Display panel and preparation method thereof and display device

A display panel and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as the anode cannot receive signals, anode cracks, and the electrical performance of flexible OLED display panels deteriorate, achieving improvement Display performance, effect of preventing anode cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

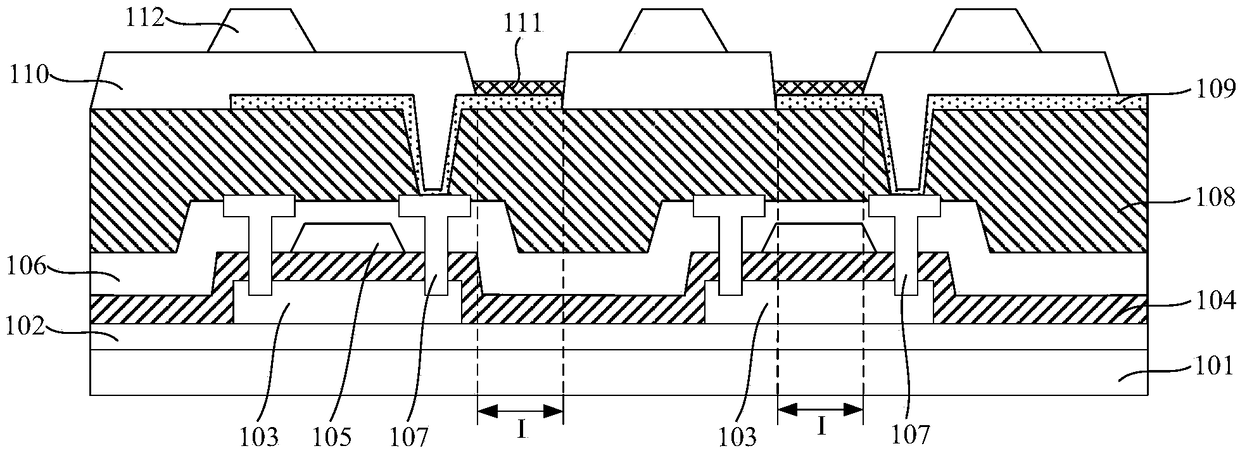

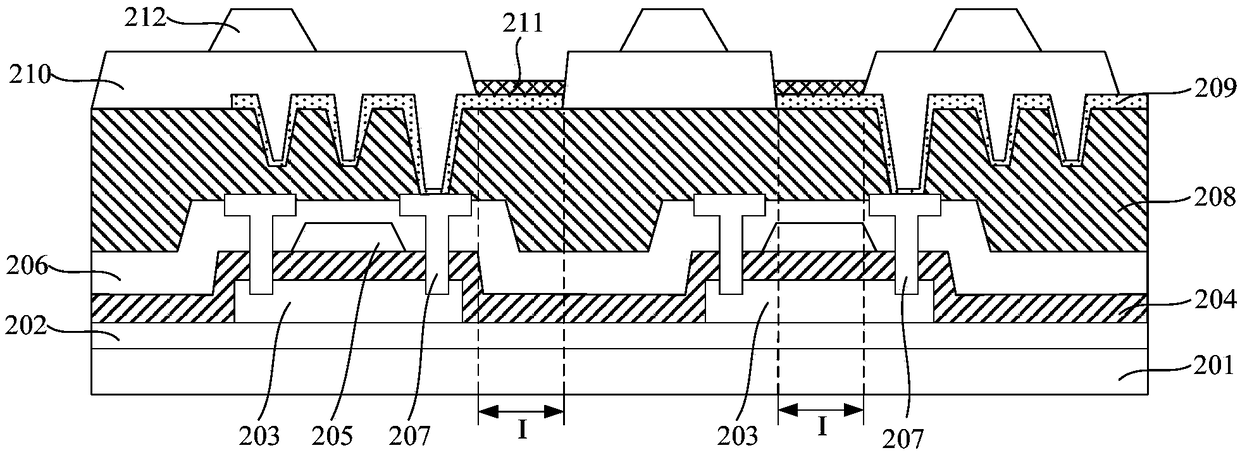

[0016] It can be known from the background art that the existing display panel has the problem that the anode is easy to crack, which affects the performance of the display panel.

[0017] The analysis found that in the flexible OLED display panel, the anode is usually a conductive transparent oxide, which has relatively low flexibility. It is used in the reliability test of the flexible OLED display panel or in the normal use of the flexible OLED display panel. As the bending radius decreases and the number of bending increases, the anode of the flexible OLED display panel after bending is prone to cracking, resulting in deterioration of the electrical performance of the flexible OLED display panel and even causing the anode to fail to receive signals.

[0018] In order to solve the above problem, the present invention provides a display panel to improve the anode cracking problem and improve the display performance and reliability of the display panel.

[0019] In order to make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com