Large bridge support base plate and connecting method thereof

A bridge bearing and connection method technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of post-weld stress of bearing backing plate deformation, affecting the safety of bridge use, connection weld cracking and other problems, to eliminate welding Stress, avoid welding stress, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

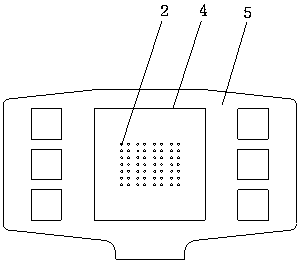

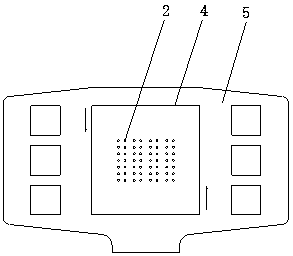

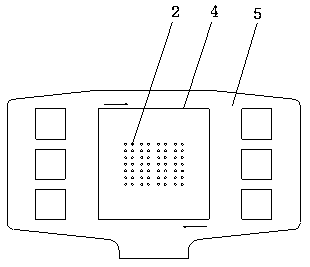

[0041] Such as figure 1 , 2 As shown, the backing plate of the large-scale bridge bearing of the present invention is installed on the bottom of the steel beam bottom plate 5 of the bridge and includes a backing plate body 1; the backing plate body 1 is a rectangular plate-shaped structure and a plurality of countersunk bolt holes are evenly opened in the middle region 2. A plurality of high-strength bolts 3 are matched and installed in a plurality of countersunk head bolt holes 2, and connecting welds 4 are fixed to the bridge support on the four sides in the circumferential direction.

[0042] Such as image 3 , 4 As shown, the connection method of the large bridge bearing backing plate of the present invention is suitable for the connection of the large bridge bearing backing plate and the control of the connection accuracy. First, the middle part of the bearing backing plate 1 is equipped with a countersunk head bolt hole 2 The bolt 3 is assembled and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com