Cage rotor for an asynchronous motor

A technology for asynchronous motors and cage rotors, applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of reduced risk of fracture, fracture, and existence, and achieve the effects of reducing inertia moment and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

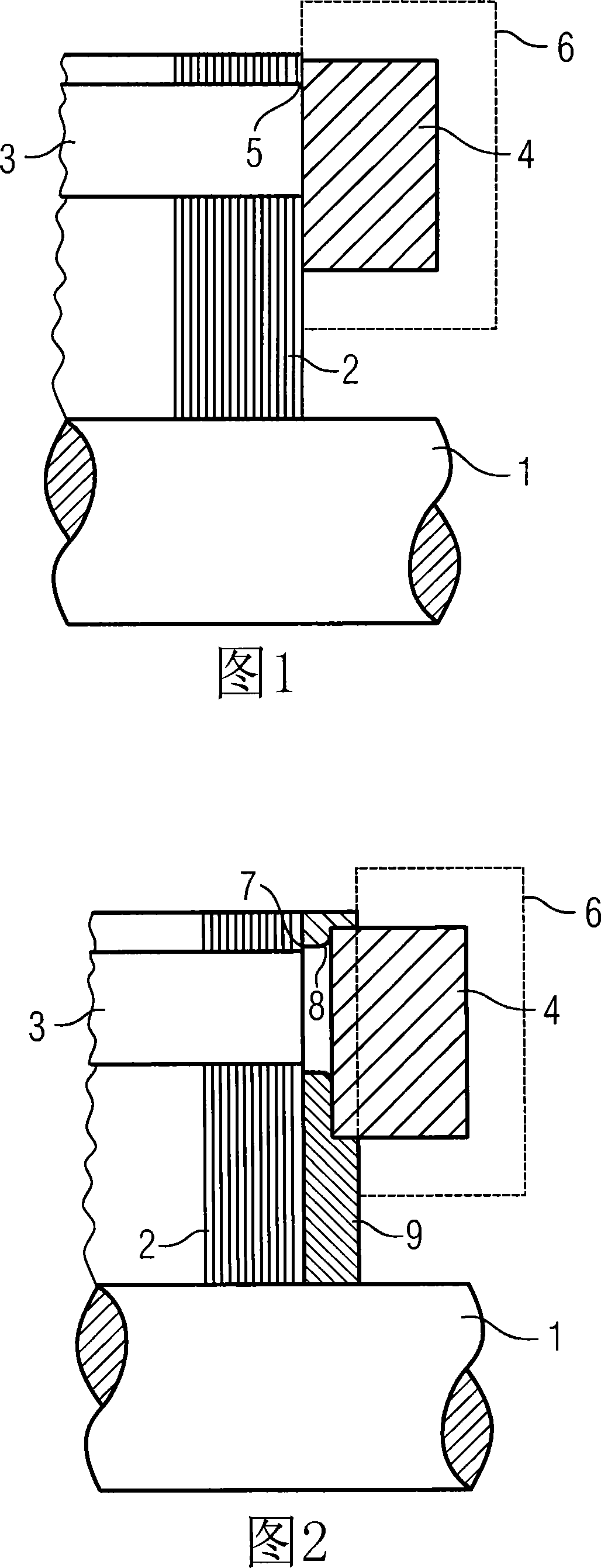

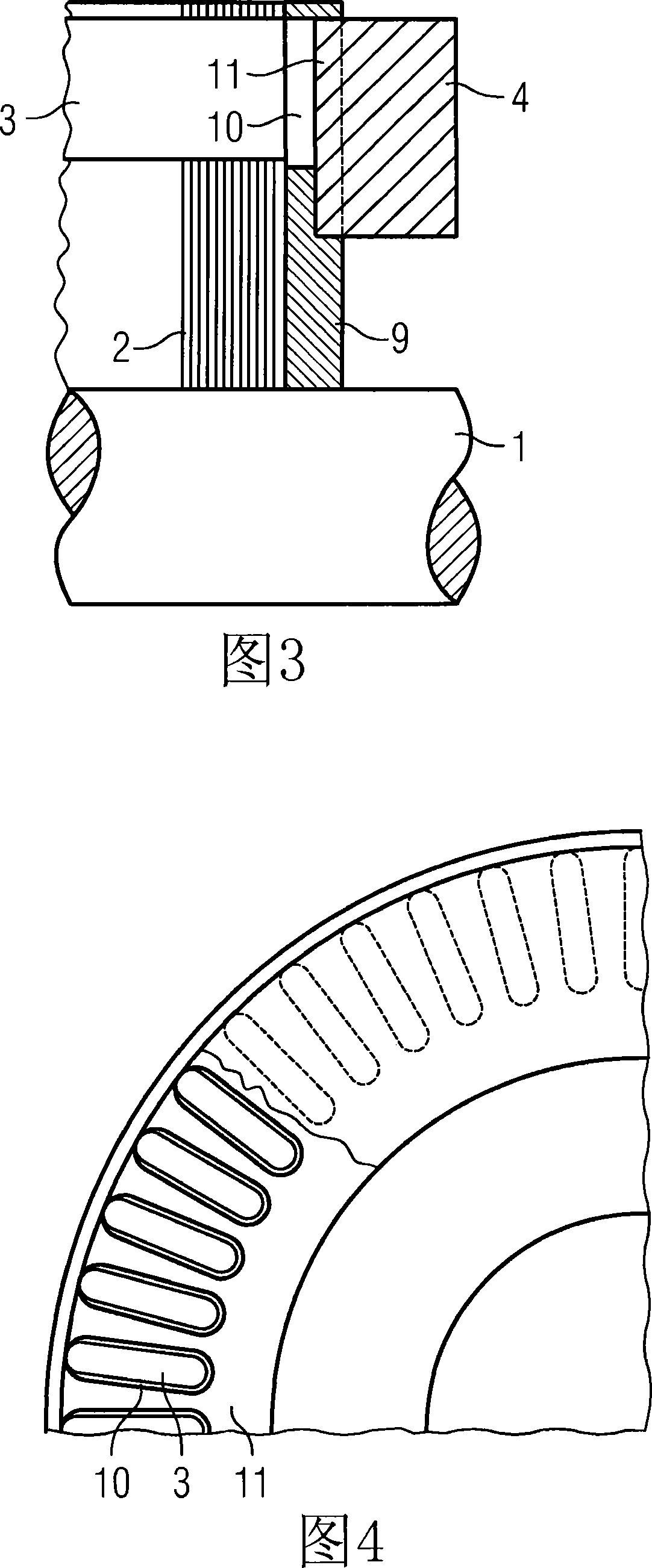

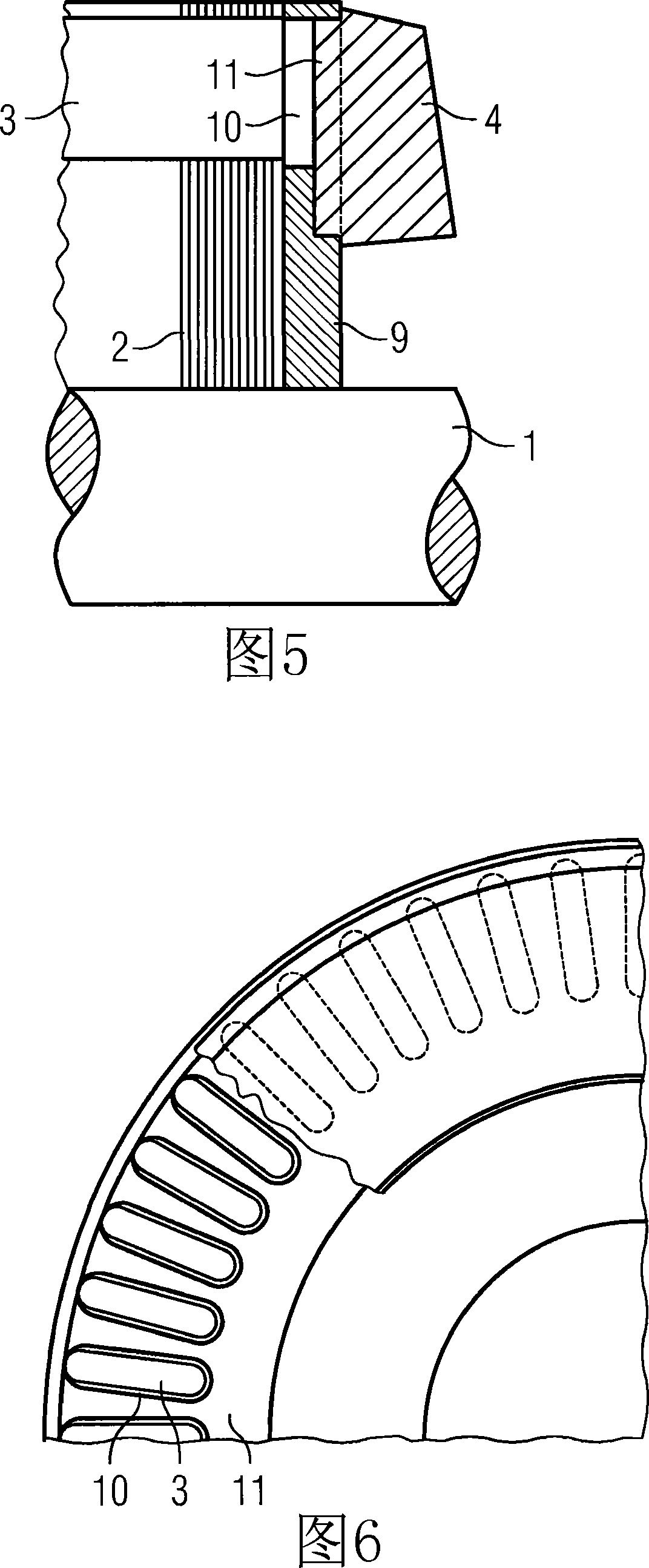

[0032] Figure 1 shows a partial view of a cage rotor in the prior art. In rotary electric machines working on the principle of induction, the short-circuit winding in the rotor is made of a material with good electrical conductivity, in particular copper or aluminium. On the one hand, this short-circuit winding is formed by a number of rotor bars 3 with a defined cross section, which are embedded in the rotor lamination stack 2 . On the other hand, a short-circuit ring 4 is respectively arranged on the end faces of the laminated core, which short-circuit ring connects all the rotor bars 3 on the respective rotor side to one another, ie electrically shorts these rotor bars. Currently, rotor windings are generally produced from aluminum by die-casting.

[0033] As shown in FIG. 1, during casting, the lamination stack 2 is located between two die-casting molds 6 arranged on its end faces, thereby forming a cavity formed by the rotor bar 3 and the short-circuit ring 4 in the lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com