Stationary shaft shoulder assistant supporting inclined penetration friction-stir welding device and method

A static shoulder, friction stir technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult non-welding defects and large heat input, so as to reduce welding heat input and avoid non-welding The effect of defect formation, reducing the likelihood of pin breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

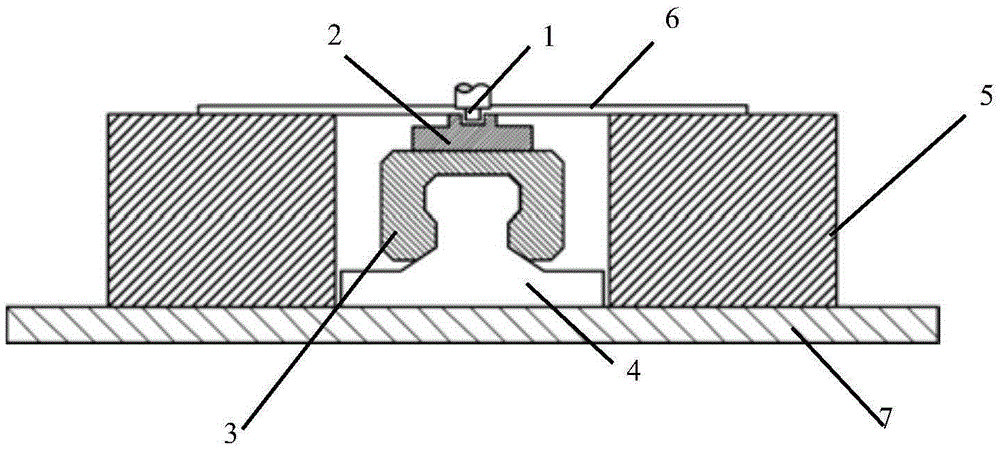

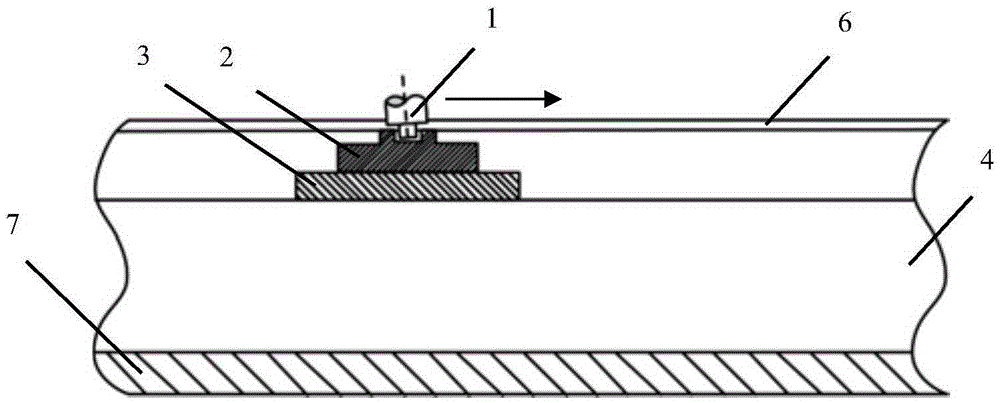

[0022] Specific implementation mode 1: Combination Figure 1 to Figure 2 To illustrate this embodiment, a stationary shaft shoulder auxiliary support inclined penetration friction stir welding device of this embodiment is characterized in that it includes a long needle stirring head 1, a stationary shaft shoulder 2, a translational slider 3, a linear guide 4 and Positioning fixture 5, the long needle stirring head 1 is composed of the upper shaft shoulder and the long stirring needle, the long stirring needle is fixedly installed at the lower end of the upper shaft shoulder, and the long stirring needle is arranged coaxially with the upper shaft shoulder, and the long needle stirring head 1 stirs The length of the needle is greater than the thickness of the workpiece to be welded; the cross section of the upper shaft shoulder and the long stirring needle are both circular;

[0023] The center of the stationary shaft shoulder 2 is processed with a circular blind hole, the diameter...

specific Embodiment approach 2

[0026] Specific implementation manner two: combination Figure 1 to Figure 2 To illustrate this embodiment, the length of the long stirring needle of the long needle stirring head 1 in this embodiment is 2mm larger than the thickness of the workpiece to be welded. This arrangement can eliminate root unwelded defects, and the rest is the same as the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 1 to Figure 2 To describe this embodiment, the diameter of the end face of the stationary shoulder 2 of this embodiment is 5 mm larger than the diameter of the upper shoulder of the long needle stirring head 1. With this arrangement, the axial pressure completely acts on the stationary shaft shoulder 2, and good weld formation can be obtained. The other connection modes are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com