Spherical hinge sliding rod connecting device connecting disc for converter transformation

A connection device and connection pad technology, applied in the manufacture of converters, etc., can solve problems affecting the welding quality and bearing strength of the connection pad, unfavorable welding of the connection pad, and affecting the reliability of the connection pad, etc., to achieve ideal welding vision and operating space , Guarantee the strength and eliminate the effect of poor welding vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

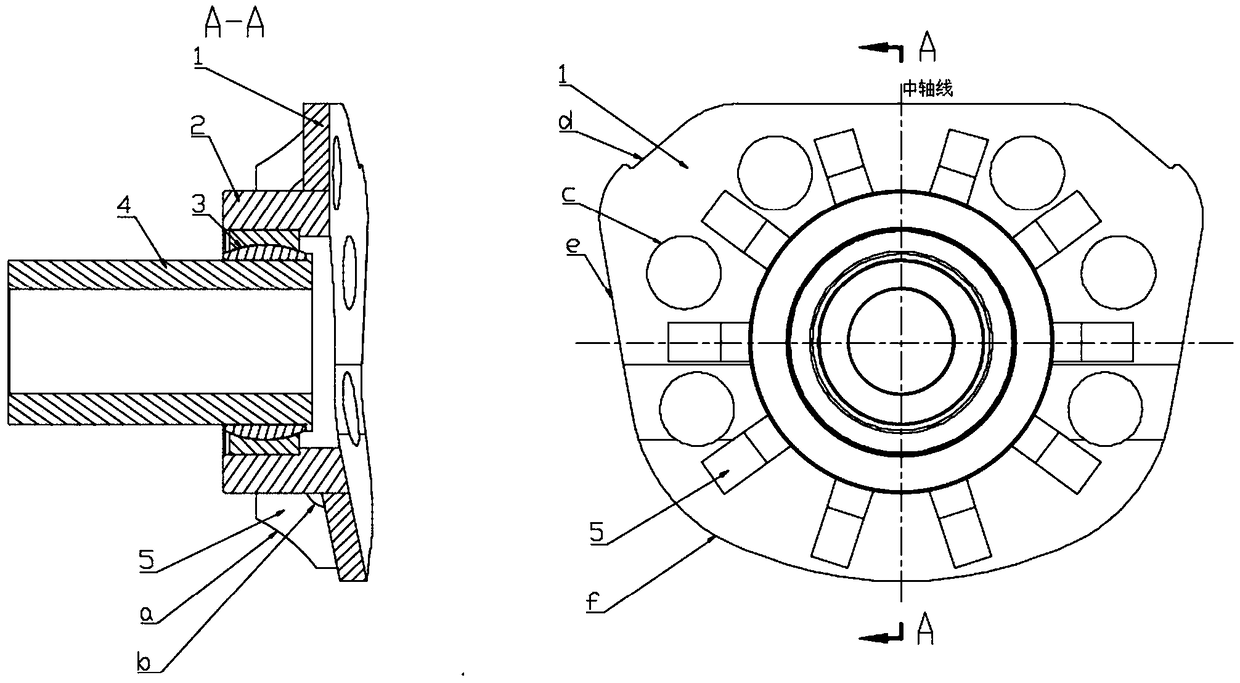

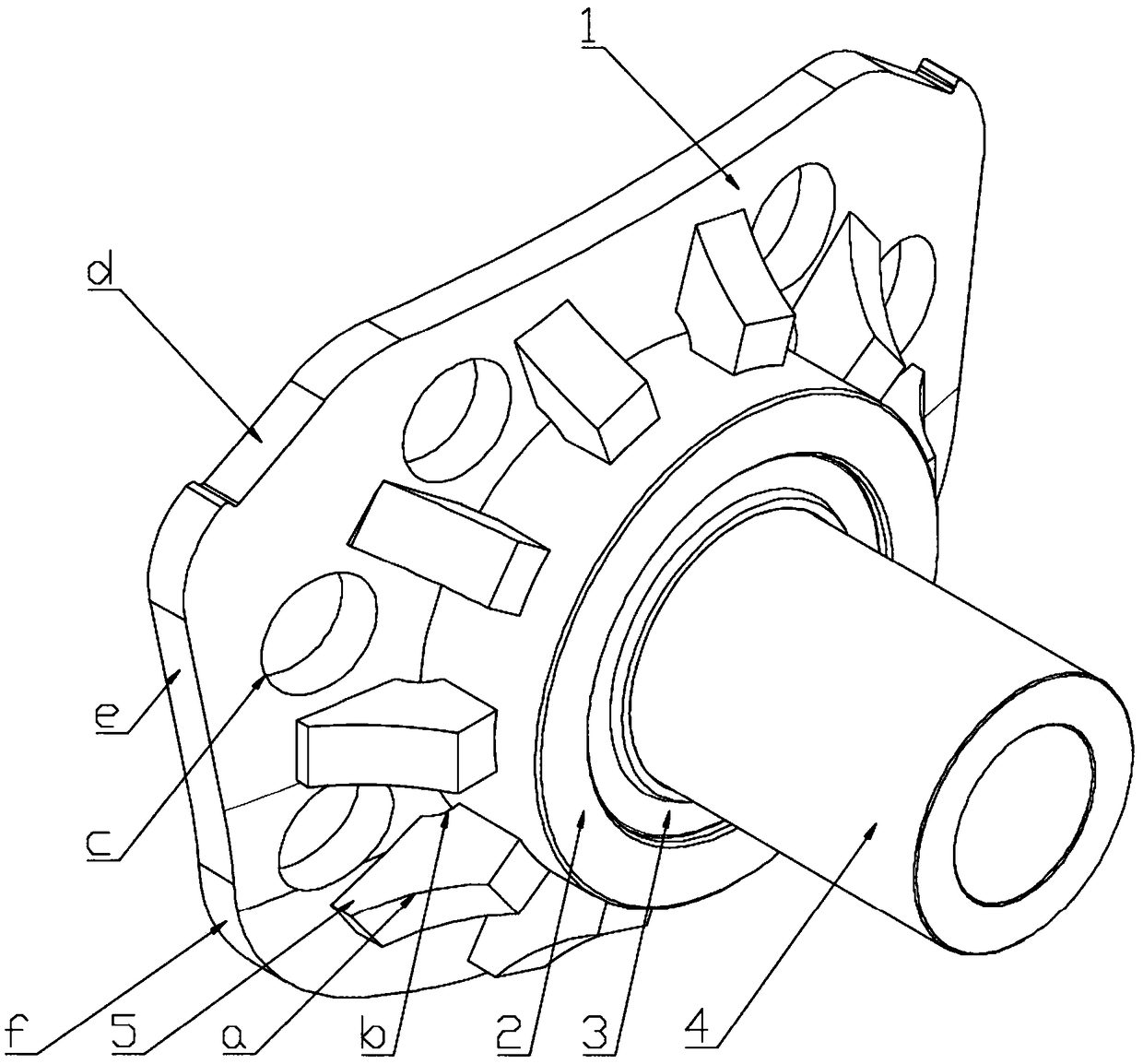

[0023] like figure 1 and figure 2 As shown, a connection plate of a spherical hinge sliding rod connection device for converter transformation, including an arc-shaped plate 1 that is close to and fixed at a designated position on the outer wall of the converter shell by edge welding, and is welded and fixed on the arc-shaped plate 1 and is designed A support ring 2 with a shaft hole, a ball joint bearing 3 fitted in the shaft hole, a support shaft 4 fitted in the inner ring of the ball joint bearing 3, and several support ribs 5 (support ribs) uniformly distributed along the outer wall of the support ring 2 The number of 5 depends on the actual situation), the support rib 5 is welded and fixed with the outer wall of the support ring 2 and the arc-shaped plate 1 and points to the axis of the shaft hole, the edge of the arc-shaped plate 1 and the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com