Method and device for reducing oil and gas well annulus belt pressure

A technology for annular pressure and oil and gas wells, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc. It can solve the problems of volume shrinkage, corrosion of annular components in the wellhead section, and rising management costs, etc., so as to slow down or reduce the sharp rise , Reduce the number of maintenance, reduce the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

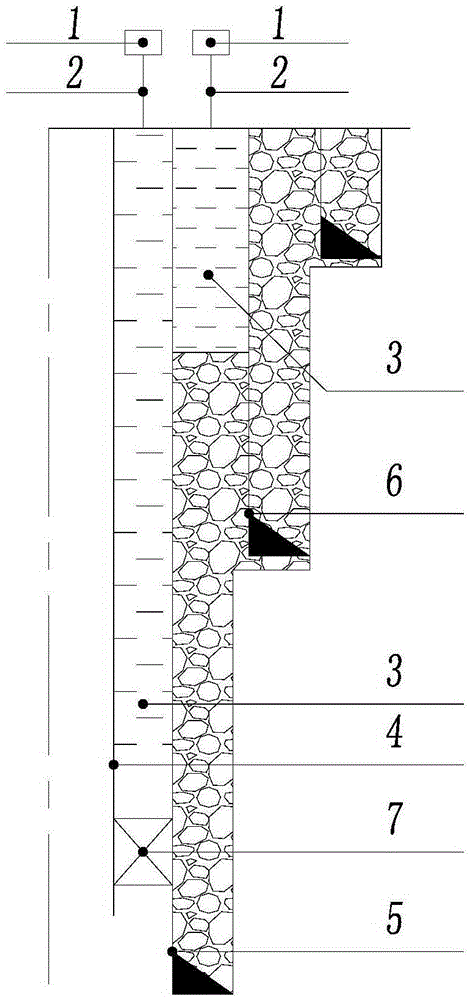

[0031] Such as figure 1 As shown, the present invention provides a kind of method for slowing down the annular pressure of oil and gas well, and it comprises the steps:

[0032] a) provide a gas storage tank 1, the gas storage tank 1 is communicated with the annulus 3 of the oil and gas well through the pipeline 2;

[0033] b) Filling the gas storage tank 1 with a predetermined volume of inert gas.

[0034] Specifically, in step a), the gas storage tank 1 is arranged at the wellhead, and communicates with the annulus 3 of the oil and gas well through a pipeline 2 . In this embodiment, the annulus 3 of the oil and gas well is completely filled with liquid.

[0035] In step b), in this embodiment, the inert gas injected into the gas storage tank 1 is nitrogen, and its volume is V. The annulus 3 of the oil and gas well is composed of an inner pipe and an outer pipe sleeved outside the inner pipe. The formed annular space, the lower part of which is sealed by the packer 7, wher...

Embodiment approach 2

[0110] Such as figure 1 As shown, the present invention also provides a device for relieving pressure in the annulus of oil and gas wells, which includes a gas storage tank 1, which communicates with the annulus 3 of the oil and gas well through a pipeline 2, and the gas storage tank 1 Filled with inert gas.

[0111] Specifically, the inner pipe can be the production string 4, the outer pipe can be the casing 5, the gas storage tank 1 is arranged at the wellhead, and it is connected to the annular space formed between the production string 4 and the casing 5 through the pipeline 2 Or, in other embodiments, the inner pipe can be the casing 5, the outer pipe can be the technical casing 6, the gas storage tank 1 is arranged at the wellhead, and it is connected to the casing 5 and the technical casing 6 through the pipeline 2 An annular space is formed between them.

[0112] The device for alleviating the pressure in the annulus of oil and gas wells needs to know the pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com