Aqueous graphene conductive ink

A technology of water-based graphene and conductive ink, which is applied in the direction of ink, electric heating devices, electrical components, etc., can solve the problems of unstable performance, electrical conductivity can not meet the requirements, etc., to improve adhesion, improve electrical conductivity and long-term stability, The effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

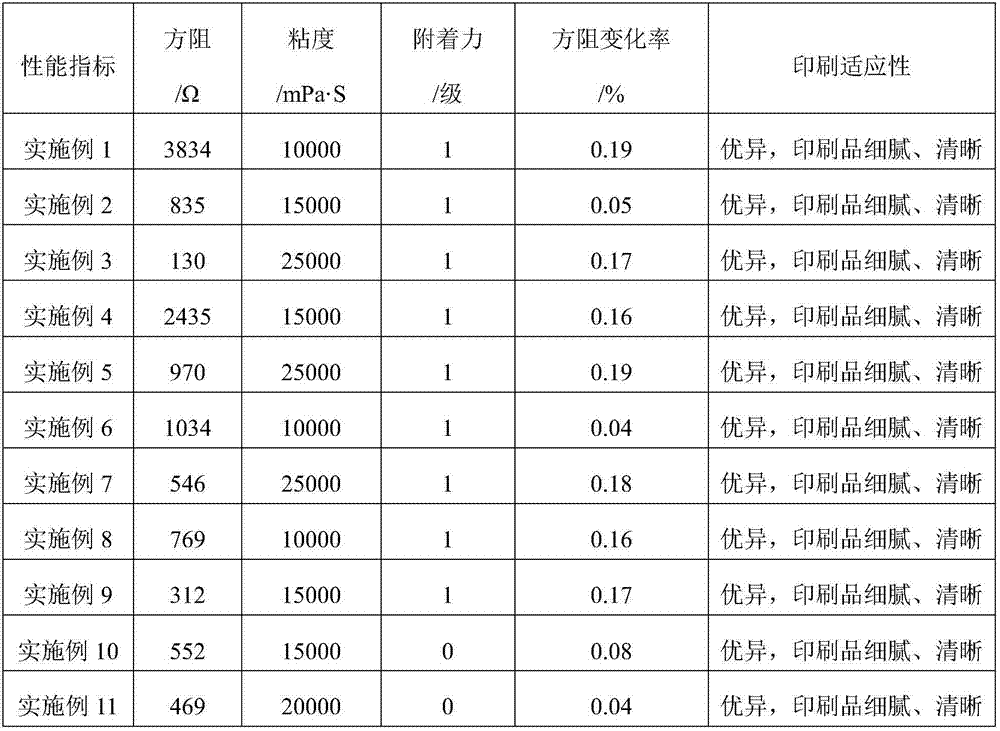

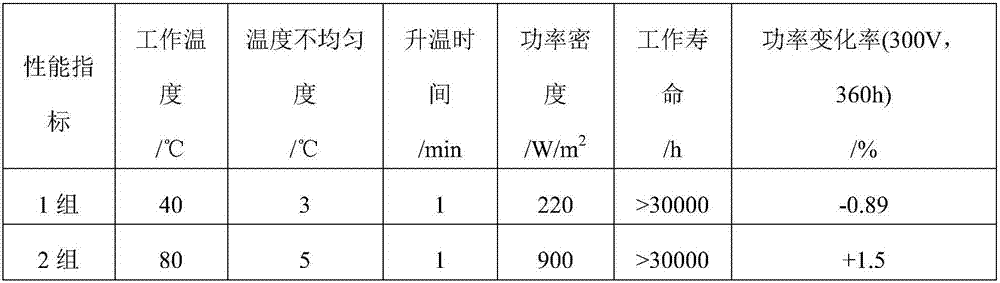

Examples

preparation example Construction

[0059] A preparation method of water-based graphene conductive ink, comprising the following steps:

[0060] (1) Take graphene, water, grinding media, conductive particles, the second auxiliary agent, resin binder, the first auxiliary agent according to the above-mentioned mass percentage;

[0061] (2) described grinding medium, water-based graphene slurry and the first auxiliary agent are mixed to obtain the first mixture;

[0062] (3) Mix the conductive particles with the first mixture, disperse and stir evenly, and obtain the second mixture;

[0063] (4) Grinding the second mixture until the solid particle size is less than 5 μm, and filtering to obtain graphene conductive black paste.

[0064] (5) After the graphene conductive black paste, the resin binder and the first auxiliary agent are dispersed and stirred evenly, the water-based graphene conductive ink is obtained.

[0065] As preferably, in the step (2), the conditions of the dispersing and stirring include: the s...

Embodiment 1

[0081] This embodiment is used for illustrating and adopts the method for preparing water-based graphene conductive ink of the present invention.

[0082] (1) 100g water-based acrylic resin, 700g water-based graphene slurry (3% by mass of solid matter, containing 3.5g of surfactant), 10g dispersant SN-5027, 20g dispersant 760W, 5g wetting Add agent BYK-349, 15g defoamer 901W into the grinding tank, disperse and stir at 1000rpm for 2h, then add 150g of spherical conductive carbon black, disperse and stir at 1500rpm for 2h; then add 0.8~1.0μm zirconia beads Into the step (1) mixture, grind to a particle size of less than 5 μm, and discharge to obtain graphene conductive black paste;

[0083] (2) Add 500g graphene conductive black paste, 400g water-based acrylic resin emulsion, 20g dispersant BYK190, 15g defoamer BYK-024, 40g film forming agent, 15g leveling agent, 10g coupling agent KH550 into the dispersion tank , disperse and stir at 1000rpm for 3h, add pH regulator DMAE and ...

Embodiment 2

[0087] This embodiment is used for illustrating and adopts the method for preparing water-based graphene conductive ink of the present invention.

[0088] (1) 150g water-based acrylic resin, 600g water-based graphene slurry (5% by mass of solid matter, containing 6g of surfactant), 10g dispersant SN-5027, 20g dispersant 760W, 5g wetting agent Add BYK-349, 15g defoamer 901W into the grinding tank, disperse and stir at 1000rpm for 2h, then add 200g of rod-shaped zinc oxide, disperse and stir at 1500rpm for 2h; then add 0.8~1.0μm zirconia beads into the step (1) in the mixture, grind to a particle size of less than 5 μm, and discharge to obtain graphene conductive black paste;

[0089] (2) Add 600g graphene conductive black paste, 300g water-based acrylic resin emulsion, 20g dispersant BYK190, 15g defoamer BYK-024, 40g film forming agent, 15g leveling agent, 10g coupling agent KH550 into the dispersion tank , disperse and stir at 1000rpm for 3h, add pH regulator DMAE and thicken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com