Waste discharging device for protective film waste and waste discharging method

A technology of waste discharge device and protective film, which is used in thin material handling, transportation and packaging, and winding strips, etc., can solve the problems of product inclination, product bending, and low efficiency, so as to reduce labor costs and waste discharge. time, and the effect of improving waste discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

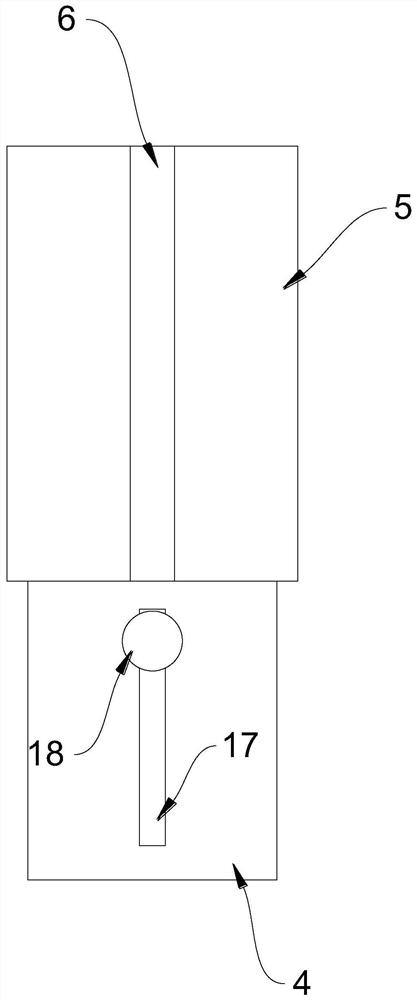

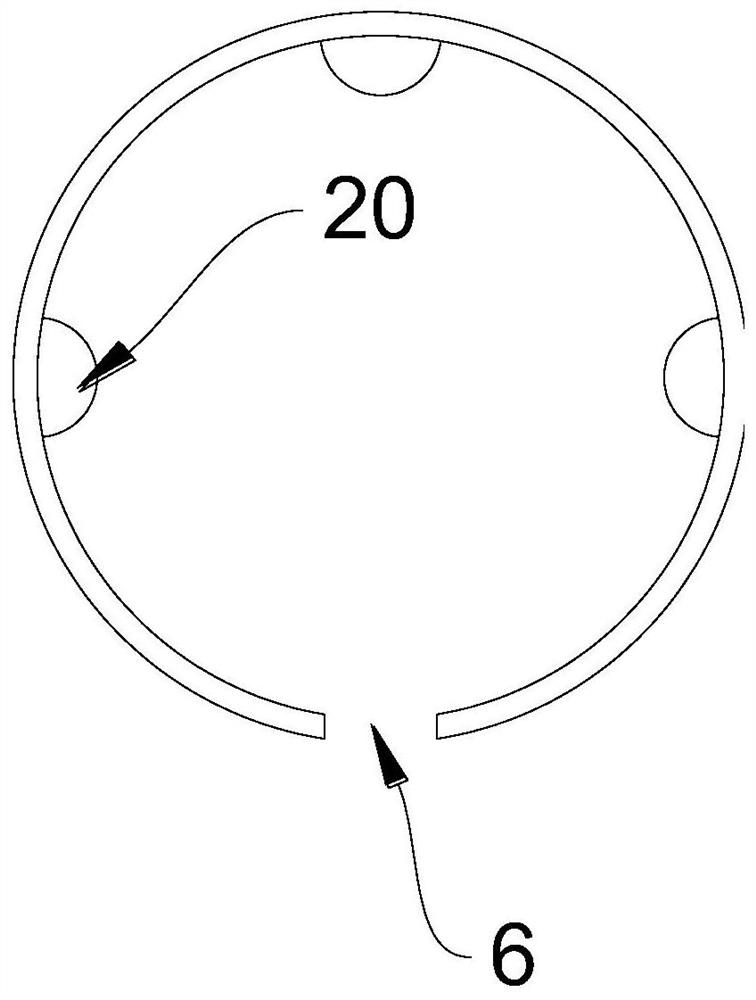

[0054] Please refer to Figure 1-11 , this embodiment provides a protective film waste discharge device, including: a frame 1, a tape main body 2, a conveying roller set 3, a driving roller 4, a winding roller 5, a first opening 6, an accommodating chamber 7, a second opening 8. The first clamping plate 9, the second clamping plate 10, the driving member 11, the installation groove 12, the first driving groove 13, the second driving groove 14, the first sliding rod 15, the second sliding rod 16, the limit Groove 17, driving handle 18, stop groove 19 and limiting rib 20.

[0055] The frame 1 has a conveying roller group 3 for conveying the tape main body 2; the driving roller 4 is rotatably arranged on the frame 1; the winding roller 5 is detachably connected with the driving roller 4, and can rotate synchronously with the driving roller 4 to The protective film is wound on the take-up roller 5; the clamping assembly is used to clamp the end of the protective film.

[0056] I...

Embodiment 2

[0098] Please combine Figure 12 , this embodiment is basically the same as Embodiment 1, except that two groups of waste discharge devices are symmetrically arranged on the frame 1, and the central axis of the driving roller 4 in the two groups of waste discharge devices is perpendicular to the central axis of the conveying roller group 3; wherein The driving mode of the driving roller 4 in the two sets of waste discharge devices can be driven by the motor alone, or the existing transmission mechanism can be used to connect with the conveying roller group 3 .

[0099] It should be noted that the rotational speeds of the two driving rollers 4 should be the same to avoid the belt main body 2 from inclining.

[0100] The purpose of the design of the two sets of waste discharge devices is to separately collect the half-divided protective film (due to technical reasons, part of the protective film is divided into two halves along the axial direction of the tape main body 2) to imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com