A CNC grinding machine

A technology of CNC grinding machine and frame, applied in the field of machinery, can solve the problems of inconvenient operation of operators, unfavorable production and processing, large floor space, etc., and achieve the effect of smooth conveying process, high work efficiency and small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

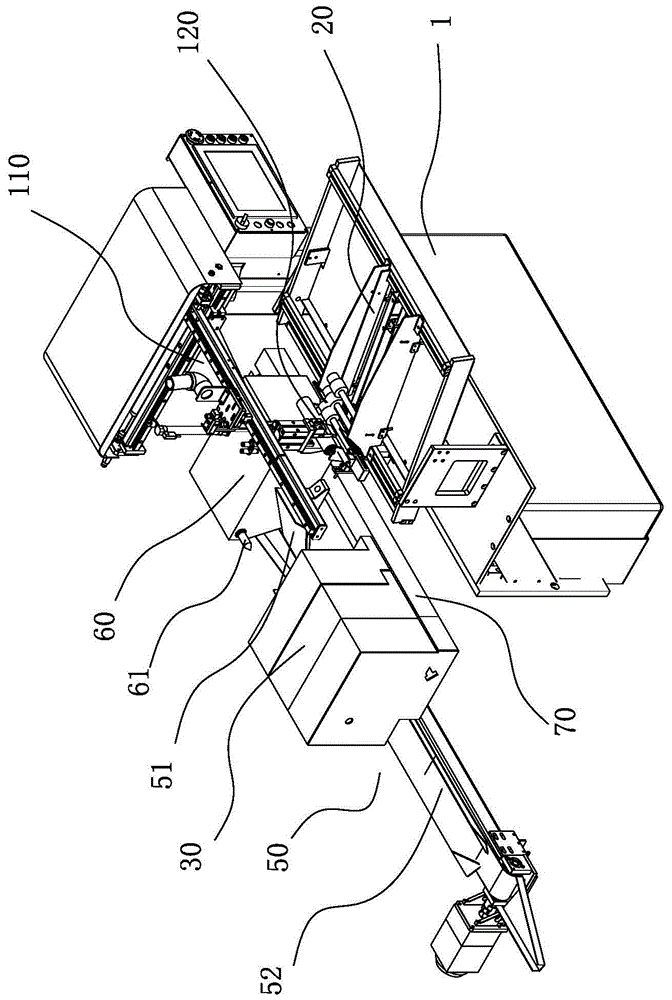

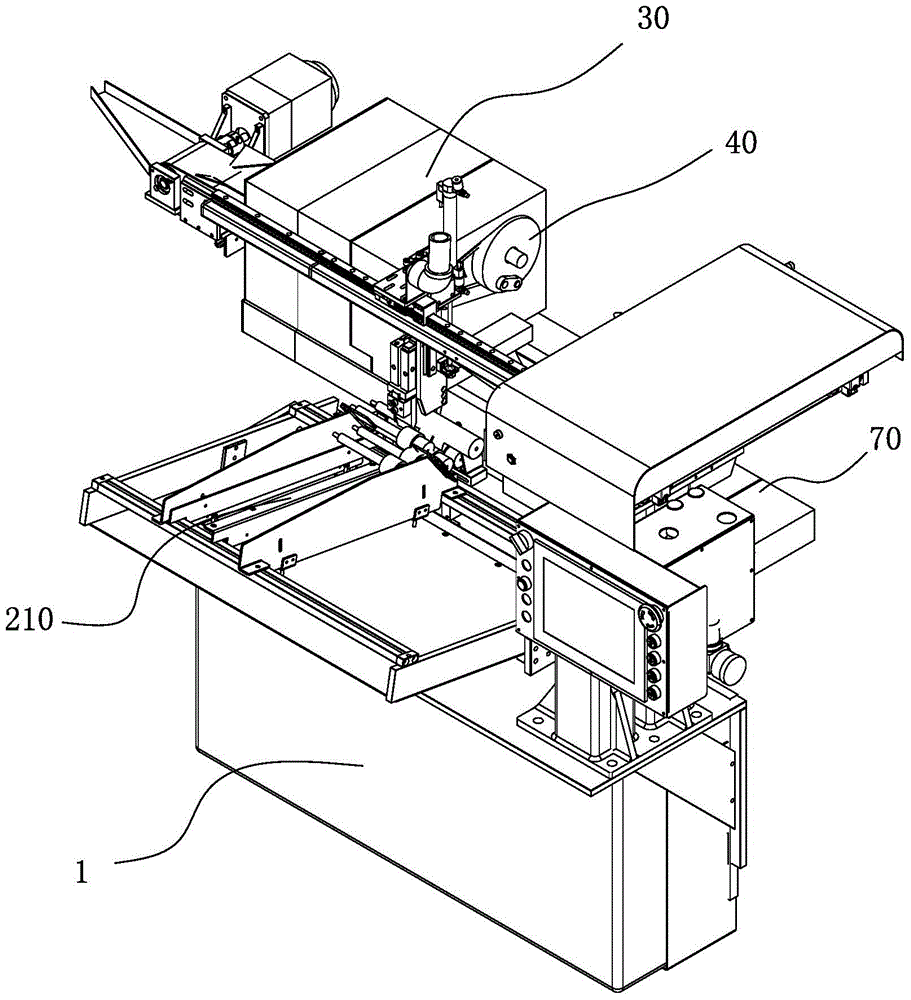

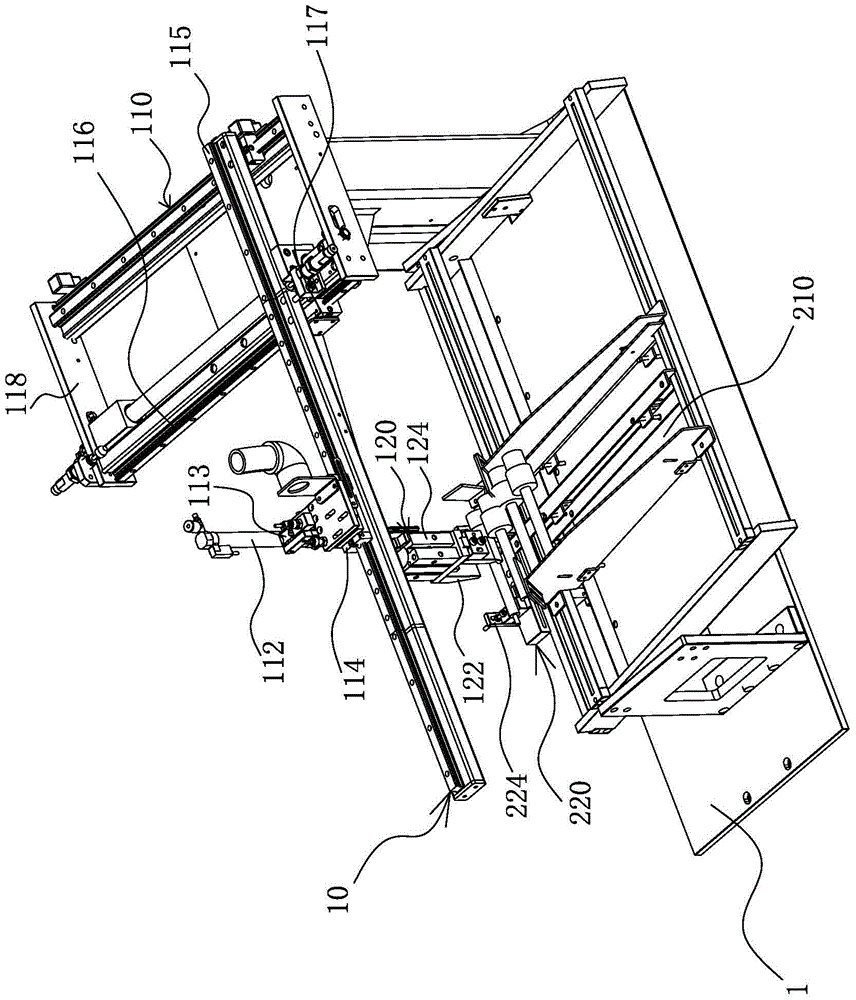

[0037] Such as Figure 1 to Figure 14As shown, the CNC grinding machine includes a frame 1, a grinding tool and a workbench 70 movably installed on the frame 1. The frame 1 is divided into a feeding area and a processing area from front to back. The material mechanism 20 and the material feeding mechanism 10 are provided with a spindle box 30 and a material unloading mechanism 50 in the processing area. And it can linearly reciprocate between the incoming material mechanism 20 and the spindle box 30, a floating chuck 40 is installed on the spindle box 30, and a top material seat 60 is also provided on the frame 1 and the top material seat 60 is located at the spindle box 30 Right in front, the abrasive tool is installed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com