Super-span steel skew arch construction method

A construction method and technology of inclined arch, which are applied in the direction of arch structure, building component, dome roof structure, etc., can solve the problems of high construction difficulty, high assembly difficulty and high hoisting height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

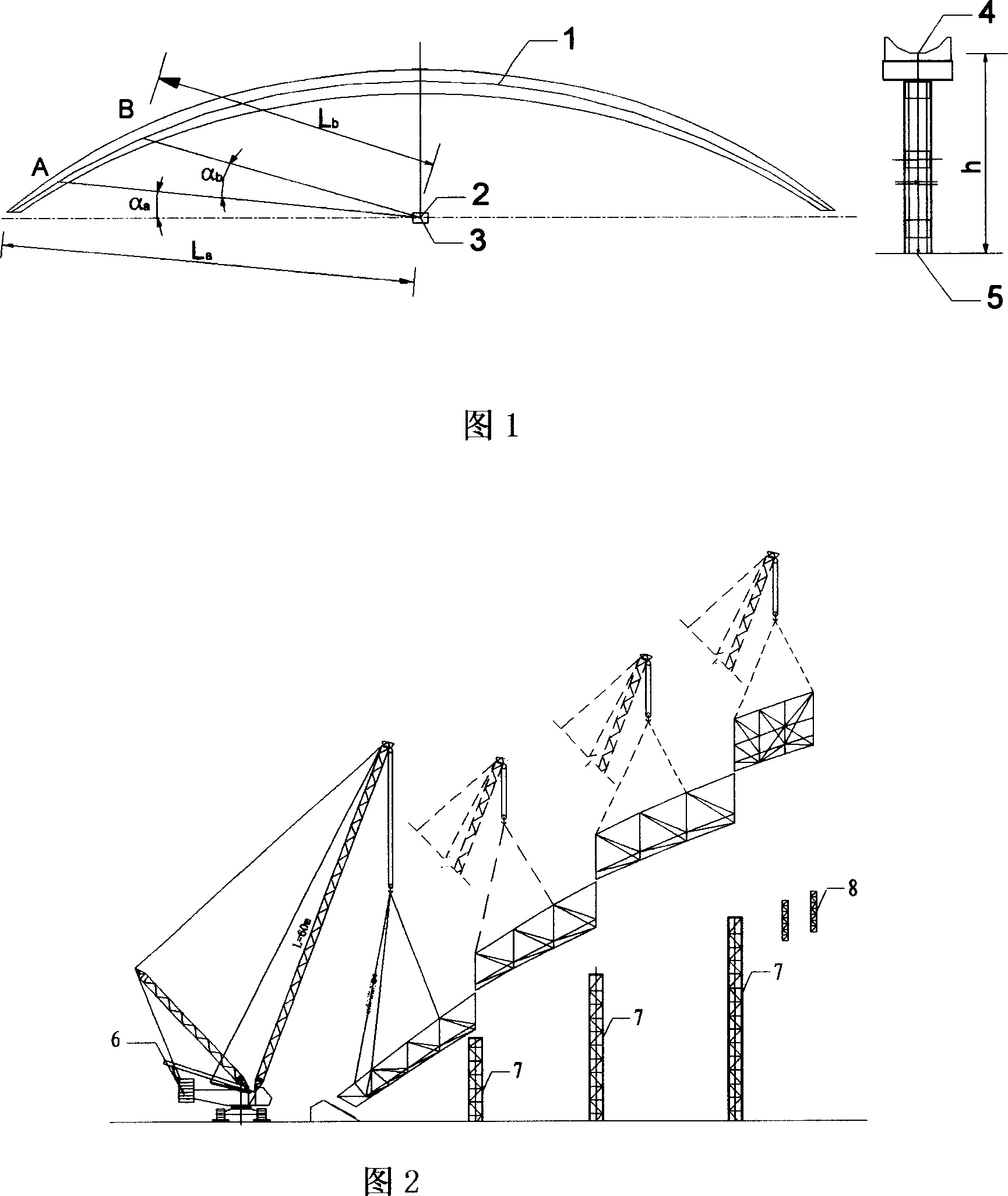

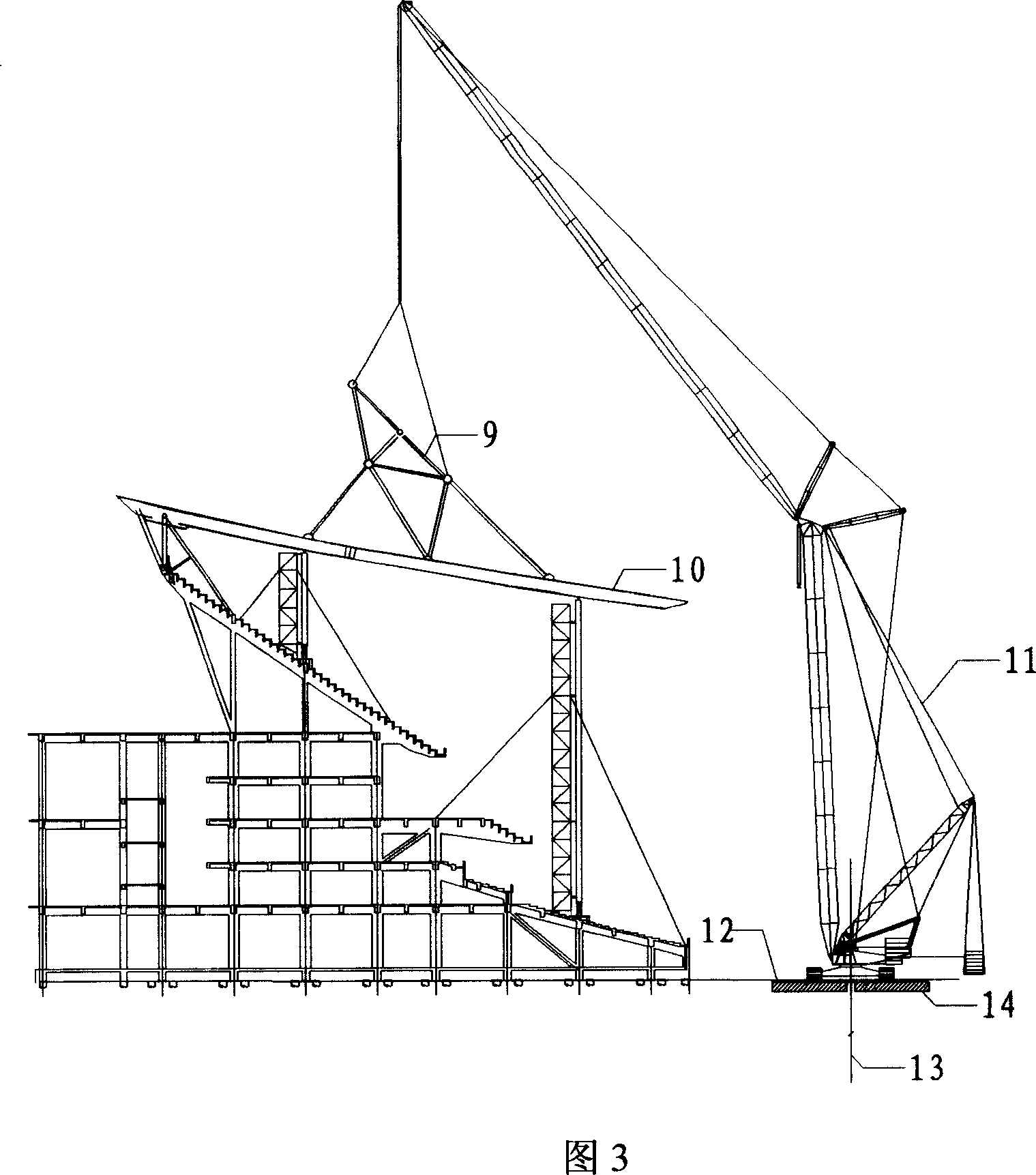

[0015] The specific implementation of the invention will be described in further detail below with reference to the drawings and embodiments. The two main arches with a span of 372m in the north-south direction of the main stadium of the Nanjing Olympic Sports Center have a large span, heavy weight, and a single arch weighing 1606t. The highest point of the vault is 65m high. The main arch is a spatial structure tube truss with an arc length of up to 429.26m, its section is triangular, with three main chords arranged at the midpoint of the three vertices and the base of the oblique triangle. The angle between the base of the triangular section and the ground is 45°. In view of construction problems such as large span and heavy weight, the steel arch is divided into 21 structural units during construction. The main arch is assembled by horizontal assembly method. After the assembly is completed, it is turned over before hoisting to facilitate the assembly and ensure the accuracy of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com