Marine floating oil collecting ship

An oil slick and floating hull technology, applied in special-purpose ships, ships, motor vehicles, etc., can solve the problems of intermittent operation, small collection range, inability to effectively deal with the position change of oil slicks, etc., so as to prolong working time and save internal space. , to avoid the effect of re-diffusion of oil layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

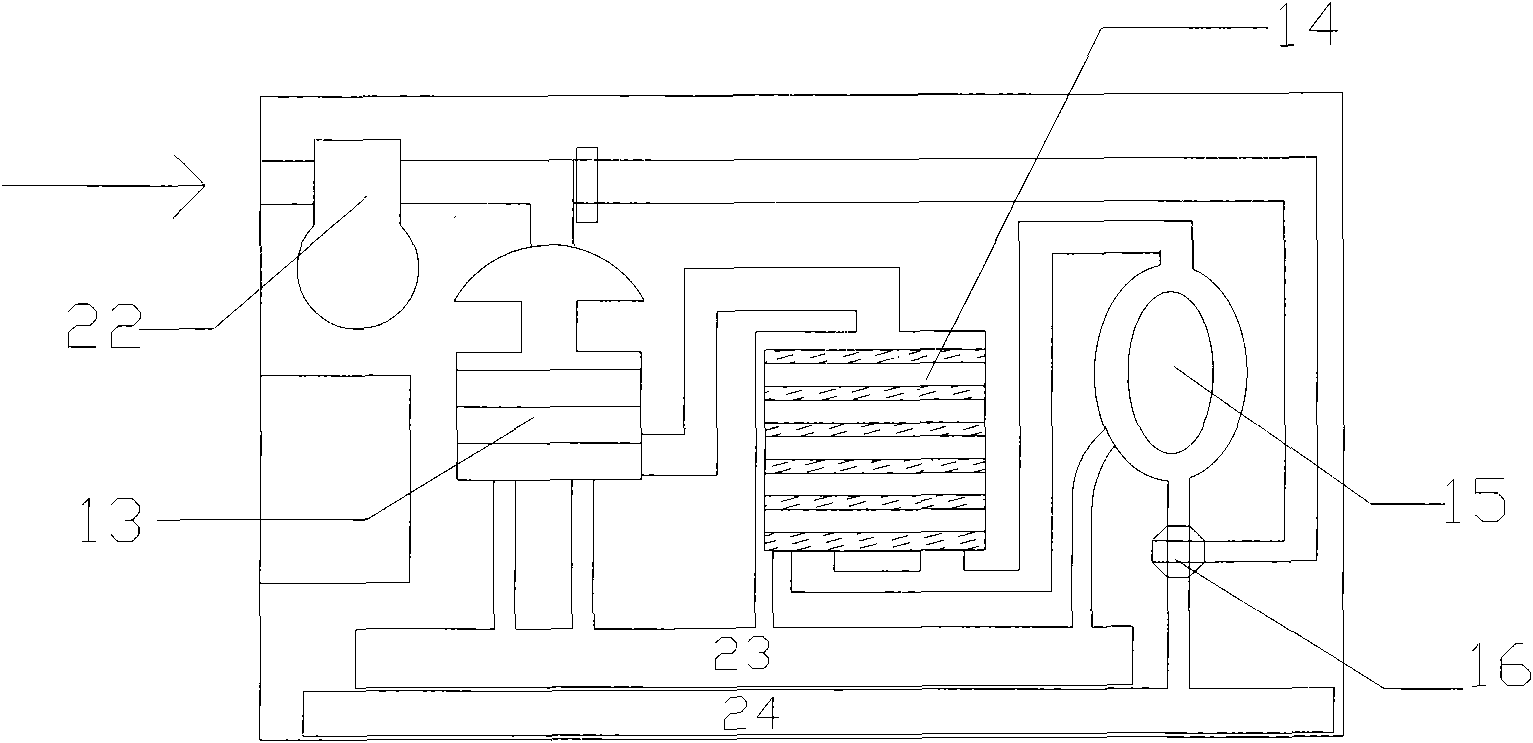

[0025] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

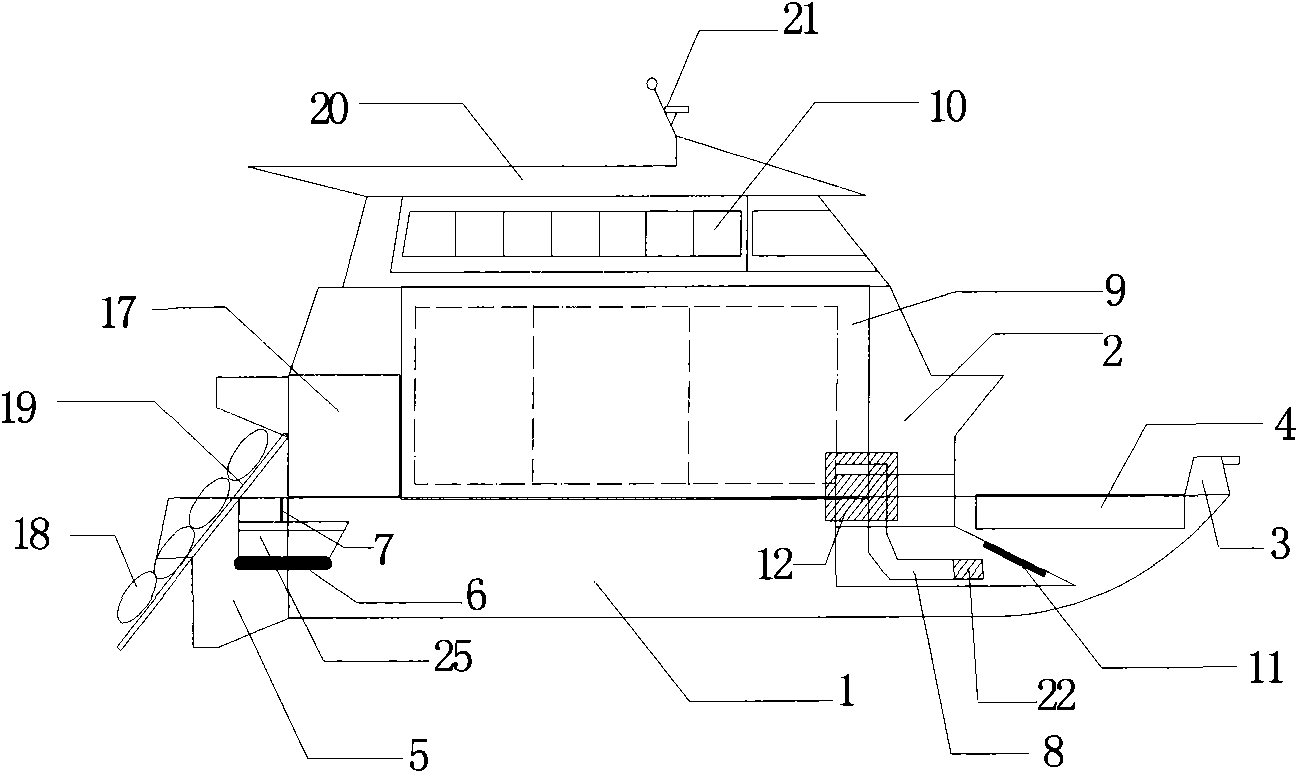

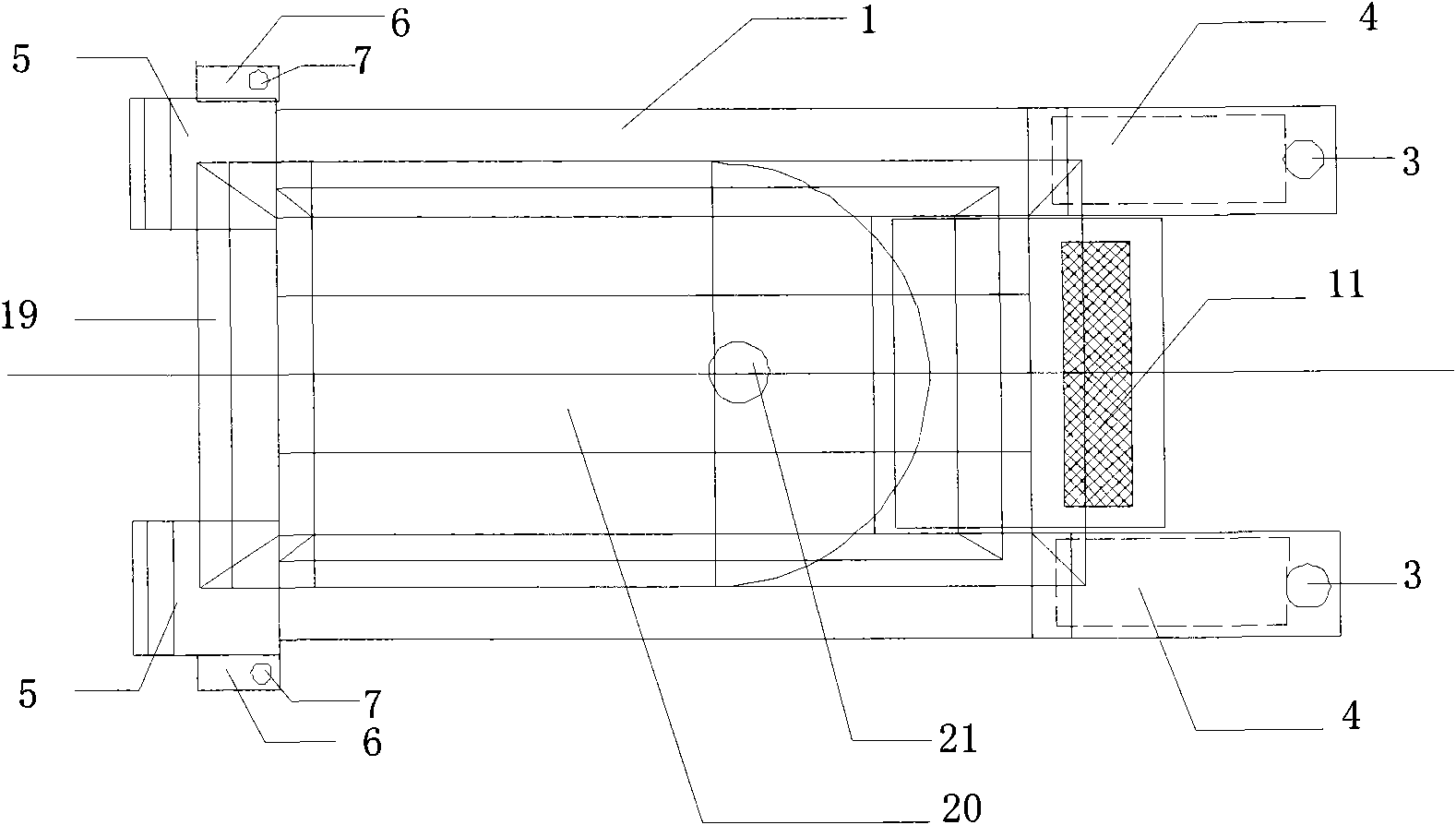

[0026] like figure 1 and 2 As shown, the present embodiment consists of a floating hull 1 and a main hull 2. The floating hull 1 has a certain draft to provide the required buoyancy of the device. The main hull 2 is supported by the floating hull 1 and is located above the water surface.

[0027] There are two pontoon hulls 1, and the equipments thereon are arranged symmetrically about the mid-longitudinal section of the device. The deck at the bow of the floating hull 1 is provided with a reagent spraying device 3, and the deck at the tail is provided with a self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com