Tailor welded blank integral drawing forming device and method for large-scale curved surface part

A technology for tailor-welded blanks and curved parts, which is applied in the field of tailor-welded blank integral forming devices, can solve the problems of inability to form large-scale tailor-welded blank curved parts, and weld cracks, etc. The effect of strong pressure capacity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

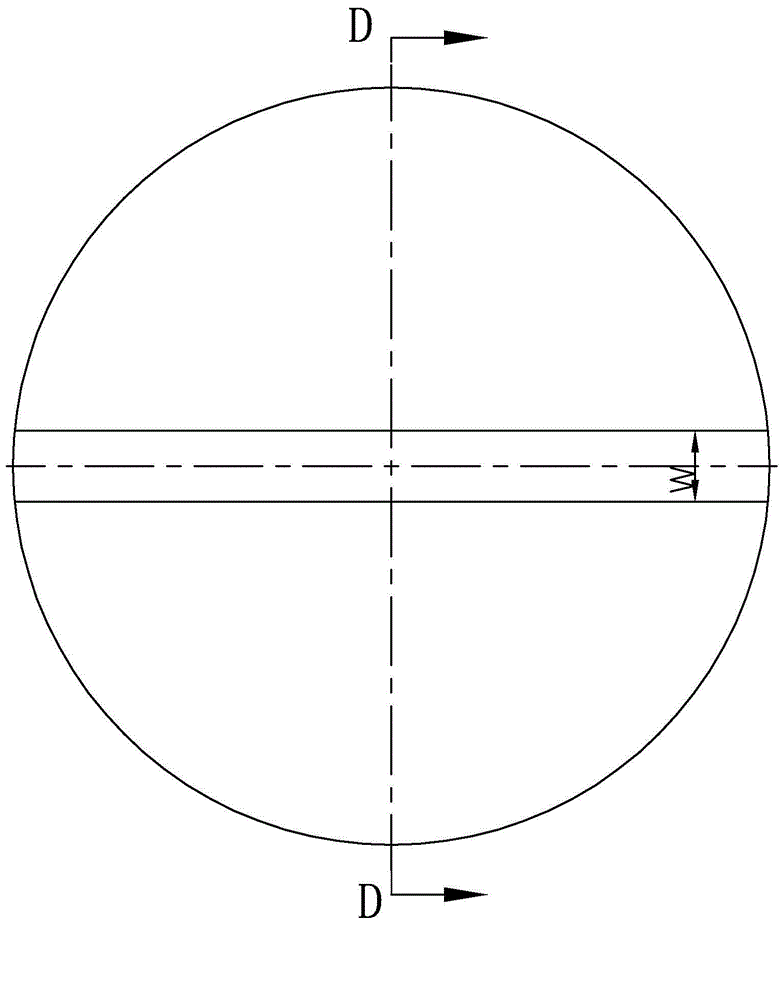

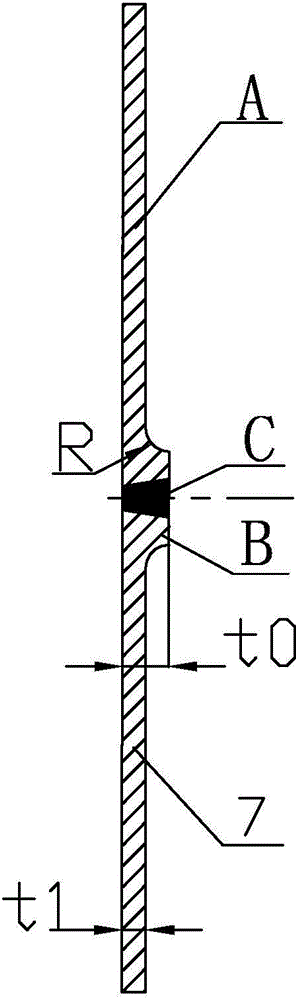

[0028] Specific implementation mode one: as Figures 1 to 7 As shown, the overall drawing and forming device for tailor-welded blanks of large curved surface parts in this embodiment includes a punch 1, a blank holder 2, a die 3, and a liquid-filled chamber 4; the die 3 is placed between the liquid-filled chamber 4 The upper and the two are sealed and connected by the sealing ring 6, and the lower plane of the die 3 is fixedly connected with the upper plane of the liquid-filled chamber 4; the blank holder 2 is arranged above the die 3; The mold 3 moves up and down; the liquid filling chamber 4 is provided with a liquid injection hole 4-1 connected with the medium chamber 5, and the liquid injection hole 4-1 is used to connect with the hydraulic system; the blank holder 2 and the die 3 are used to place Sheet 7, the sheet 7 refers to tailor-welded blanks of non-equal thickness;

[0029] like Figure 2-5 On the surface of the punch 1, there is a punch groove 1-1 that matches t...

specific Embodiment approach 2

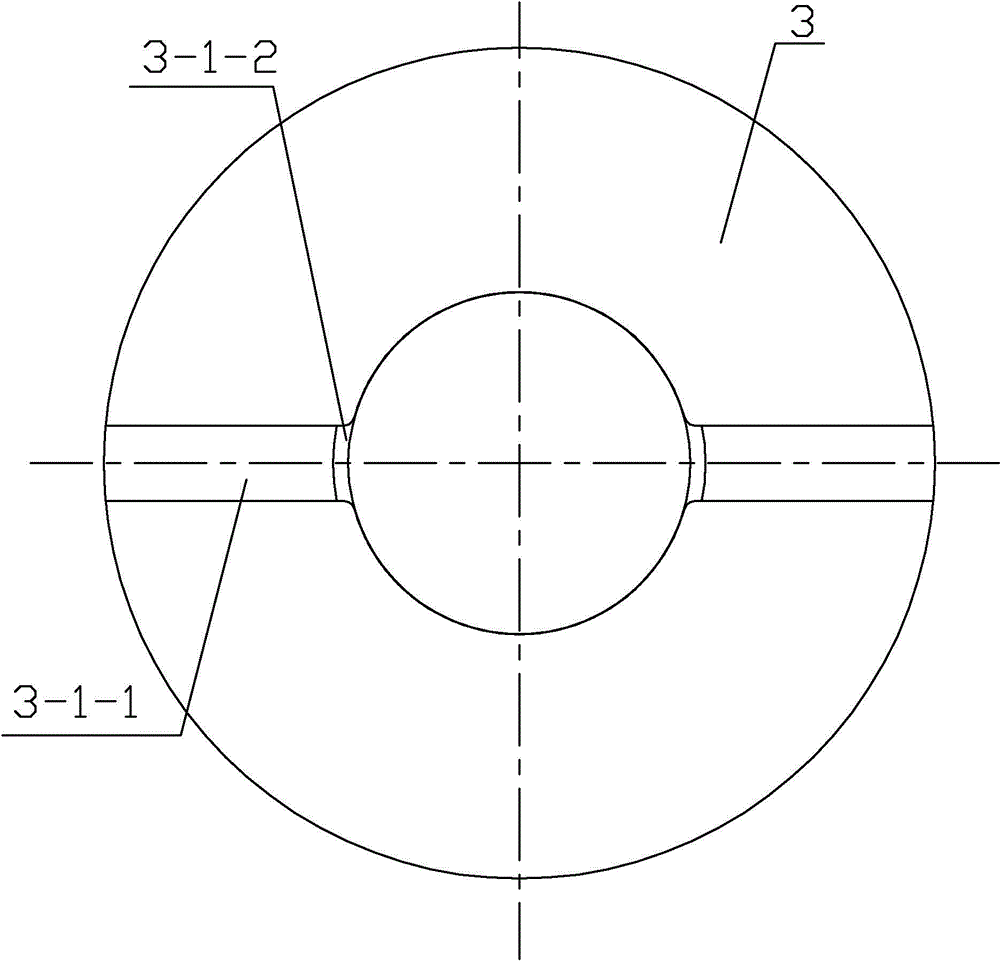

[0034]Specific implementation mode two: as Figure 8 and 9 As shown, in the tailor-welded blank overall drawing forming device for large curved surface parts described in this embodiment, there are only holes on the upper surface and inner hole of the die 3 that match the shape of the thick-walled area where the weld seam of the sheet metal is located. Die groove 3-1 is used to restrict the deformation of the thick-walled area perpendicular to the direction of the welding seam. The concave mold groove 3-1 is a two-part groove arranged opposite to the mirror image along the axis of the concave mold 3, and each part of the groove includes a concave mold upper surface groove 3-1- 1 and the concave mold inner hole groove 3-1-2 arranged on the inner hole wall of the concave mold and equal to the inner hole, and the groove 3-1-1 on the upper surface of the concave mold and the inner hole groove 3 of the concave mold -1-2 is smoothly transitioned and connected at the intersection; ...

specific Embodiment approach 3

[0037] Specific embodiment 3: The steps of the overall drawing and forming method of tailor-welded blanks for large curved surface parts using the forming device of specific embodiment 1 are as follows:

[0038] Step 1. The liquid filling hole of the liquid filling chamber is connected to the hydraulic system: first, the liquid injection hole 4-1 on the liquid filling chamber 4 is connected to the hydraulic system, and then the fluid medium is injected into the medium chamber 5;

[0039] Step 2, then place a non-equal-thick sheet material 7 on the upper surface of the die 3, and the sheet material 7 has a side with a stepped surface upward;

[0040] Step 3. The blankholder moves downward and applies blankholder force, and the groove of the blankholder coincides with the thick-walled area of the sheet:

[0041] The blank holder 2 is controlled to move downward by the blank holder cylinder of the hydraulic press, the groove of the blank holder 2 matches the sheet material 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com