Central-positioned switch cabinet

A switchgear, center-mounted technology, applied in pull-out switchgear, switchgear, switchgear components, etc., can solve the problems of large cabinet size, long production cycle, low protection level, etc. Easy to install and debug, avoid welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

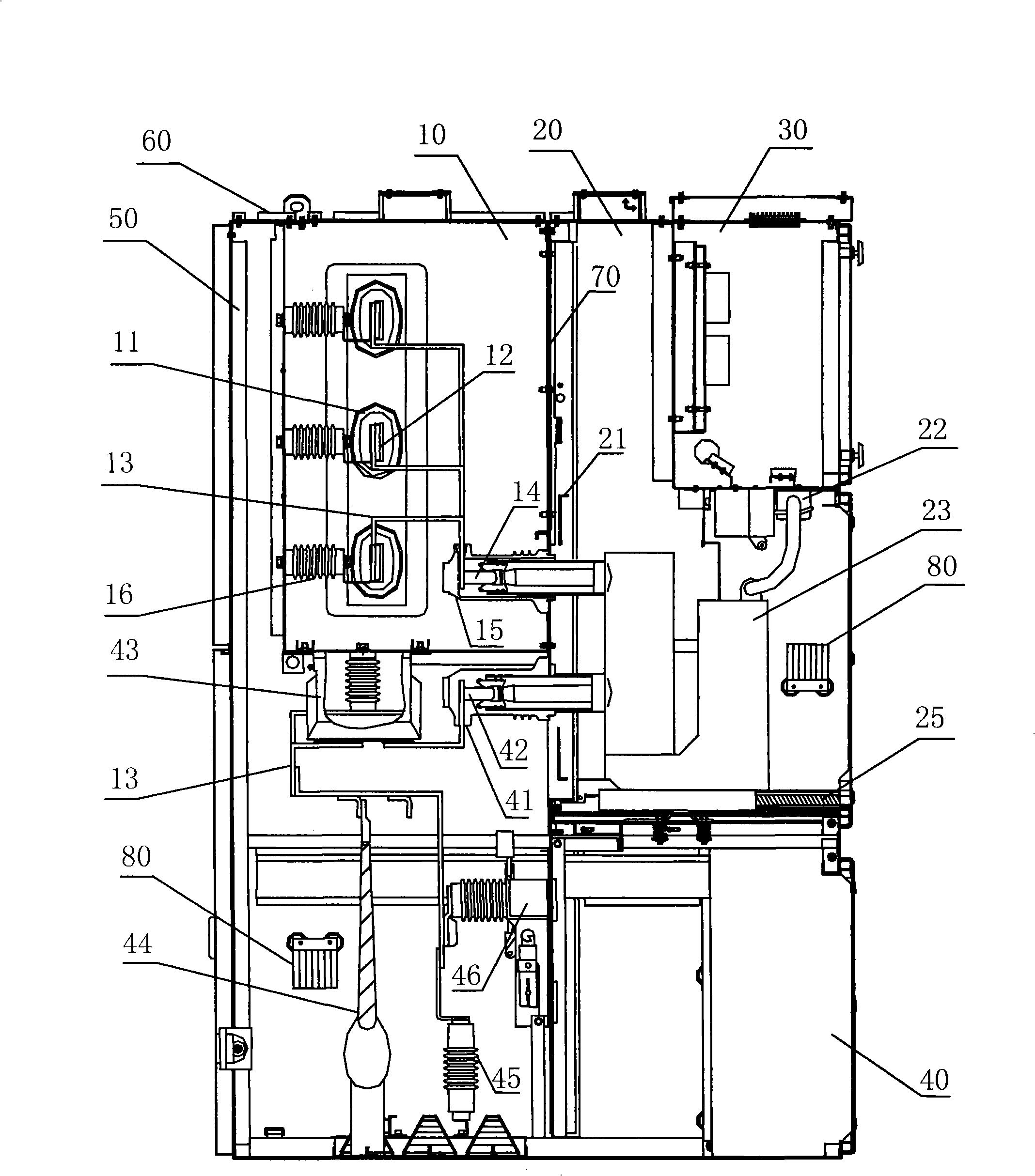

[0008] A middle-mounted switch cabinet, including a cabinet shell 50, and a partition 70 divides the enclosed space surrounded by the cabinet shell 50 into four rooms, wherein, the upper left of the cabinet shell 50 is provided with a busbar room 10, and the upper right of the cabinet shell 50 is provided with Relay instrument room 30, various control and protection devices, measuring components, instruments and low-voltage connection terminal blocks are installed in the relay instrument room 30, the handcart room 20 is located between the busbar room 10 and the relay instrument room 30, and cable rooms are installed in the rest of the space 40. The cabinet shell 50 and the partition 70 separating the four rooms are assembled into one body. The partition 70 is made of aluminum-zinc coated steel plate. The aluminum-zinc coated steel plate has strong anti-corrosion and anti-oxidation effects, and has a higher mechanical strength, such as figure 1 shown.

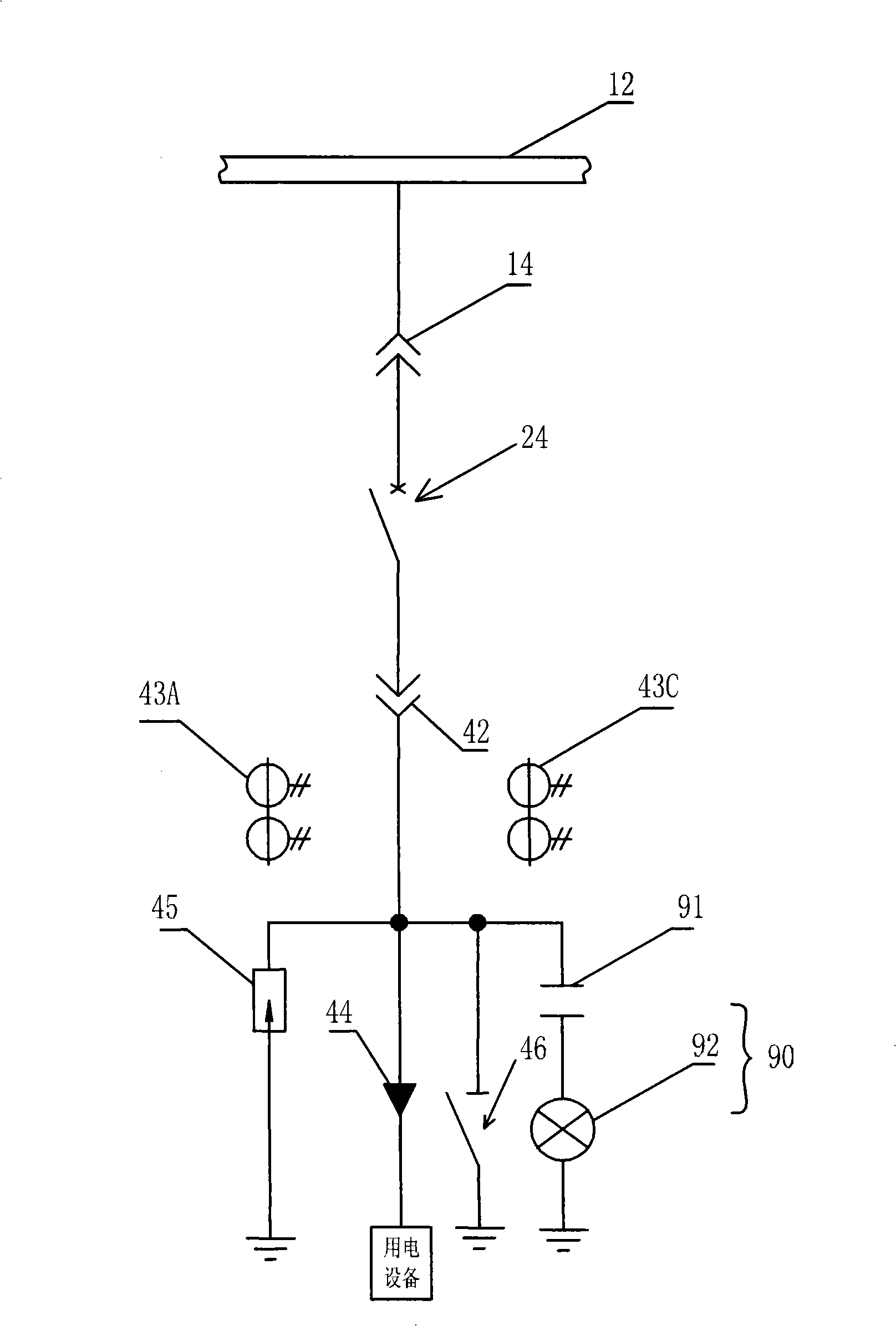

[0009] combine figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com