Bolting and grading device high in productivity and easy to maintain

An easy-to-maintain and sieving technology, used in sieves, solids separation, grids, etc., can solve the problems of large internal space of the sieve body, long maintenance period, inconvenient maintenance and cleaning, etc., to improve the screening efficiency and output, The effect of easy maintenance and maintenance, saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

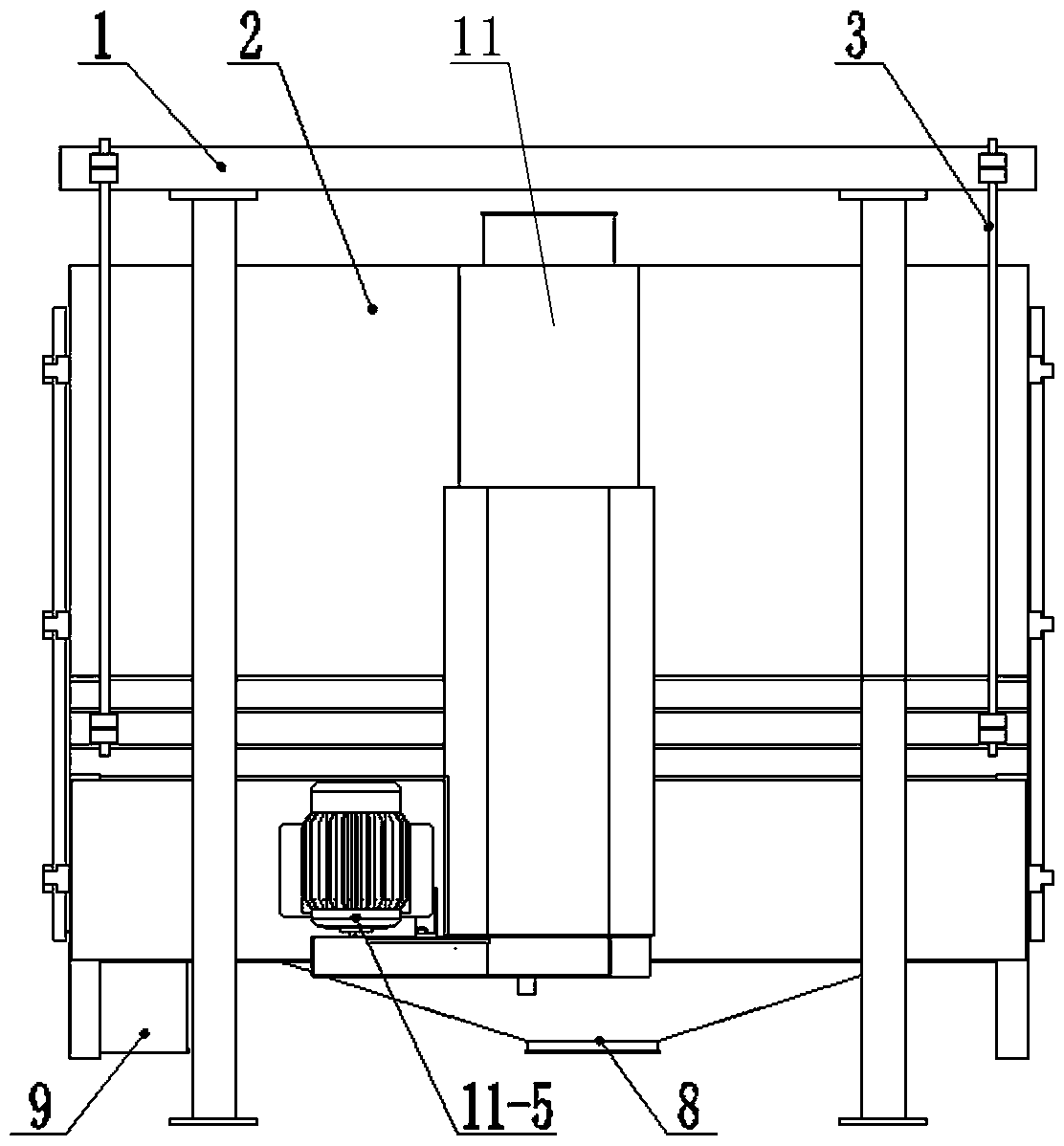

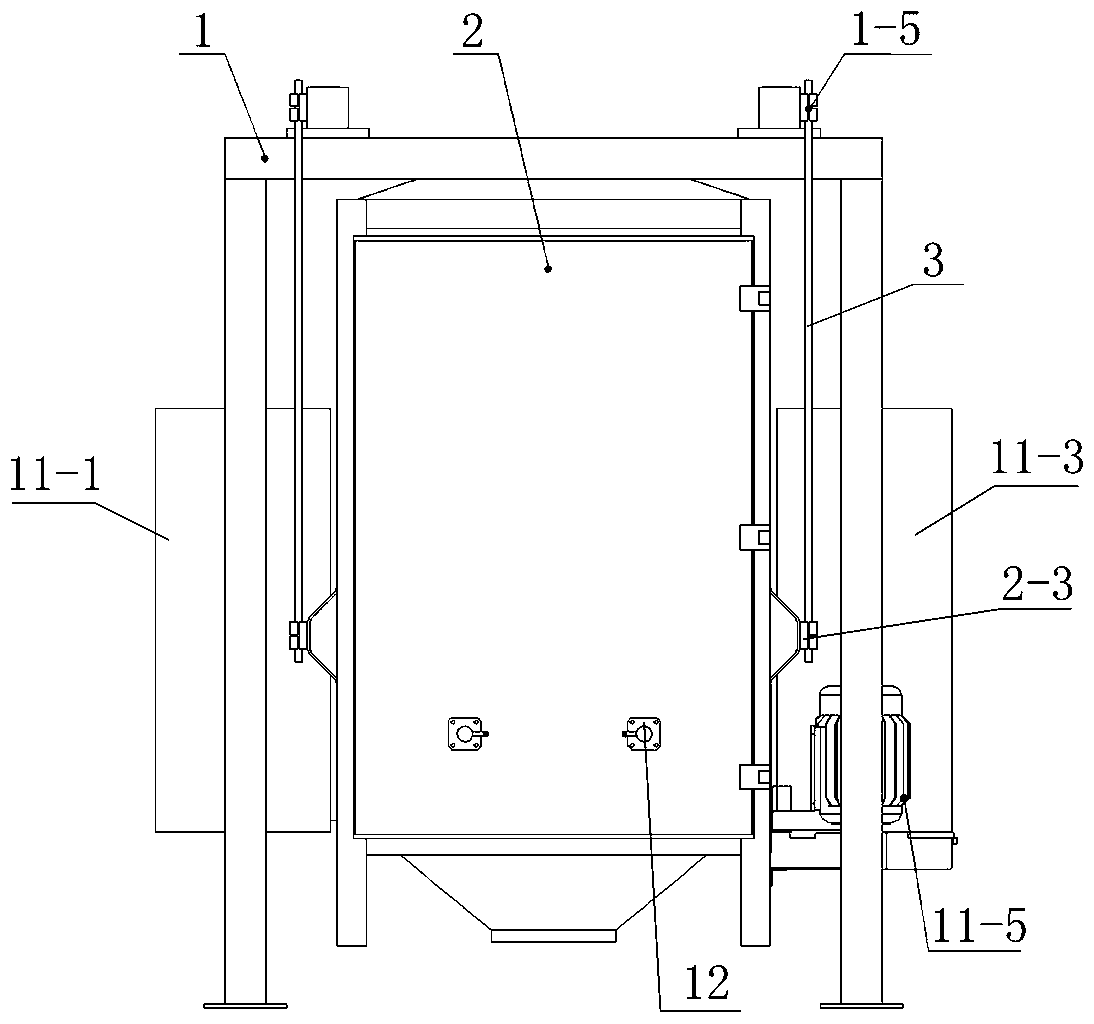

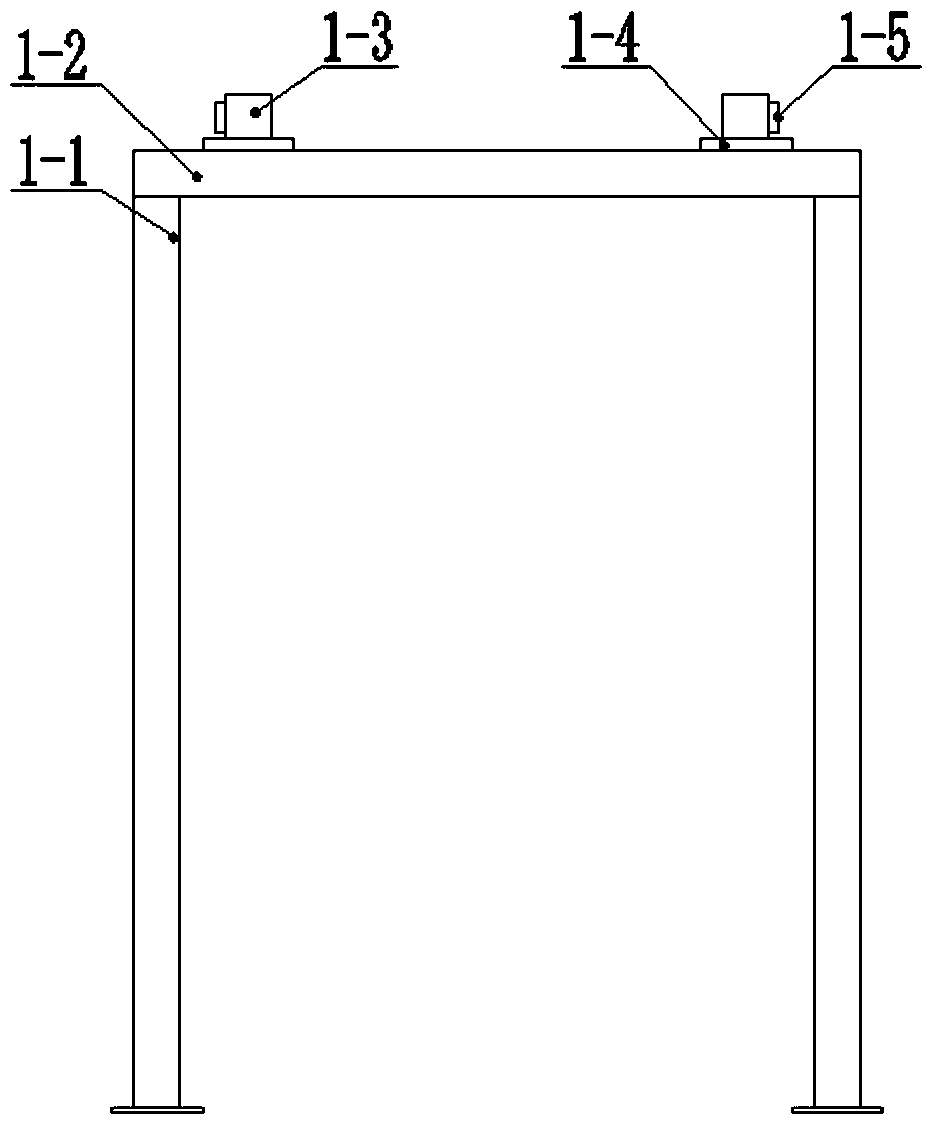

[0043] Such as Figure 1 to Figure 11 As shown, a high-capacity and easy-to-maintain screening and grading equipment of the present invention is characterized in that it includes a frame (1), and a sieve body (2) hoisted on the frame by a steel cable (3) to draw Several layers of screen grids (5) and screen frame (4) installed in the inner cavity of the screen body (2) by pulling (between the screen grid (5) and the screen body (2), between the screen frame (4) and the screen body ( 2) are combined by pulling and pulling, which is convenient for quick disassembly, cleaning and maintenance of the screen grid (5) and screen frame (4). The homogenizing mechanism (7) directly under the feed inlet (6) (accepts materials and guides them to the layered screens on both sides to play the role of uniform feeding), is set at the center of the bottom of the screen body (2) The undersize discharge port (8) is set at the bottom of the screen body (2) and the oversize discharge port (9) adj...

Embodiment 2

[0054] The difference between the second embodiment and the first embodiment is that the synchronous mechanism assembly (11-2) in the first embodiment is composed of a synchronous belt (11-2-1) and two synchronous pulleys (11-2- 2) Composition (see Figure 11 ). However, the synchronous mechanism assembly (11-2) in the second embodiment is composed of a cardan shaft (11-2-4) and two gearboxes (11-2-3) (see Figure 12 ), one of the gearboxes (11-2-3) is installed on the output end of the transmission shaft (11-3-2) in the active transmission assembly (11-3), and the other gearbox (11-2-3) is installed on The same-side input end of the transmission shaft (11-3-2) in the driven transmission assembly (11-1), the cardan shaft (11-2-4) is connected between the two gearboxes (11-2-3) (Two gearboxes (11-2-3) cooperate with cardan shafts (11-2-4) to realize the transmission shaft (11- 3-2) and the weighted block (11-3-3) operate in the same direction and synchronously, providing cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com