Gas pipeline system laying structure and laying method

A gas pipeline and pipeline technology, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of pipeline equipment and building damage, waste of resources, leakage of transported gas, etc., and reduce the risk of rupture Possibility, improved seismic capacity, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

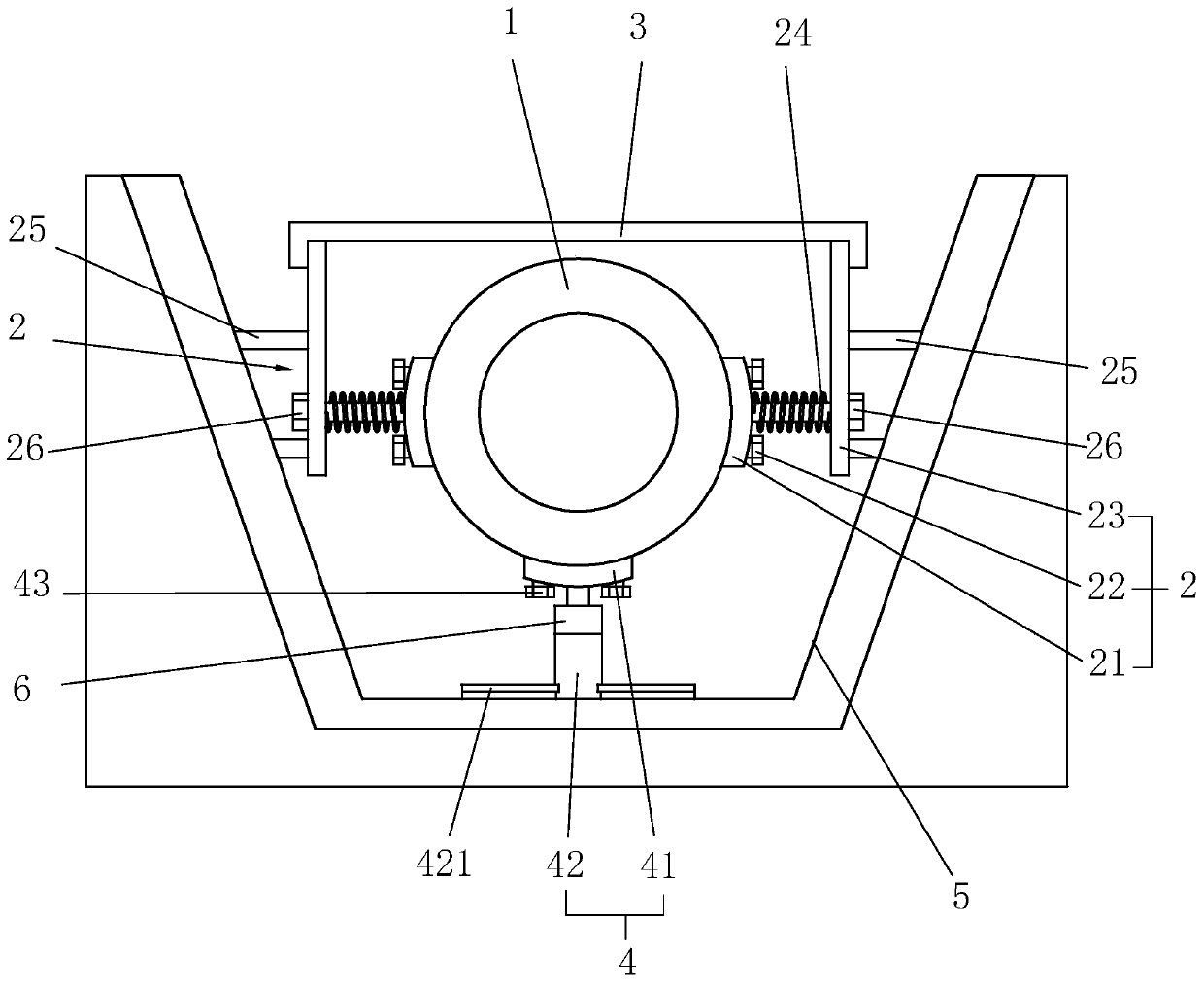

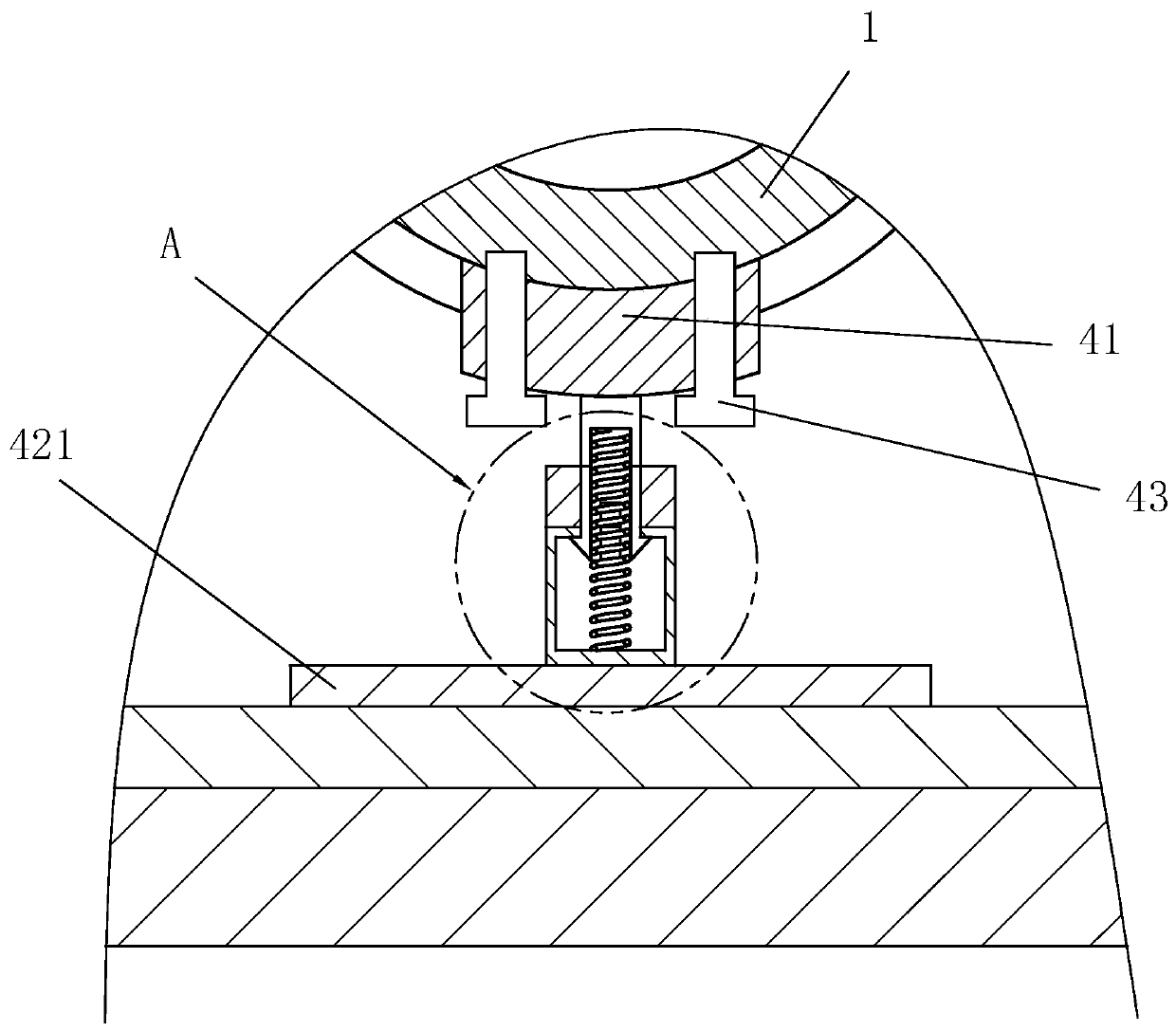

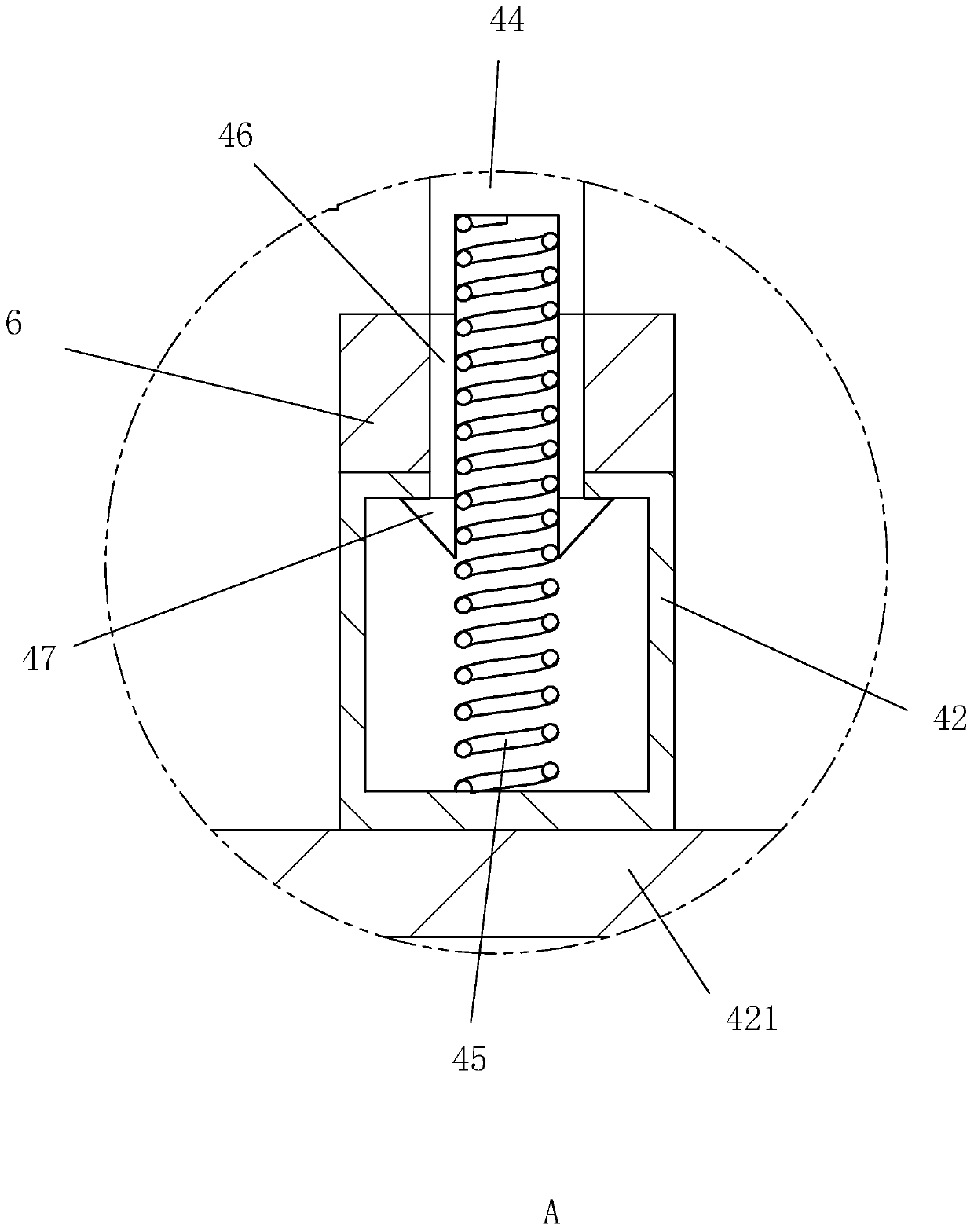

[0041] refer to figure 1 , the present invention provides a gas pipeline system laying structure, including a pipeline 1, an installation component 2, a cover plate 3 and a support component 4, when installing the pipeline 1, first set up a laying groove on the ground according to the extension direction of the pipeline 1 5. Then put the support assembly 4 on the bottom of the laying groove 5, then place the pipe 1 above the support assembly 4, install the assembly 2 on both sides of the pipe 1, and install the assembly 2 to the pipe 1 in the laying groove 5, the position inside is fixed, and finally the cover plate 3 is horizontally arranged above the pipeline 1, and finally sand is filled inside the laying groove 5. In this way, the laying of the pipeline 1 is completed.

[0042] refer to figure 1 , the mounting assembly 2 includes a mounting plate 21, a fixing bolt 22, a fixing plate 23 and a first elastic member, the mounting plate 21 is adapted to the outer surface of t...

Embodiment 2

[0057] A method for laying a gas pipeline 1 system, comprising the following steps:

[0058] S1, dig out the laying groove 5 on the ground along the laying direction of the pipeline 1;

[0059] S2. Concrete is poured on the bottom wall and side wall of the laying groove 5, and the fixing plate 23 and the receiving rod 25 are prefabricated together with the side wall of the laying groove 5 using steel bars and concrete at the same time, and the bottom of the laying groove 5 is aligned with T type slide rail 421 for pouring;

[0060] S3, use positioning bolts 43 to fix the support plate 41 on the peripheral surface of the pipeline 1, and place the pipeline 1 with the support plate 41 installed inside the laying groove 5;

[0061] S4, adding fine sand to the inside of the laying tank 5;

[0062] S5. Insert the auxiliary bolt 26 into the fixing plate 23 and rotate the auxiliary bolt 26, and use the fixing bolt 22 to fix the mounting plate 21 on the side wall of the pipeline 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com