Horizontal hydraulic machine for drawing and extending

A hydraulic press, horizontal technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems affecting the service life of products and sales, inconvenient installation, debugging and maintenance, easy to press on the surface of the bottle, etc., to achieve stress pulsation. Small change, weight reduction, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

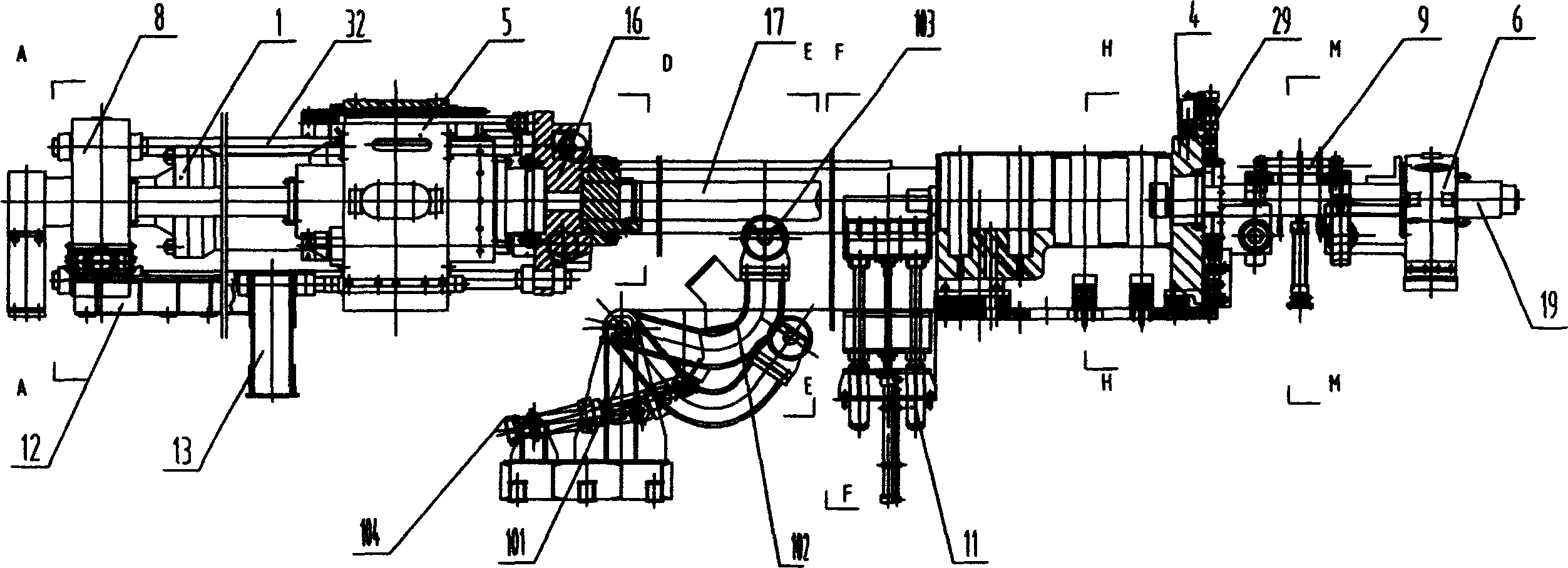

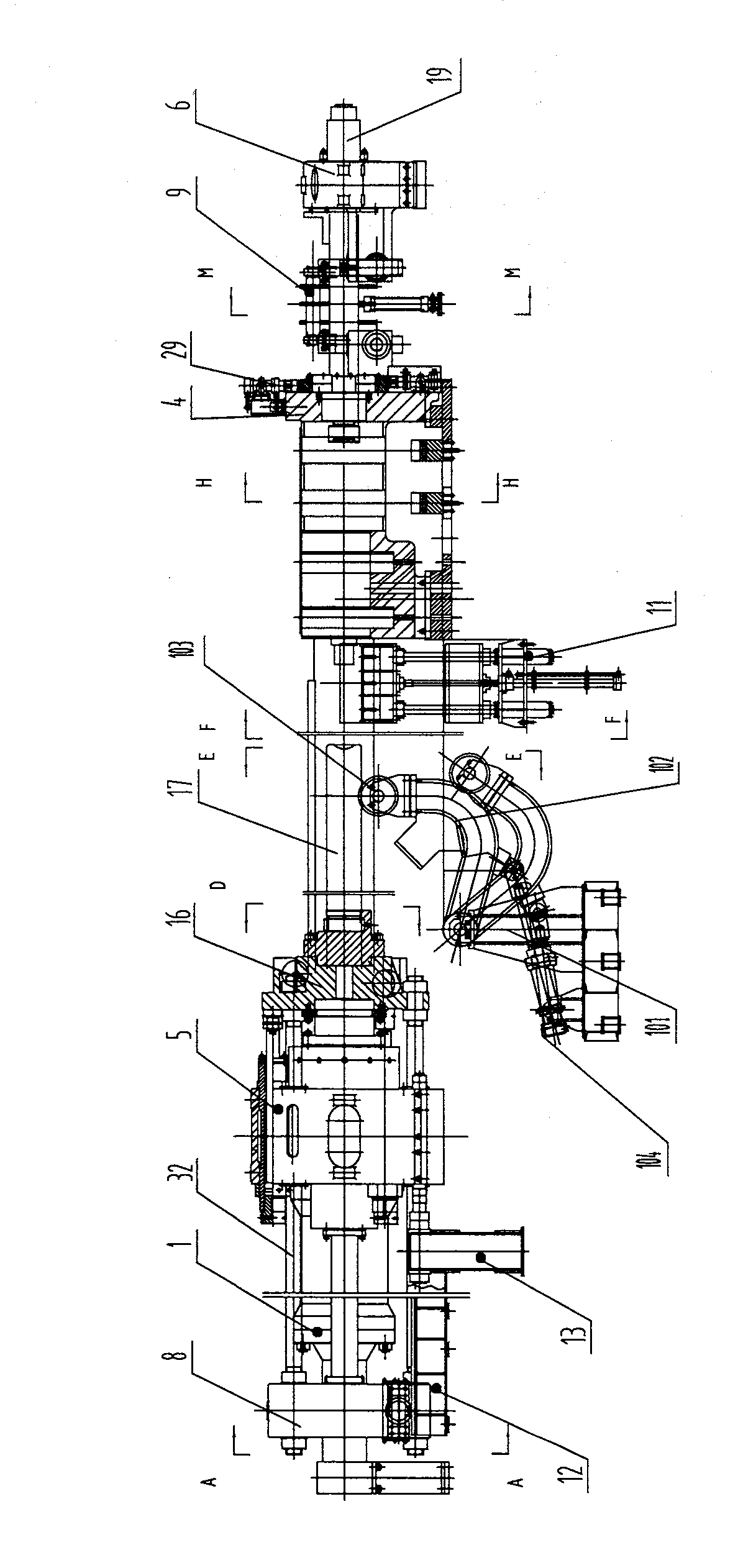

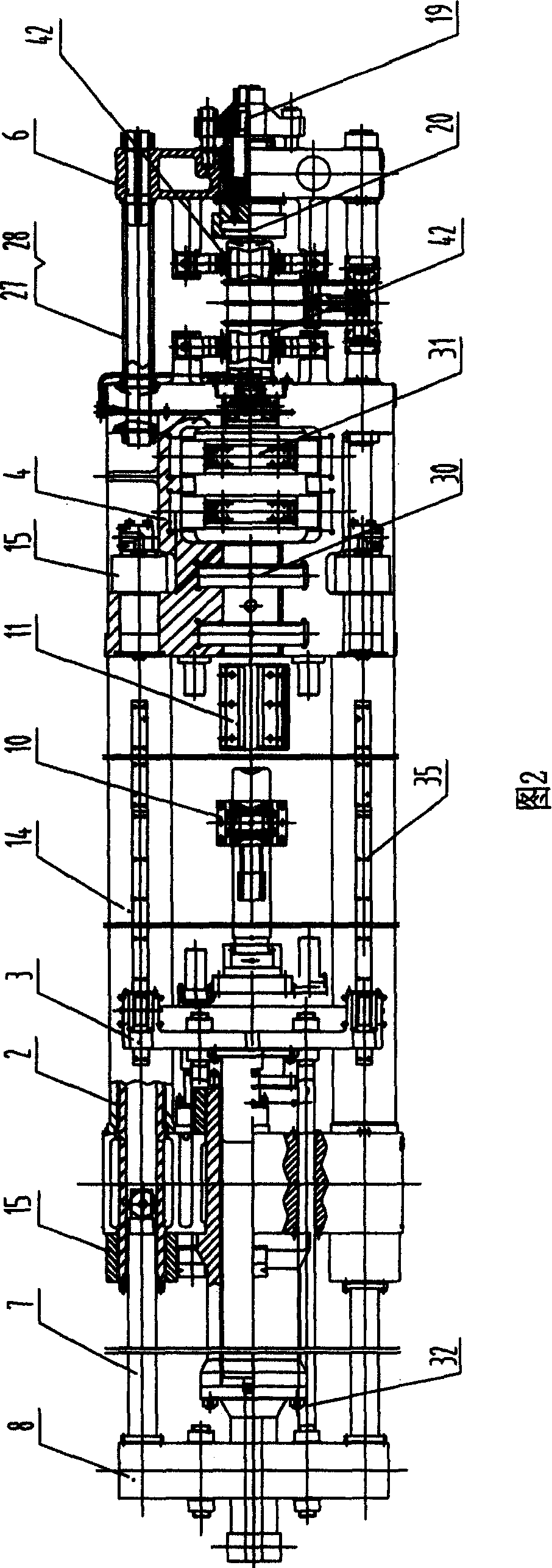

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] As shown in Figure 1 and Figure 2, the horizontal drawing hydraulic press. It has frame, main working cylinder 1, return cylinder 2, moving beam 3, front beam 4, rear beam 5, bottom mold beam 6, return cylinder plunger 7, return beam 8, feeding manipulator 9, bracket device 10, Lifting material platform 11, base beam 12, anchoring device 13, positioning sleeve 14, nut 15, drawing mandrel seat 16, drawing mandrel 17, buffer cylinder 19, bottom mold base, and bottom mold 20, etc., the whole machine is The horizontal layout is a beam-column prestressed composite frame.

[0033] The frame is a closed prestressed frame composed of the back beam 5, the front beam 4 and the tie rods used as the return cylinder 2; the two return cylinders also serve as tie rods, and their two ends are fixed with the front beam and the back beam with nuts, between the front beam and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com