Rotary cutting pick and method of using a cutting pick for mining

A cutting-edge technology, used in earth-moving drilling, slitting machinery, construction, etc., can solve problems such as wear and tear, and achieve the effect of reliable wear protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

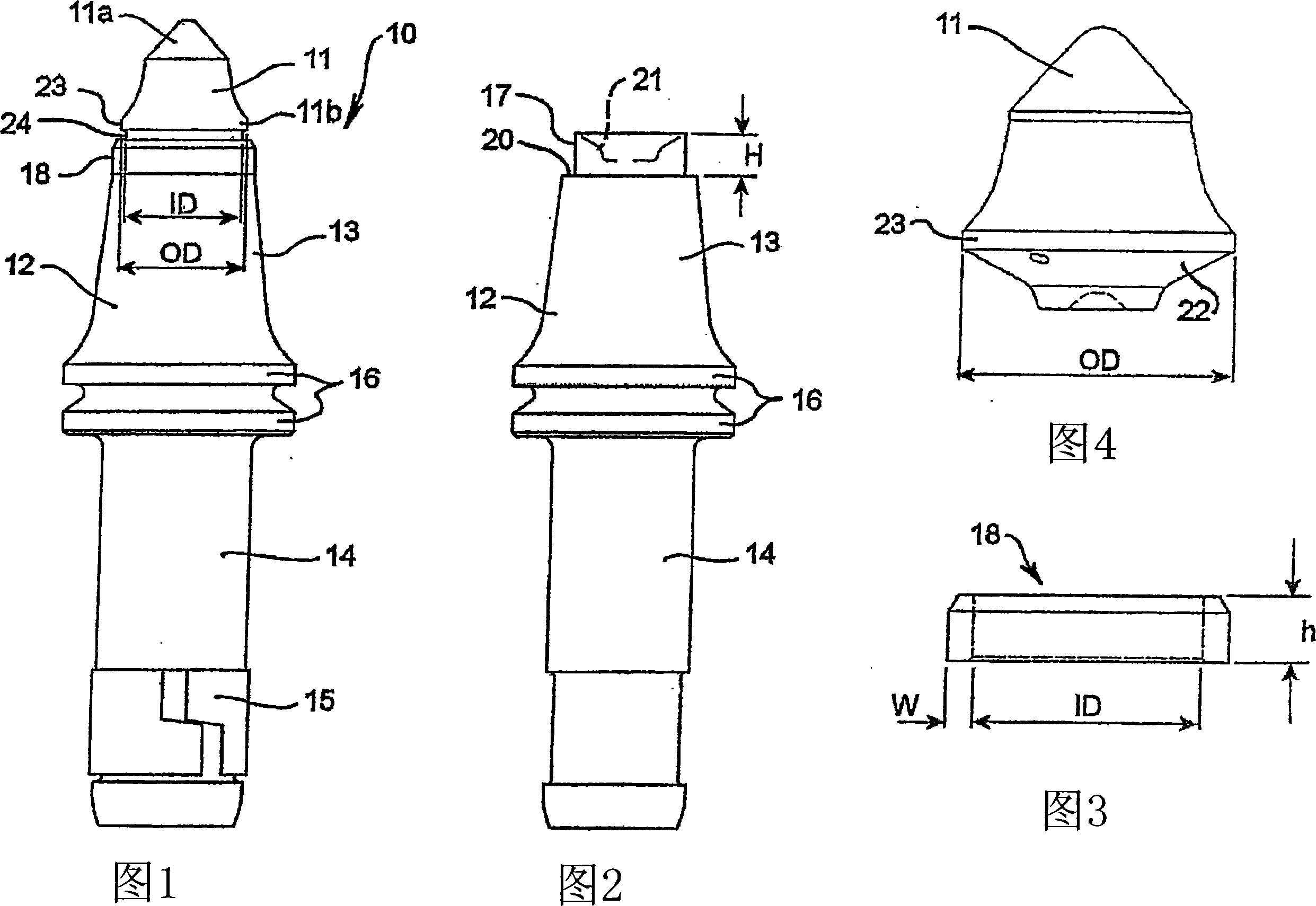

[0044] Figure 1 is a side view of a pick 10 according to the present invention. Pick 10 includes a cutting tip 11 having a leading end 11 a and a trailing end 11 b secured to an elongated shank 12 . The shank 12 includes a conical portion 13 and a cylindrical portion 14 . The cylindrical portion 14 has an attachment mechanism 15 for attaching the pick 10 to a rotating cutting drum or the like, while the pick 10 also includes a pair of flanges 16 which also facilitate mounting the pick 10 to a rotating cutting drum or the like. on the cutting barrel. The manner in which the pick 10 is mounted to the rotating cutting cartridge is not part of the invention and will be apparent to those skilled in the art.

[0045] The pick 10 also includes a cylindrical portion 17 ( FIG. 2 ) and an annular sleeve 18 extending around the cylindrical portion 17 , the sleeve 18 being located near the trailing end 11 b of the cutting tip 11 . The annular sleeve 18 is arranged to be supported on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com