New-type hinge expansion joint for high-temperature flue of flue gas turbine

A flue gas turbine and high-temperature flue technology, applied in the field of expansion joints, can solve problems such as weld bead cracking and affecting the normal operation of equipment, achieve the effects of small welding volume, eliminate thermal stress problems, and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the disclosed embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

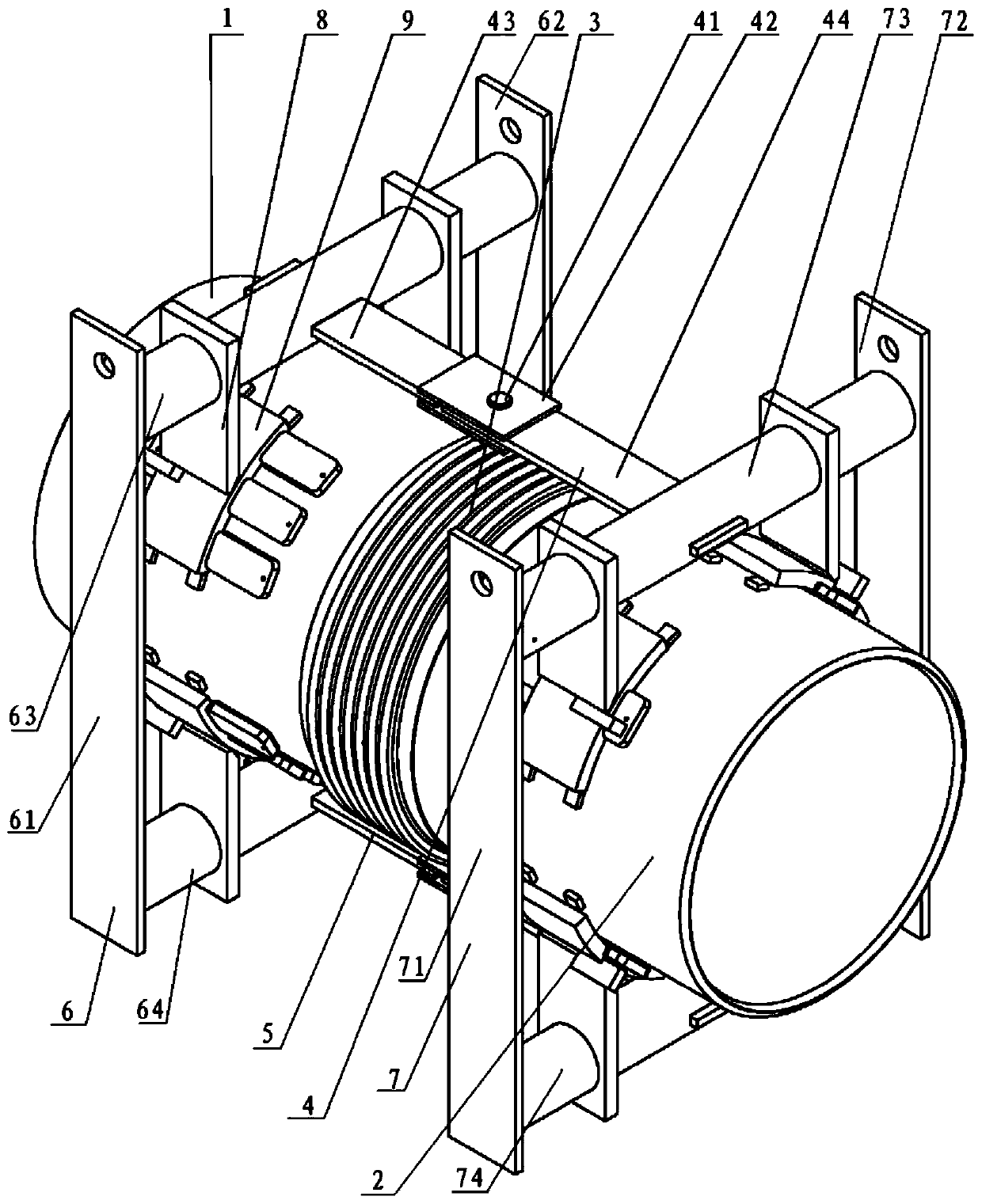

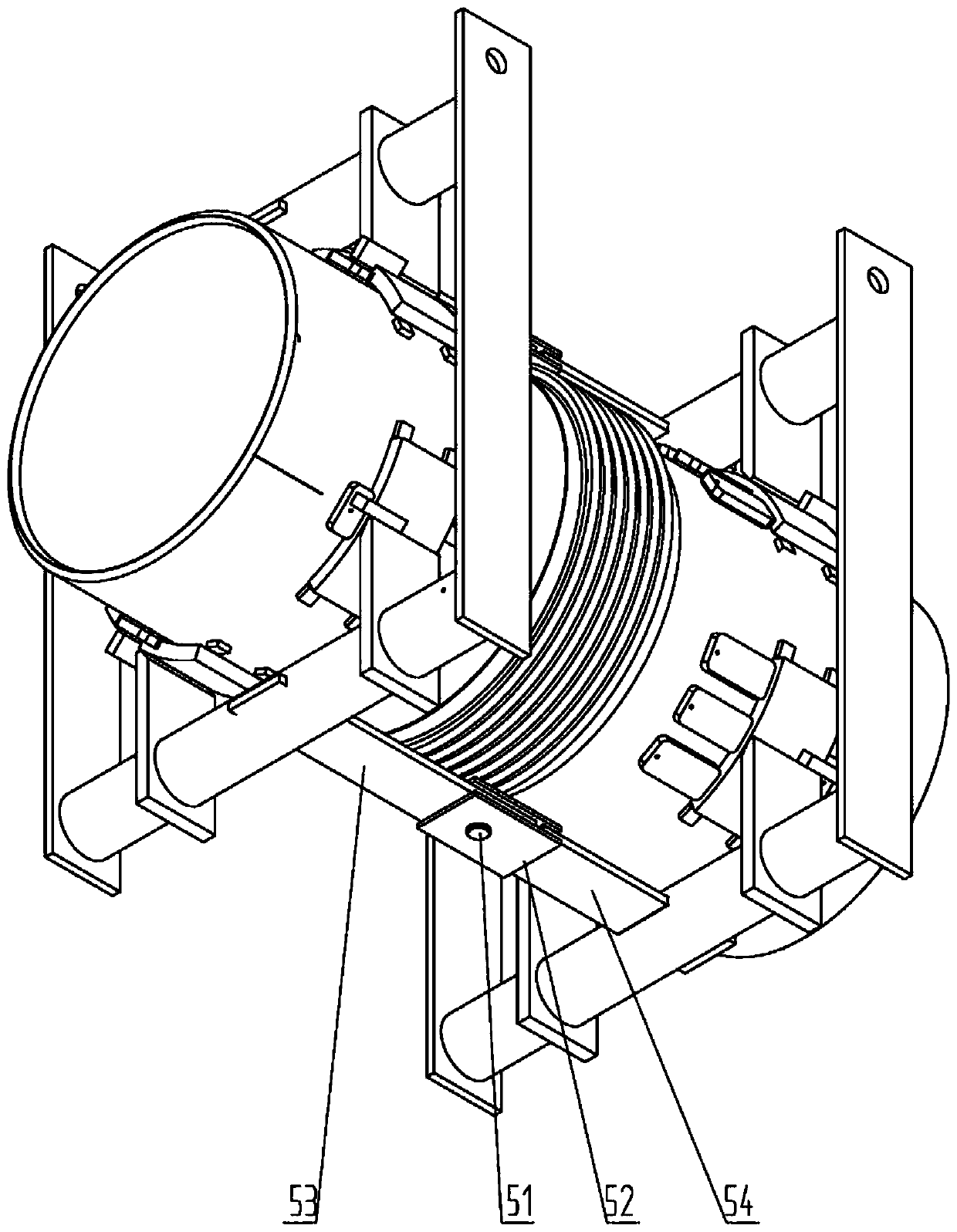

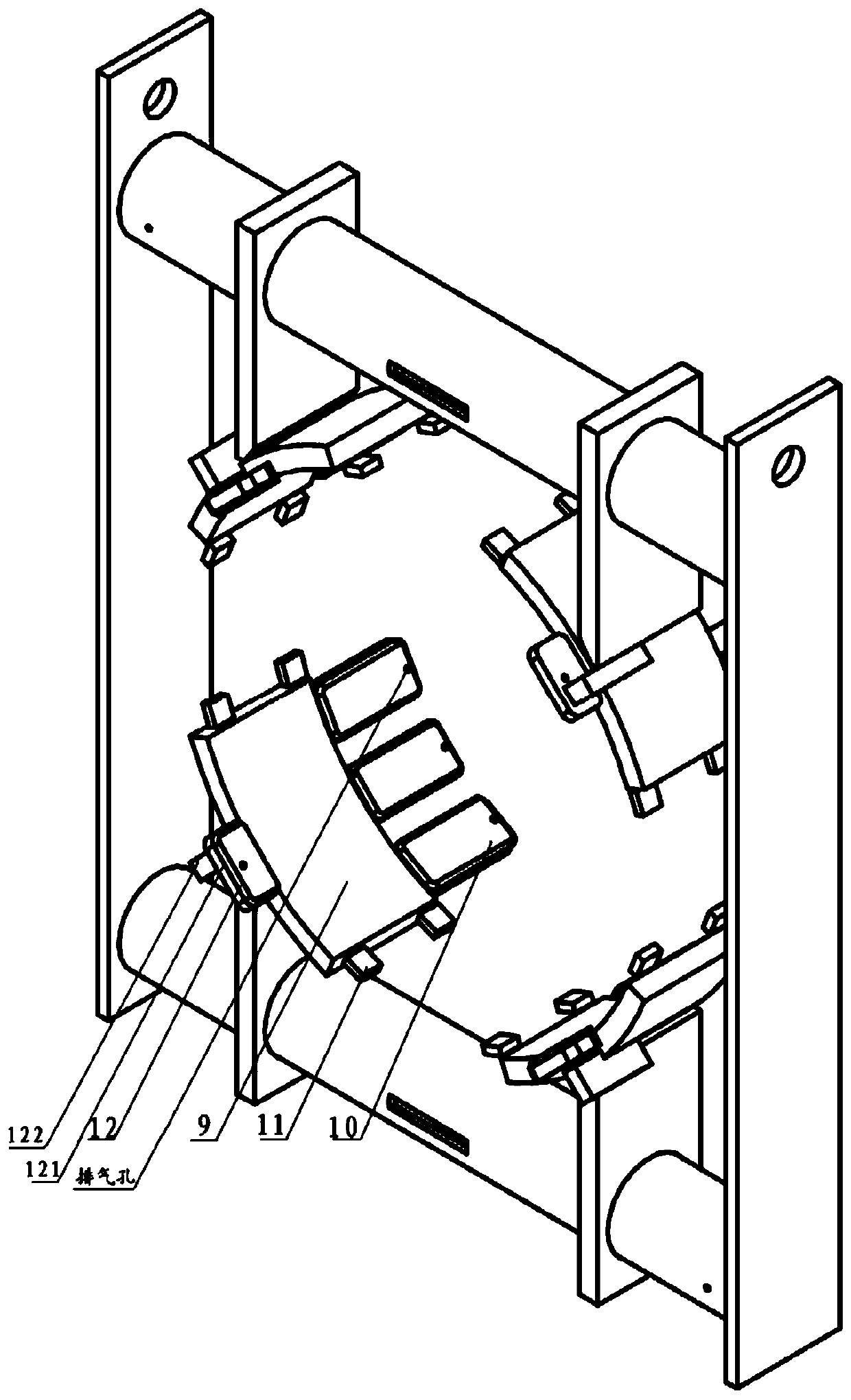

[0039] Such as figure 1 In this embodiment, the new type of hinged expansion joint for high-temperature flue gas turbine flue gas turbines includes: end connection pipe I1, end connection pipe II2, bellows 3, bearing frame I6, bearing frame II7, two sets of hinge mechanisms and eight Group support components.

[0040] The specific connection relationship is as follows: the terminal pipe Ⅰ1, the bellows 3 and the terminal pipe Ⅱ2 are connected in sequence; the bearing frame Ⅰ6 is located on the side of the terminal pipe Ⅰ1 and supports the terminal pipe Ⅰ1 through four sets of support components; the bearing frame Ⅱ7 is located on the side of the terminal pipe Ⅱ2, The other four groups of supporting components are used to support the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com