Pneumatic automatic waste discharge device of maintenance-free liquid filter of centrifugal machine

A liquid filtration, maintenance-free technology, used in centrifuges and other directions, can solve the problems of poor waste discharge effect, affect the filter work, low waste discharge efficiency, etc., to achieve structural stability and operational efficiency. High safety, good waste discharge effect, and improved waste discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following specific embodiments are only an explanation of the present invention, and are not a limitation of the present invention. After reading this specification, those skilled in the art can make modifications to this embodiment without creative contribution as needed, but as long as the rights of the present invention All requirements are protected by patent law.

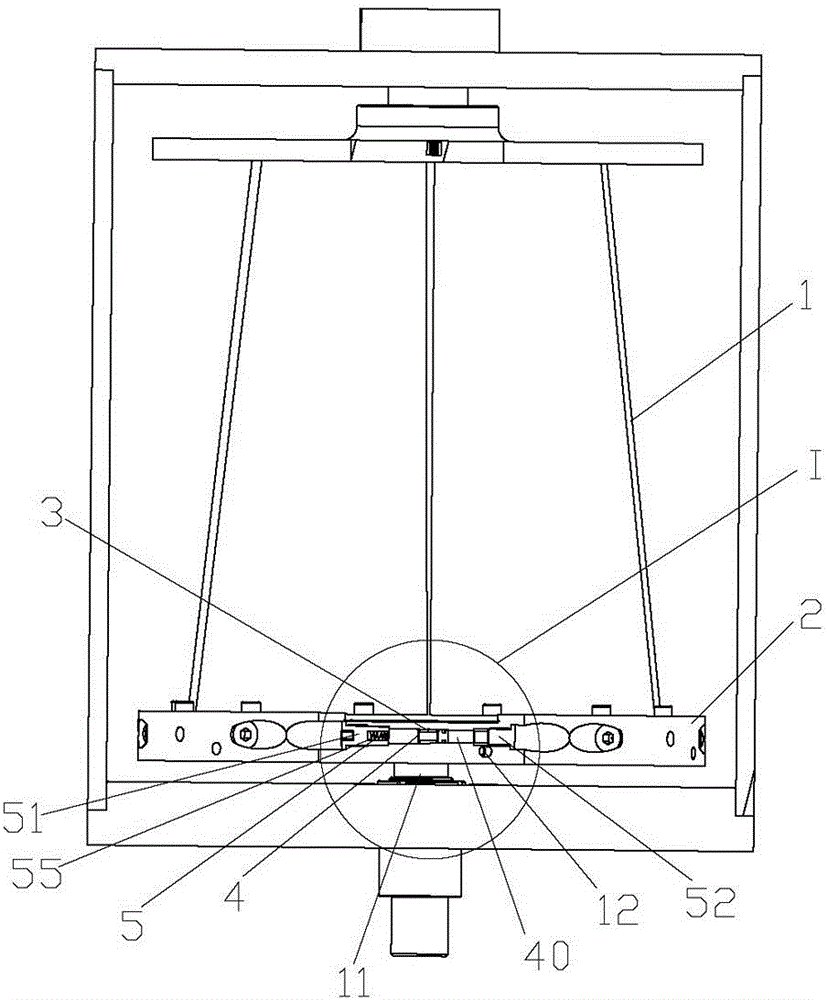

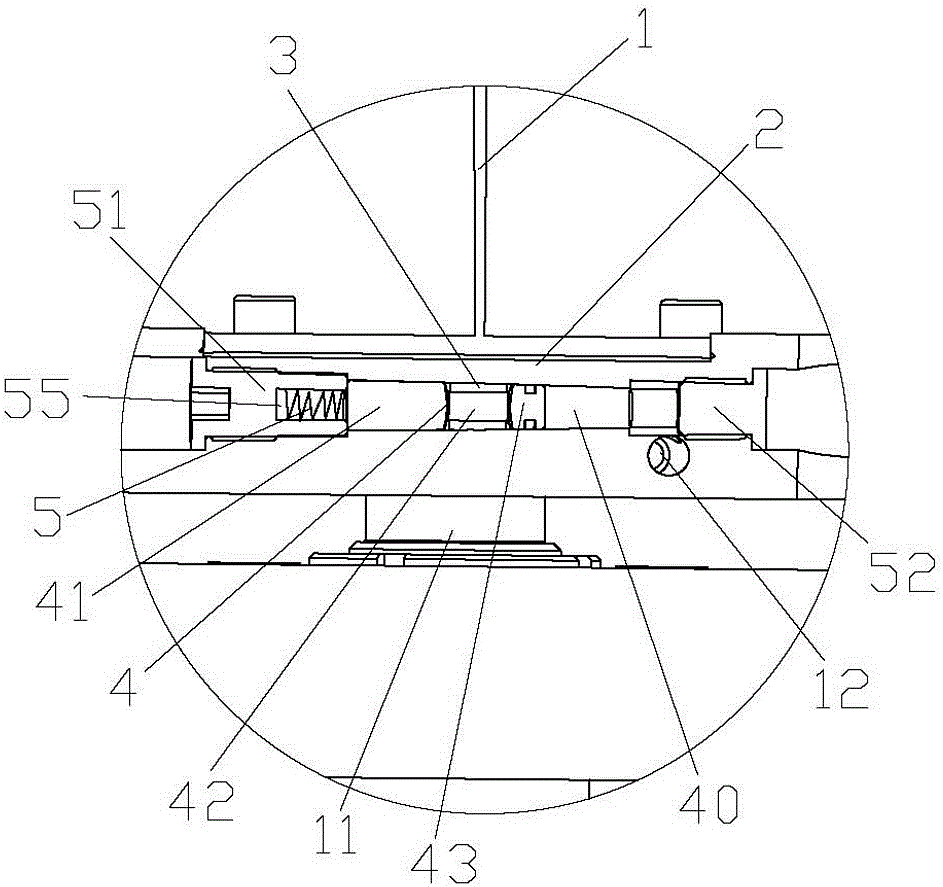

[0020] Examples such as figure 1 , 2 As shown, a pneumatic automatic waste discharge device for a maintenance-free liquid filter of a centrifuge includes a rotatable rotor main cylinder 1, and a lower part of the rotor main cylinder 1 is connected with a chassis 2, and the chassis 2 is provided with There is a horizontal waste discharge channel 3 communicating from the inside to the outside of the rotor main cylinder 1, and the waste discharge channel 3 is also equipped with a valve core 4 for closing and opening the waste discharge channel 3, and the valve core 4 is arranged at In the sliding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com