Wear-resisting antiskid plastic track and preparation method

A plastic runway, anti-skid technology, applied in chemical instruments and methods, roads, roads, etc., can solve the problems of high production safety requirements, complex processing technology, complex construction procedures, etc., to inhibit infiltration and penetration, good wear resistance, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A wear-resistant and non-slip plastic runway according to a preferred embodiment of the present invention and its preparation method;

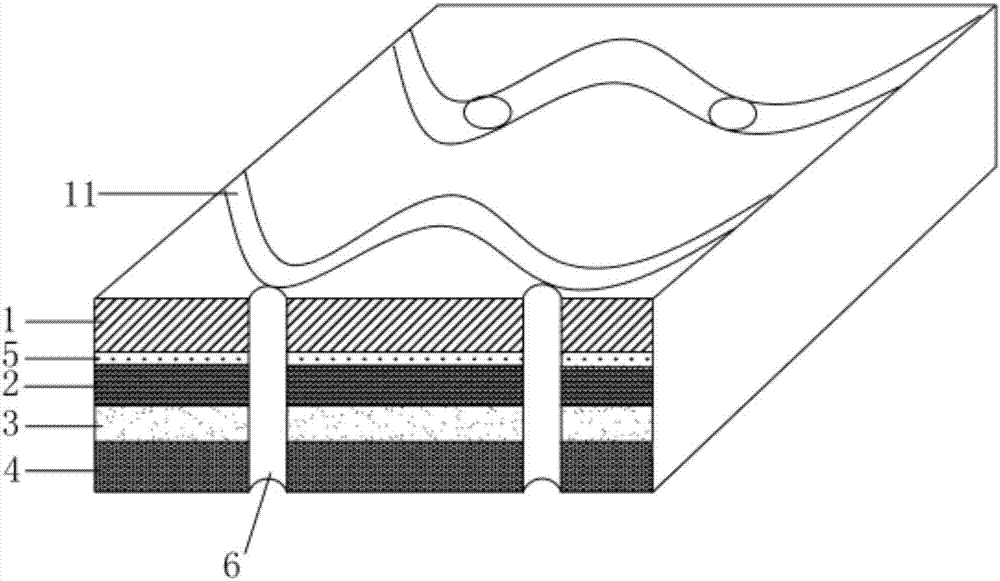

[0035] Such as figure 1 As shown, the wear-resistant and non-slip plastic runway, the wear-resistant and non-slip plastic runway is sequentially composed of a non-slip and wear-resistant layer 1, a toughness strengthening layer 2, a base layer 3 and a cement stone powder stable layer 4, and the anti-slip and wear-resistant The upper surface of the layer 1 has a pattern structure 11, and the anti-slip wear-resistant layer 1 and the toughness strengthening layer 2 are connected by an adhesive 5;

[0036] The anti-slip and wear-resistant layer includes the following components in parts by weight: 45 parts of EPDM rubber, 16 parts of polyphenylene sulfide, 12 parts of polyisocyanate, 10 parts of stearic acid, 15 parts of polyester fiber, 3 parts of anti-aging agent 18 parts of attapulgite clay, 9 parts of white carbon black, 1.2 parts of g...

Embodiment 2

[0049] A wear-resistant and non-slip plastic runway according to a preferred embodiment of the present invention and its preparation method;

[0050] The wear-resistant and anti-slip plastic runway, the wear-resistant and anti-slip plastic runway consists of an anti-slip and wear-resistant layer, a toughness strengthening layer, a base layer and a cement stone powder stable layer from top to bottom, and the upper surface of the anti-slip and wear-resistant layer has a pattern structure , the anti-slip wear-resistant layer and the toughness strengthening layer are connected by adhesive;

[0051] The anti-slip and wear-resistant layer includes the following components in parts by weight: 30 parts of EPDM rubber, 10 parts of polyphenylene sulfide, 10 parts of polyisocyanate, 8 parts of stearic acid, 12 parts of polyester fiber, 1 part of anti-aging agent 10 parts, 10 parts of attapulgite clay, 5 parts of white carbon black, 0.3 parts of graphene, 15 parts of plasticizer, 0.1 part...

Embodiment 3

[0064] A wear-resistant and non-slip plastic runway according to a preferred embodiment of the present invention and its preparation method;

[0065] The wear-resistant and anti-slip plastic runway, the wear-resistant and anti-slip plastic runway consists of an anti-slip and wear-resistant layer, a toughness strengthening layer, a base layer and a cement stone powder stable layer from top to bottom, and the upper surface of the anti-slip and wear-resistant layer has a pattern structure , the anti-slip wear-resistant layer and the toughness strengthening layer are connected by adhesive;

[0066] The anti-slip and wear-resistant layer includes the following components in parts by weight: 50 parts of EPDM rubber, 20 parts of polyphenylene sulfide, 15 parts of polyisocyanate, 17 parts of stearic acid, 20 parts of polyester fiber, 3 parts of anti-aging agent 20 parts, 20 parts of attapulgite clay, 12 parts of white carbon black, 1.5 parts of graphene, 28 parts of plasticizer, 0.5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com