Defect detection device and method for train wheel tread

A technology for train wheel and defect detection, which is applied in the direction of measuring devices, wheel rim measurement/measurement, instruments, etc., can solve problems such as no measurement results, loss of measurement reference, and plate separation, etc., to improve measurement efficiency, structure optimization, and structural stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

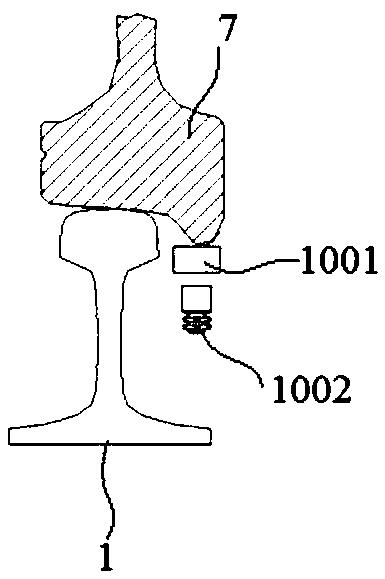

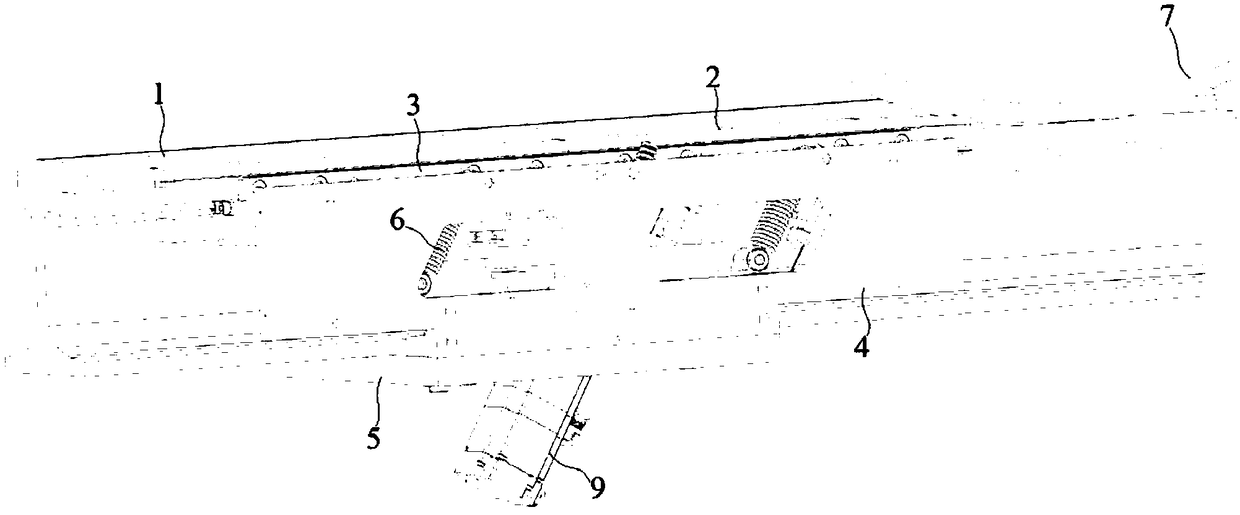

[0052] combine Figure 2-Figure 5 , a kind of device that is used for the defect detection of train wheel tread of the present embodiment, comprises movable plate installed on the inner side of track 1 along the length direction of track 1, fixed plate 4 and movable plate displacement sensing unit and movable plate balance mechanism, said The movable plate is connected to the fixed plate 4 through a slide rail mechanism and an elastic mechanism, wherein the movable plate displacement sensing unit includes an induction plate 1001 fixedly connected to the movable plate, and a displacement sensor 1002 fixedly installed above or below the induction plate 1001, or The installation positions of the two are interchanged. The above-mentioned slide rail mechanism is used to guide the movement of the movable plate, and the elastic mechanism is used to make the movable plate pressed down and moved upward to return to the original position when the wheels leave.

[0053] In this embodime...

Embodiment 2

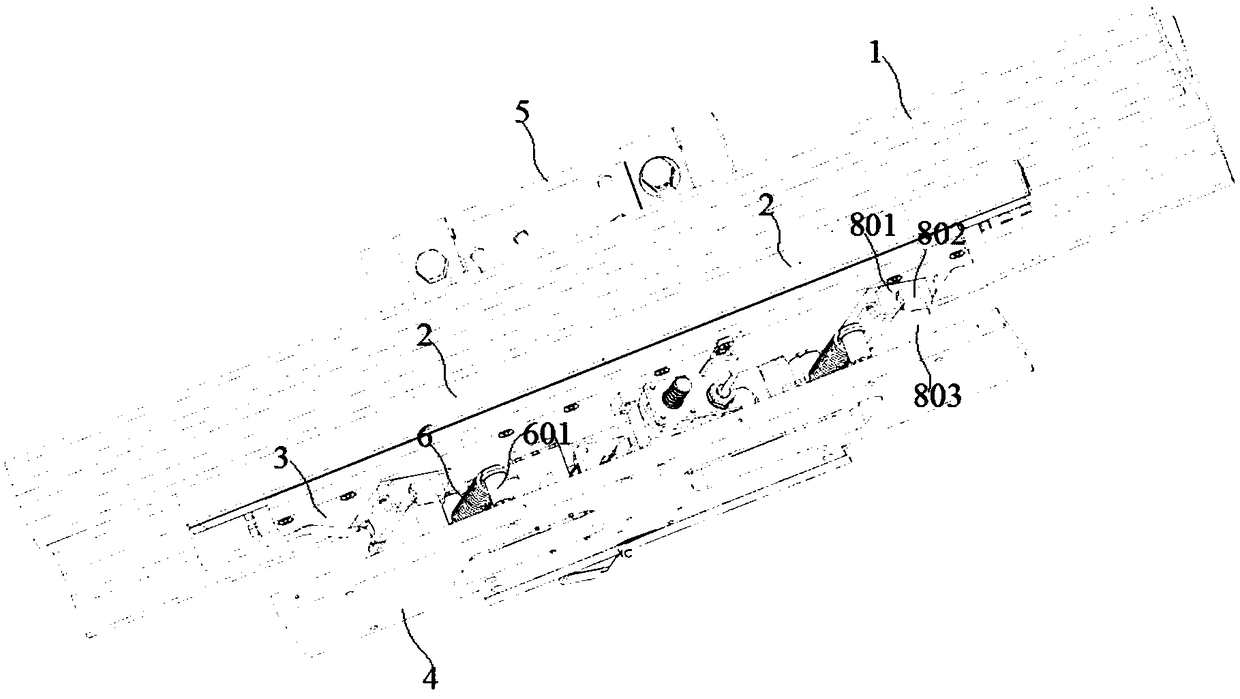

[0058] A kind of device that is used for the defect detection of train wheel tread of this embodiment, its structure is basically the same as embodiment 1, and its difference mainly lies in: as Figure 8 , Figure 10 As shown, the movable plate balance mechanism of this embodiment includes a slider fixing plate 1403 and a swing rod 1404, wherein one end of the swing rod 1404 is connected to the movable plate in rotation, and the other end is connected to the slider fixing plate 1403 in rotation, and the slider fixing plate 1403, the movable plate and the swing rod 1404 together form a parallelogram mechanism. Specifically, both ends of the swing rod 1404 are equipped with bearings, which are rotationally connected with the movable plate and the slider fixed plate 1403 through bearing pins, and the slider fixed plate 1403 is slidably installed on the bottom plate 5 through a slide rail mechanism. The bottom plate 5 is compressed and fixed on the bottom of the track 1 . The sl...

Embodiment 3

[0061] A device for detecting defects of train wheel treads in this embodiment has basically the same structure as that in Embodiment 2, the main difference being that it also includes a lifting drive mechanism 9 for adjusting the height of the movable plate.

[0062] Because in actual use, the rim heights of all the wheels on a train will be different, and the movable plate will be higher than the wheel rim by a certain value as the preload during measurement. The preload value should not be too large, otherwise the wheel will It will seriously hit the movable plate, causing damage to the movable plate and reducing the measurement accuracy; the preload should not be too small, otherwise the wheel rim will not be able to press the movable plate, resulting in no data detection. In this embodiment, the initial height of the movable plate can be adjusted by setting the lifting drive mechanism 9, so as to meet the measurement requirements of wheels with different rim heights, reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com