Patents

Literature

39results about How to "Avoid Welding Stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

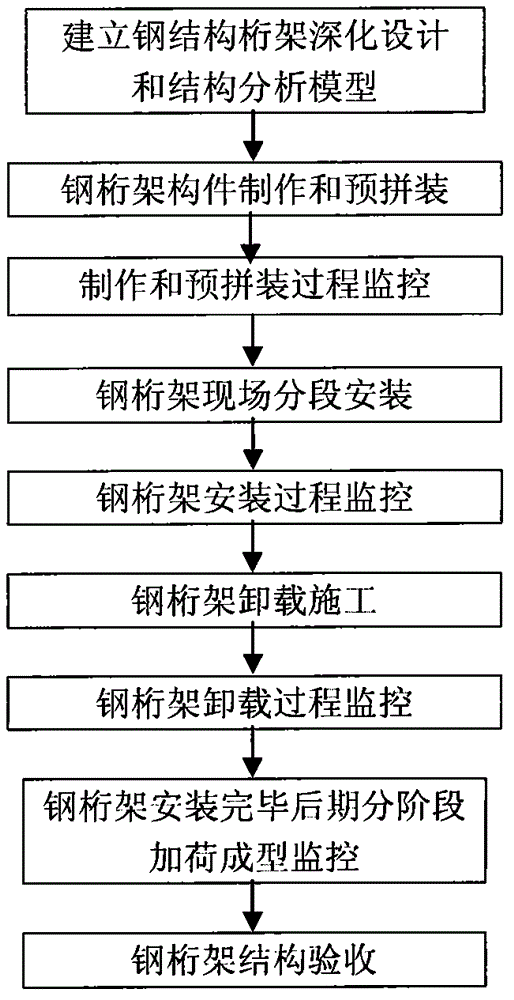

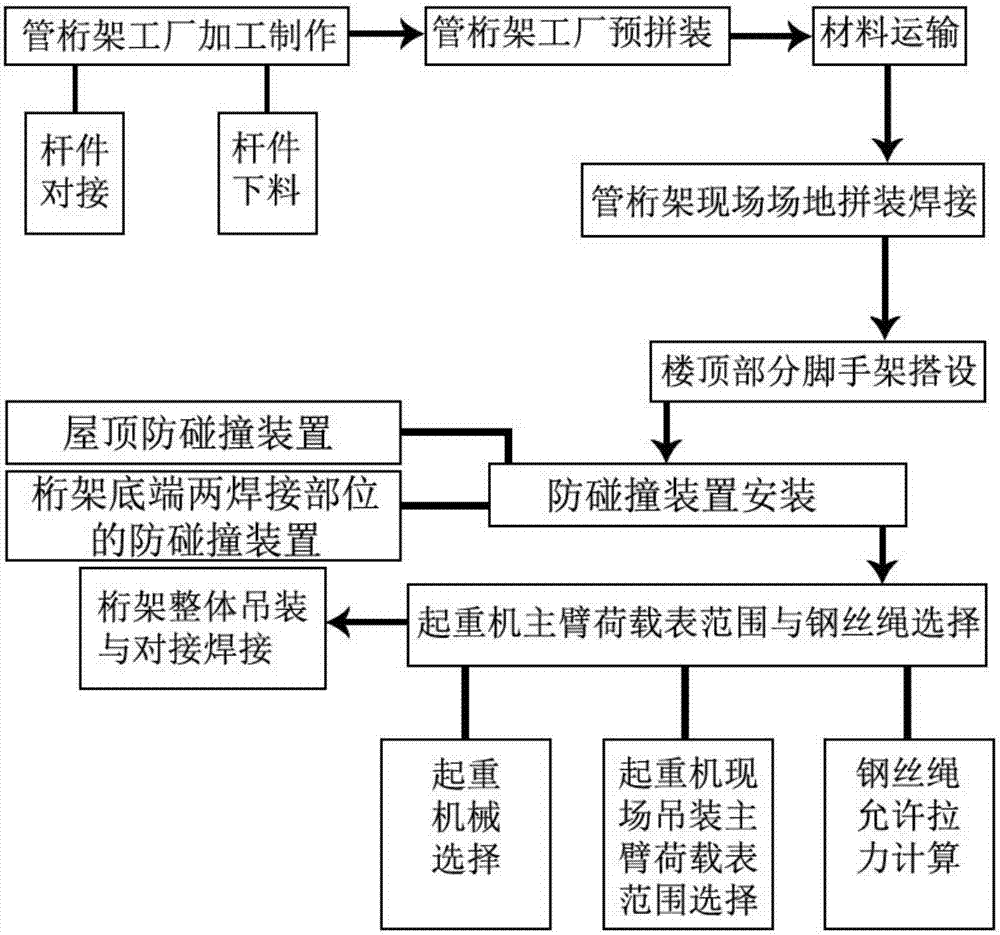

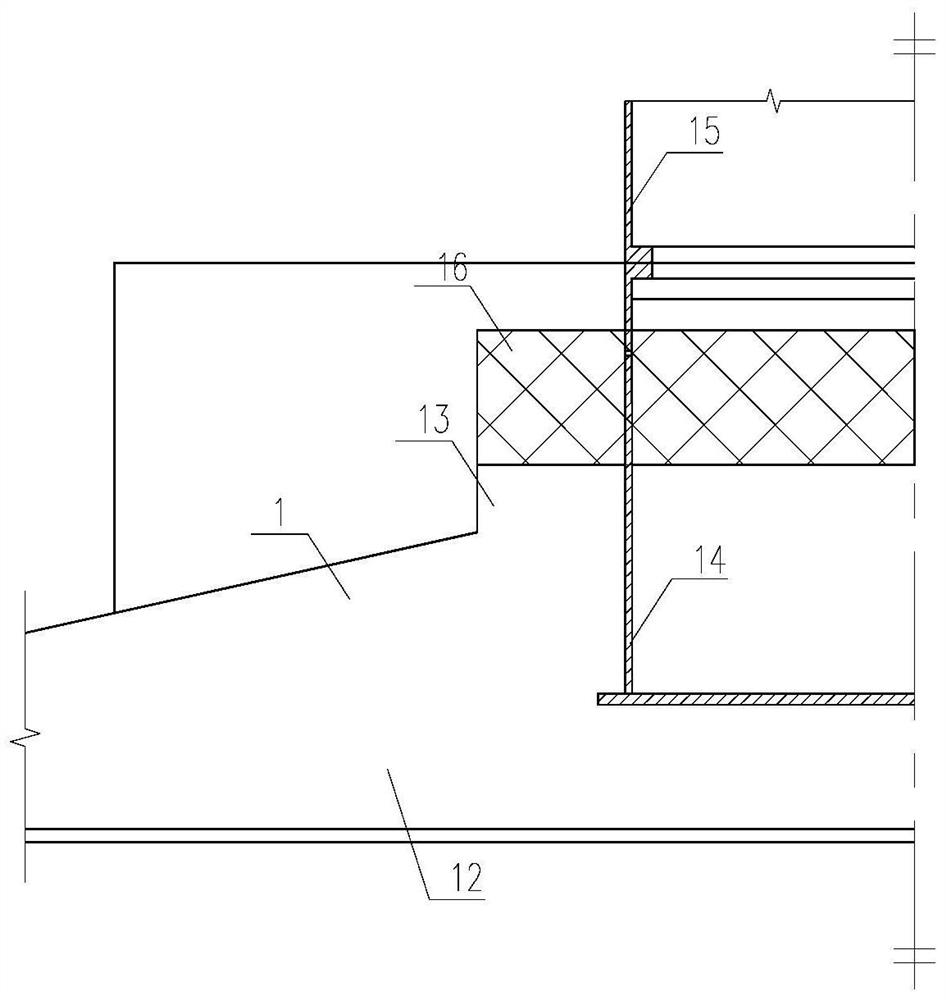

Method for installing abnormal-shaped extremely-large overhung steel truss under process monitoring construction

InactiveCN104631838AEasy to installEven by forceBuilding material handlingSupporting systemStructure analysis

The invention discloses a method for installing an abnormal-shaped extremely-large overhung steel truss under process monitoring construction. The installing method includes the steps that a steel structure truss deepening design and structure analysis model is built; steel truss parts are manufactured and pre-assembled, and the manufacturing process and the pre-assembling process are monitored; the steel truss is installed in site in a sectioned mode, and the steel truss installation process is monitored; unloading construction is carried out on the steel truss, and the steel truss unloading process is monitored; loading forming is monitored in the later period after the steel truss is installed in a staged mode; the structure of the steel truss is checked and accepted. The installation technology that a temporary supporting system and altitude spread assembling are combined is adopted, the large-span abnormal-shaped space lattice pipe truss is accurately installed, and the truss is evenly stressed and is not prone to deformation in the installation process. Heat accumulation, welding stress and welding deformation are prevented with the altitude spread roof-member method.

Owner:YONGSHENG CONSTR GRP

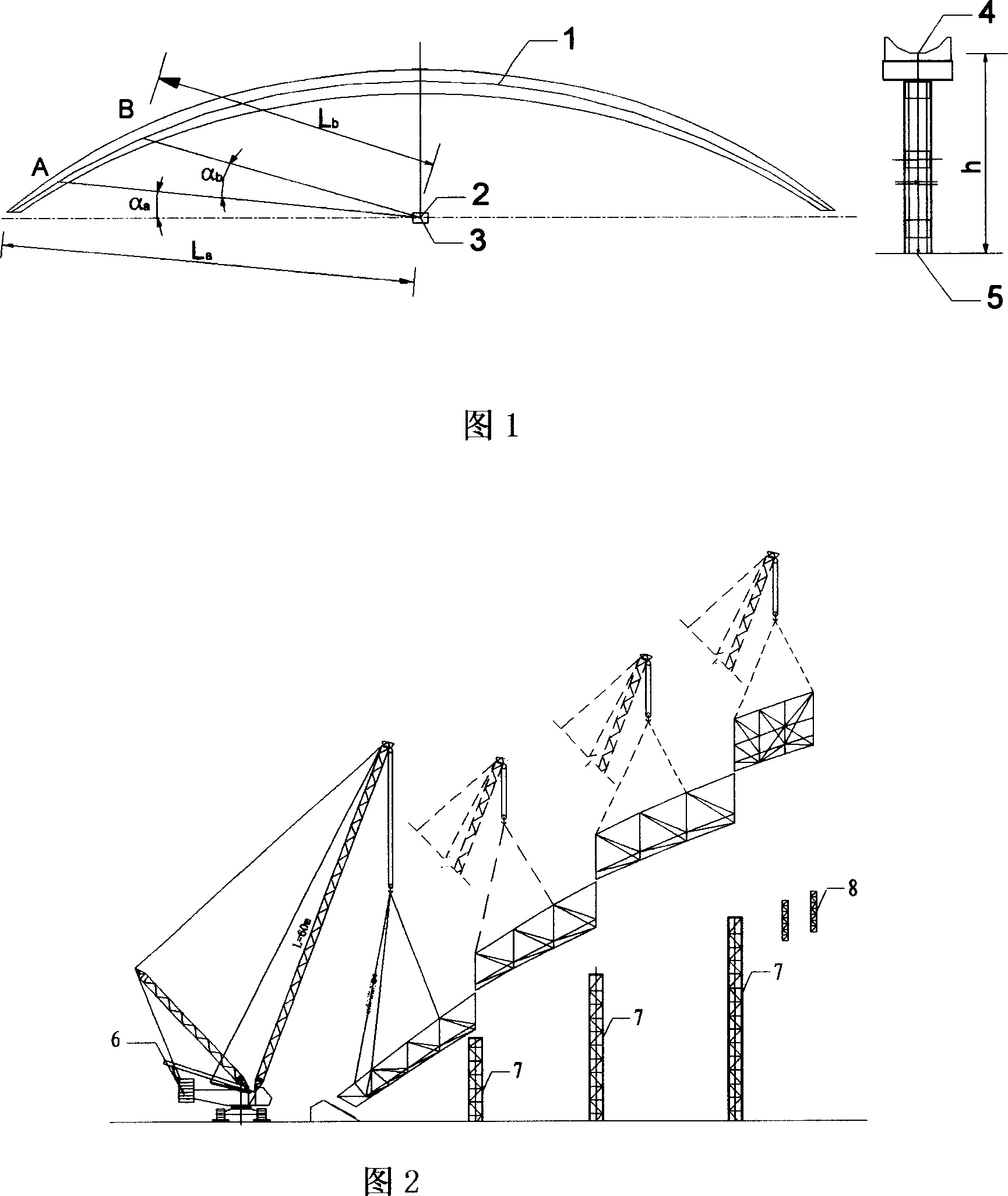

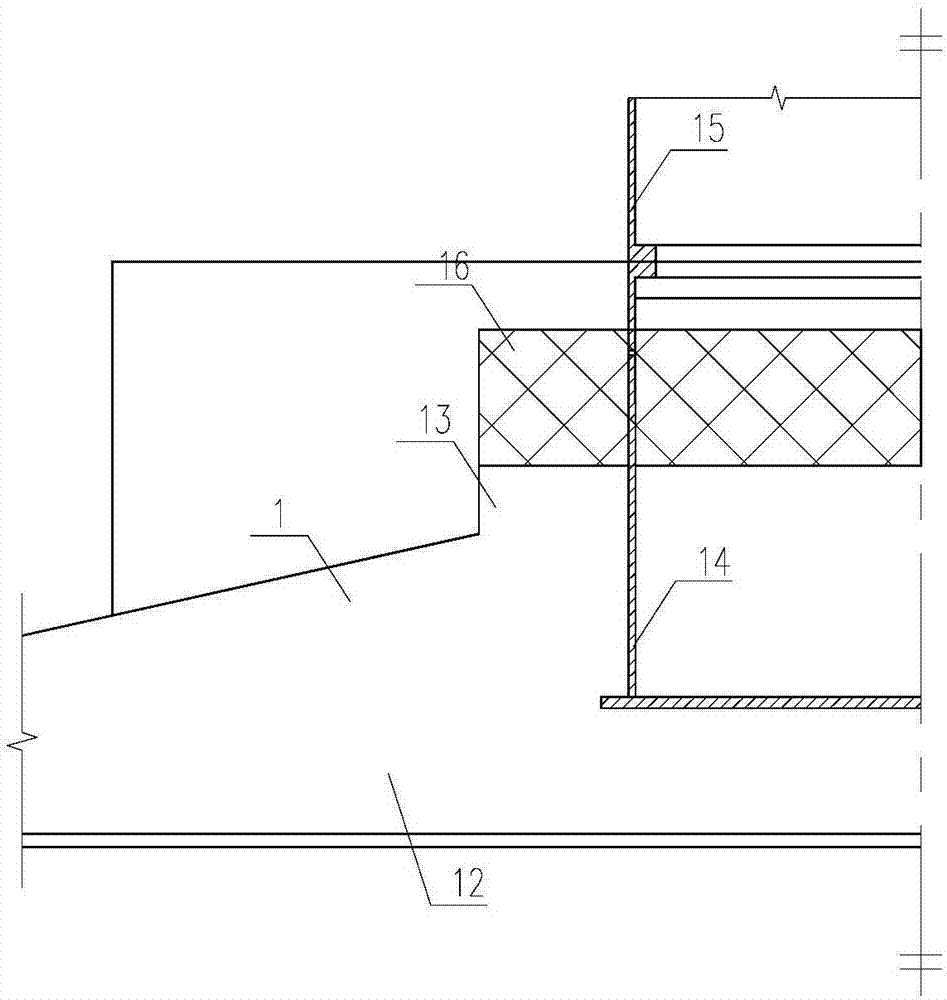

Super-span steel skew arch construction method

ActiveCN1978801AAvoid WeldingAvoid Welding StressArched structuresVaulted structuresArchitectural engineeringTotal station

The invention discloses super span steel skew arch construction method. Its feature is that it adopts molding bed support sectionalizing installation method which includes the following steps: dividing the super span steel skew arch into twenty one construction units; assembling each of them by horizontal type assembling method; laying off and locating supporting molding bed by total stations instrument; installing supporting molding bed; orderly installing the 1-4, 18-21 sections steel skew arch in roof covering, the 5-10, 12-17 sections out roof covering, the eleventh healing section in roof covering; removing the supporting molding bed. The invention can eliminate installing accumulative error, increase insurance coefficient for whole project to ensure steel skew arch healing successful at a time. The method can be used in large scale hall super span steel skew arch construction.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

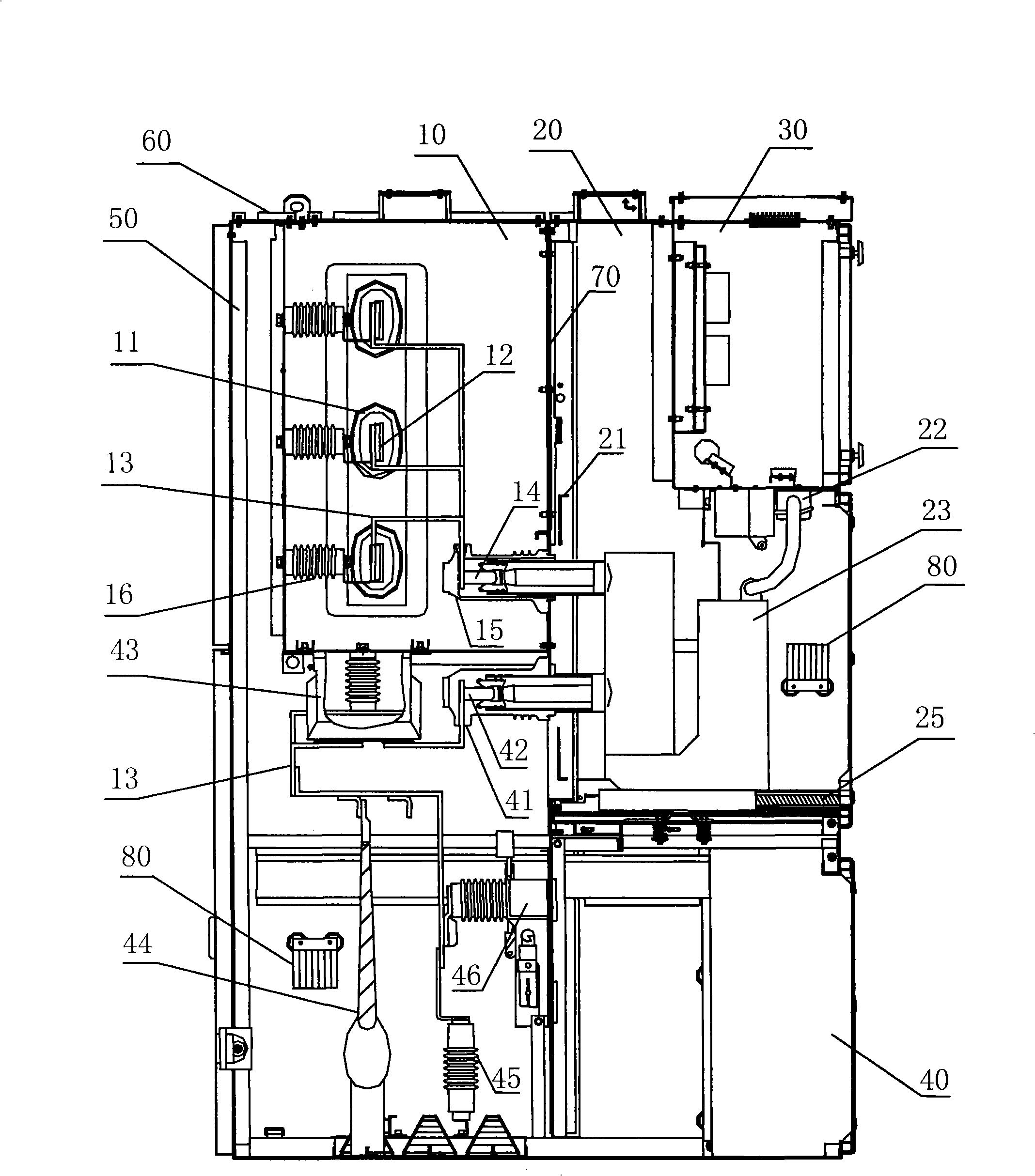

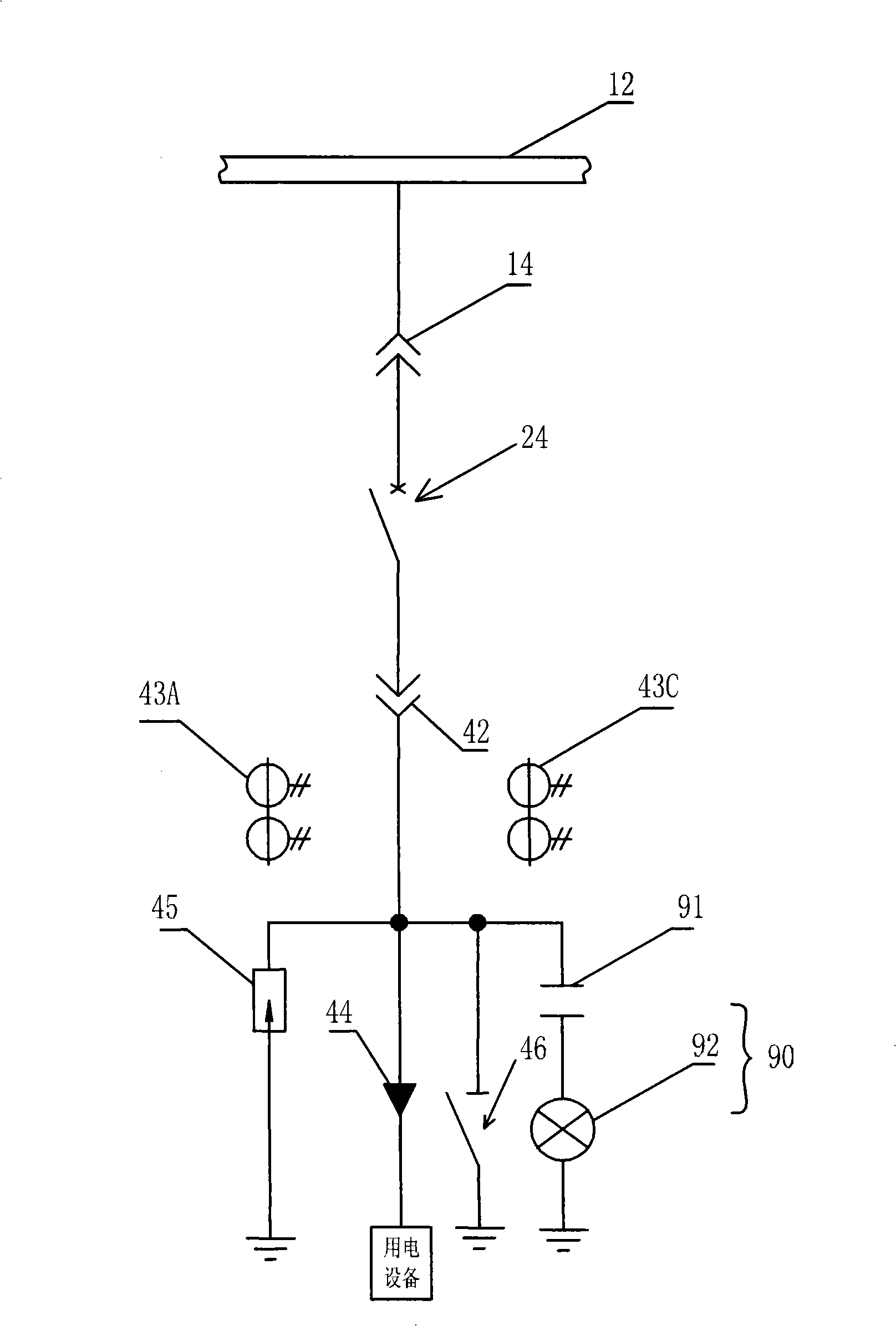

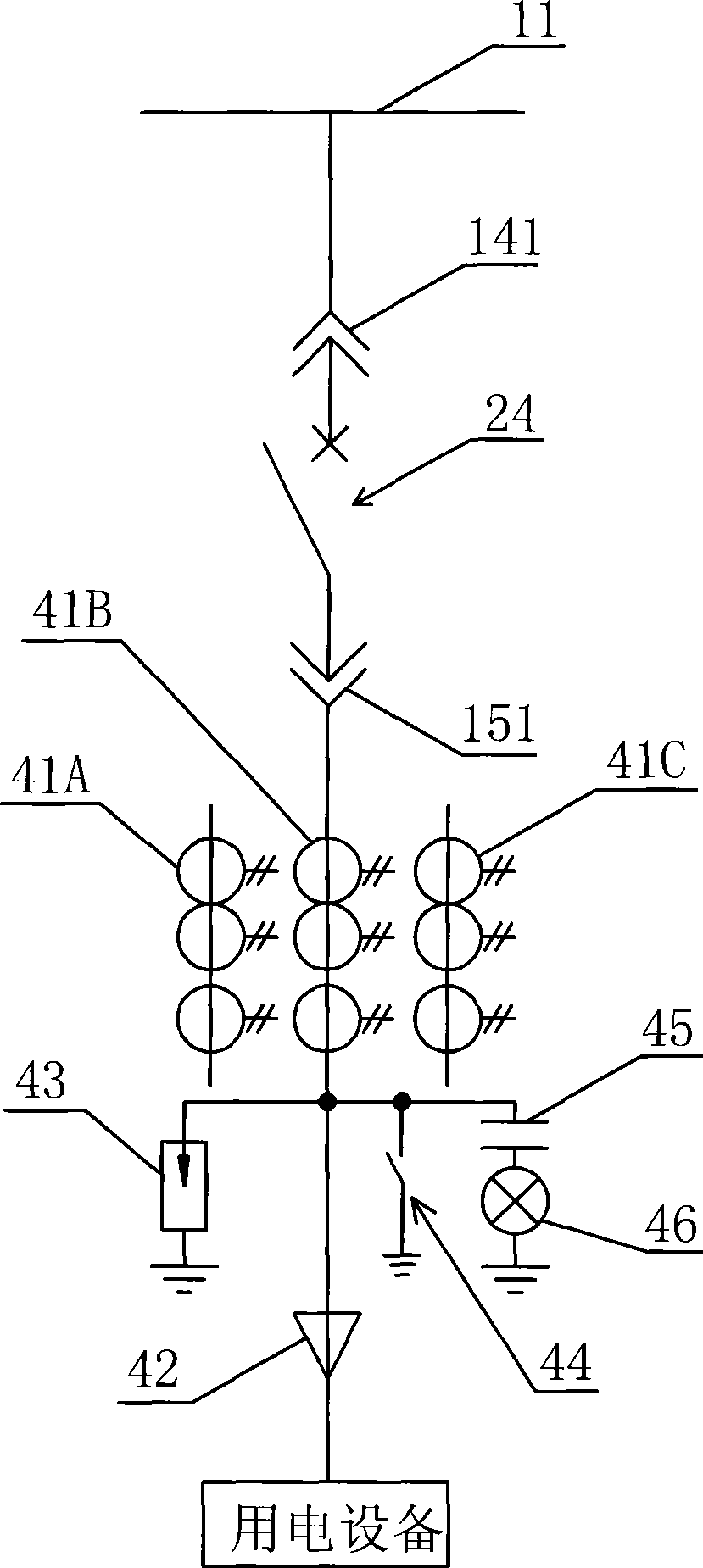

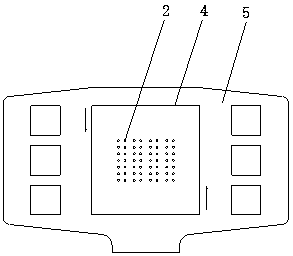

Central-positioned switch cabinet

InactiveCN101345398AAvoid Welding StressReduce volumeBus-bar/wiring layoutsSwitchgear detailsEngineeringSwitchgear

The invention relates to an intermediate switchgear cabinet comprising a cabinet housing and a diaphragm integrating with the cabinet housing which divides the enclosure space enclosed by the cabinet housing into a busbar room, a handcart room, a relay instrument room and a cable room according to the function. The cabinet housing and the insulation diaphragm of the invention adopt assembly rather than welding, thereby avoiding welding stress. Furthermore the size of the invention is small and the installation and trial run is convenient.

Owner:安徽中安恒宇电气传动有限公司

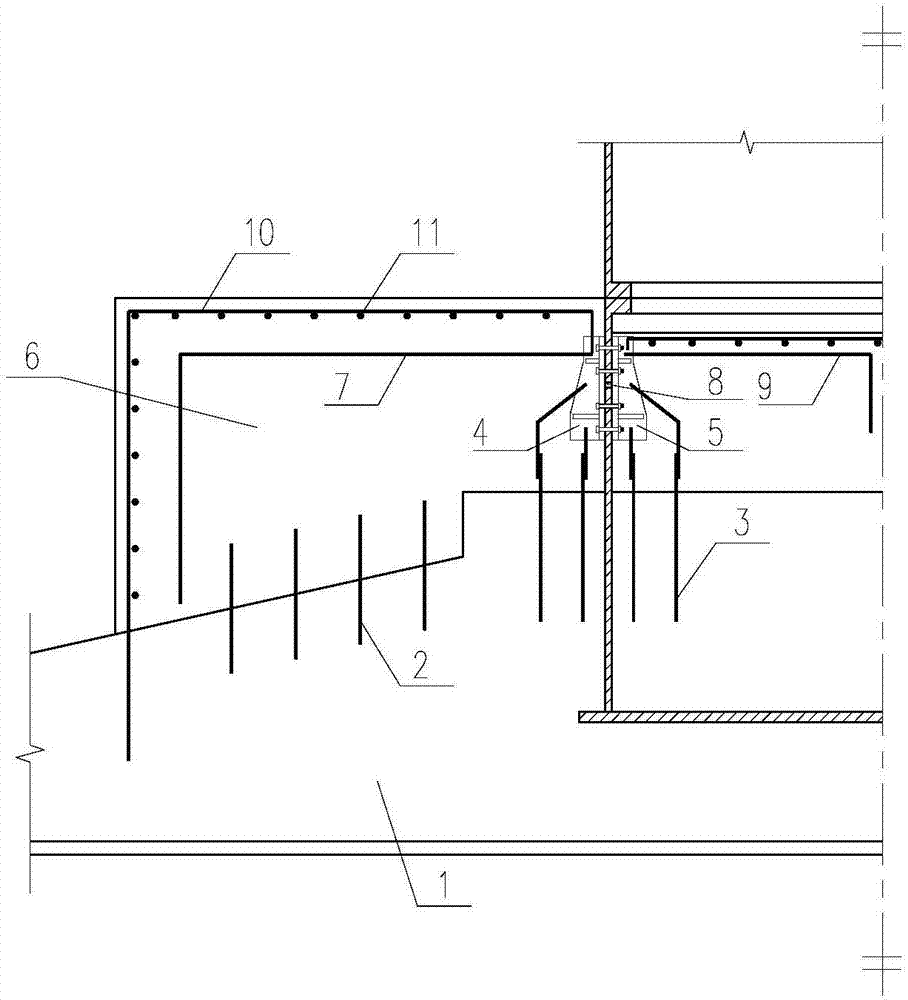

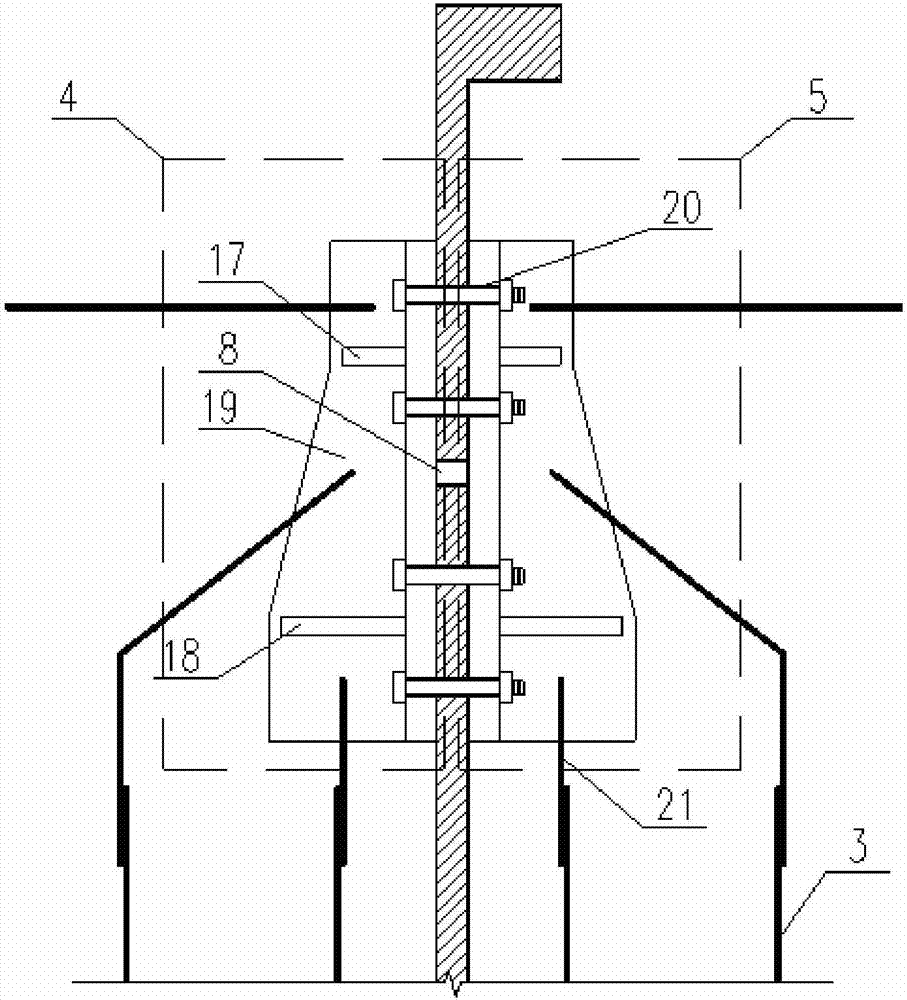

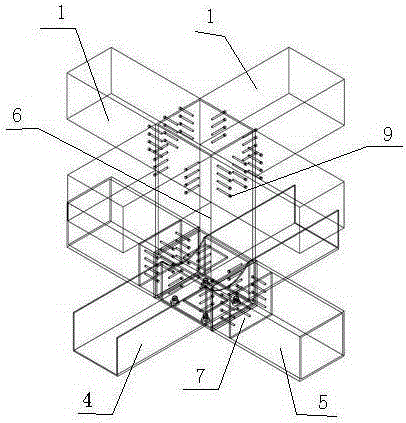

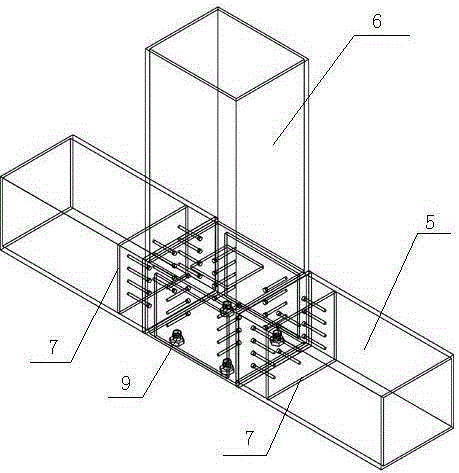

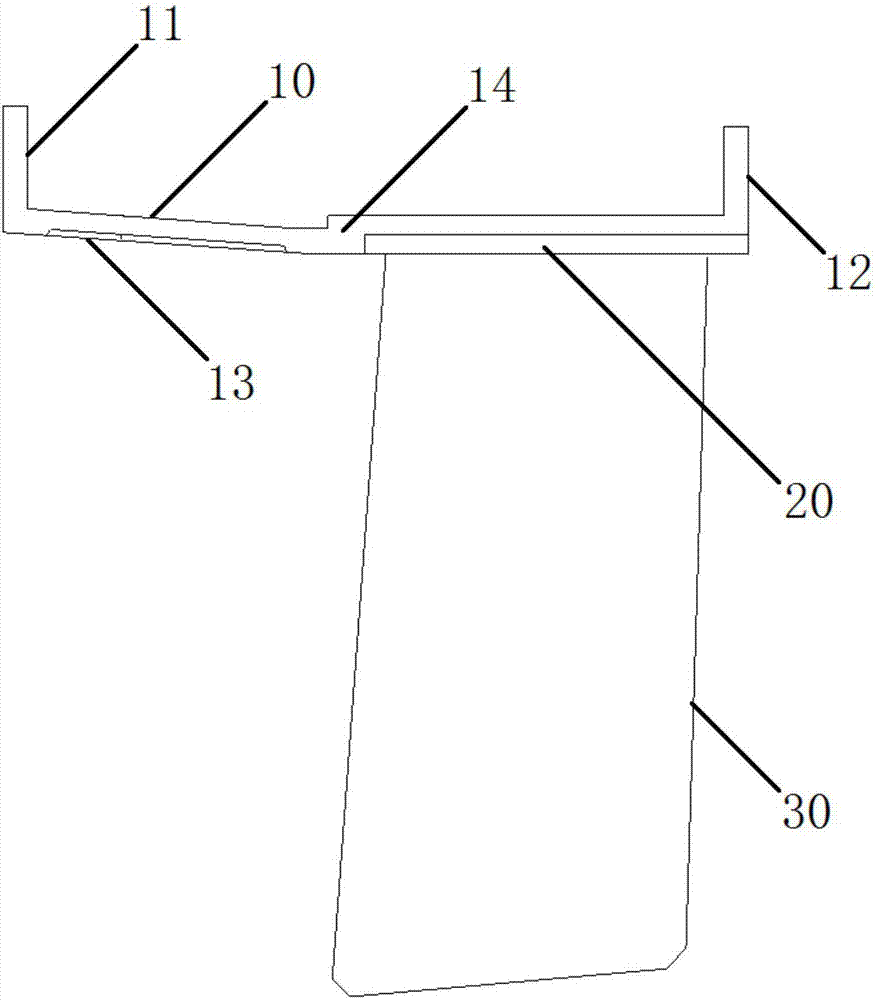

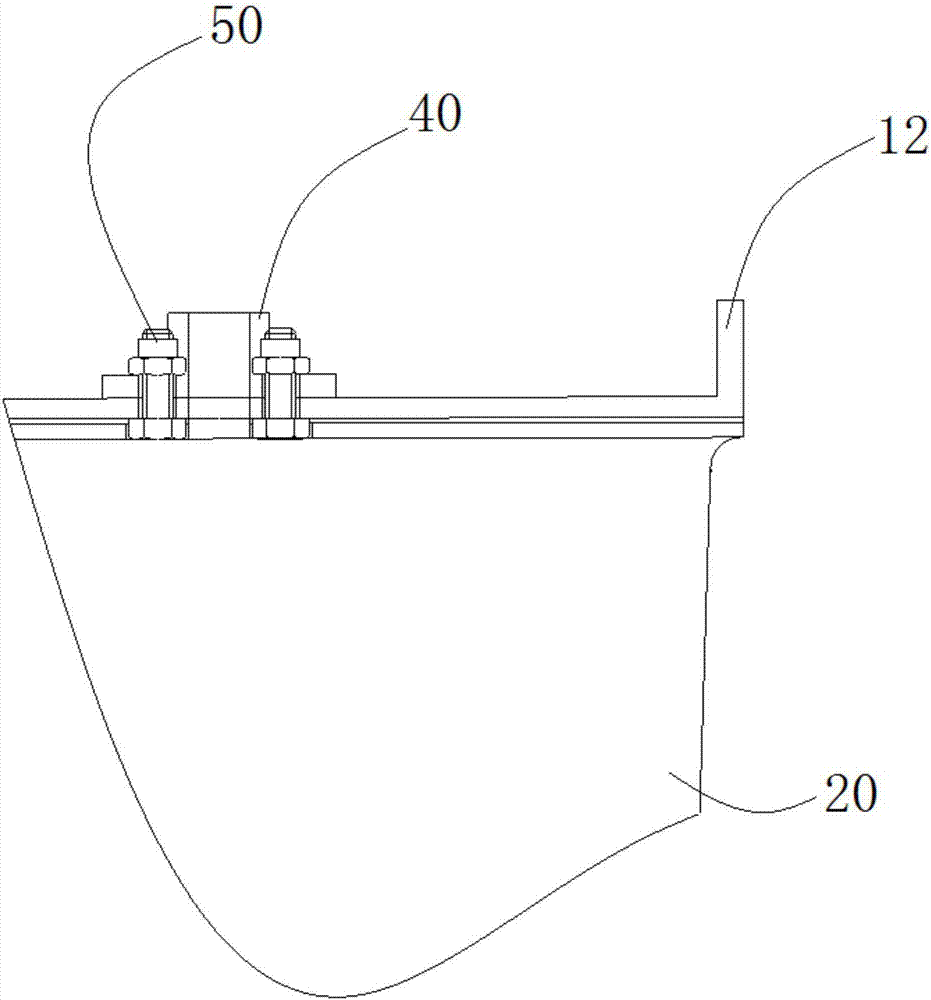

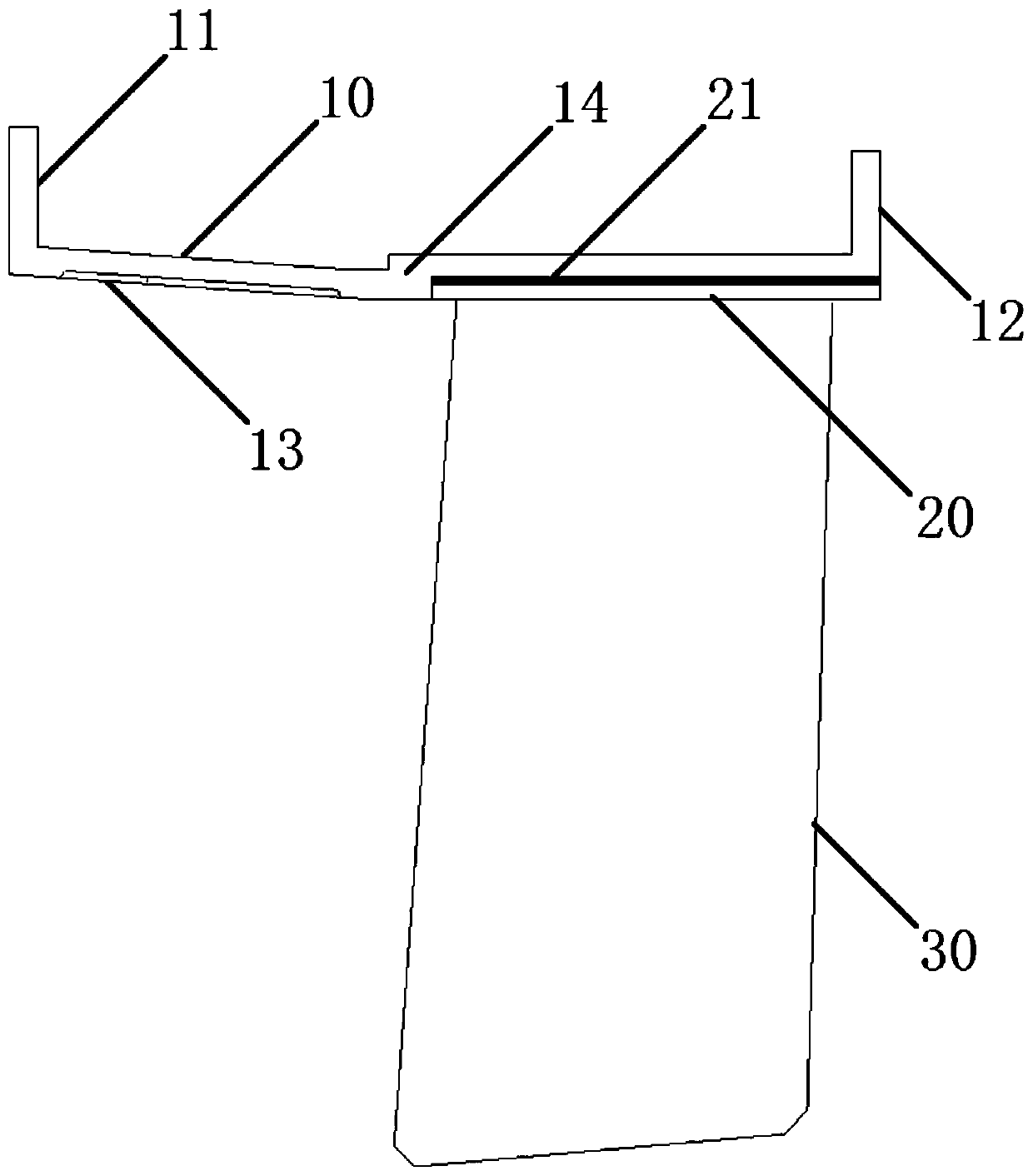

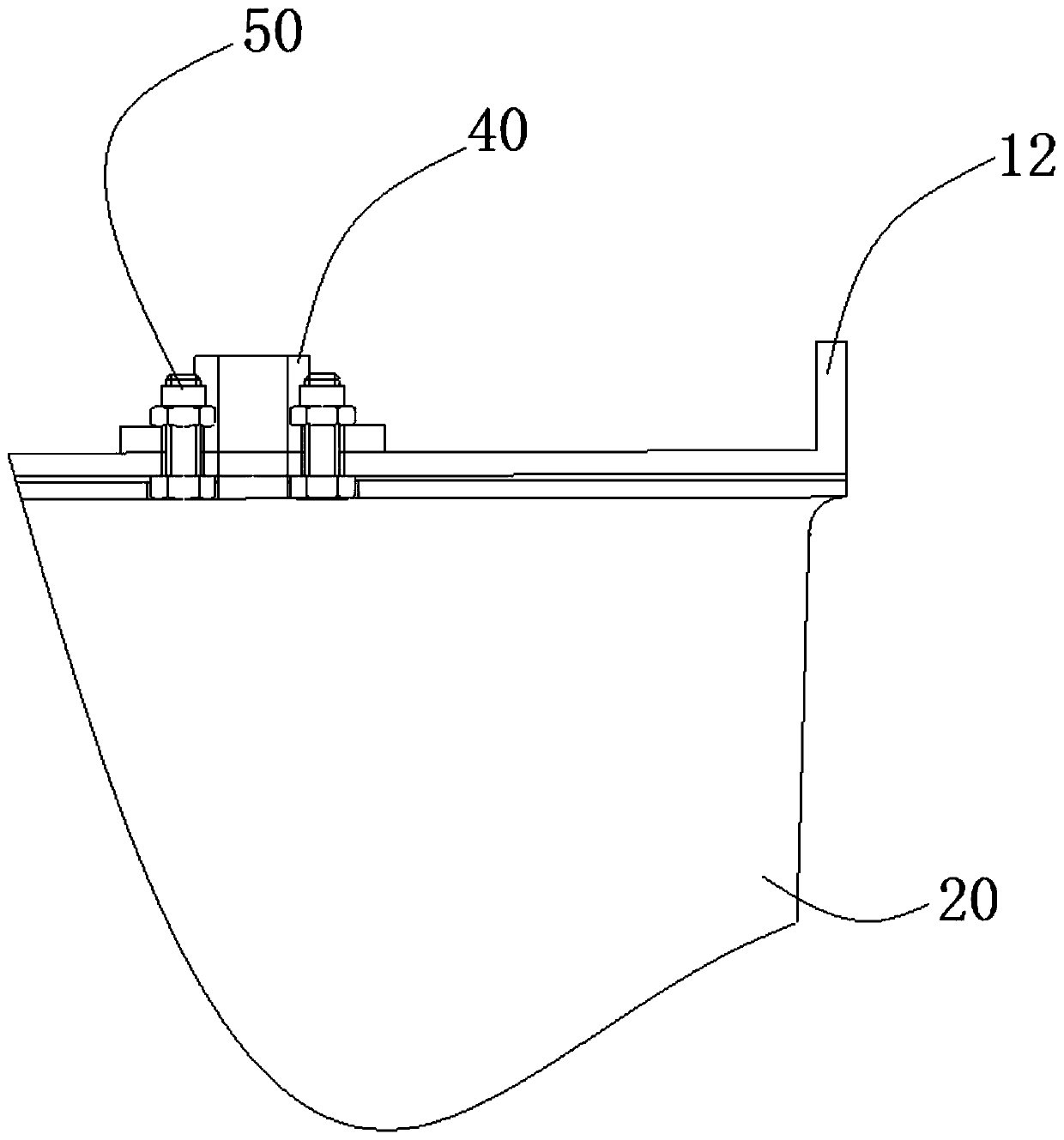

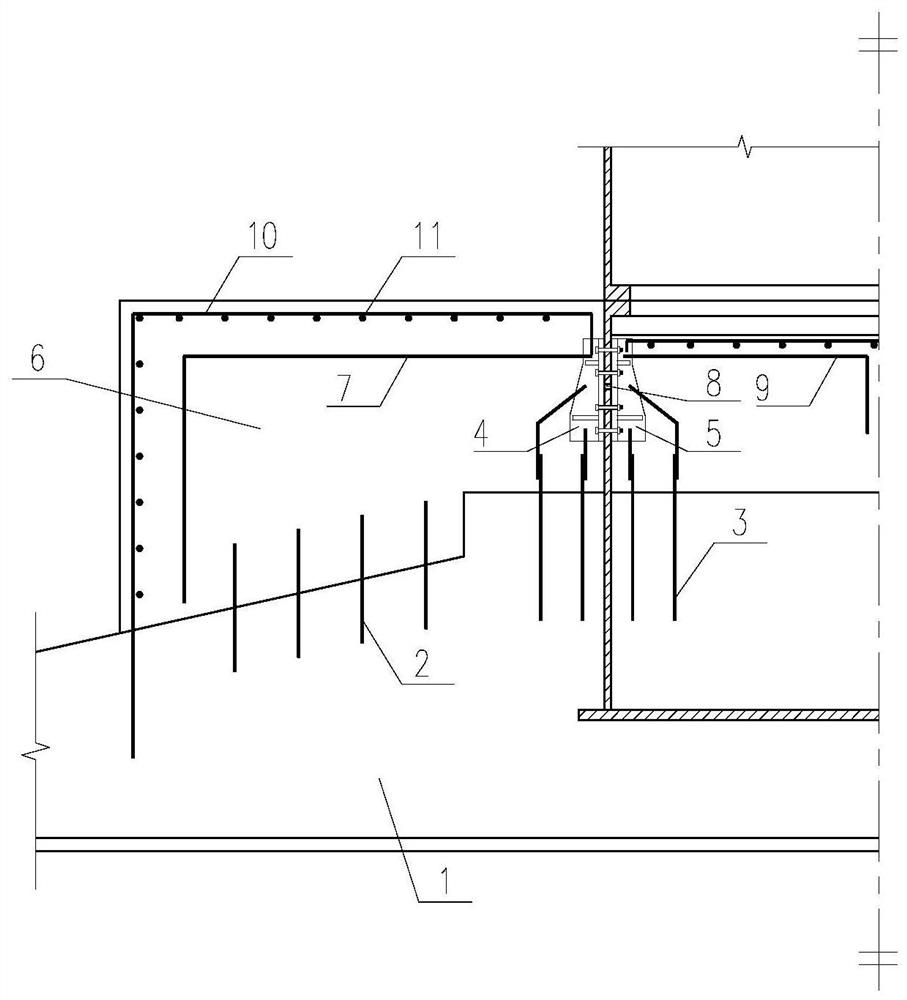

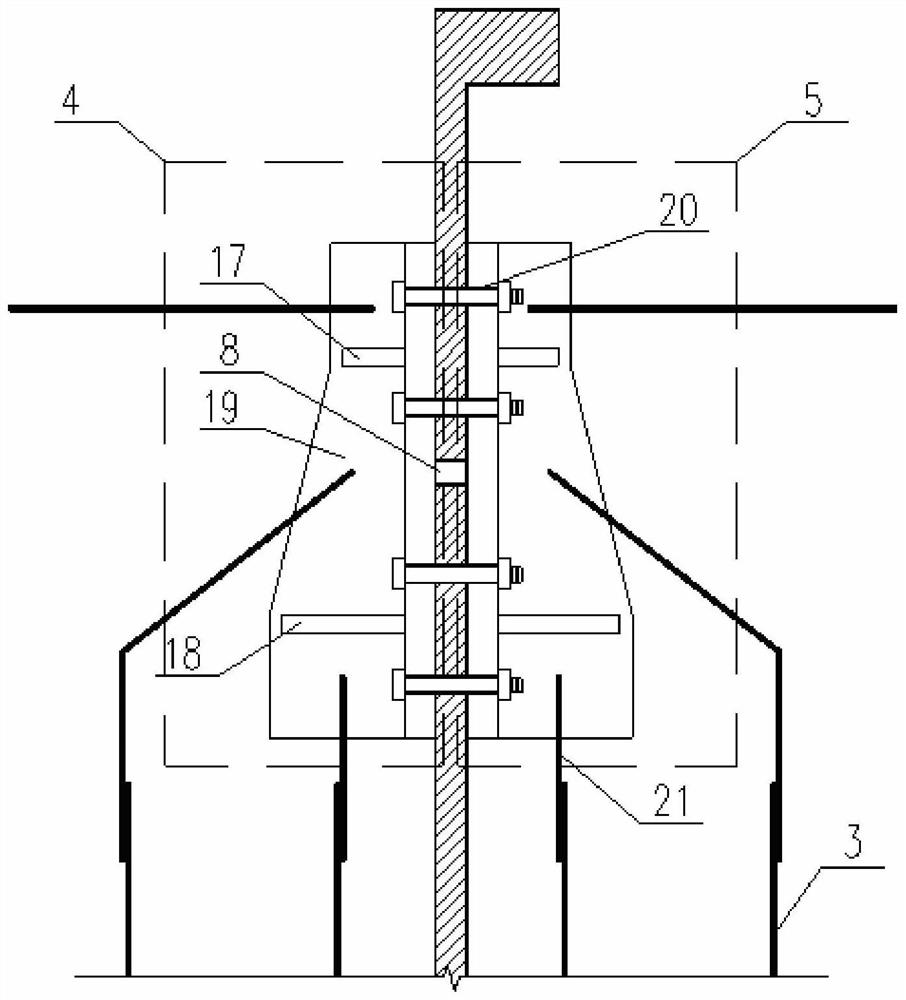

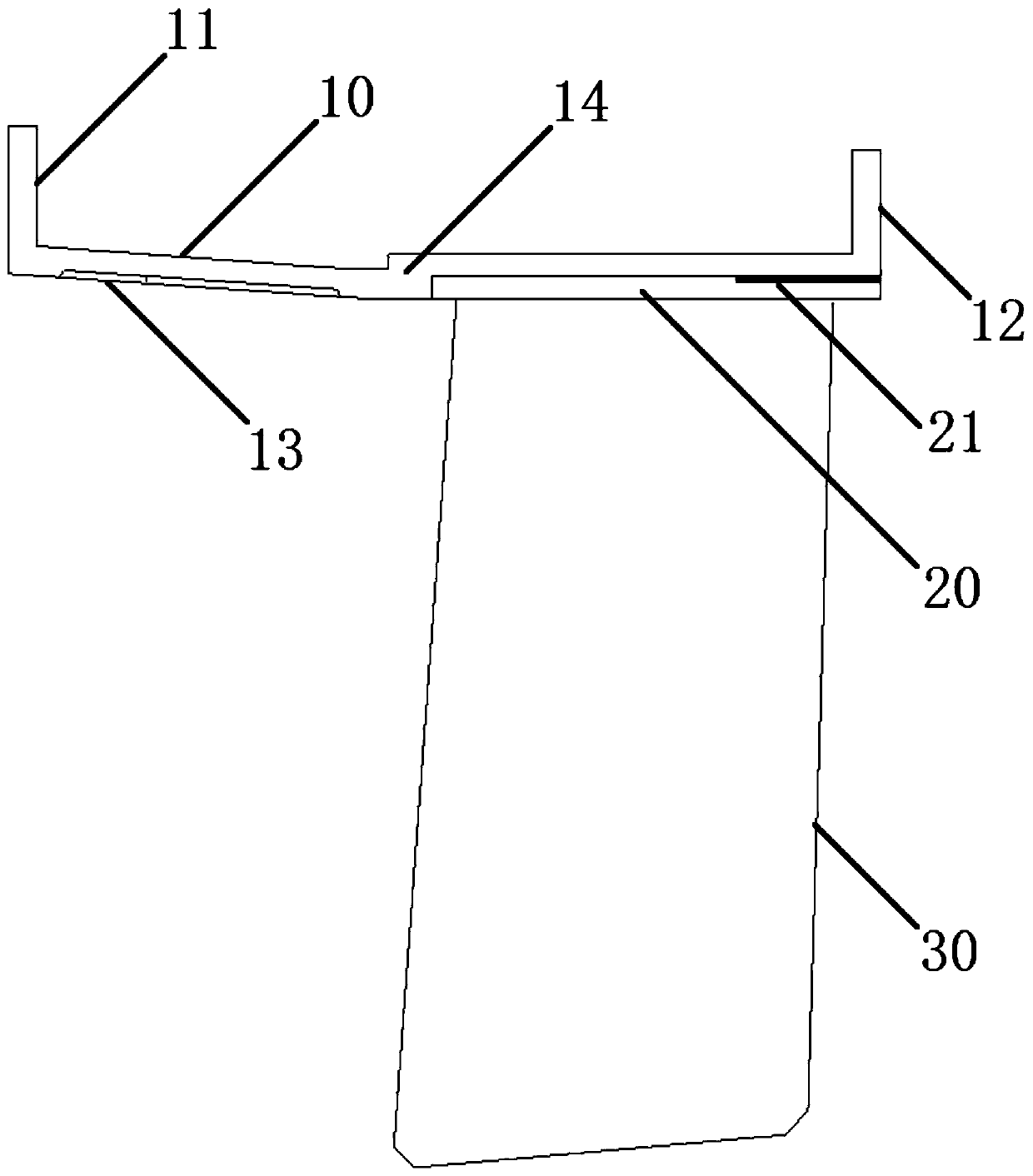

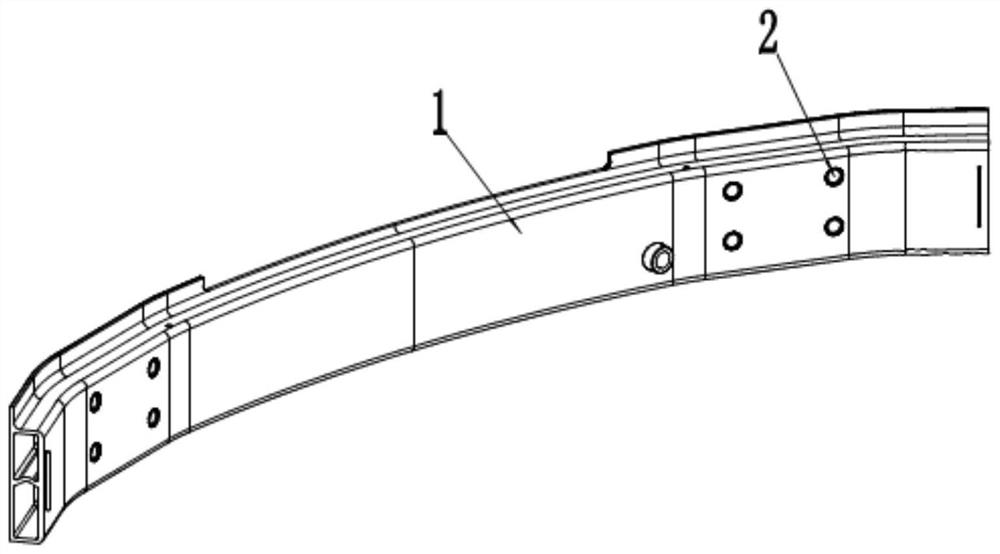

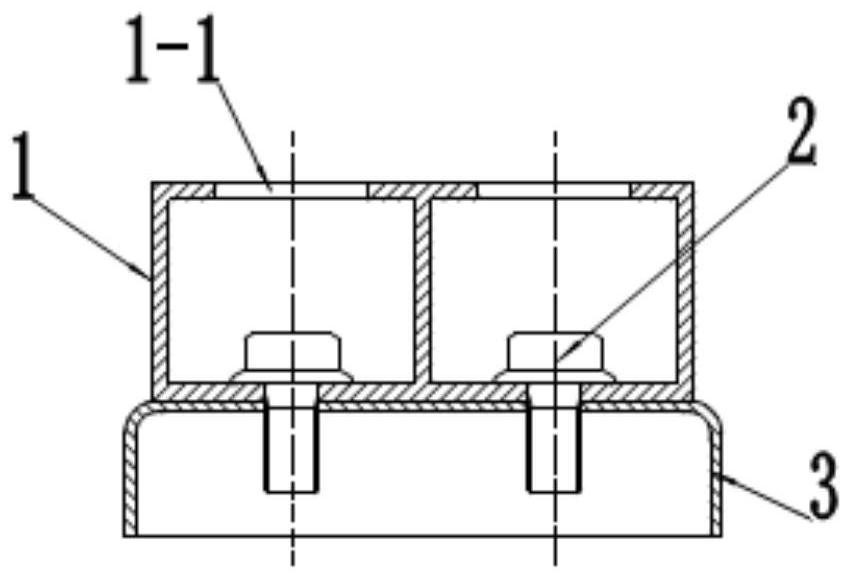

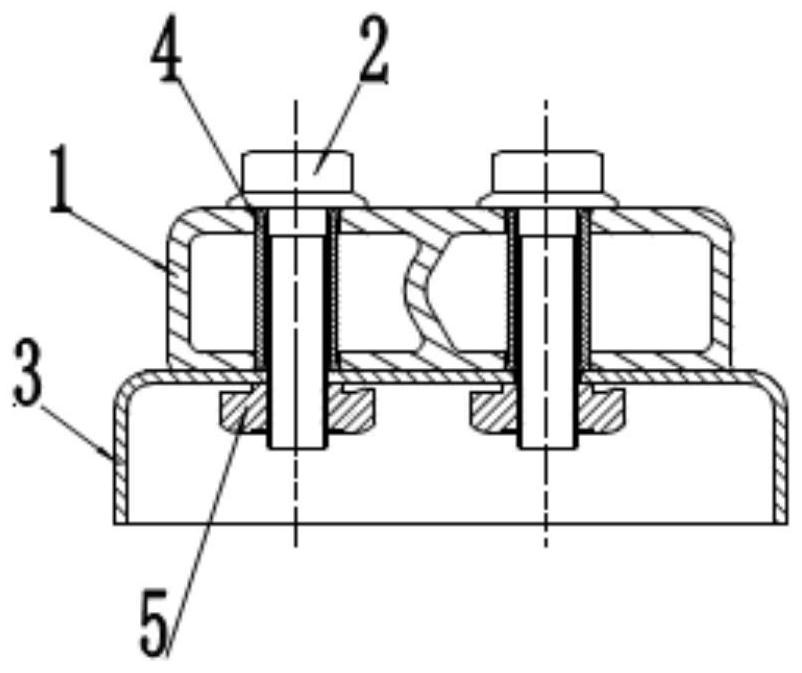

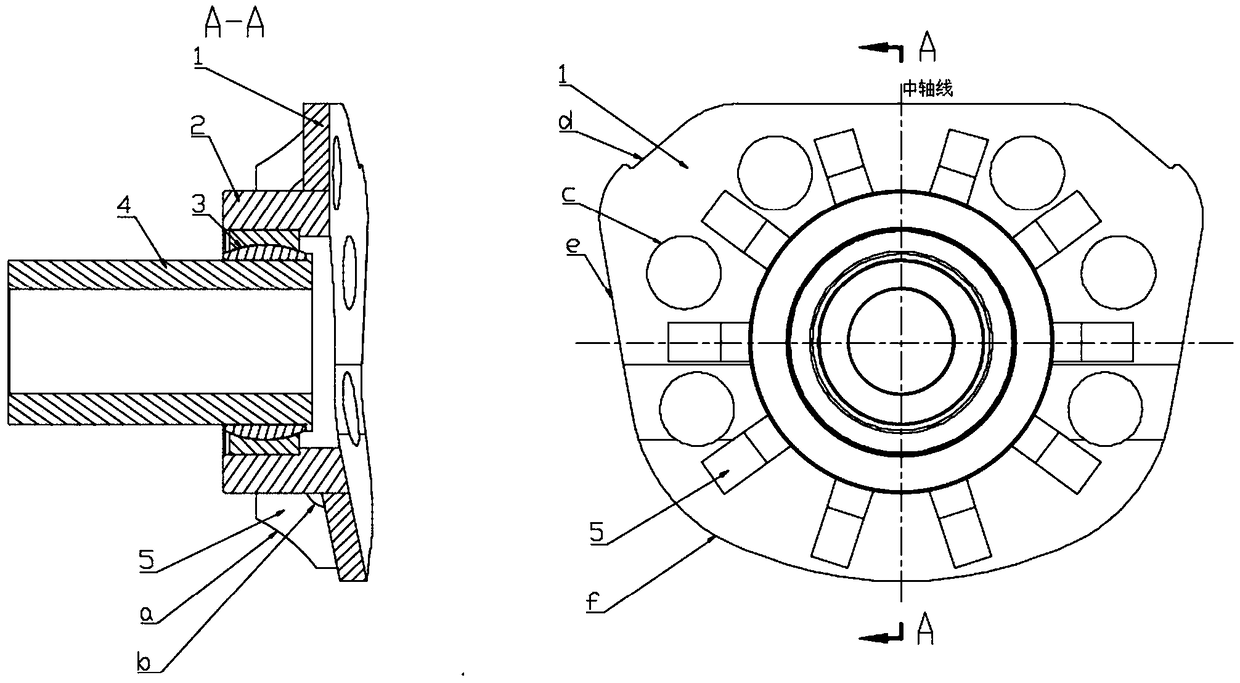

Local reinforcing equipment and method for wind power generator unit foundation ring

ActiveCN107100192AReduce fatigue damageEasy to useFoundation repairWind energy generationFatigue damageReinforced concrete

The invention discloses local reinforcing equipment for a wind power generator unit foundation ring. The local reinforcing equipment comprises an original reinforced concrete foundation and a local reinforcing device. The local reinforcing device comprises a newly-poured reinforced concrete foundation, inner side steel clamping plate units and outer side steel clamping plate units. The multiple inner side steel clamping plate units are arranged on the inner wall of the upper portion of a foundation ring of the original reinforced concrete foundation in an annular mode, and the multiple outer side steel clamping plate units are arranged on the outer wall of the upper portion of the foundation ring in an annular mode; and the newly-poured reinforced concrete foundation is poured on the original reinforced concrete foundation. According to the local reinforcing equipment for the wind power generator unit foundation ring, loads which are borne by the foundation ring and generated by a draught fan in a running state are dispersedly transmitted through the inner side steel clamping plate units, the outer side steel clamping plate units, connecting steel bars, inner foundation negative bend steel bars and outer foundation negative bend steel bars, stress in the reinforced foundation ring is effectively reduced, fatigue damage to a draught fan foundation is reduced, and the service life period of the reinforced draught fan foundation is greatly prolonged. The invention further discloses a local reinforcing method for the wind power generator unit foundation ring.

Owner:HUNAN UNIV OF SCI & TECH

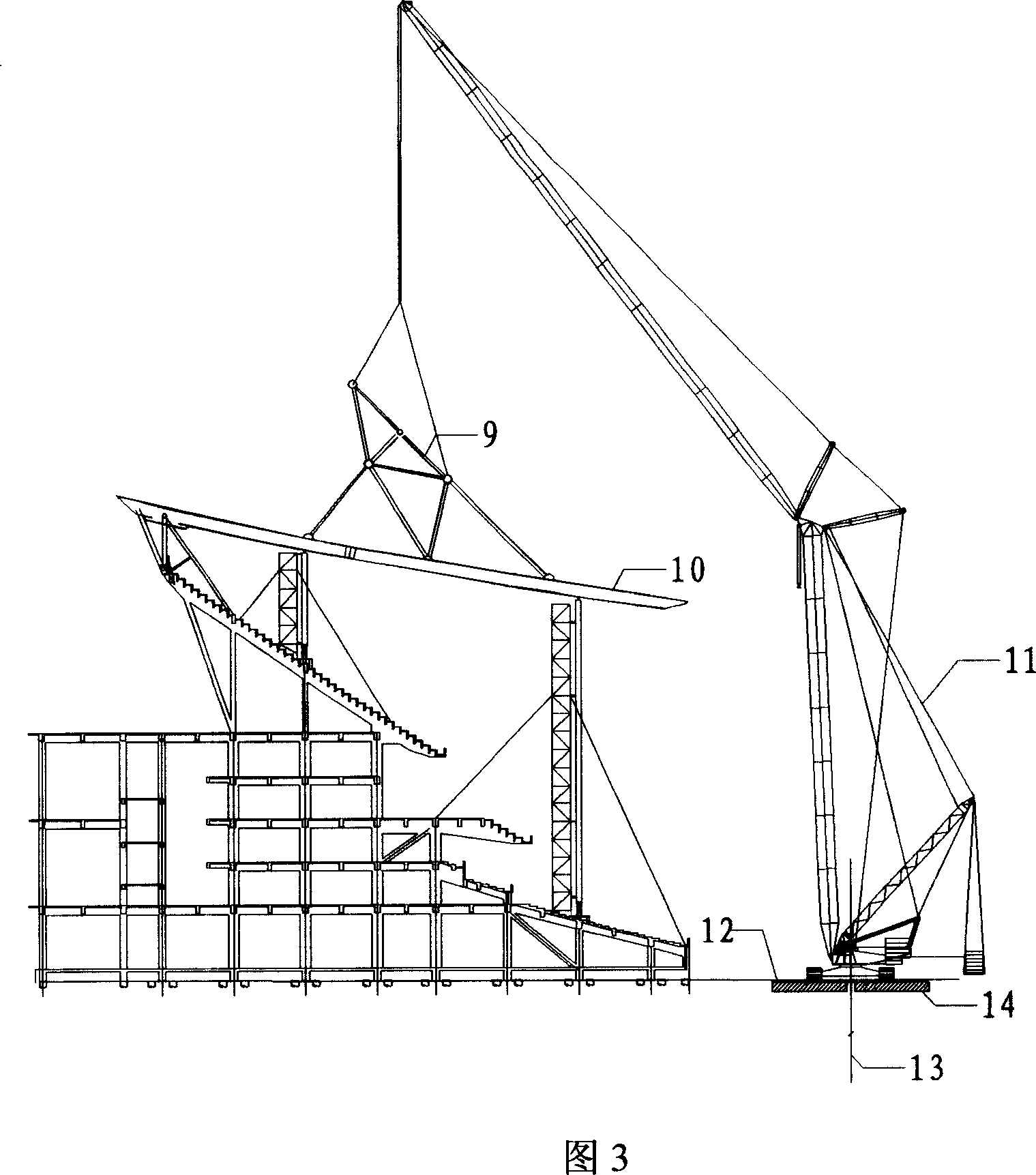

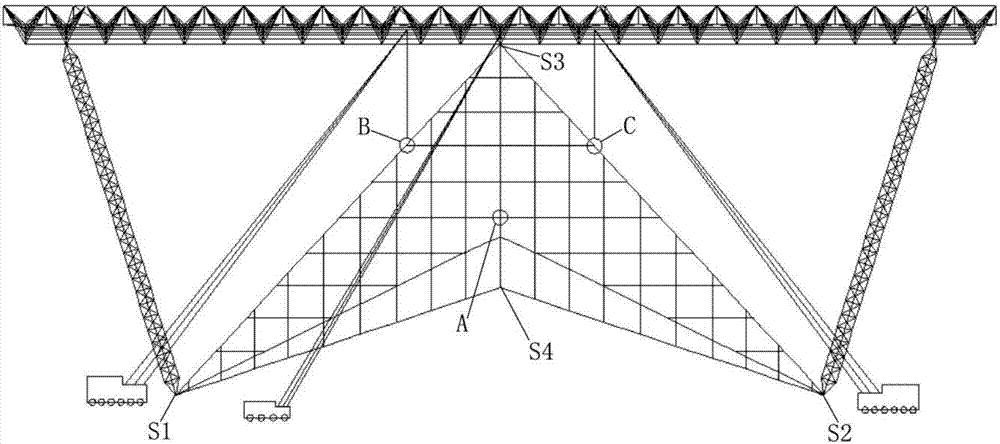

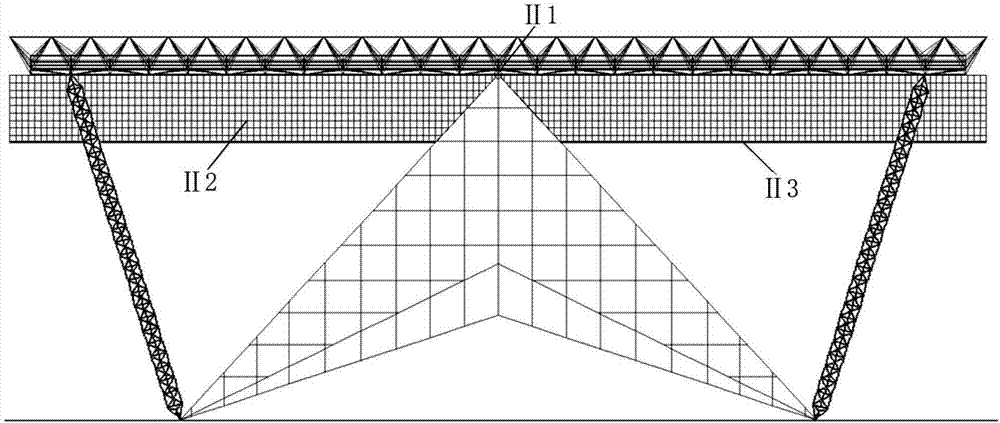

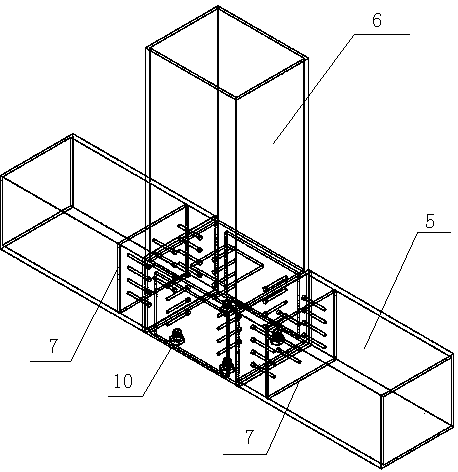

Construction method for integrally hoisting large-size multi-edge-and-corner overhanging truss

ActiveCN107100309AImprove assembly efficiencyEasy constructionBuilding roofsBuilding material handlingTerrainButt welding

A construction method for integrally hoisting a large-size multi-edge-and-corner overhanging truss is disclosed. Integral assembling of a steel pipe truss is conducted on site, and integral hoisting is conducted after assembling is completed; the truss is connected with three welding positions in a butt-joint mode and then is welded firmly; two 500 t all-terrain cranes and a 350 t all-terrain crane are adopted to hoist the whole truss simultaneously, and step-by-step hoisting is conducted from south to north; the truss is totally provided with three main stress support joints which are all fixed by adopting butt welding, a third calibration point support is located at the top of the truss, a welded ball joint at the position of the third calibration point is a support point of a steel rainshed grid frame actually, a first calibration point support and a second calibration point support are located on both the left and right sides of the bottom of the truss correspondingly, and the first calibration point support and the second calibration point support are global stress supporting points of the truss. The construction method for integrally hoisting the large-size multi-edge-and-corner overhanging truss has the characteristics that the construction safety is high, the construction period is short, the engineering quality is easy to guarantee, the ground integral assembling efficiency is high, and the construction cost is reduced greatly.

Owner:FUJIAN MINNAN CONSTR ENG

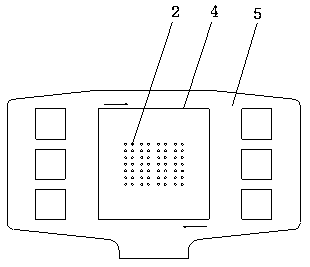

Armored withdraw type metal enclosed switch cabinet

InactiveCN101483322ANice appearanceAvoid welding stressBus-bar/wiring layoutsSwitchgear detailsCartClosed space

The present invention relates to a metal-clad movable metal-enclosed switchgear, which comprises a housing, a clapboard that surround the housing to be closed space of a bus-bar room, a cart room, a electric relay meter cabinet and a cable house; a circuit breaker cart is set in the cart room; the housing and the clapboard are made of Al-Zn coated steel sheet and they two riveted as a whole after bending; the circuit breaker cart is disposed on the chassis. The housing and the insulating clapboard in the invention is assembled but not welded with good-look appearance, welding stress is avoided, furthermore, the present invention is secure and reliable in use, and has good protective performance.

Owner:安徽中安恒宇电气传动有限公司

Motor rotor web crack welding repair method

ActiveCN103894702AAvoid Welding StressChange stressArc welding apparatusManufacturing stator/rotor bodiesPower flowRepair method

The invention discloses a motor rotor web crack welding repair method and solves the problems that a saw-toothed or crescent electrode is originally used to increase bath width and weld width, thermal stress is large and cracking occurs easily. A linear electrode manipulation method is adopted, a low-current small width welding method is adopted, arc ending is slow, a segment is re-welded to fill an end arc pit, the weld shape is changed, and cracking is avoided accordingly. A welding electrode A507 with higher tensile strength is used, a series of welding processes is taken, and the tensile strength of special equipment and special welds is met. The use of symmetric welding prevents excess welding stress effectively.

Owner:DATANG SHANDONG ELECTRIC POWER OVERHAUL & OPERATION

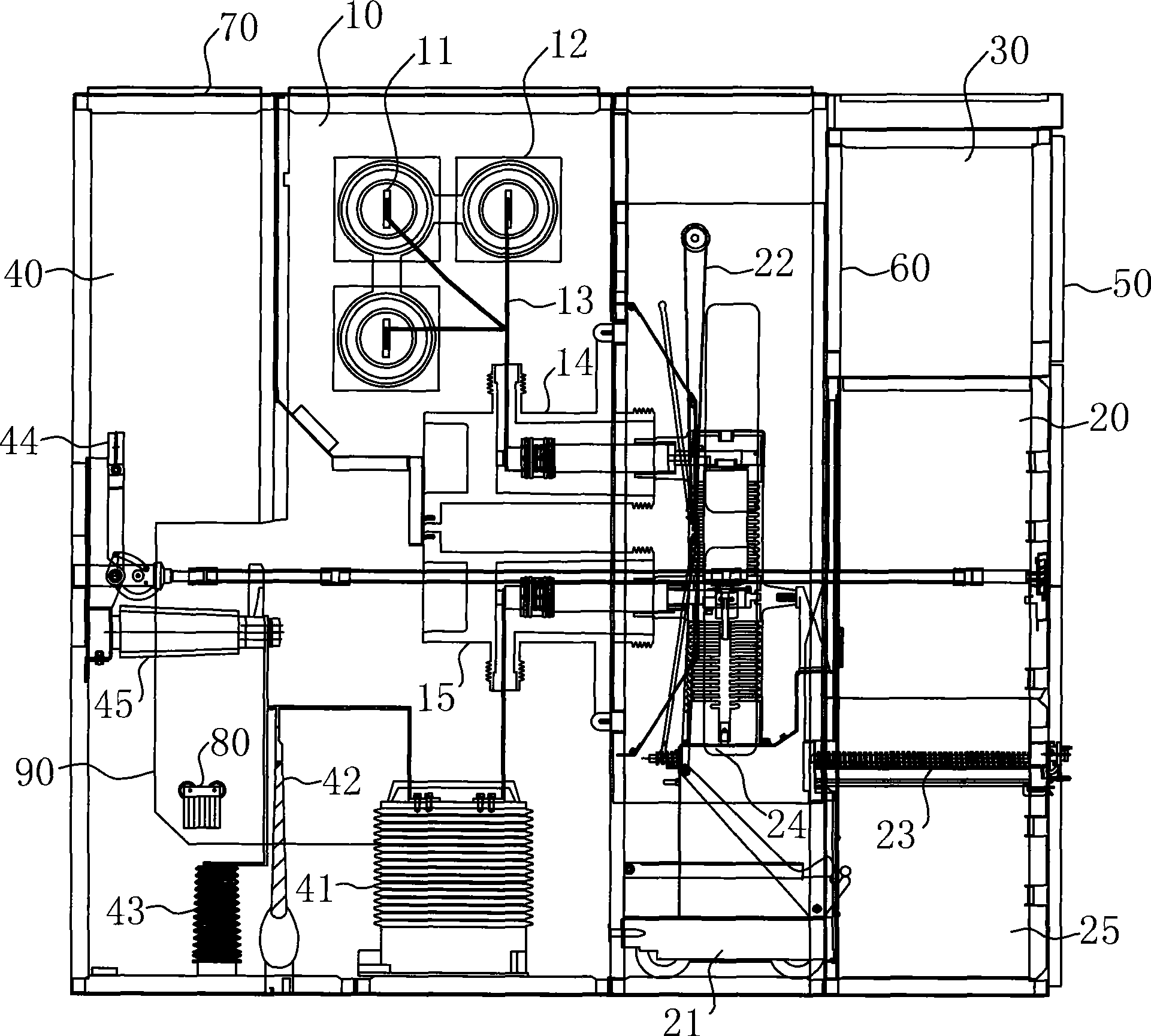

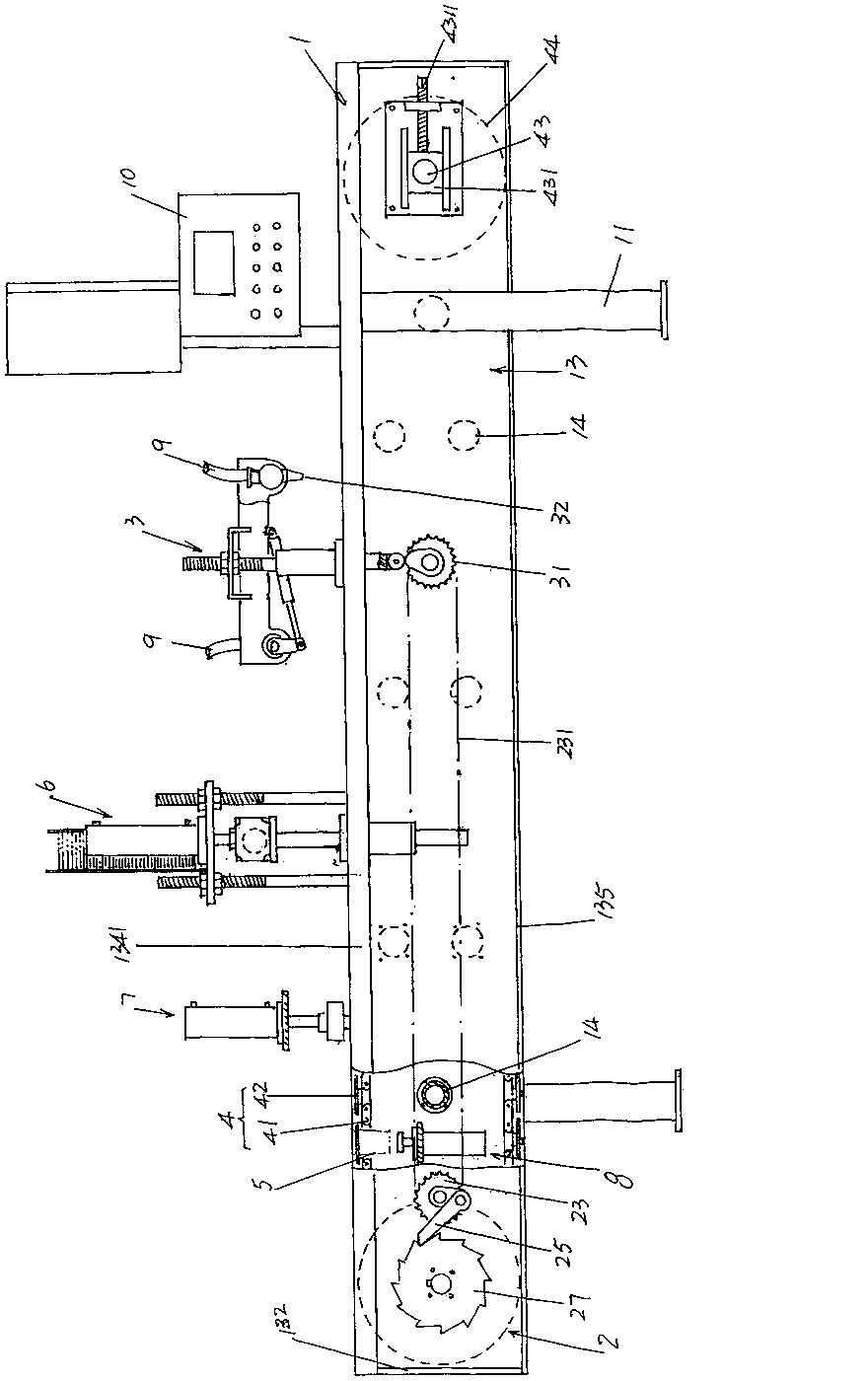

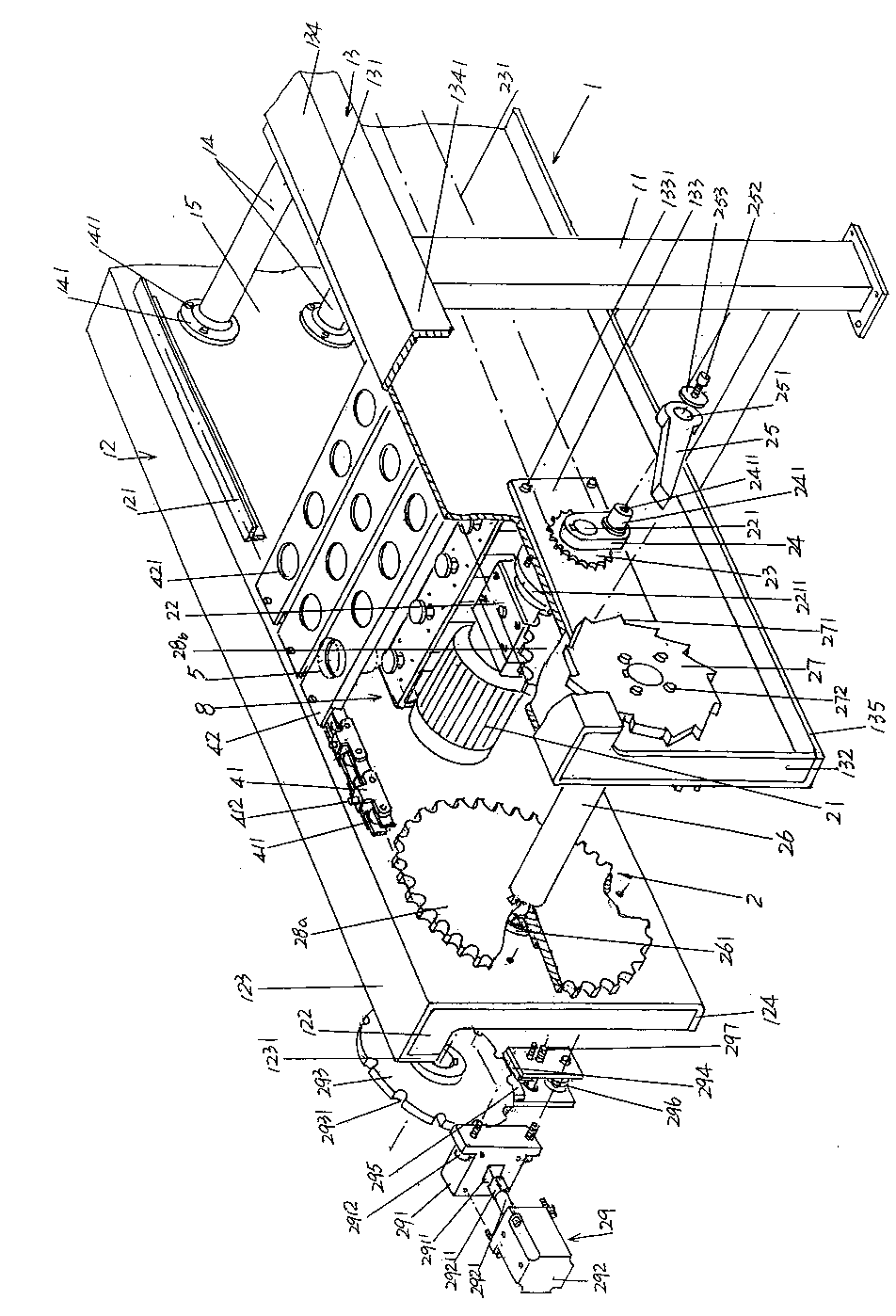

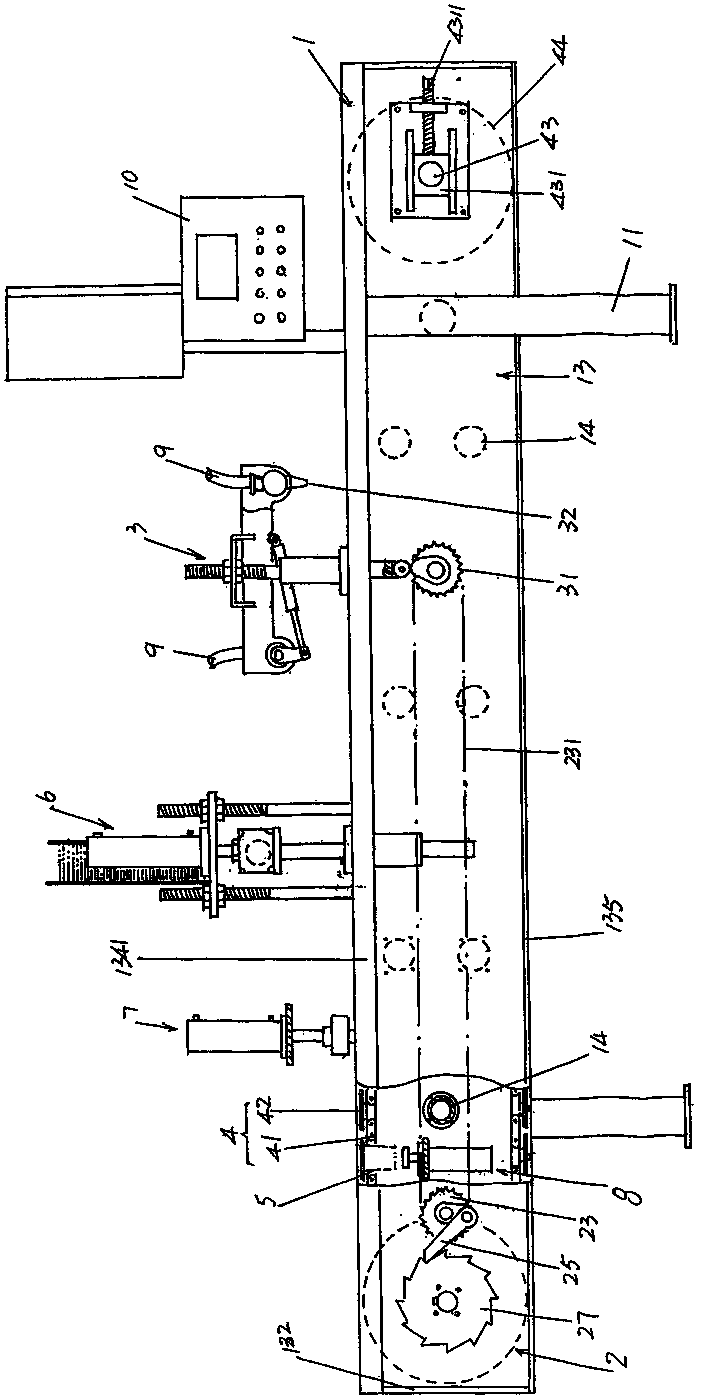

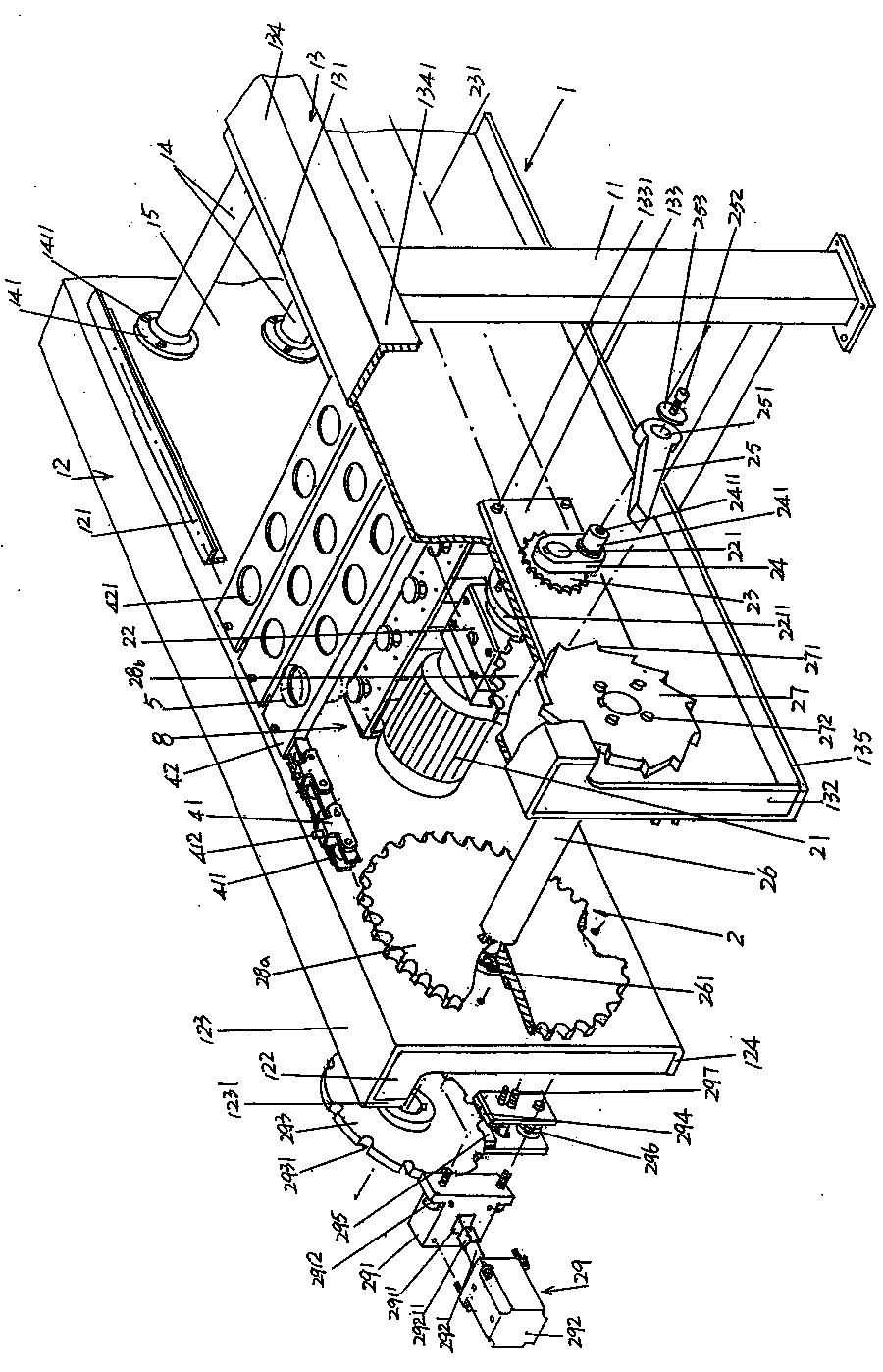

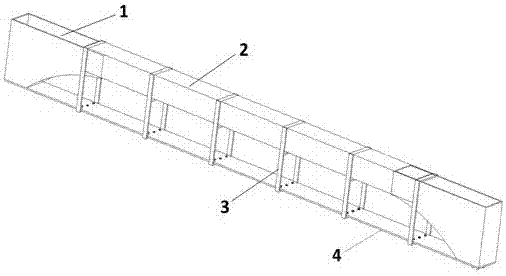

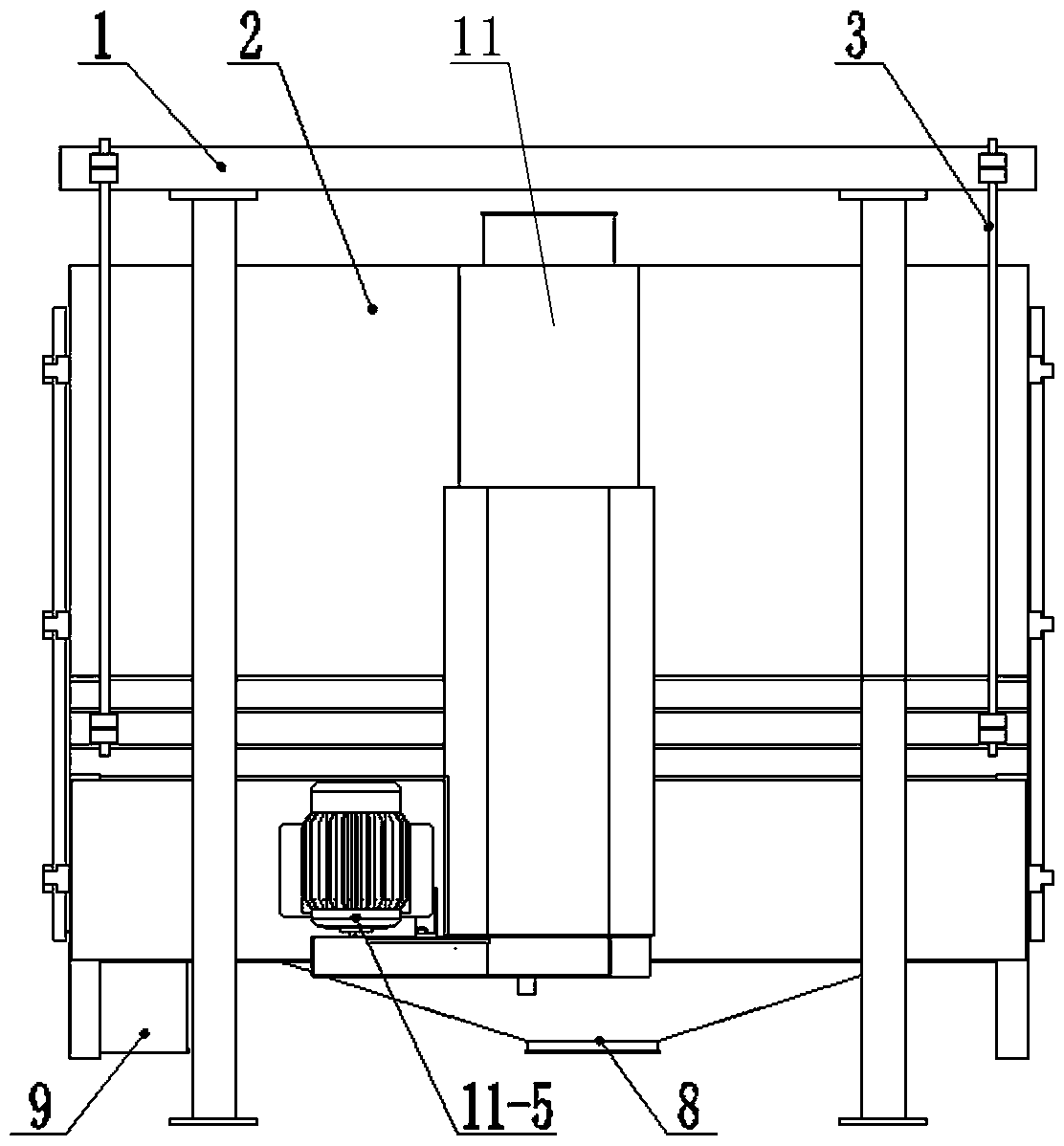

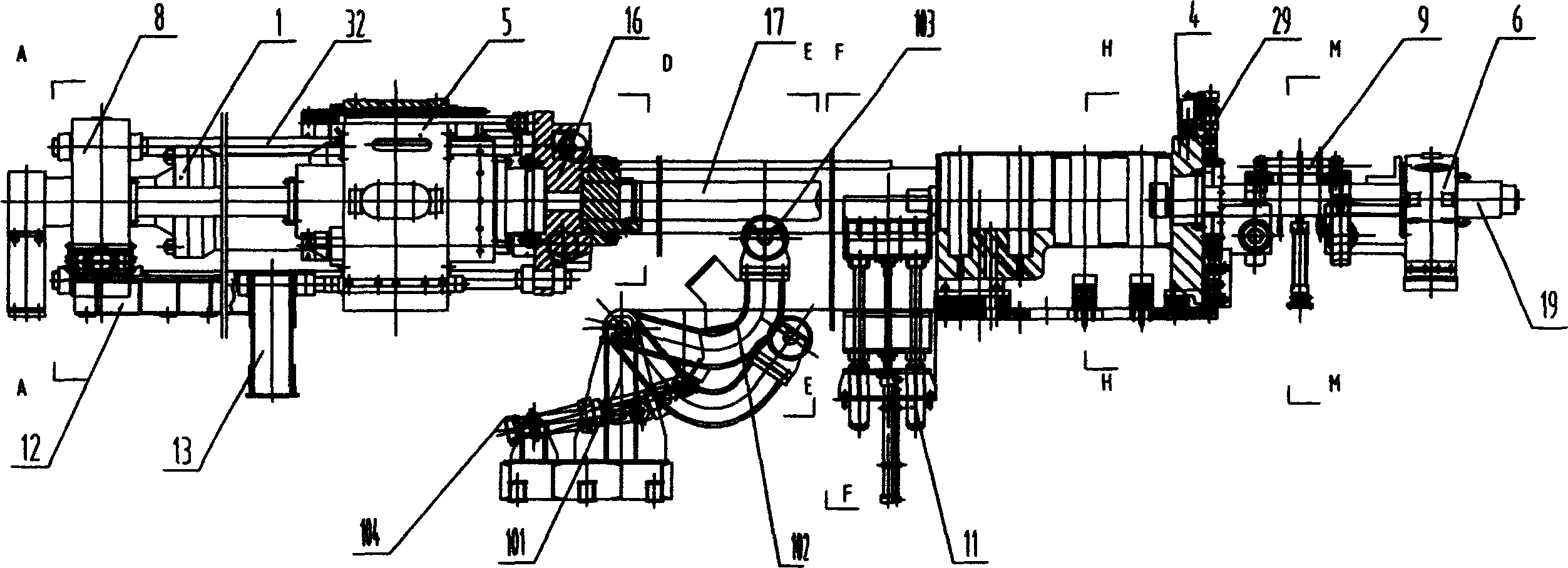

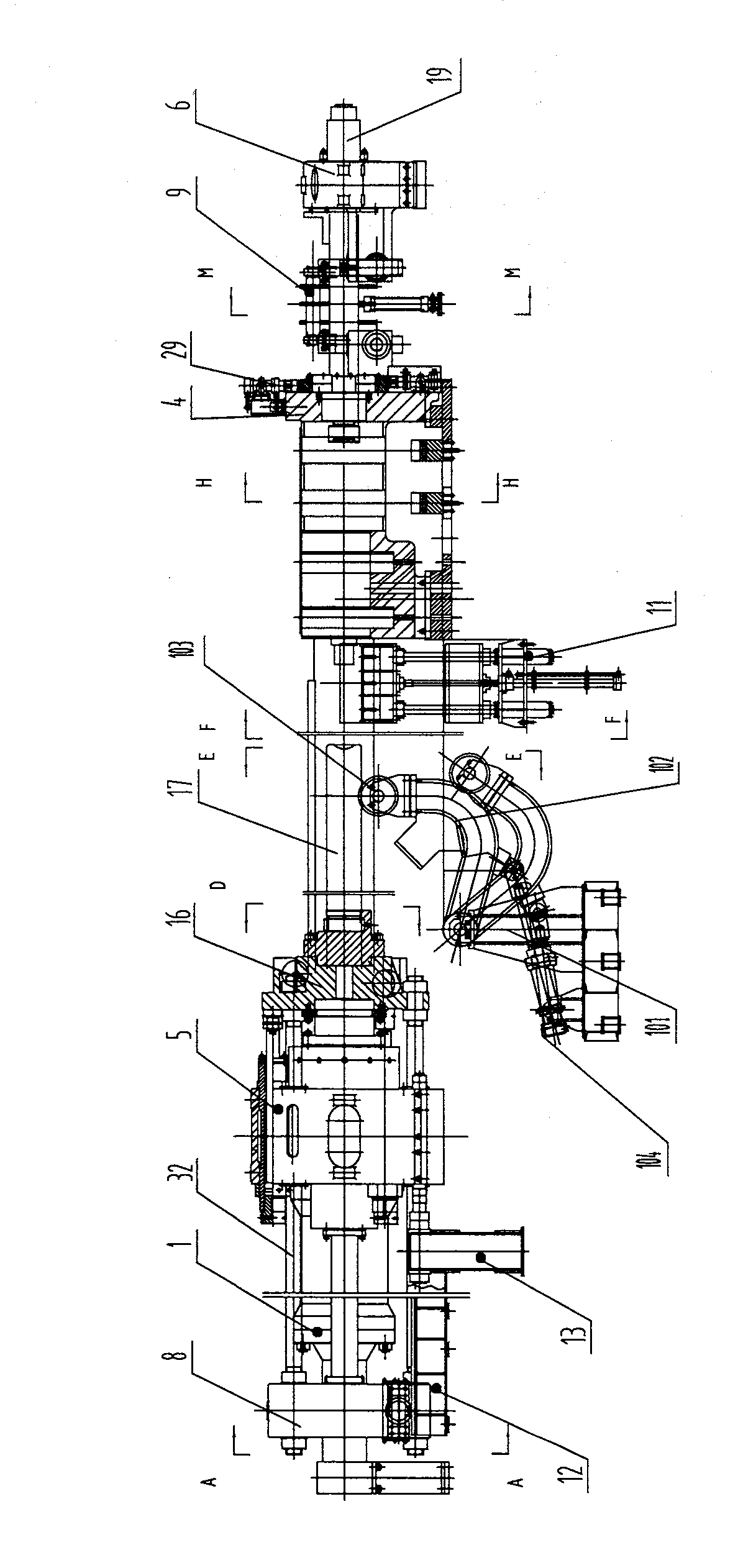

Automatic paper-cup ice cream filling machine

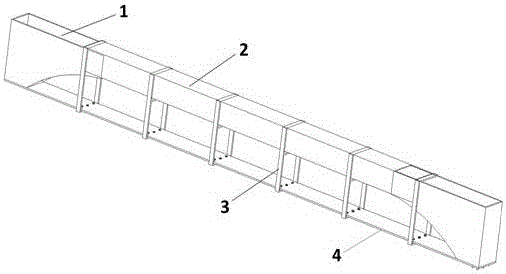

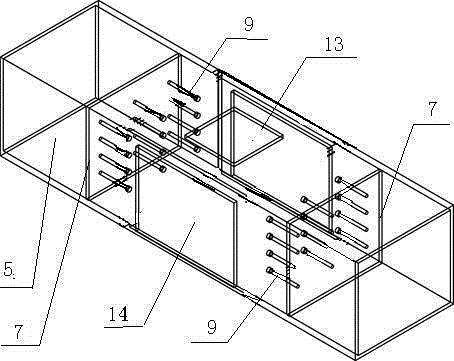

The invention discloses an automatic paper-cup ice cream filling machine belonging to food filling machinery. The automatic paper-cup ice cream filling machine comprises a rack, a power mechanism, a filling mechanism and a caterpillar mechanism, wherein the rack consists of a cross beam support, a first cross beam, a second cross beam and a group of cross beam supports; the power mechanism is arranged at one end of the rack; the filling mechanism is arranged at the other end of the rack; the caterpillar mechanism is arranged between the first cross beam and the second cross beam; a first horizontal folding edge is formed at the upper part of the first cross beam, a first vertical folding edge is formed on the first horizontal flange, a second horizontal folding edge is formed at the lower part of the first cross beam, a third horizontal folding edge is formed at the upper part of the second cross beam, a second vertical folding edge is formed on the third horizontal folding edge, and a fourth horizontal folding edge is formed at the lower part of the second cross beam; fixed flange seats are respectively fixed at the two ends of the group of cross beam supports; and the power mechanism comprises a motor, a reduction gearbox, a main transmission wheel, a cam, a pawl, a large sprocket shaft, a ratchet wheel disc, a first large sprocket, a second large sprocket and an inertia elimination device. The intensity of the cross beams is ensured, the safety is ensured, and the reliability of movement and pause of paper cups carried by the caterpillar mechanism is ensured.

Owner:常熟威玛乳品机械有限公司

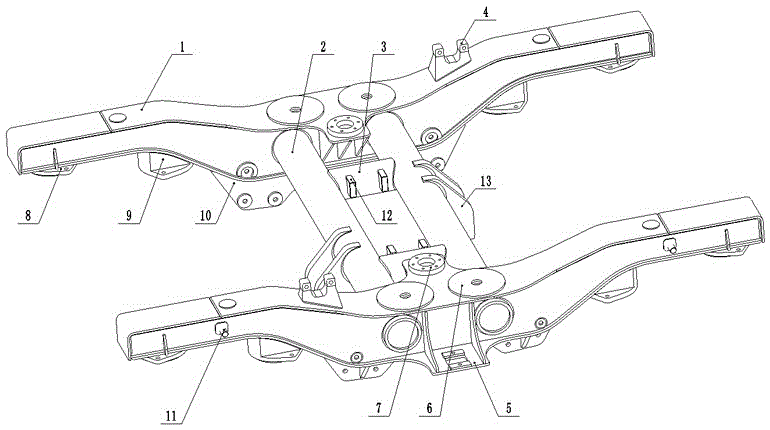

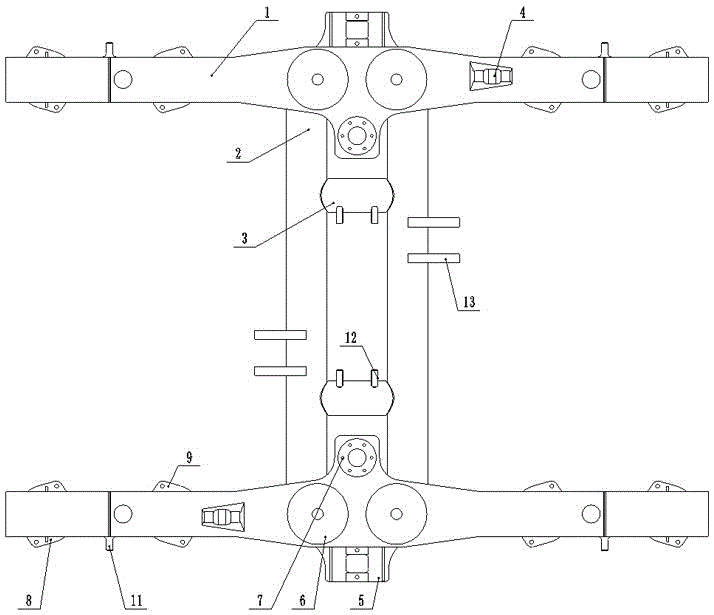

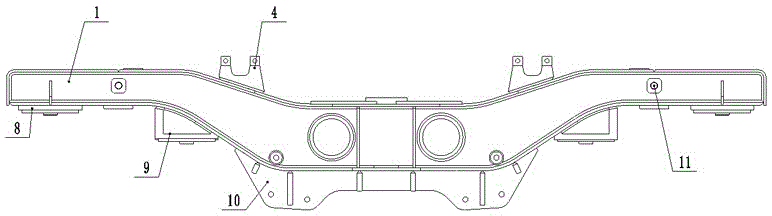

Engineering detection vehicle bogie frame

PendingCN107176179ARealize the purpose of lightweight designGuaranteed production costBogiesBogieBrake

The invention discloses an engineering detection vehicle bogie frame. The engineering detection vehicle bogie frame comprises an H-shaped frame body composed of two side beams of a box-shaped structure and two cross beams of a hollow structure. Hollow auxiliary beams are fixed between the inner sides of the two cross beams. The middles of the side beams are sunken to form sunken parts used for mounting secondary spring seats. The outer sides of the middles of lower cover plates of the side beams protrude outward to form vertical oil pressure shock absorber seats. According to the trailer engineering detection vehicle bogie frame suitable for tread brake, the side beams are of the box-shaped structure, the cross beams and the auxiliary beams all adopt hollow steel pipes, thus the whole weight of the frame is effectively decreased while strength is guaranteed, and the purpose that a vehicle body is lightweight is achieved.

Owner:CRRC LUOYANG CO LTD

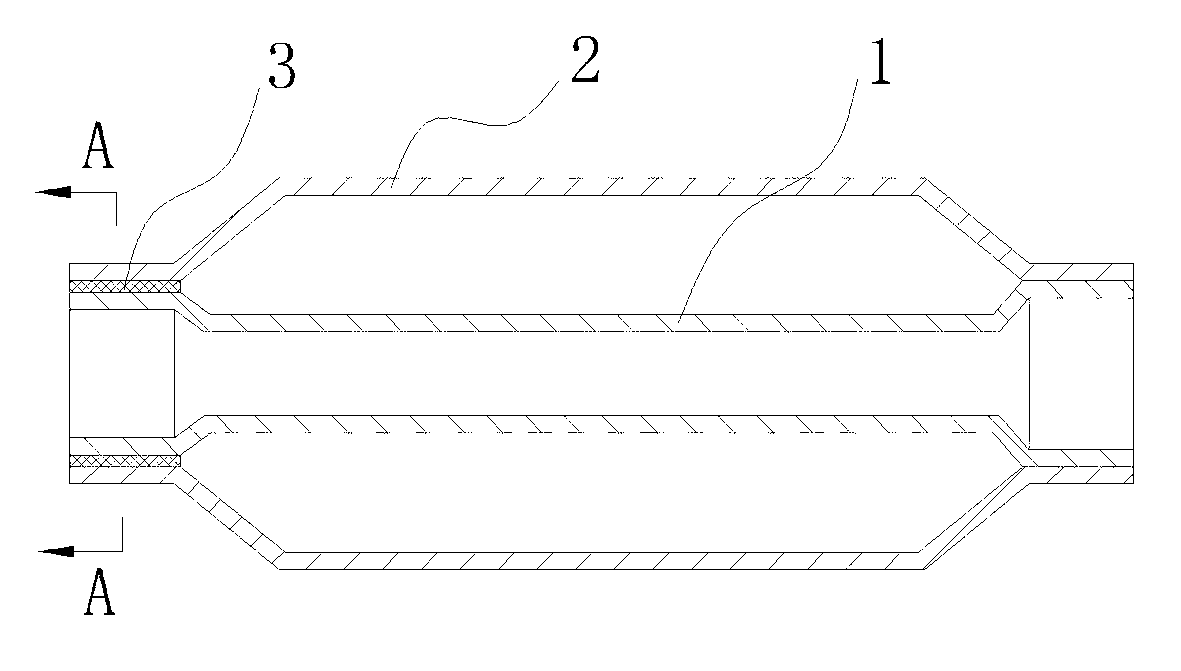

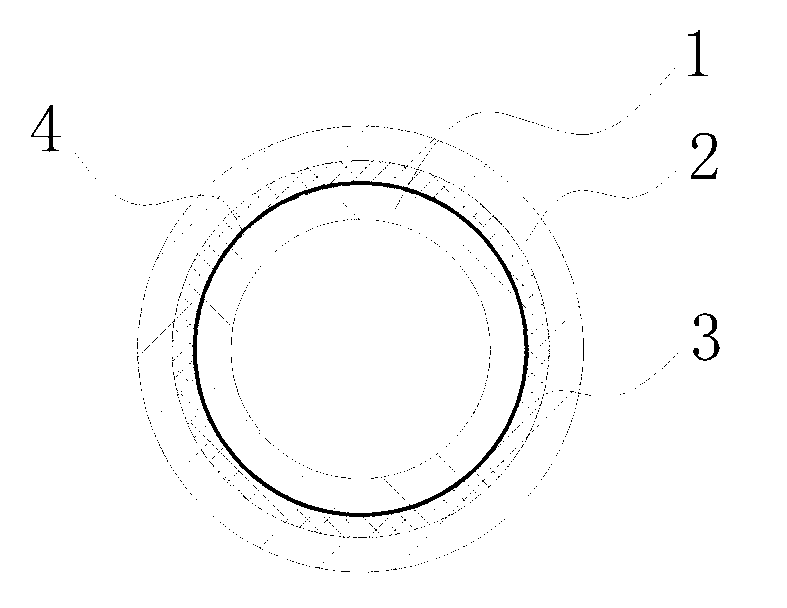

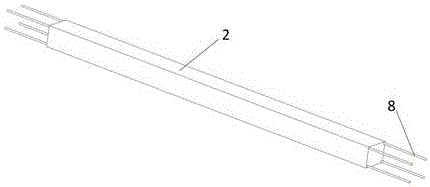

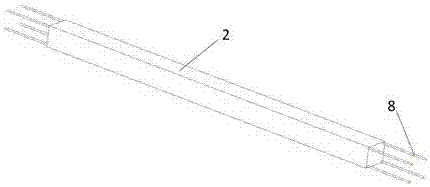

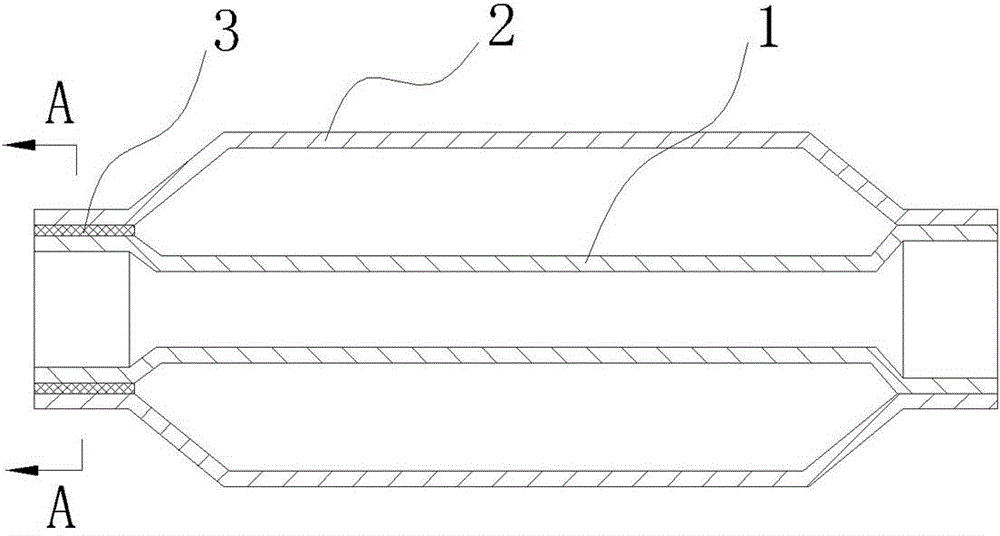

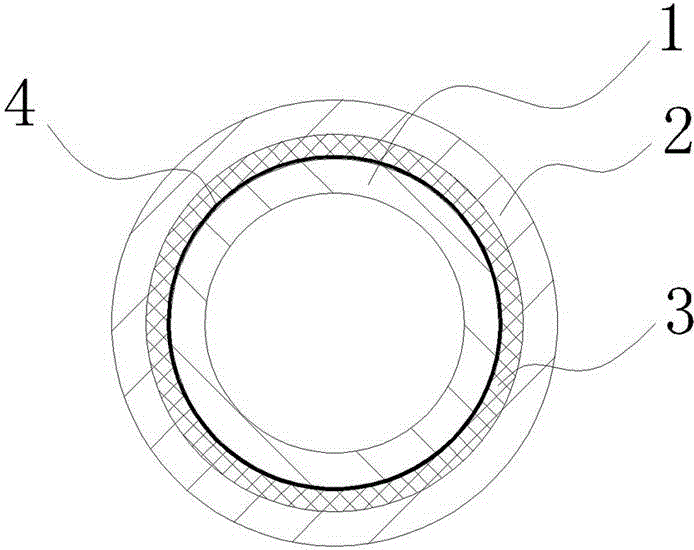

Exhaust pipe structure capable of eliminating welding stress

InactiveCN103291432AGuaranteed validityPrevent axial slippageExhaust apparatusSilencing apparatusStructural engineeringMechanical engineering

The invention discloses an automobile exhaust pipe structure, and provides an exhaust pipe structure which is simple in structure and ingenious in conception, can eliminate welding stress and avoid breakage of welding ports of an inner pipe and an outer pipe of the exhaust pipe due to high temperature and low temperature alternation, and solves the technical problems that when an automobile runs in a cold area, the welding ports at the two ends of the exhaust pipe are easy to break due to the high temperature and low temperature alternation, the abnormal sound of the exhaust pipe is caused, and even seriously, the failure of the exhaust pipe is caused in the prior art. The exhaust pipe structure comprises an inner barrel and an outer barrel, wherein the inner barrel is coaxially sleeved and covered with the outer barrel; one end of the outer barrel is welded and fixed on the corresponding inner barrel; an elastic piece is sandwiched between an internal wall surface at the other end of the outer barrel and a corresponding external wall surface of the inner barrel; and the inner barrel is supported in the outer barrel by the elastic piece elastically.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

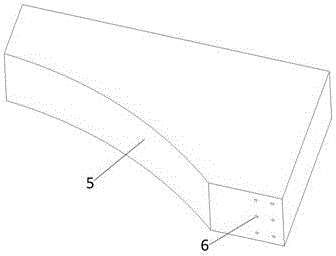

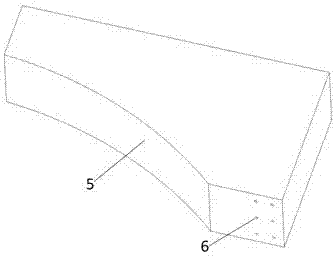

Novel steel-concrete combined open web girder and manufacturing method thereof

InactiveCN105888135AAvoid Welding StressAvoid deformationLoad-supporting elementsSheet steelLine tubing

The invention discloses a novel steel-concrete combined open web girder and a manufacturing method thereof. The open web girder comprises upper-portion rectangular portion reinforced concrete, lower-portion pulled steel plates, end arc-shaped steel pipes and steel plate hoops, wherein longitudinal steel bars are reserved at two ends of the upper-portion rectangular portion reinforced concrete, the longitudinal steel bars are inserted into the end arc-shaped steel pipes together with the ends of the upper-portion rectangular portion reinforced concrete, then concrete is cast into the end arc-shaped steel pipes, and the upper-portion rectangular portion reinforced concrete is anchored and connected with the end arc-shaped steel pipes together after the concrete reaches the design strength. The problems of slippage between the concrete and section steel in a traditional steel-concrete combined girder, welding stress and deformation caused by welding, large formwork consumption, low construction efficiency and the like are solved, the steel-concrete combined open web girder has good mechanical properties, the open web position of the girder facilitates layout of special water heating and electrical pipelines, and accordingly building space is saved.

Owner:GUIZHOU UNIV

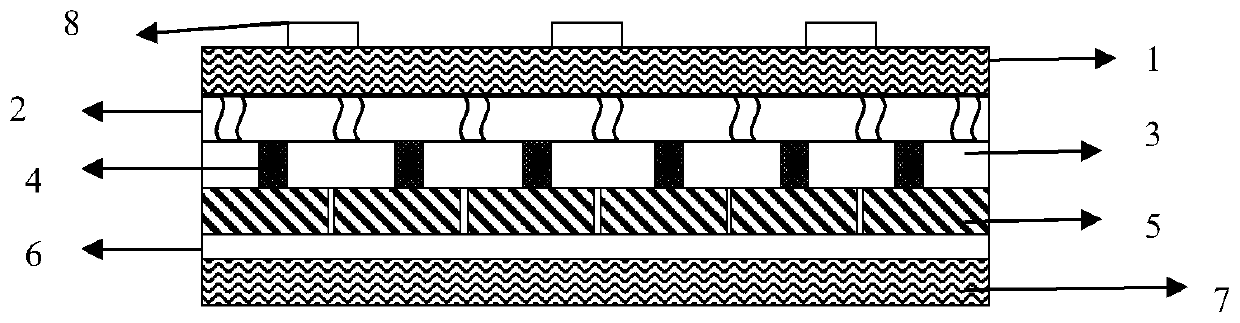

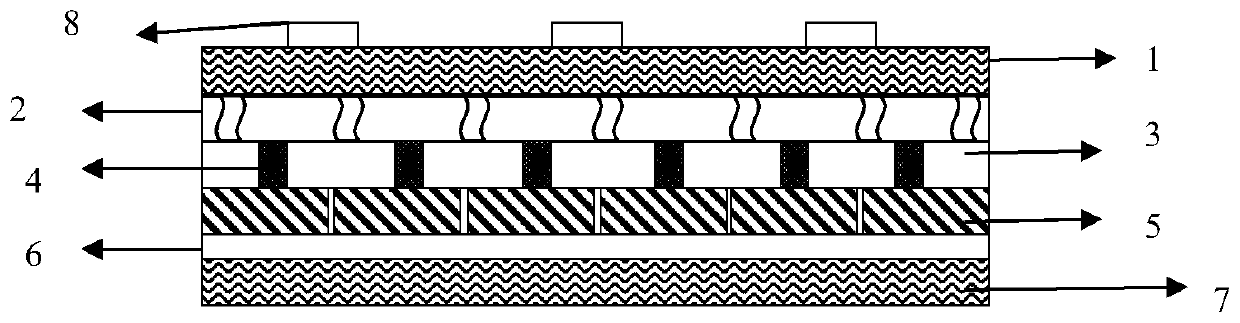

Double-sided double-glass assembly for back contact solar cell, and manufacturing method of double-sided double-glass assembly

InactiveCN109713068AAchieve double-sided power generationHigh back light transmittanceFinal product manufacturePhotovoltaic energy generationCell layerTransmittance

The invention discloses a double-sided double-glass assembly for a back contact solar cell, and a manufacturing method of the double-sided double-glass assembly. The manufactured assembly comprises afirst glass layer, a transparent conductive circuit layer, a first packaging material layer, a back contact cell layer, a second packaging material layer, a second glass layer and a junction box, which are sequentially laminated together from bottom to top. A conductive adhesive medium connecting point layer is arranged on the transparent conductive circuit layer; and the transparent conductive circuit layer is a conductive circuit formed on the first glass layer by a nano-silver conductive material. According to the invention, the double-sided power generation of the back contact battery canbe realized, the back light transmittance is high, and the higher double-sided rate can be realized. Meanwhile, the back contact technology and the double-sided power generation technology are superposed, and the transparent conductive thin film is adopted, so that the double-sided assembly achieves a high double-sided rate, welding stress caused by using a welding strip is avoided, hidden crack of the assembly is reduced, and assembly attenuation is small.

Owner:JIANGSU SUNPORT POWER CORP LTD

Automatic paper-cup ice cream filling machine

The invention discloses an automatic paper-cup ice cream filling machine belonging to food filling machinery. The automatic paper-cup ice cream filling machine comprises a rack, a power mechanism, a filling mechanism and a caterpillar mechanism, wherein the rack consists of a cross beam support, a first cross beam, a second cross beam and a group of cross beam supports; the power mechanism is arranged at one end of the rack; the filling mechanism is arranged at the other end of the rack; the caterpillar mechanism is arranged between the first cross beam and the second cross beam; a first horizontal folding edge is formed at the upper part of the first cross beam, a first vertical folding edge is formed on the first horizontal flange, a second horizontal folding edge is formed at the lower part of the first cross beam, a third horizontal folding edge is formed at the upper part of the second cross beam, a second vertical folding edge is formed on the third horizontal folding edge, and a fourth horizontal folding edge is formed at the lower part of the second cross beam; fixed flange seats are respectively fixed at the two ends of the group of cross beam supports; and the power mechanism comprises a motor, a reduction gearbox, a main transmission wheel, a cam, a pawl, a large sprocket shaft, a ratchet wheel disc, a first large sprocket, a second large sprocket and an inertia elimination device. The intensity of the cross beams is ensured, the safety is ensured, and the reliability of movement and pause of paper cups carried by the caterpillar mechanism is ensured.

Owner:常熟威玛乳品机械有限公司

Large bridge support base plate and connecting method thereof

PendingCN111485489ASimple structural designReasonable structural designBridge structural detailsBridge erection/assemblyStructural engineeringOperation safety

The invention relates to a large bridge support base plate and a connecting method thereof. The base plate is installed at the bottom of the steel beam bottom plate of a bridge and comprises a base plate body. Countersunk bolt holes are evenly formed in the middle area of the base plate body, and connecting weld joints welded and fixed to the steel beam bottom plate are arranged on the four sidesin the circumferential direction. The base plate body is installed at the bottom of the steel beam bottom plate in a matched mode through the countersunk bolt holes and countersunk bolts and is weldedand fixed to the bottom of the steel beam bottom plate through the connecting weld joints. The connecting method comprises the following steps: (1) controlling the connecting precision of the supportbase plate; (2) eliminating the welding stress of the support base plate; and (3) controlling the deformation of the support base plate. The problems existing in the prior art can be effectively solved, the mounting precision and stress safety of the ultra-large support base plate are guaranteed, the service life of a bridge is prolonged, and operation safety is improved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

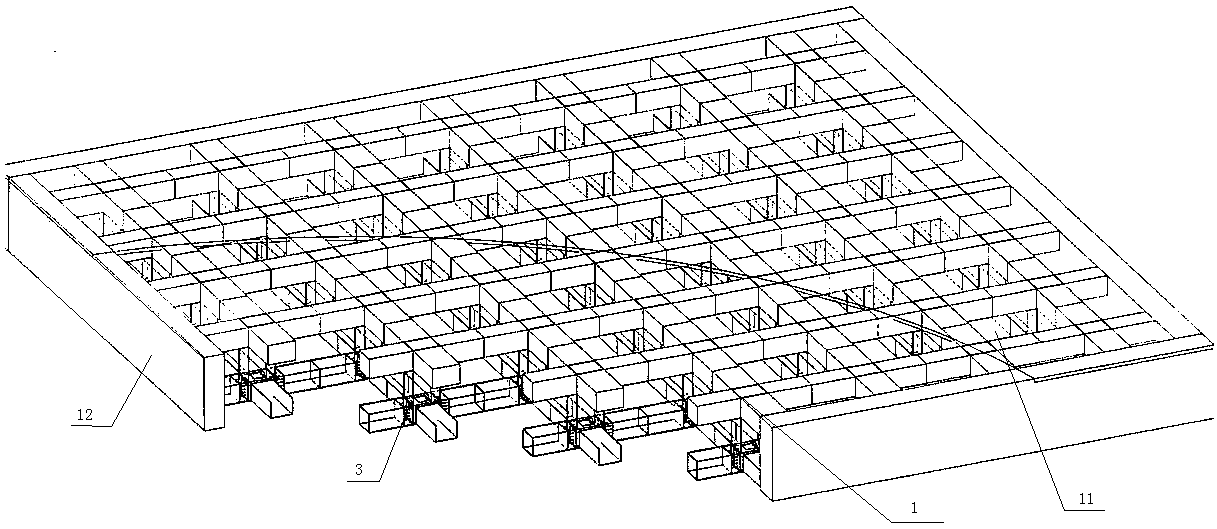

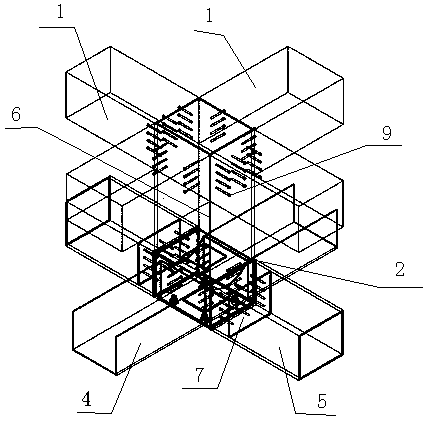

Novel steel-concrete combined open web girder system

Concrete upper ribs and floors of a novel steel-concrete combined open web girder system are made of cast-in-place concrete and form an orthogonal cross shape; holes are formed in reverse T-shaped joints of combined components so that concrete can be conveniently cast into the holes and shear connectors can be formed; reverse T-shaped steel pipes and U-shaped steel plates are all prefabricated in a factory, in the use process, the U-shaped steel plates penetrate through reserved holes in the bottoms of the reverse T-shaped steel pipes, and the T-shaped steel pipes and the U-shaped steel plates are positioned through high-strength bolts of bottom plates, and concrete is cast into the shear connectors into a whole. The system has the advantages that the structural deadweight is reduced, and rigidity is less reduced; the size of the shear connectors is reduced, and the rigidity of the shear connectors is improved; tensile force is borne by the square steel pipes, the steel pipes participate in shear resistance at the joint shear connectors, and the mechanical performance of materials is brought into full play; no welding or formworks are needed, welding stress and deformation are avoided, construction procedures are reduced, and construction efficiency is greatly improved.

Owner:CHINA AEROSPACE CONSTR GROUP

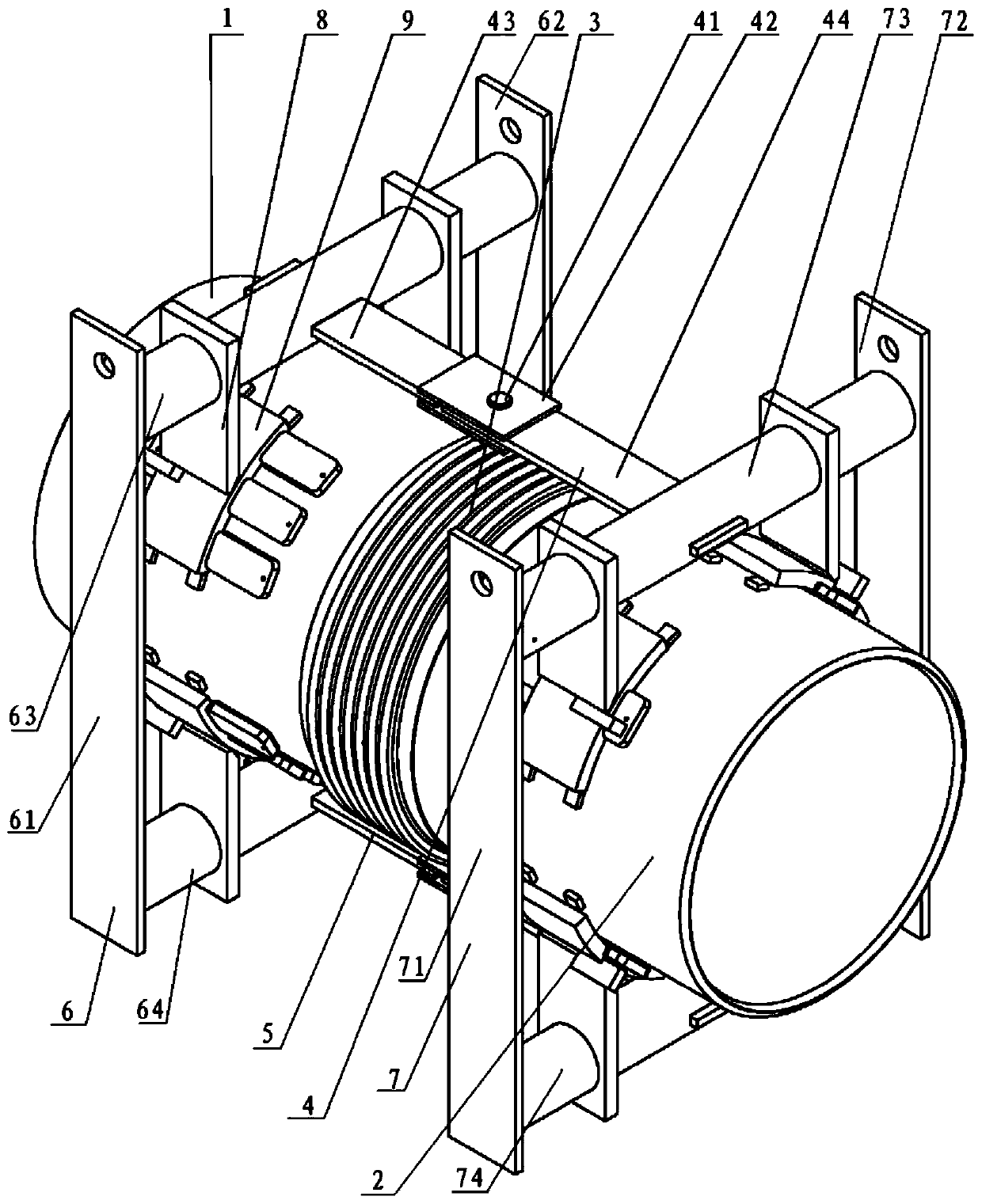

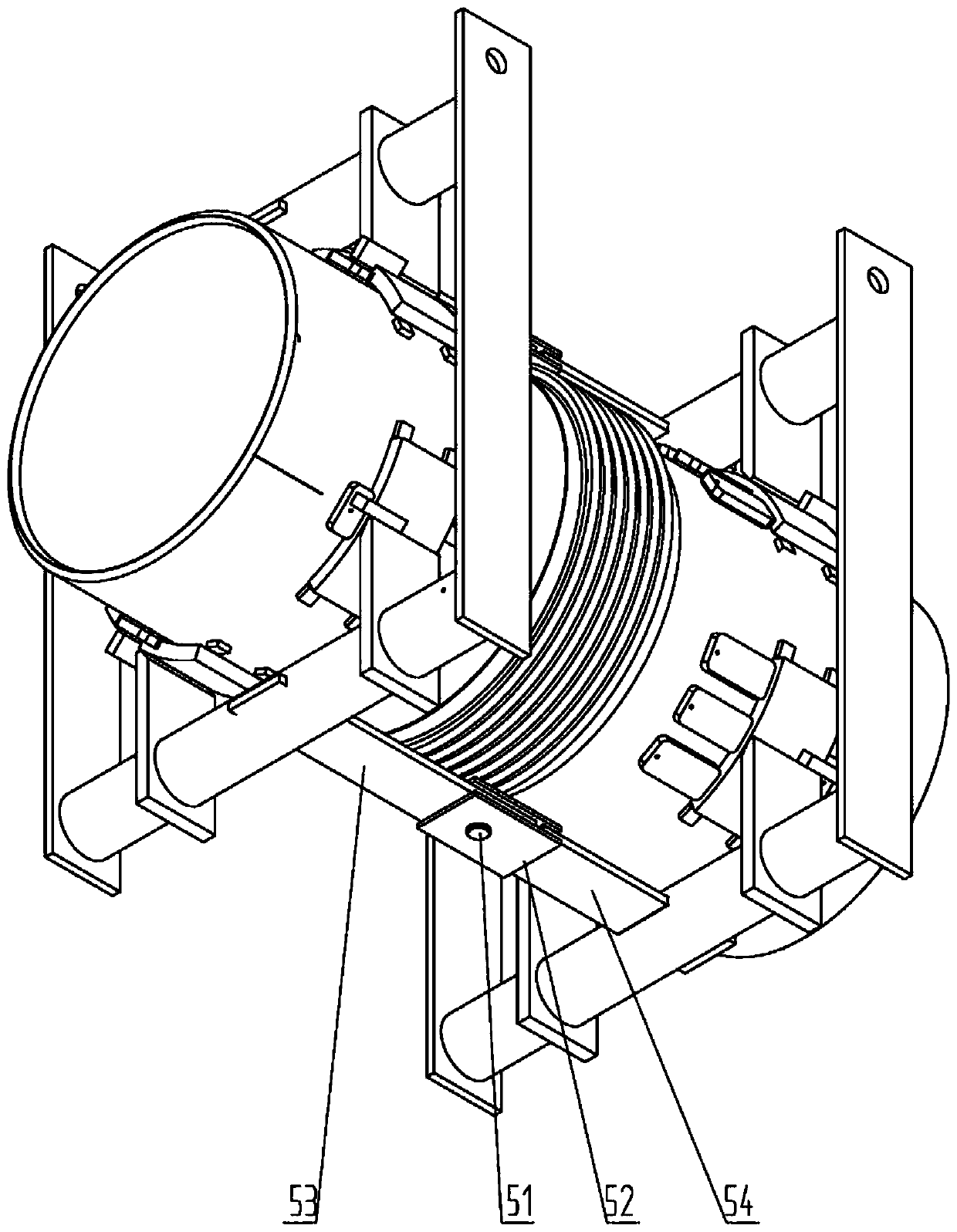

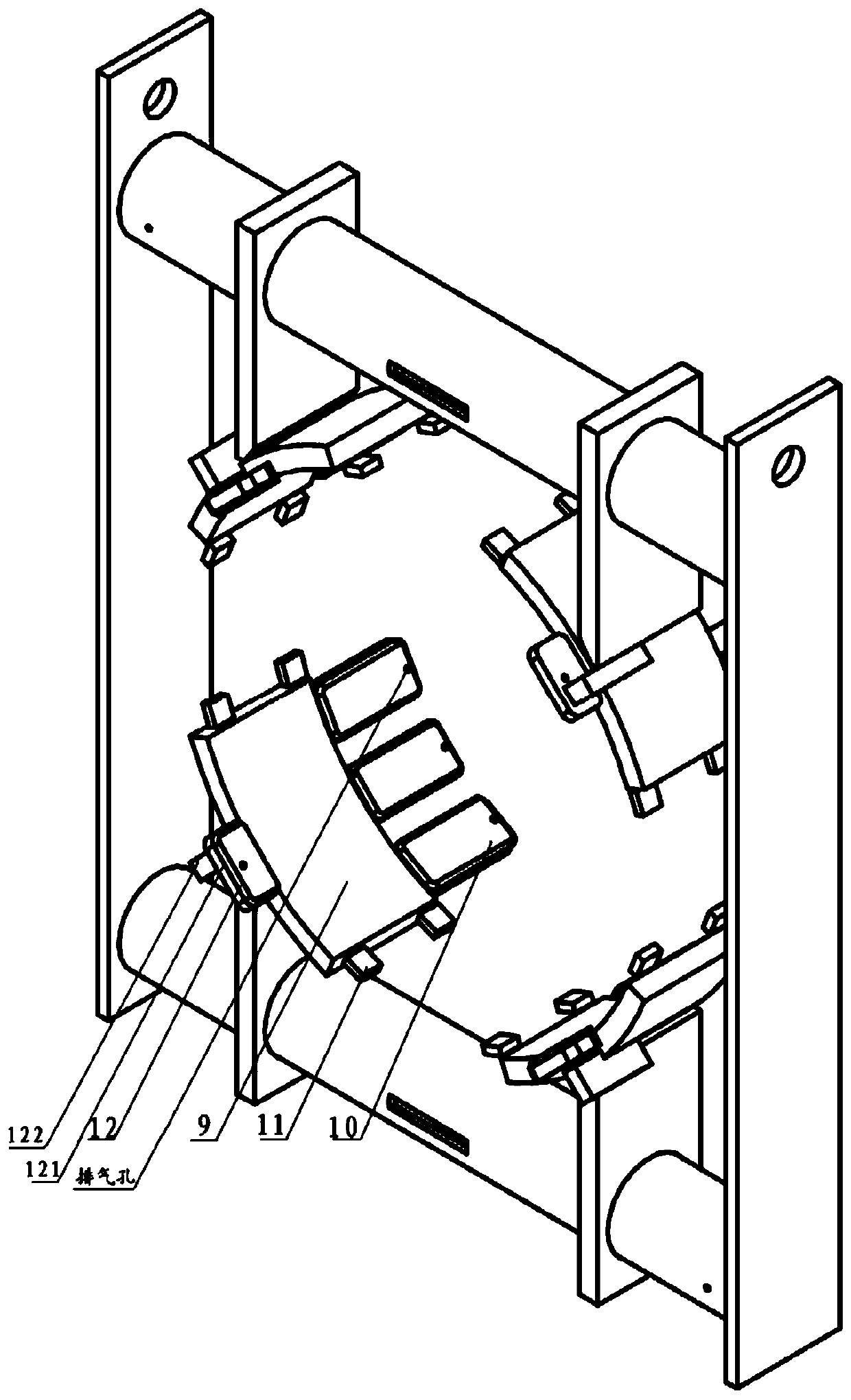

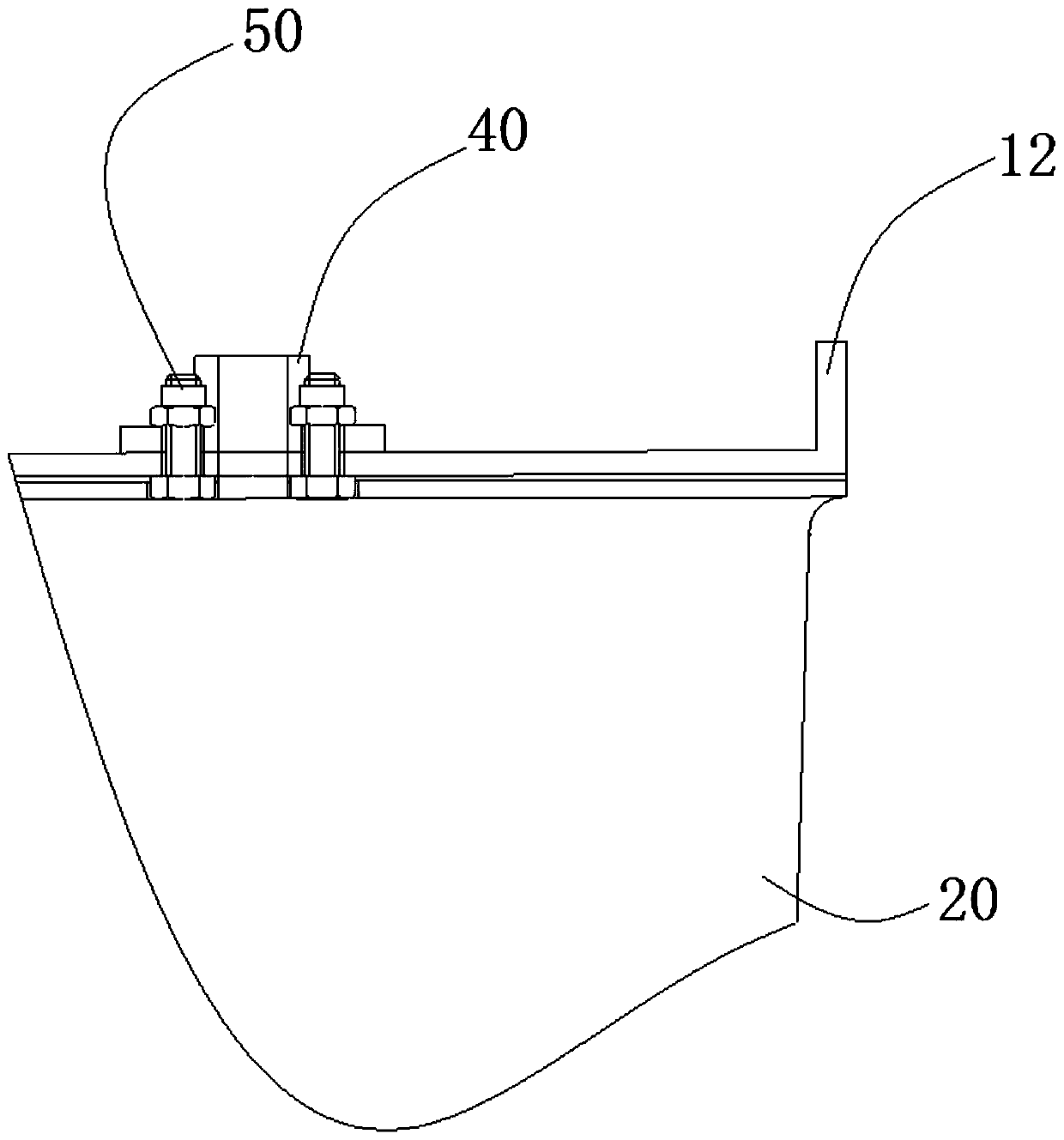

New-type hinge expansion joint for high-temperature flue of flue gas turbine

PendingCN110953429AWork lessReduce thermal stressPipe supportsPipeline expansion-compensationFlue gasExpansion joint

The invention discloses a new-type hinge expansion joint for a high-temperature flue of a flue gas turbine. The new-type hinge expansion joint comprises a pipe nipple I, a pipe nipple II, a corrugatedpipe, a load-bearing frame I, a load-bearing frame II, two sets of hinge mechanisms and eight sets of support assemblies, wherein the pipe nipple I, the corrugated pipe and the pipe nipple II are connected in sequence; the load-bearing frame I is located on the side where the pipe nipple I is located and supports the pipe nipple I through four of the sets of support assemblies; the load-bearing frame II is located on the side where the pipe nipple II is located and supports the pipe nipple II through the other four sets of support assemblies; and the two sets of hinge mechanisms are mounted between the load-bearing frame I and the load-bearing frame II. The invention ensures the persistent working of the expansion joint under high temperature, thereby prolonging the service life of the product.

Owner:QINHUANGDAO TAIDY FLEX TECH

Fan casing

ActiveCN107542499AAvoid Welding StressImprove rigidityStatorsMachines/enginesWear resistantHeat treated

The invention relates to the technical field of aero-engines and particularly provides a fan casing. A processing scheme of welding the casing with each stator blade is adjusted into a scheme that whole-ring stator blades with second outer rings are inserted into first outer rings, and welding and heat treatment processes are eliminated, so that the problems that the casing is deformed, the bodiesof the stator blades are misplaced, the axial length of a wear-resistant coating is insufficient due to a small axial clearance between a rotor and a stator, and the allowance of the casing is smalldue to a big margin plate are solved, and the vibration resistance of the casing is enhanced.

Owner:AECC SHENYANG ENGINE RES INST

Damped fan case

The invention relates to the technical field of aeroengines, and particularly provides a fan case with damping. The machining scheme that a case is welded with each stator blade is adjusted to the scheme that an integral-ring stator blade with a second external ring is inserted into a first external ring, welding and heat treatment processes are removed, and a damping layer is additionally arranged between the case and a blade external ring, so that the problems that the axial length of a wear-resistant coating is not sufficient, a margin plate is large and the case allowance is small caused by case deformation, stator blade body dislocation and a small axial clearance of a rotating stator are solved, and the antivibration ability of the fan case is improved.

Owner:AECC SHENYANG ENGINE RES INST

A local reinforcement device and reinforcement method for the foundation ring of a wind power generating set

ActiveCN107100192BReduce fatigue damageEasy to useFoundation repairWind energy generationFatigue damageReinforced concrete

The invention discloses a local reinforcement device for the foundation ring of a wind power generating set, which includes the original reinforced concrete foundation and a local reinforcement device; the local reinforcement device includes a newly poured reinforced concrete foundation, an inner steel splint unit, an outer steel splint unit, and a plurality of inner steel splints The units are arranged in a ring on the upper inner wall of the foundation ring of the original reinforced concrete foundation, and a plurality of outer steel splint units are arranged in a ring on the upper outer wall of the foundation ring, and the newly poured reinforced concrete foundation is poured on the original reinforced concrete foundation. The present invention disperses and transmits the load generated by the fan operating state borne by the foundation ring through the inner and outer steel splint units, connecting steel bars, and inner and outer foundation negative bending bars, effectively reducing the stress in the reinforced foundation ring and slowing down the fatigue of the fan foundation damage, greatly increasing the service life of the reinforced wind turbine foundation. The invention also discloses a local reinforcement method for the foundation ring of the wind power generating set.

Owner:HUNAN UNIV OF SCI & TECH

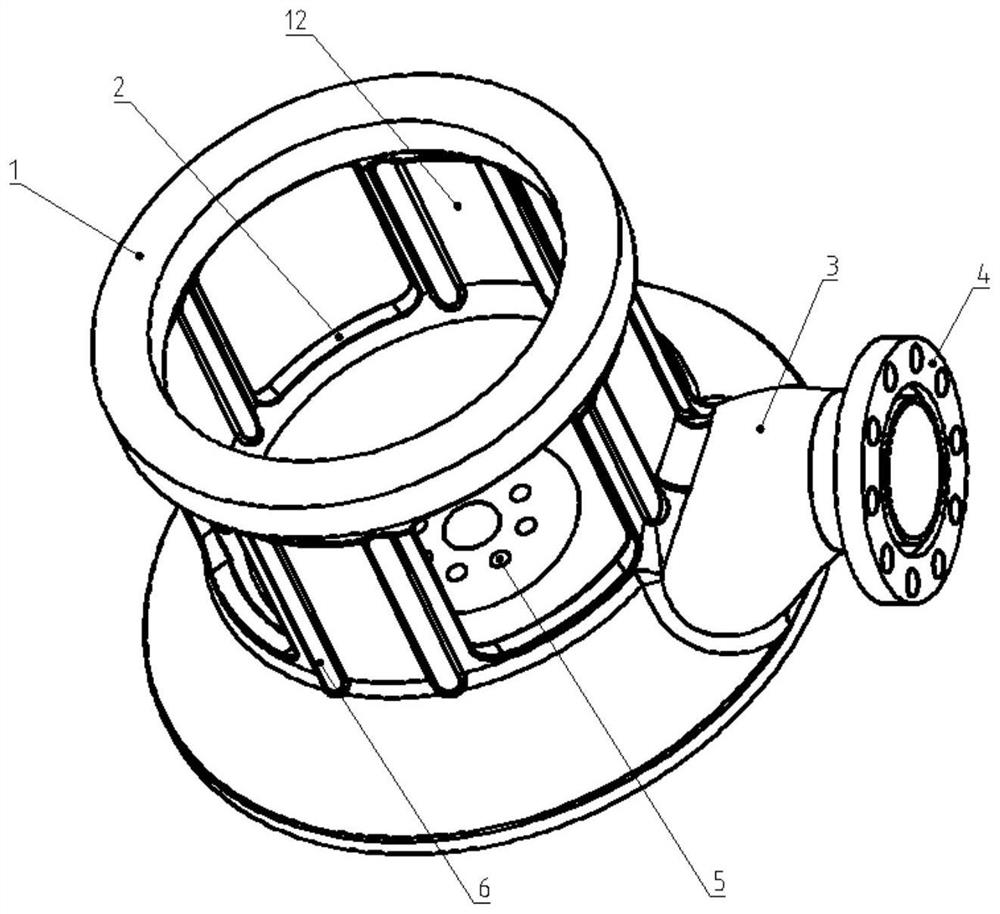

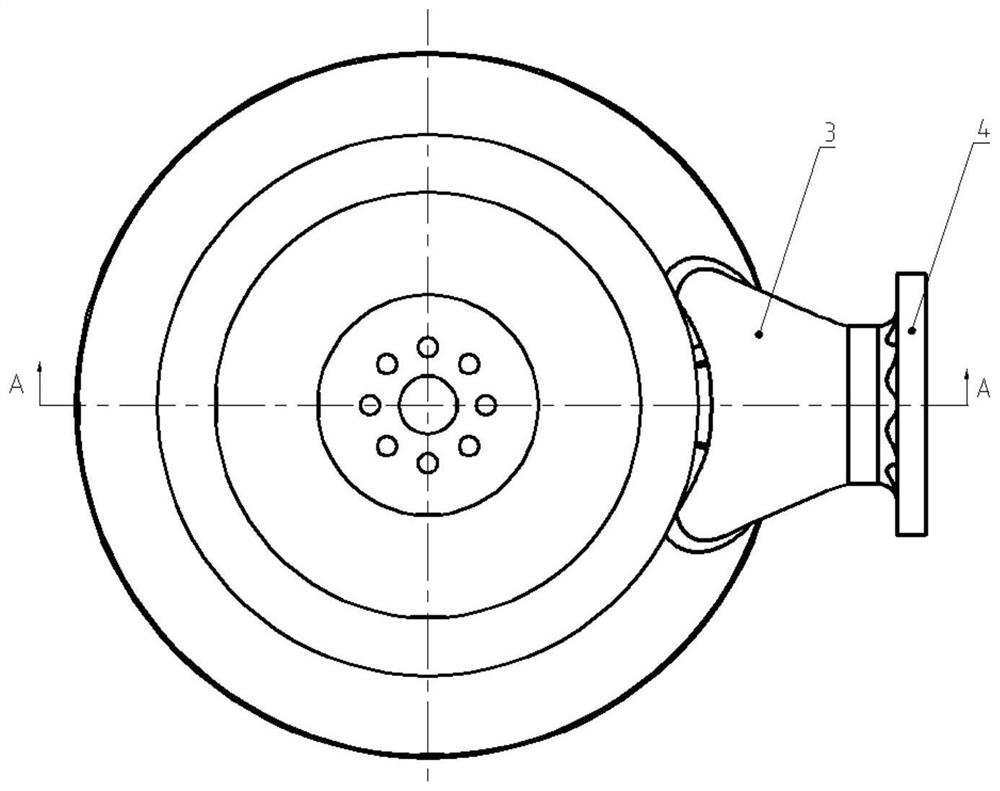

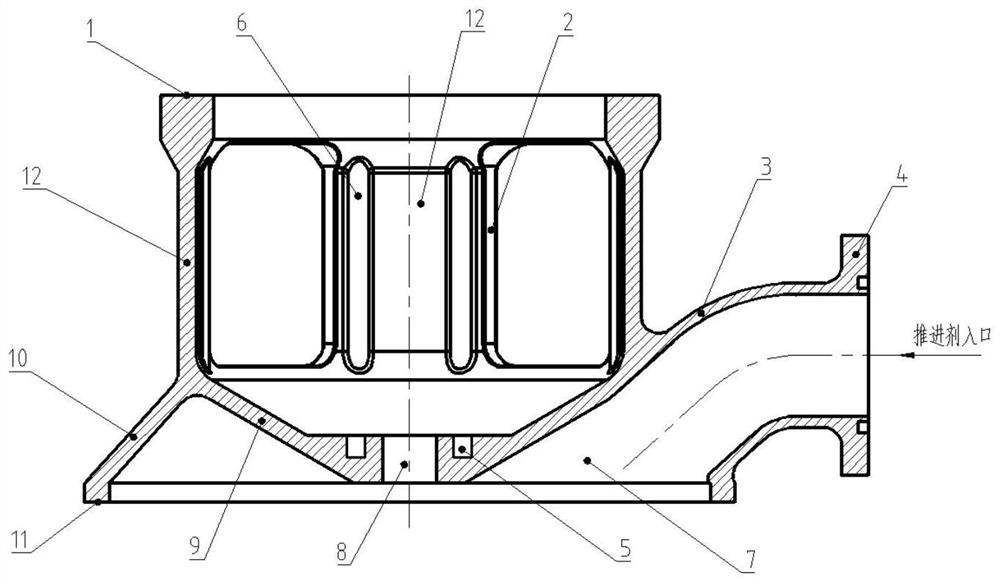

Integrated liquid rocket engine thrust chamber top cover structure

ActiveCN114412663AReduce total pressure distortionImprove reliabilityRocket engine plantsThrust chamberClassical mechanics

The invention discloses an integrated liquid rocket engine thrust chamber top cover structure, and belongs to the technical field of machinery. The top cover comprises a force bearing end face, a propellant inlet bent pipe, a propellant inlet flange, a top cover inner cavity, an inner conical surface, an outer conical surface, a top cover bottom surface and a force bearing wall. Thrust generated by a thrust chamber of the liquid rocket engine is transmitted to the top cover from the bottom face of the top cover, transmitted to the force bearing wall through a triangular force bearing structure formed by the inner conical face and the outer conical face and finally transmitted to an engine rack through the force bearing end face. Propellant enters the top cover from a propellant inlet in the propellant inlet flange, flows through the propellant inlet bent pipe, enters the inner cavity of the top cover and then enters the downstream nozzle.

Owner:BEIJING AEROSPACE PROPULSION INST

A steel-concrete composite vierendeel beam system

Concrete upper ribs and floors of a novel steel-concrete combined open web girder system are made of cast-in-place concrete and form an orthogonal cross shape; holes are formed in reverse T-shaped joints of combined components so that concrete can be conveniently cast into the holes and shear connectors can be formed; reverse T-shaped steel pipes and U-shaped steel plates are all prefabricated in a factory, in the use process, the U-shaped steel plates penetrate through reserved holes in the bottoms of the reverse T-shaped steel pipes, and the T-shaped steel pipes and the U-shaped steel plates are positioned through high-strength bolts of bottom plates, and concrete is cast into the shear connectors into a whole. The system has the advantages that the structural deadweight is reduced, and rigidity is less reduced; the size of the shear connectors is reduced, and the rigidity of the shear connectors is improved; tensile force is borne by the square steel pipes, the steel pipes participate in shear resistance at the joint shear connectors, and the mechanical performance of materials is brought into full play; no welding or formworks are needed, welding stress and deformation are avoided, construction procedures are reduced, and construction efficiency is greatly improved.

Owner:CHINA AEROSPACE CONSTR GROUP

A new steel-concrete composite vierendeel beam and its manufacturing method

InactiveCN105888135BAvoid Welding StressAvoid deformationLoad-supporting elementsLine tubingSheet steel

The invention discloses a novel steel-concrete combined open web girder and a manufacturing method thereof. The open web girder comprises upper-portion rectangular portion reinforced concrete, lower-portion pulled steel plates, end arc-shaped steel pipes and steel plate hoops, wherein longitudinal steel bars are reserved at two ends of the upper-portion rectangular portion reinforced concrete, the longitudinal steel bars are inserted into the end arc-shaped steel pipes together with the ends of the upper-portion rectangular portion reinforced concrete, then concrete is cast into the end arc-shaped steel pipes, and the upper-portion rectangular portion reinforced concrete is anchored and connected with the end arc-shaped steel pipes together after the concrete reaches the design strength. The problems of slippage between the concrete and section steel in a traditional steel-concrete combined girder, welding stress and deformation caused by welding, large formwork consumption, low construction efficiency and the like are solved, the steel-concrete combined open web girder has good mechanical properties, the open web position of the girder facilitates layout of special water heating and electrical pipelines, and accordingly building space is saved.

Owner:GUIZHOU UNIV

Installation process of large tuyere blades

ActiveCN113865068AEasy to installImprove installation efficiency and installation accuracyLighting and heating apparatusAir-flow control membersPull forceWelding defect

The invention relates to an installation process of large tuyere blades. The installation process comprises the steps that S1, a blade positioning device is established and comprises a positioning structure, an alignment structure and a tie bar structure; S2, multiple blade bodies are sequentially and correspondingly inserted into notches of multiple positioning seats, so that the distribution direction of the multiple blade bodies is consistent with the extension direction of the long axis of the positioning seats; S3, tie bar rods are inserted into aluminum pipes, and then the aluminum pipes inserted with the tie bar rods penetrate through penetrating holes of the multiple blade bodies; S4, under the contraction action of second driving cylinders, limiting baffles enable the tie bar rods to be embedded in limiting grooves of the limiting baffles; S5, pulling assemblies are started, and the tie bar rods are pulled out of the aluminum pipes under the horizontal pulling force of the corresponding pulling assemblies; and S6, the installed tuyere blades are subjected to integral discharging from the positioning seats. The installation process has the following advantages that the mounting precision and the mounting efficiency are improved, welding stress and welding defects caused by traditional welding fixation are avoided, and the connecting stability of the blade body is guaranteed.

Owner:江苏盈达机电科技有限公司

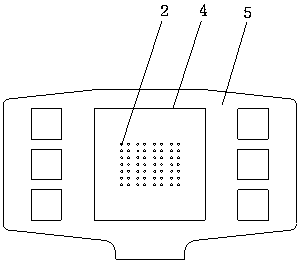

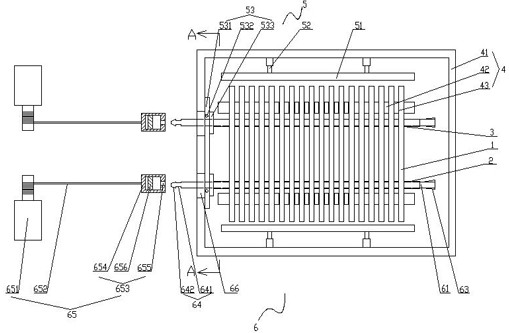

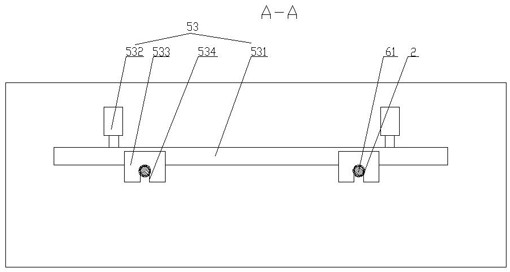

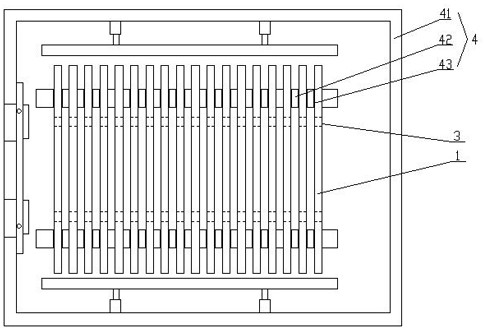

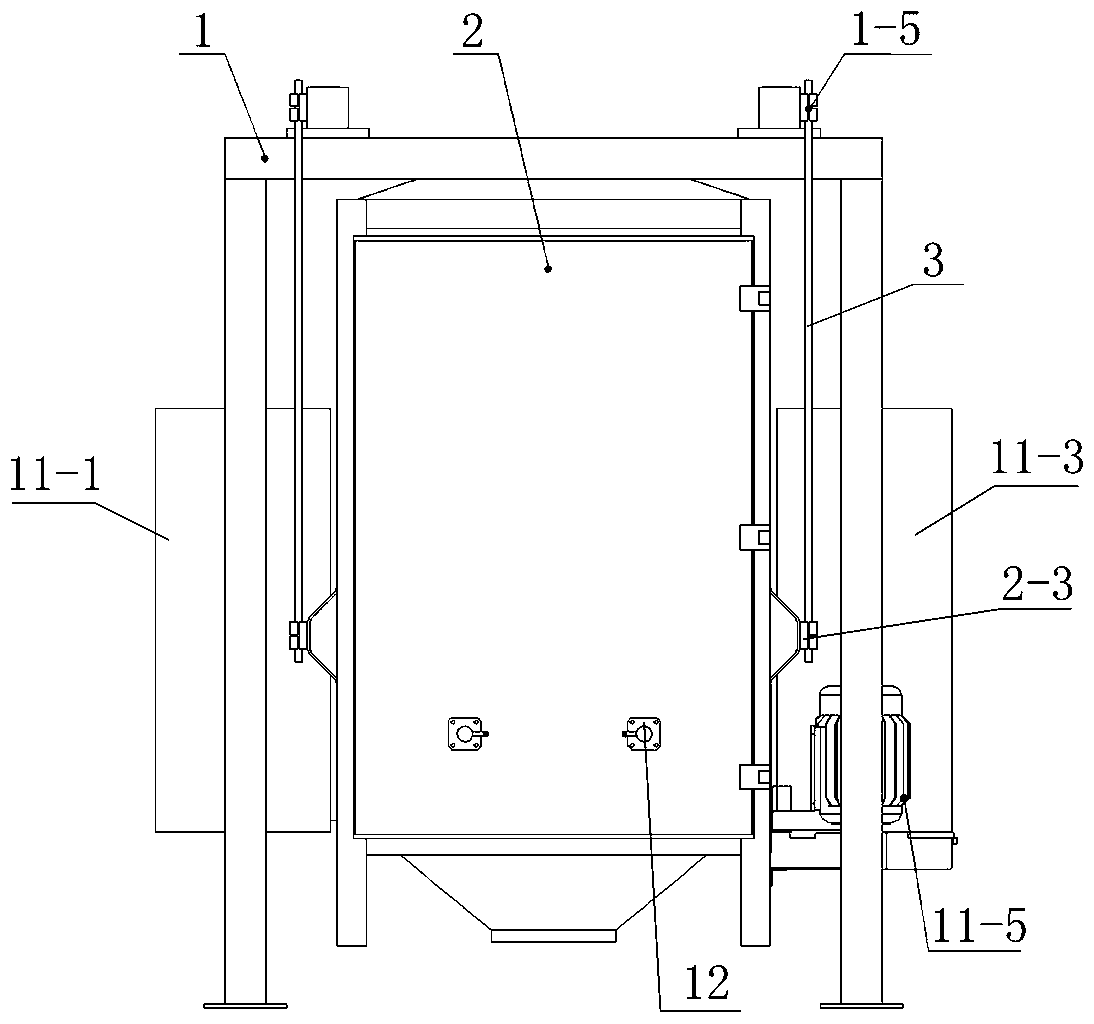

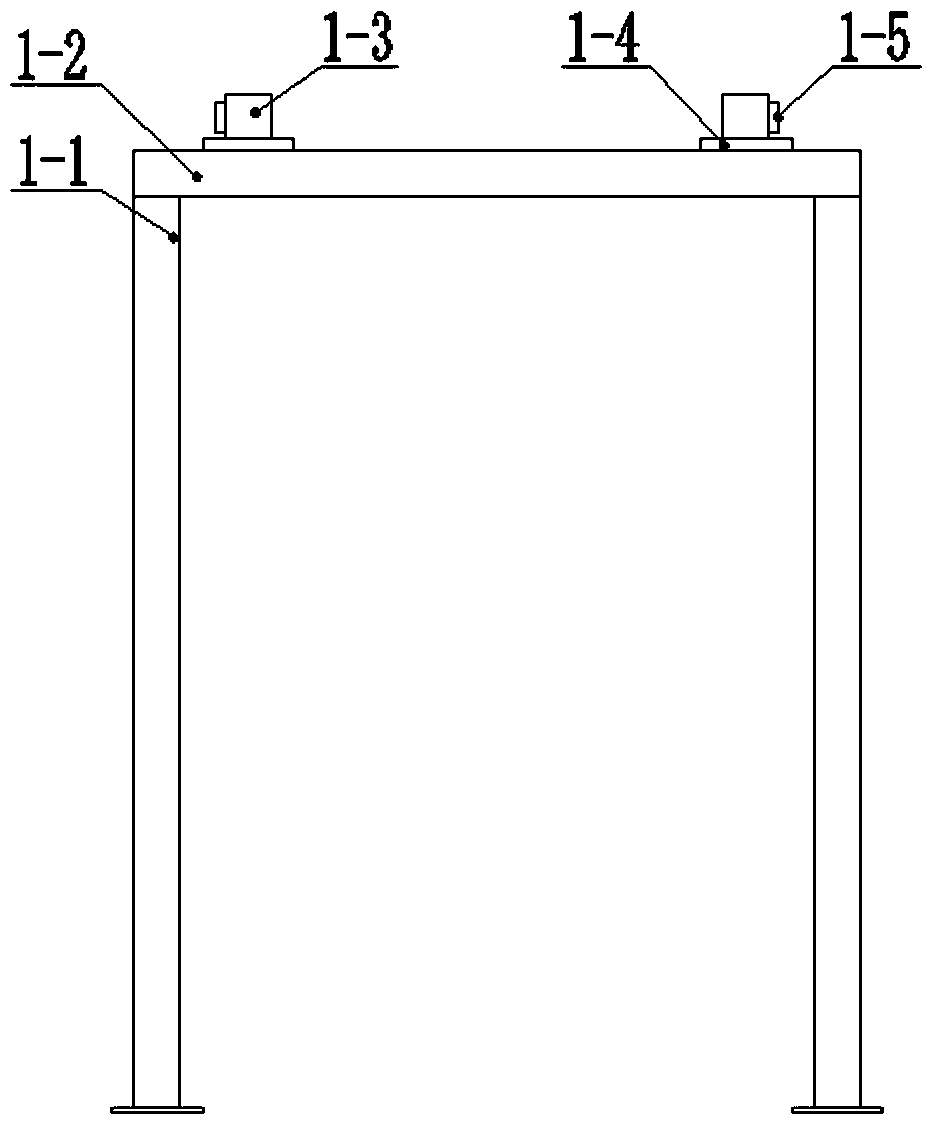

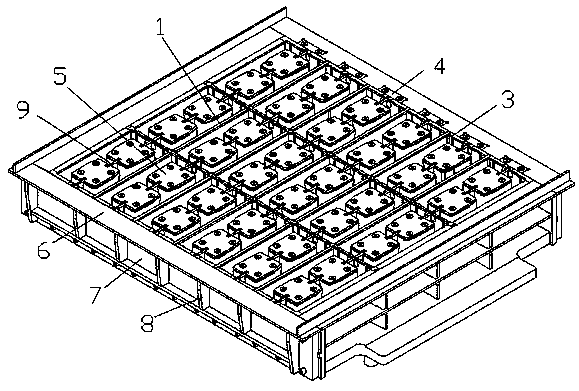

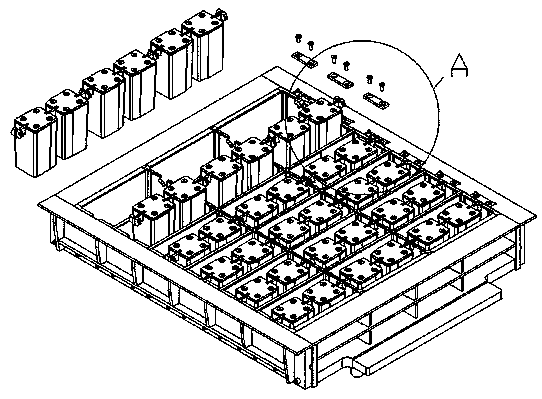

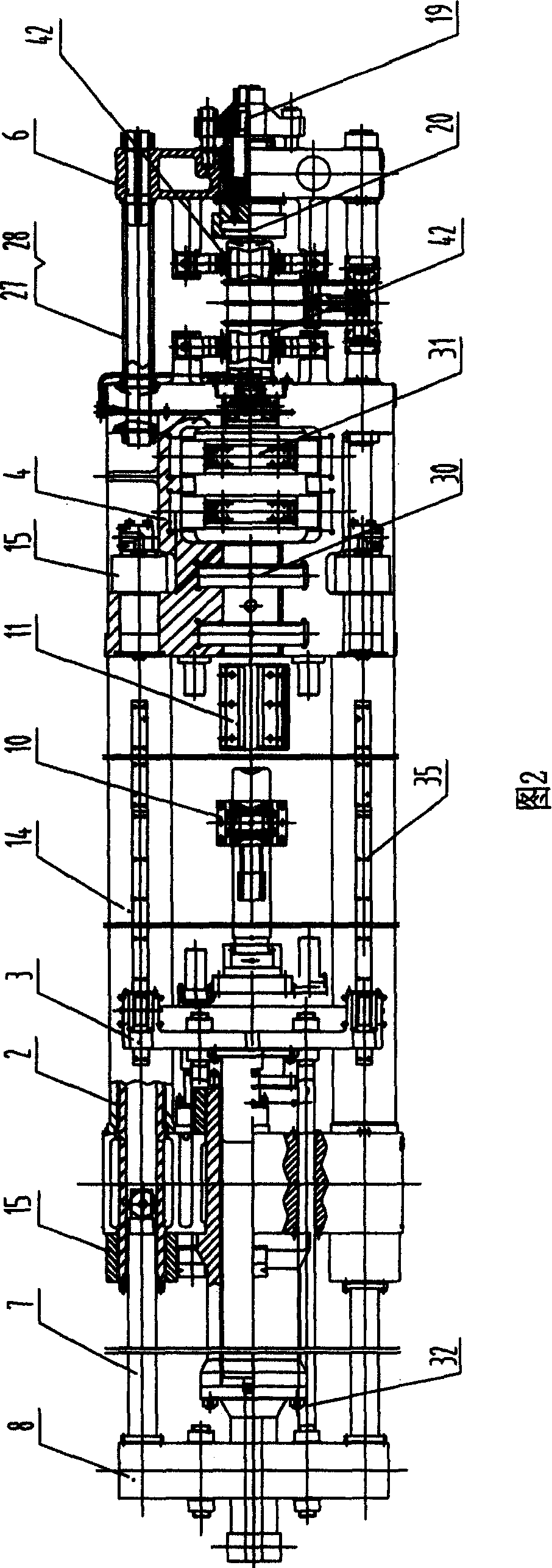

Bolting and grading device high in productivity and easy to maintain

ActiveCN110404756ASave internal spaceQuick disassemblySievingScreeningInterior spaceMechanical equipment

The invention discloses a bolting and grading device high in productivity and easy to maintain and belongs to the technical field of mechanical equipment. According to the bolting and grading device high in productivity and easy to maintain, two external transmission device synchronous operating structures are adopted, running is stable and reliable, and maintaining is easy; and meanwhile, a lot of screen body inner space is saved, optimized design of a screen way is facilitated, and the productivity is improved. In the bolting and grading device high in productivity and easy to maintain, thescreen way structure in multi-way feeding is adopted, and screen lattices and a screen frame are of a pulling structure; a screen door is in hinge connection and can achieve compressing of the screenlattices and the screen frame through a compressing handle after closing of the screen door; an oleophobic layer is added on a screen frame bottom plate; a rack is of a movable connection structure; apulse valve is used for being connected with external high pressure gas, and periodical automatic gas spraying for screen net clearing is achieved, and the productivity is improved due to many optimized design; and meanwhile operating and installing are facilitated, and the maintaining difficulty is lowered. The bolting and grading device achieves the characteristics that the productivity is highand maintaining is easy.

Owner:ZHAOFENG GRAINS & OIL MACHINERY ZHENGZHOU

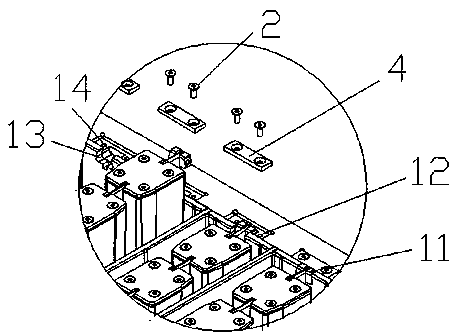

Brick making die structure with hanging rods and cores flexibly replaced

PendingCN110682421AStable structureAccurate installation and positioningMould auxillary partsCeramic shaping mandrelsStructural engineeringMechanical engineering

The invention discloses a brick making die structure with hanging rods and cores flexibly replaced. The structure comprises a die core frame, the hanging rods and the cores. The die core frame comprises transverse baffle plates and longitudinal baffle plates, the cores are arranged on the hanging rods and extend into a brick making die cavity, the tops of the longitudinal baffle plates are provided with first clamping grooves corresponding to the hanging rods, the outer side of the die core frame is provided with guard plates, and the tops of the guard plates are provided with cover plates extending horizontally outwards; and second clamping grooves corresponding to the first clamping grooves are formed in the tops of the guard plate positioned on one side of the die core frame or on the outer sides of the longitudinal baffle plates on the two sides, and first positioning blocks positioned in the corresponding first clamping grooves are arranged on the two sides of the hanging rods. Through the mode, the brick making die structure with the hanging rods and the cores flexibly replaced, the hanging rods and the cores are assembled and positioned accurately, and are independently replaced after being disassembled, so that the maintenance cost is greatly reduced, and the service life of a die is prolonged.

Owner:TAICANG FLEXSYS MOLD TECH CO LTD

Threaded fan case

The invention relates to the technical field of aero-engines and particularly provides a fan cartridge receiver assembled through a thread. A machining scheme of welding the cartridge receiver and each stator blade is adjusted into a scheme of screwing a whole ring of stator blades with a second outer ring into a first outer ring, welding and heat treatment processes are omitted, the problems of insufficient abrasion-resistant coating axial length, large-margin-plate small cartridge receiver allowance and the like caused by cartridge receiver deformation, stator blade body malposition and small axial clearances of the stator blades are solved, and the vibration-resistant capability of the cartridge receiver is improved.

Owner:AECC SHENYANG ENGINE RES INST

An Exhaust Pipe Structure for Eliminating Welding Stress

InactiveCN103291432BGuaranteed validityPrevent axial slippageExhaust apparatusSilencing apparatusThermodynamicsEngineering

The invention discloses an automobile exhaust pipe structure, and provides an exhaust pipe structure which is simple in structure and ingenious in conception, can eliminate welding stress and avoid breakage of welding ports of an inner pipe and an outer pipe of the exhaust pipe due to high temperature and low temperature alternation, and solves the technical problems that when an automobile runs in a cold area, the welding ports at the two ends of the exhaust pipe are easy to break due to the high temperature and low temperature alternation, the abnormal sound of the exhaust pipe is caused, and even seriously, the failure of the exhaust pipe is caused in the prior art. The exhaust pipe structure comprises an inner barrel and an outer barrel, wherein the inner barrel is coaxially sleeved and covered with the outer barrel; one end of the outer barrel is welded and fixed on the corresponding inner barrel; an elastic piece is sandwiched between an internal wall surface at the other end of the outer barrel and a corresponding external wall surface of the inner barrel; and the inner barrel is supported in the outer barrel by the elastic piece elastically.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

Horizontal hydraulic machine for drawing and extending

InactiveCN101011868BSignificant technological progressHigh centering accuracyPress ramPre stressEngineering

Owner:TAIYUAN HEAVY IND

Automobile anti-collision beam mounting structure and mounting method

PendingCN114734945AHigh strengthImprove impact resistanceInternal combustion piston enginesBumpersEngineeringStructural engineering

The invention discloses an automobile anti-collision beam mounting structure and a mounting method. The automobile anti-collision beam mounting structure comprises an anti-collision beam, an automobile body longitudinal beam, a bolt, a reinforcing sleeve and a welding nut, the anti-collision beam is an arc-shaped cross beam matched with the outline shape of the front end of a vehicle body, the cross section of the anti-collision beam is of a hollow cavity structure, the two ends of the anti-collision beam are fixedly assembled with the front end face of a vehicle body longitudinal beam through bolts, and reinforcing sleeve assembly holes are formed in the inner side arc face and the outer side arc face of the matched position of the anti-collision beam and the front end face of the vehicle body longitudinal beam. A welding nut is pre-welded on the inner side wall of the front end surface of the vehicle body longitudinal beam; the two ends of the reinforcing sleeve are embedded in reinforcing sleeve assembly holes formed in the inner side arc face and the outer side arc face of the anti-collision beam respectively. The bolt penetrates through the reinforcing sleeve to be assembled with the welding nut. The strength of the joint of the anti-collision beam and the longitudinal beam of the automobile is effectively enhanced, the problem that a collision force transmission path is changed due to the fact that the anti-collision beam is pulled out too early at the joint is solved, and the purposes of improving the impact resistance of an automobile body and guaranteeing the safety of the automobile are achieved.

Owner:SHANGHAI LINGYUN IND TECH CO LTD

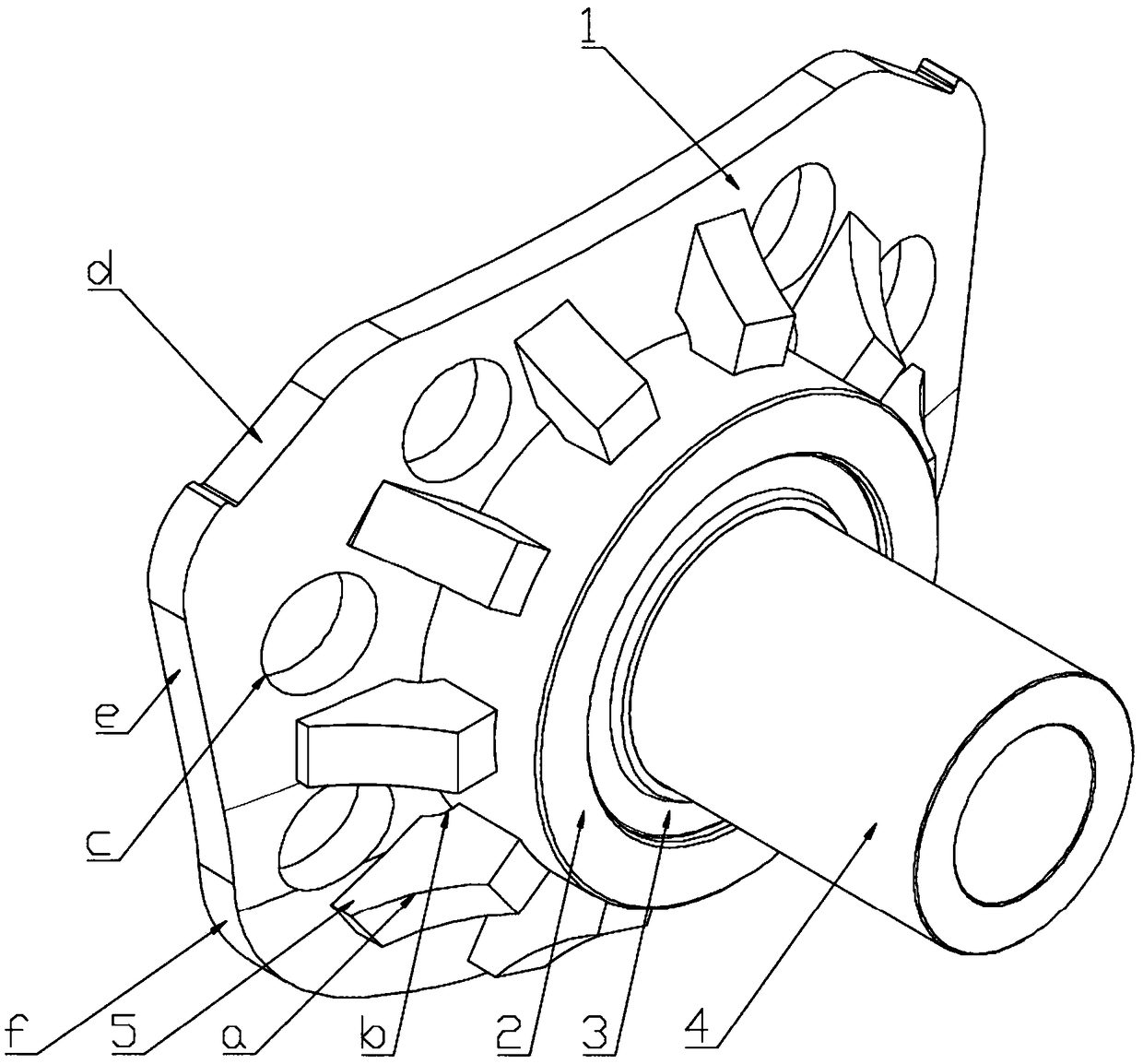

Spherical hinge sliding rod connecting device connecting disc for converter transformation

PendingCN109182645AImprove reliabilityGuaranteed structural strengthManufacturing convertersEngineeringUltimate tensile strength

The invention relates to a spherical hinge sliding rod connecting device connecting disc for converter transformation. The spherical hinge sliding rod connecting device connecting disc for converter transformation comprises an arc plate, a bearing ring, a spherical hinge bearing, a bearing shaft and multiple bearing ribs. The arc plate is tightly attached to and welded and fixed to the designatedposition of the outer wall of a shell of a converter through the edge, the bearing ring is welded and fixed to the arc plate and provided with a shaft hole, the spherical hinge bearing is arranged inthe shaft hole in a matched manner, the bearing shaft is matched in the inner ring of the spherical hinge bearing, and the bearing ribs are evenly distributed along the outer wall of the bearing ring.The bearing ribs, the outer wall of the bearing ring and the arc plate are welded and fixed into a whole, and point to the axis of the shaft hole, and the edge of the arc plate and the shaft hole aresymmetric about the middle axis. The connecting disc has a certain motion freedom degree, extra stress generated inside due to rotation and swing of the arc plate and the bearing ring in the converter and converter partial deforming can be avoided, whole reliability of the connecting disc is improved, the whole weight is reduced, the whole structural strength and welding strength can be ensured,and the whole reliability is improved.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com