working temperature is 105℃; the heater area is 200M 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com