Local reinforcing equipment and method for wind power generator unit foundation ring

A wind power generation unit, local reinforcement technology, applied in the direction of wind power generation, infrastructure engineering, foundation structure repair, etc., can solve problems such as not taking into account the gap between the foundation ring and concrete, and the increase of the gap between the foundation ring and concrete, etc., Achieve the effects of increasing service life, slowing down fatigue damage, and avoiding welding stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

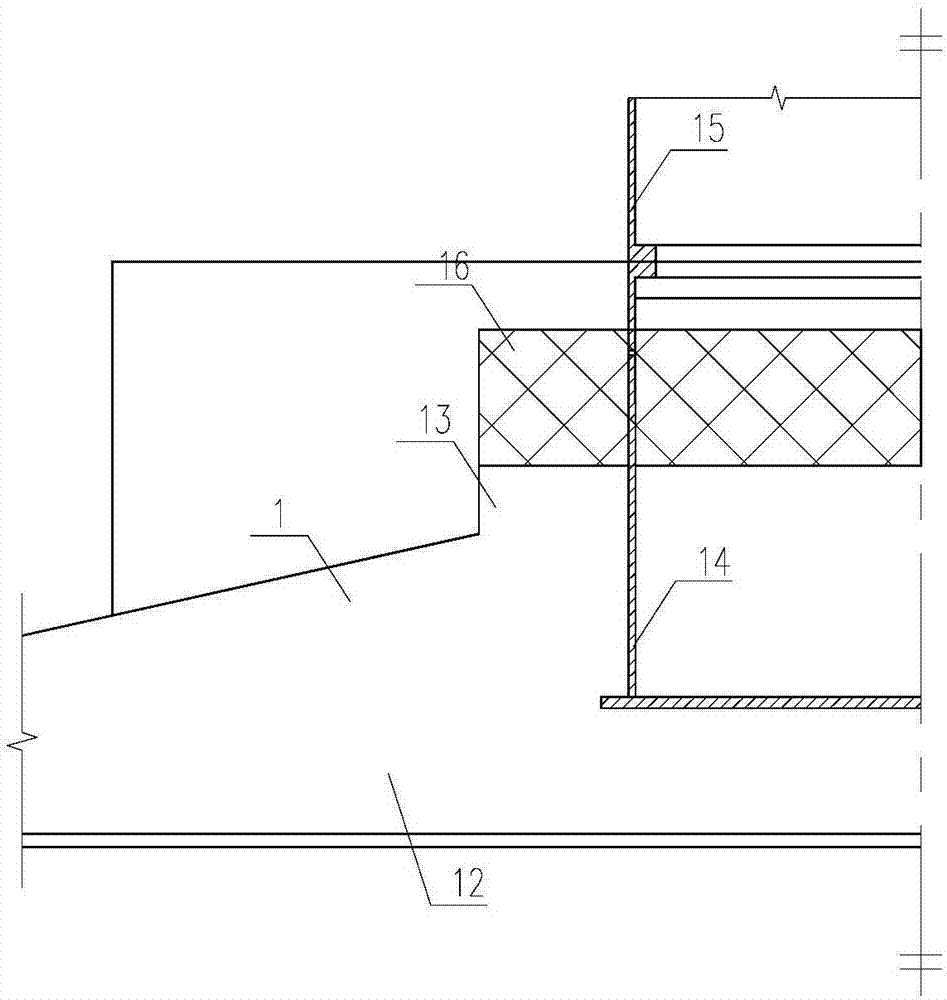

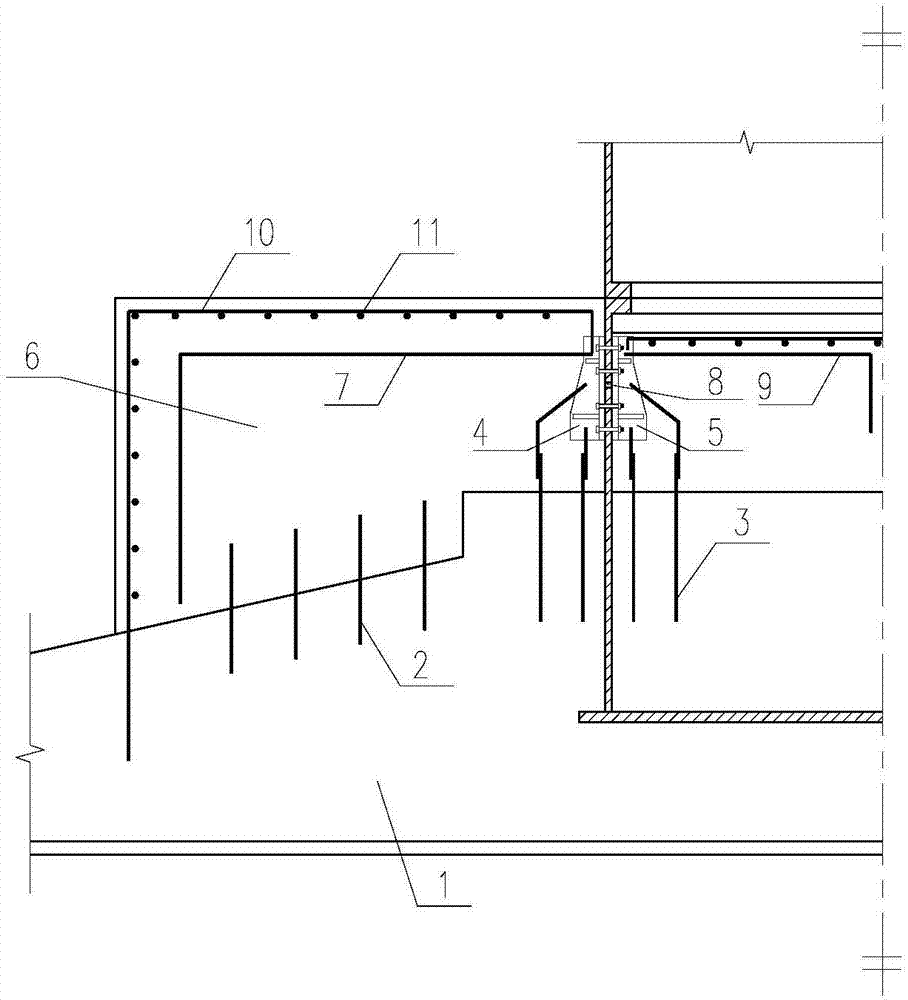

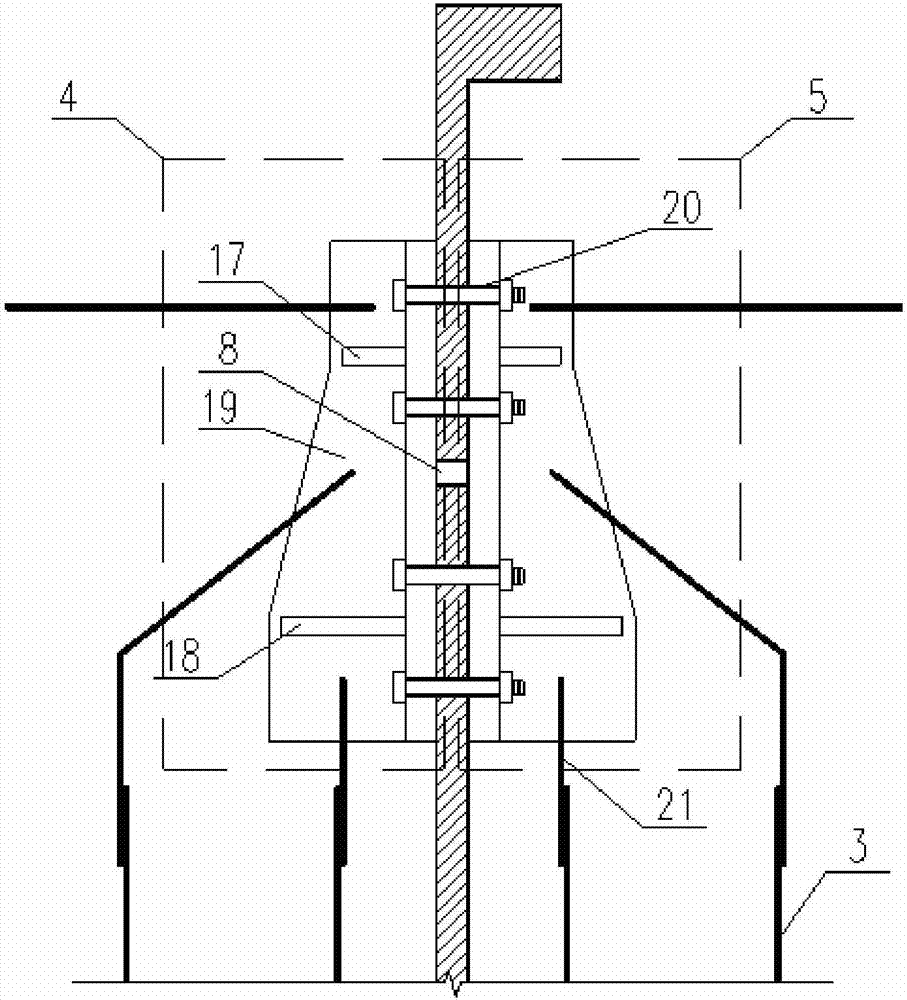

[0033] Such as figure 2 As shown, a local reinforcement device for the foundation ring of a wind power generating set includes an original reinforced concrete foundation 1 and a local reinforcement device; the original reinforced concrete foundation 1 includes a base plate 12, a pier 13 and a base ring 14, and the base plate 12 is embedded in the ground , the middle part of the foundation bottom plate 12 is provided with a pier 13, the foundation ring 14 is embedded in the pier 13, the top of the foundation ring 14 is connected with the tower tube 15, and the part of the foundation bottom plate 12 located outside the pier 13 is vertically provided with a plurality of insertion ribs 2 , the local reinforcement device includes a newly poured reinforced concrete foundation 6, an inner steel splint unit 5, and an outer steel splint unit 4, and a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com