High absorptivity diaper core

A technology of absorption rate and diapers, which is applied in the direction of absorbent pads, medical science, bandages, etc., can solve the problem of low absorption rate of the core, achieve the effect of increasing absorption utilization rate, increasing air permeability, and saving raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

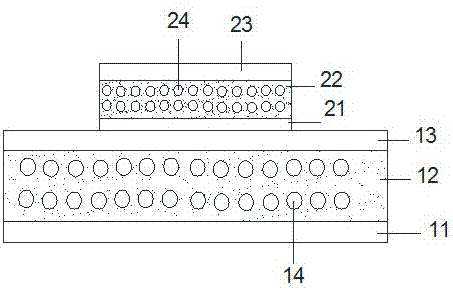

[0031] A high-absorbency diaper core body includes a lower core body 1 and an upper core body 2. The lower core body 1 includes a first fluffy cotton 12 containing a first polymer water-locking bead 14, and an upper core body 2 includes a second high The second fluffy cotton 22 with molecular lock water beads 24, the dosage of the first fluffy cotton 12 is 300 g / m², the dosage of the second fluffy cotton 22 is 200 g / m², and the size of the first fluffy cotton 12 is 40 *10 cm, the size of the second fluffy cotton 22 is 20*5 cm, the mass of a complete core is 14 grams, and the thickness of the middle absorbent part is 500 grams / square meter. The amount of fluffy cotton used in the core of the conventional diaper is 450 g / m2, and the mass of a complete core is 18 g. The core in this technical solution can reduce the raw material cost by 4 g compared with the core of the traditional technology, and The absorption rate of the middle part is higher, and at the same time, it makes the...

Embodiment 2

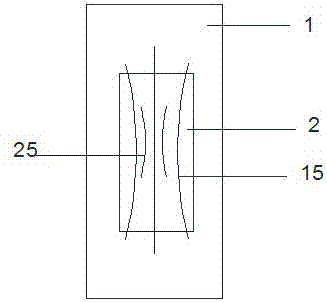

[0033] A high-absorbency diaper core body, comprising a lower core body 1 and an upper core body 2. The lower core body 1 comprises a first fluffy cotton 12 containing a first polymer water-locking bead 14, and the upper core body 2 is a plurality of longitudinally arranged and distributed The wood pulp absorbent block 3 on the lower core 1 has a strong absorption capacity of mixed polymer wood pulp, and the wood pulp has better skin affinity for infants and young children, and the raw material cost of wood pulp is lower than that of fluffy cotton. The diaper core using the wood pulp absorbent block 3 not only has better absorption capacity than the ordinary diaper core, but also saves the cost of raw materials, saves resources, and is environmentally friendly.

Embodiment 3

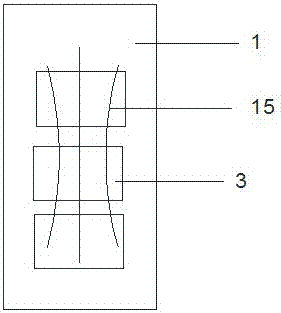

[0035] A high-absorbency diaper core body, comprising a lower core body 1 and an upper core body 2. The lower core body 1 comprises a first fluffy cotton 12 containing a first polymer water-locking bead 14, and the upper core body 2 is a wood pulp absorbent block Or it is a core containing the second fluffy cotton. The upper core 2 has two pieces, which are respectively arranged horizontally on the front half and the back half of the lower core 1. In the process of using diapers, the infants and young children have different postures. , The body fluid may penetrate forward or backward. The upper core 2 placed horizontally at the front and rear ends can prevent the body fluid from leaking at the front and rear ends and absorb the body fluid, thereby improving the absorption of the upper core and the middle area. rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com