A steel-concrete composite vierendeel beam system

A technology of concrete and hollow beams, which is applied to building components, floor slabs, buildings, etc., can solve the problems of difficulty in splicing U-shaped steel plate grids with combined lower ribs, failure to ensure square and straight grids, and heavy on-site welding workload. Achieve fewer construction procedures, reduce size, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

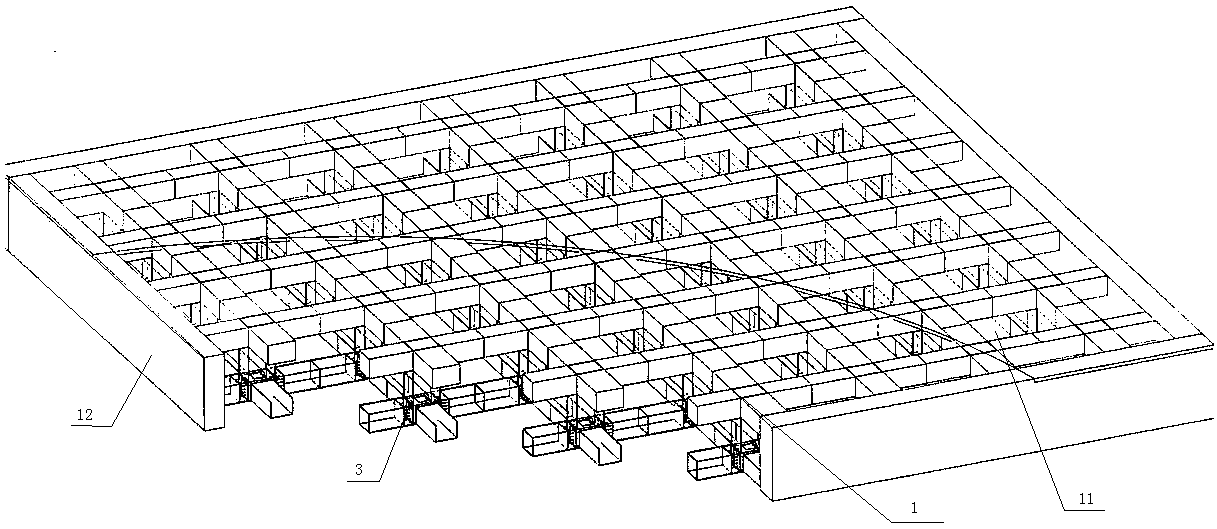

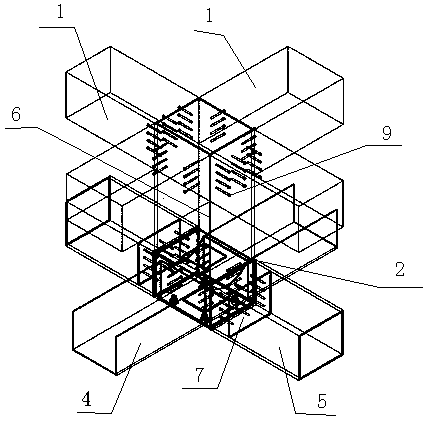

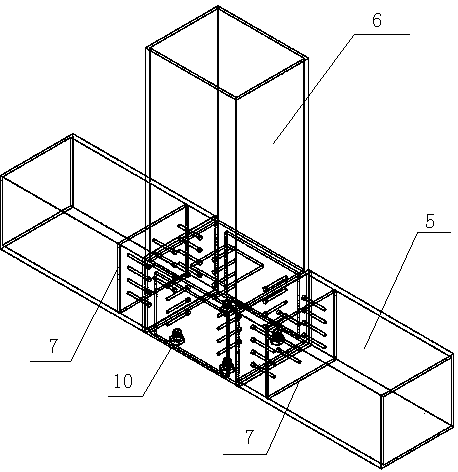

[0039] Such as figure 1 , figure 2 and image 3 As shown, the steel-concrete composite vierendeel beam system of the present invention is analyzed from the overall structure, which includes two parts: the concrete upper rib 1 and the lower rib 2, wherein the lower rib 2 includes the lower rib Square steel pipe 3, lower rib U-shaped steel plate 4 and pouring into the lower rib Concrete with square steel tubes. Among them, the lower rib The square steel pipe 3 includes a horizontal hollow steel pipe 5 and a vertical hollow steel pipe 6, and the vertical hollow steel pipe 6 is equivalent to the shear key of the whole structure in the combined vierendeel beam system of the present invention.

[0040] The concrete upper rib 1 of the present invention is a "ten" structure, and the upper part of the concrete upper rib 1 is a floor 11, and the lower rib The two ends of the horizontal hollow steel pipe 5 of the shaped steel pipe 3 and the U-shaped square steel pipe 4 of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com