Array baseplate and manufacturing method thereof as well as display panel using same

A technology of an array substrate and a manufacturing method, which is applied in the field of flat panel display, can solve the problems of lack of function of a single data line, dark lines of liquid crystal display, and high production cost, achieve good display effect, prevent display defects, and improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to illustrate the array substrate provided by the present invention, its manufacturing method, and the display panel using the array substrate, the following will be described in detail in conjunction with the accompanying drawings.

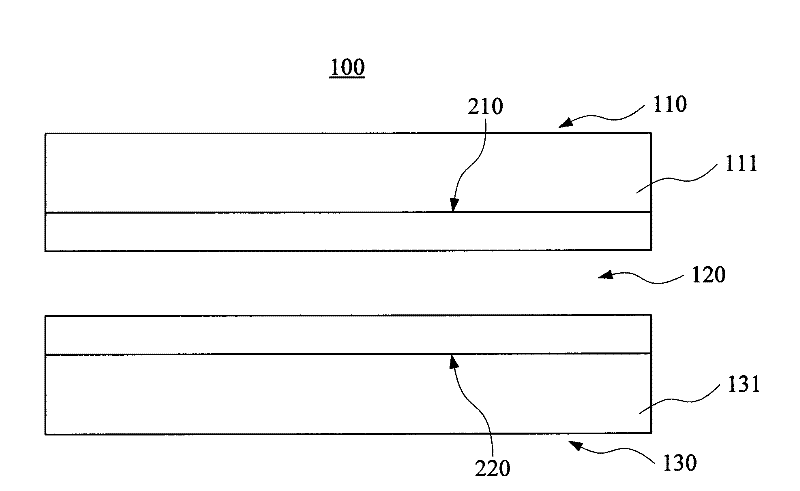

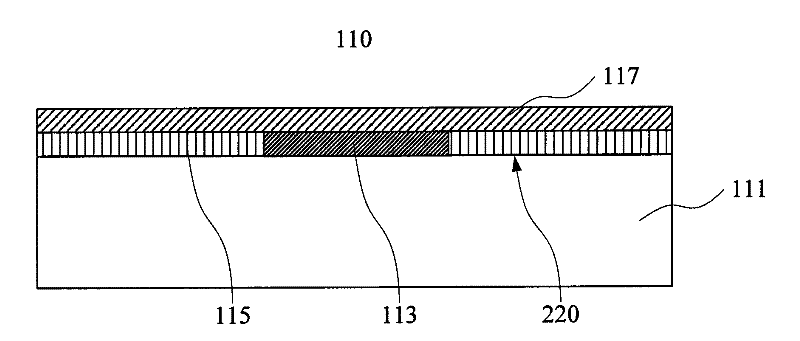

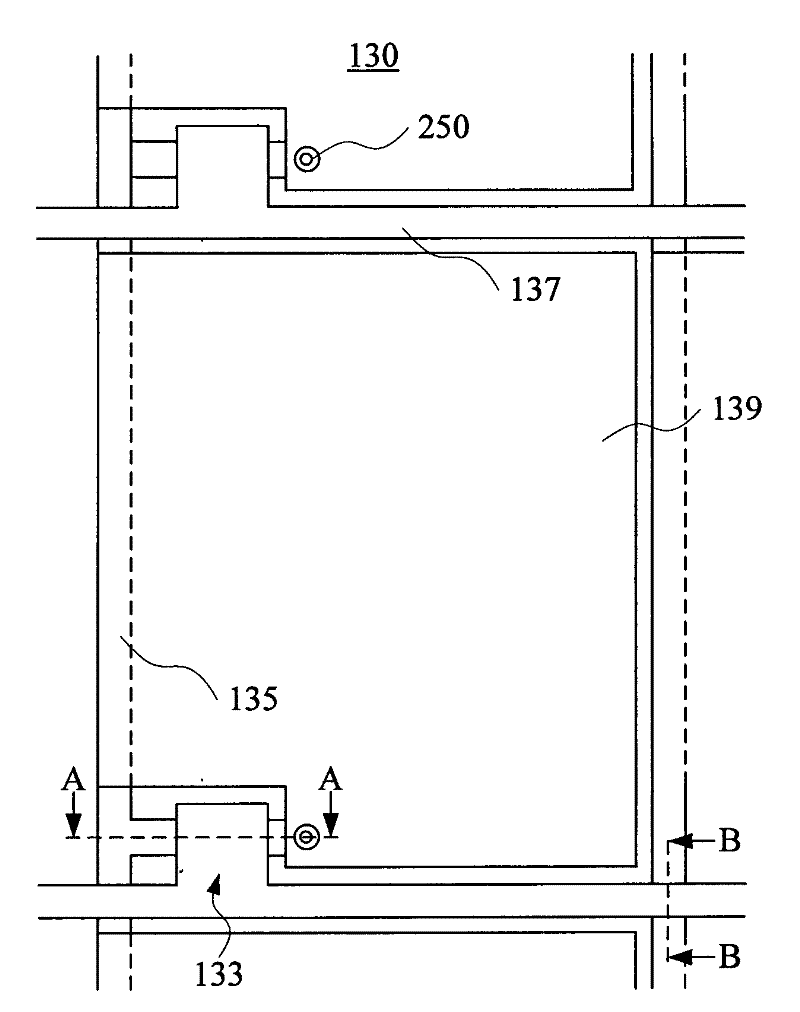

[0041] see figure 1 , which is a schematic diagram and a cross-sectional schematic diagram of a display panel according to a preferred embodiment of the present invention. The display panel 100 includes a color filter substrate 110 , a functional layer 120 and an array substrate 130 . The color filter substrate 110 is disposed opposite to the array substrate 130 , and there is a gap between the color filter substrate 110 and the array substrate 130 for accommodating the functional layer 120 . In this embodiment, the functional layer 120 is a liquid crystal layer. The color filter substrate 110 includes a first transparent substrate 111 having a first surface 210, and the array substrate 130 includes a second transparent substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com