Automatic paper-cup ice cream filling machine

A technology of ice cream and filling machine, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of wasting frozen materials, affecting the quality of filling cups, and difficult filling mechanisms, so as to avoid welding stress, improve visual effect, The effect of filling quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

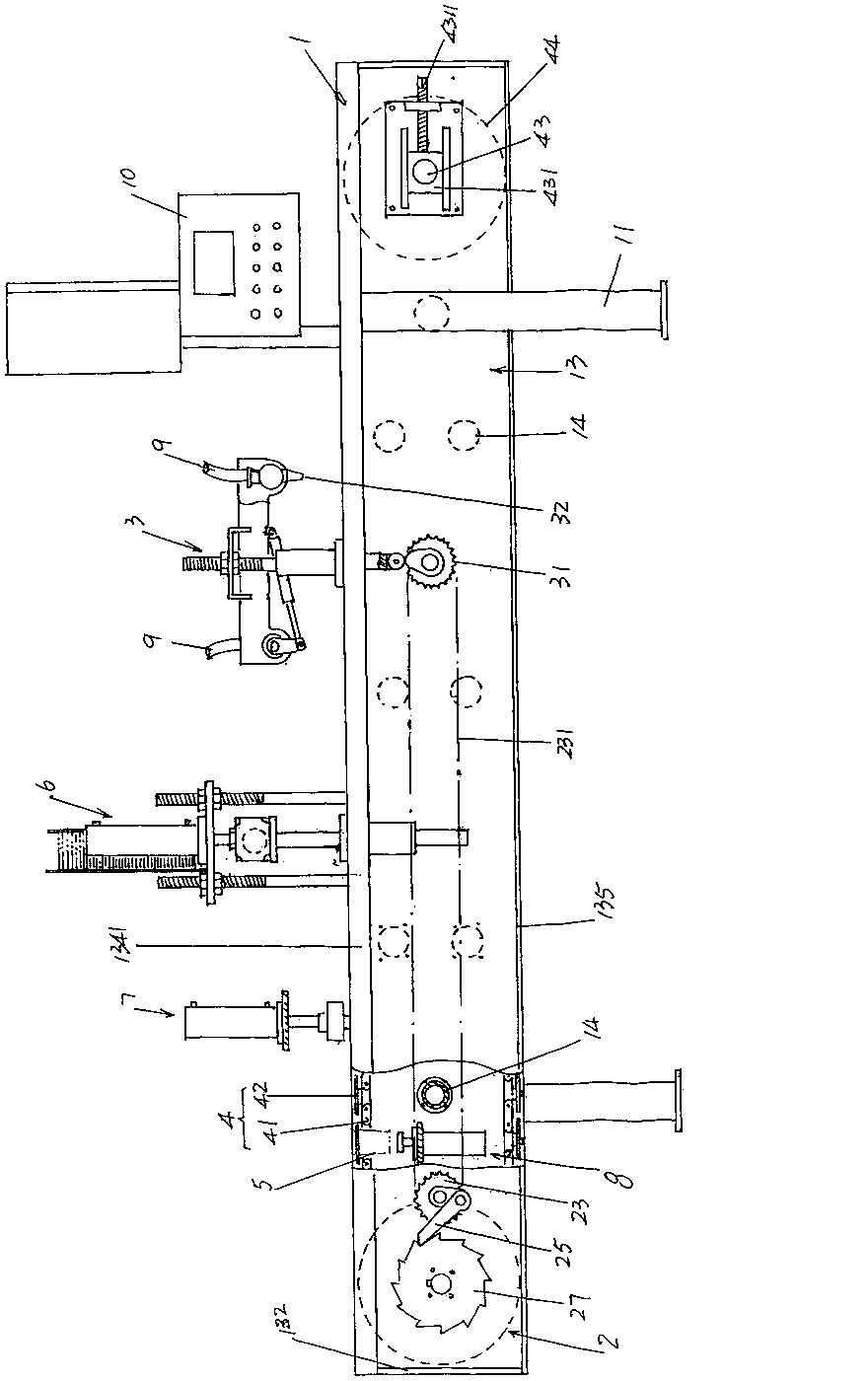

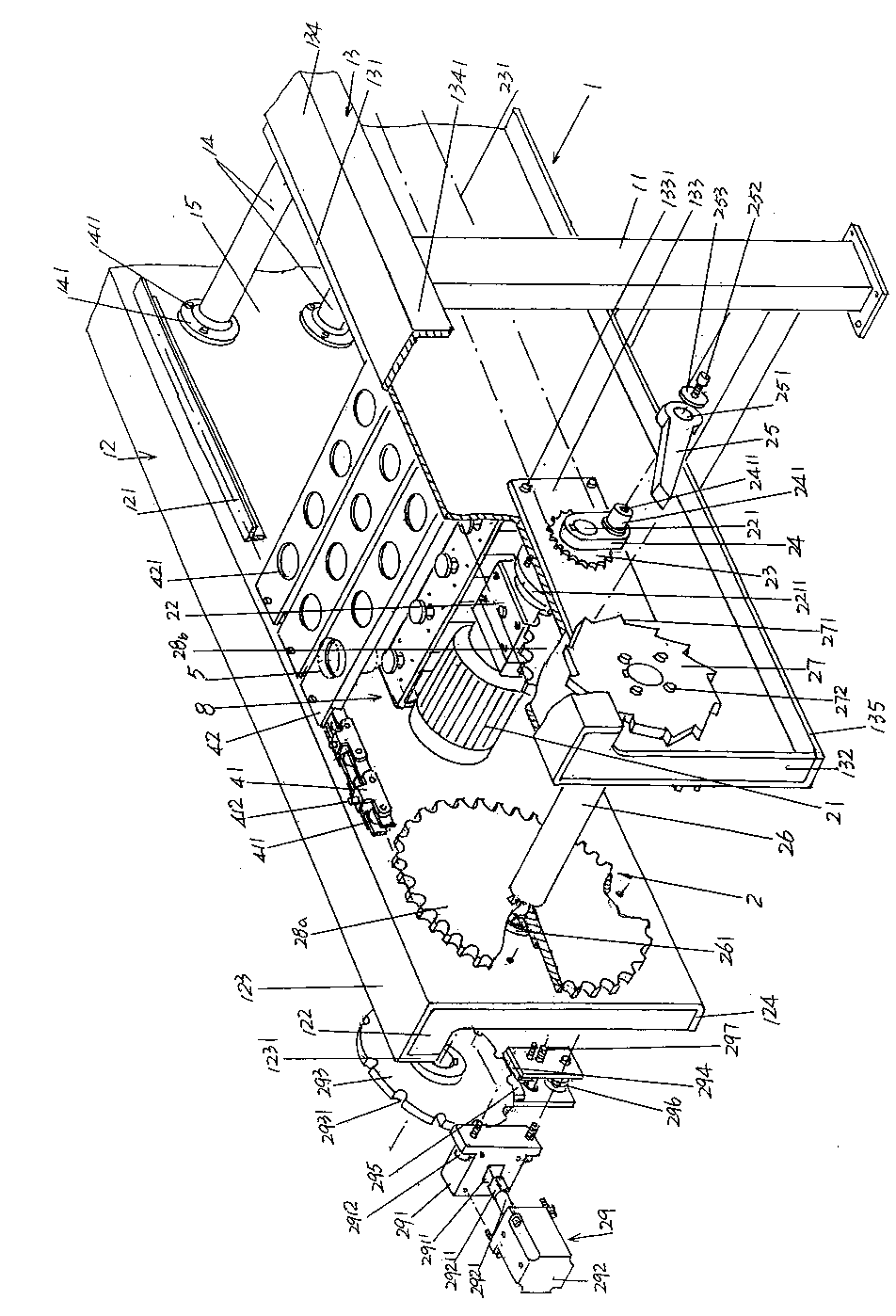

[0023] See figure 1 , a frame 1 is given, a power mechanism 2 is arranged at one end of the frame 1, that is, the left end of the position shown in the figure, and a power mechanism 2 is arranged at the other end of the frame 1, that is, the right end of the position state shown in the figure and corresponding to the frame 1 A filling mechanism 3 is provided at the position above, and the filling mechanism 3 is connected with the power mechanism 2 in transmission, and the paper cup 5 ( figure 2 shown) filling frozen ice cream, and a chain rail mechanism 4 is provided on the frame 1, the chain rail mechanism 4 is connected with the power mechanism 2, and moves around the length direction of the frame 1 under the drive of the power mechanism 2 (line shift). If in order to expand the function of the ice cream automatic filling machine, by figure 1 As shown, a cap suction mechanism 6, a capping mechanism 7 and a full cup ejection mechanism 8 are set on the frame 1 ( fig...

Embodiment 2

[0035] Not shown, the difference between this embodiment and Embodiment 1 is that the entire inertia canceling device 29 is arranged on the side of the second beam 13 facing away from the first beam 12 , that is, on the side of the second beam 13 facing outward. In this case, the locking disc 293 of the inertia eliminating device 29 is fixed on one end of the large sprocket shaft 26 protruding from the second beam 13, that is to say, the locking disc 293 and the ratchet disc 27 are jointly fixed on the same end of the large sprocket shaft 26. end. Also, in this case, the end of the large sprocket shaft 26 facing the first cross beam 12 basically does not need to protrude from the first cross beam 12 , that is, it remains flush with the outer wall of the first cross beam 12 . The rest are the same as the description of the inertia eliminating device 29 in Embodiment 1.

[0036] applicant combined figure 1 with figure 2 Briefly describe the use of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com