Ultra-clean rare earth steel and occluded foreign substance modification control method

A technology of inclusions and rare earths, applied in the field of alloys, can solve problems such as poor lattice matching, lack of systematic in-depth research, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

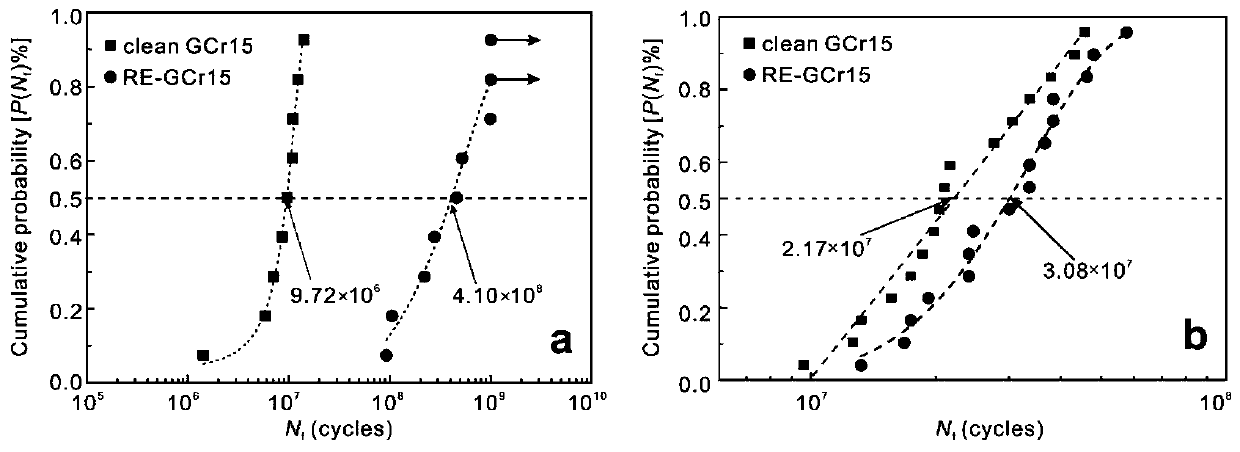

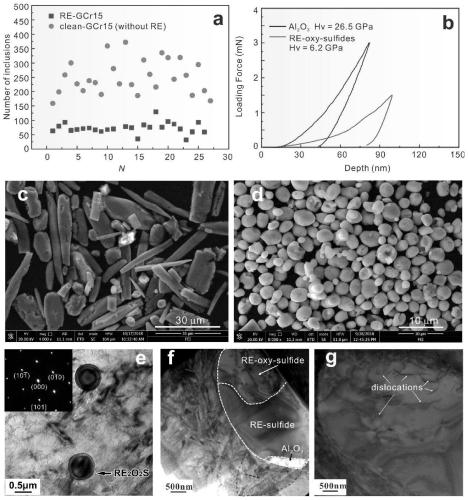

[0085] This embodiment is a method for inclusion denaturation of RE-GCr15 bearing steel. The production process route is electric arc furnace→LF refining→RH refining→continuous casting→heating→rolling, including the following steps:

[0086] 1) Electric arc furnace smelting;

[0087] 2) LF refining: Reasonably adjust the refining slag system, stabilize the slag alkalinity > 5, ensure the white slag time is more than 20min, control T[O]m≤10ppm and T[S]m content in molten steel not higher than 0.005%.

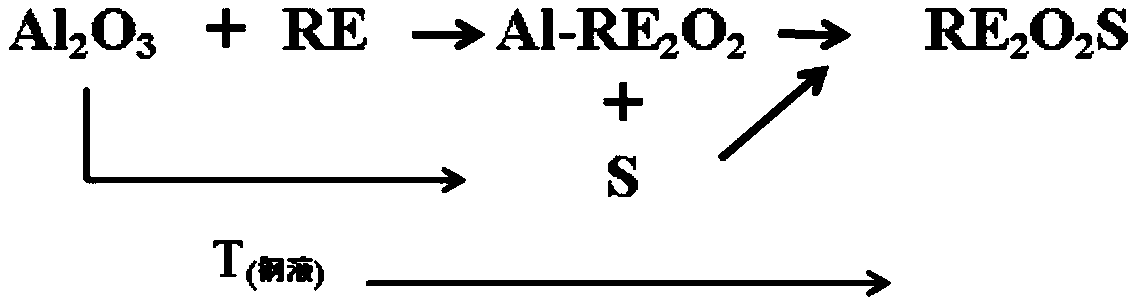

[0088] 3) RH refining: After RH vacuum treatment for at least 5 minutes, add high-purity rare earth metals into the silo, and the amount of high-purity rare earths to be added satisfies the following formula:

[0089] W RE ≥α×T[O]m+T[S]m,

[0090] Wherein: α is a correction factor, the value is 6-30, preferably 8-20, T[O]m is the total oxygen content (ppm) in the steel, and T[S]m is the total sulfur content (ppm) in the steel;

[0091] The T[O]r of high-purity rare earth metal...

Embodiment 2

[0098] This embodiment is a kind of Al in IF steel 2 o 3 Inclusion denaturation method, production process: molten iron pouring station - molten iron pretreatment - converter smelting - RH refining - continuous casting - hot rolling - pickling - cold rolling - annealing, including the following steps:

[0099] 1) Converter smelting:

[0100] Converter process ladle top slag modification, while manganese pre-deoxidation and alloying are not carried out in the converter process and RH decarburization process, and the oxygen content of molten steel in the tundish is strictly controlled below 25ppm to improve the cleanliness of IF steel; Strictly control tapping temperature, hanging tank temperature and slag volume;

[0101] 2) RH refining:

[0102] In the RH process, the ladle top slag is modified, and the S content of the molten steel entering the RH station is controlled below 0.003%; the RH entering the station is oxygen-fixed, after deoxidation and alloying, the oxygen is ...

Embodiment 3

[0120] This example is a method for denaturation of inclusions in ultra-high-strength F-grade marine steel. The production process is: molten iron pretreatment-converter smelting-LF refining-RH refining-continuous casting-rolling-quenching and tempering, and the control process is as follows:

[0121] 1) Smelting and rare earth addition link: before rare earth is added, LF refining ensures that the white slag time is more than 20min, the total oxygen content of molten steel T[O]m is not higher than 10ppm, and the T[S]m content is not higher than 0.003%; high-purity rare earth Metals are added before LF exits the station or after 3 minutes of RH net circulation. When rare earths are added, steel pipes of the same material as molten steel are used to wrap or wrapped in aluminum foil. The purpose is to avoid oxidation or contact with steel slag during the addition of rare earth metals. The total oxygen content in the metal is 80-100ppm, wherein the amount of rare earth added in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com