A new steel-concrete composite vierendeel beam and its manufacturing method

A reinforced concrete and concrete technology, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problems of high cost of formwork, deformation and stress, and low construction efficiency, and achieve high construction efficiency. The effect of light weight and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

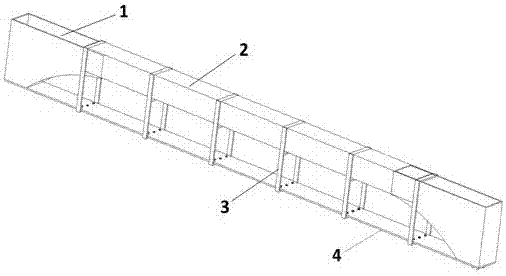

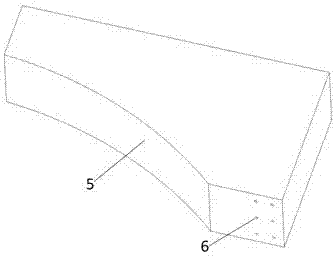

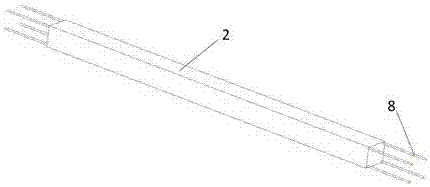

[0022] Embodiment of the present invention: the structural schematic diagram of novel steel-concrete composite hollow beam is as follows figure 1 As shown, the hollow beam includes four parts: the upper rectangular reinforced concrete 2, the lower tensile steel plate 4, the end arc-shaped steel pipe 1 and the steel plate hoop 3, see image 3 , the two ends of the upper rectangular part reinforced concrete 2 are reserved with longitudinal steel bars 8, and after the longitudinal steel bars 8 are inserted into the end arc-shaped steel pipe 1 together with the ends of the upper rectangular part reinforced concrete 2, the end arc-shaped steel pipe 1 Concrete is poured inside, and after the concrete reaches the design strength, the reinforced concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com