Optical axis consistency calibration method of airborne multi-optical axis optical load

A consistent and multi-optical axis technology, applied in the field of optical calibration, can solve problems such as uncalibration, scattered distribution of multi-optical axis optical loads, and long distances in space, etc., to achieve light equipment, low labor intensity, and guaranteed calibration The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific scheme of the airborne multi-axis optical load optical axis consistency calibration method of the present invention is as follows.

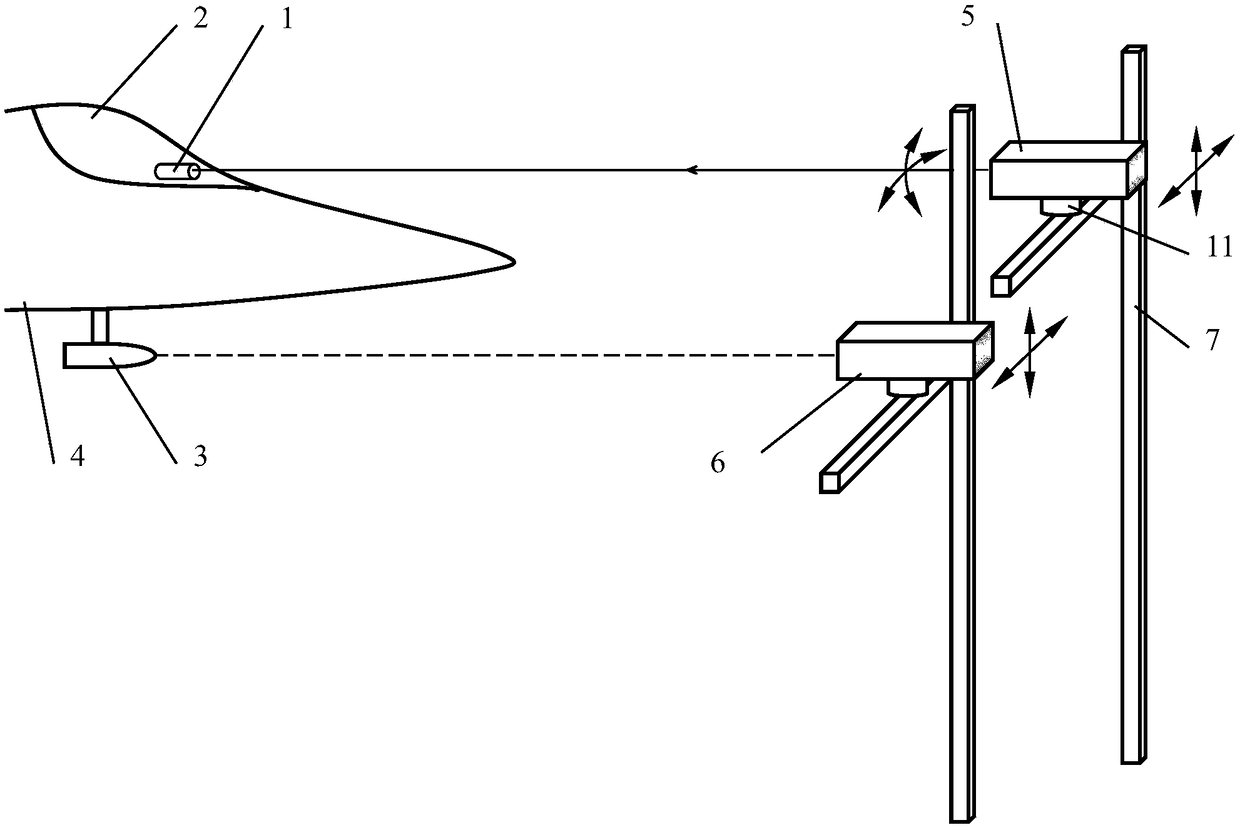

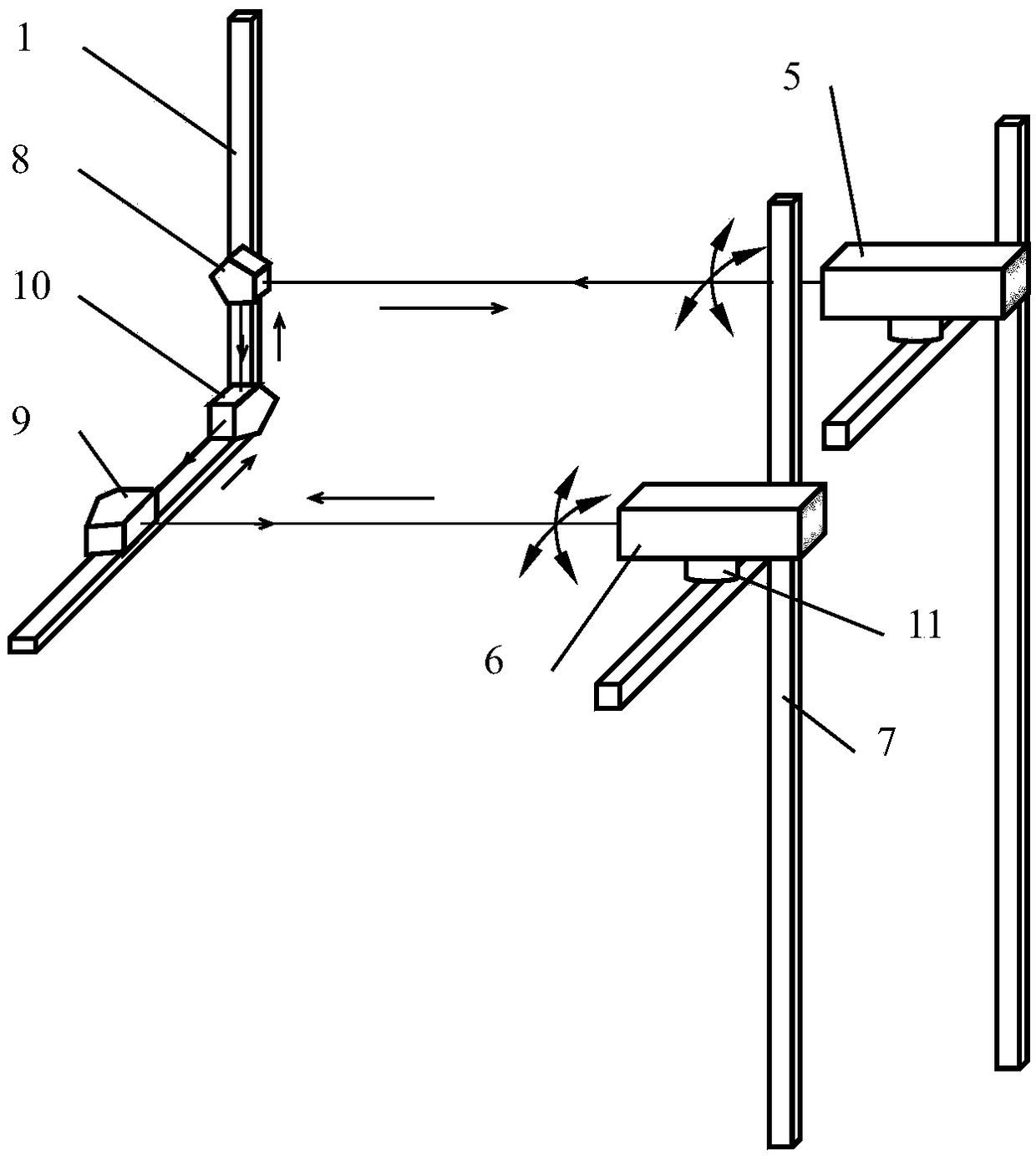

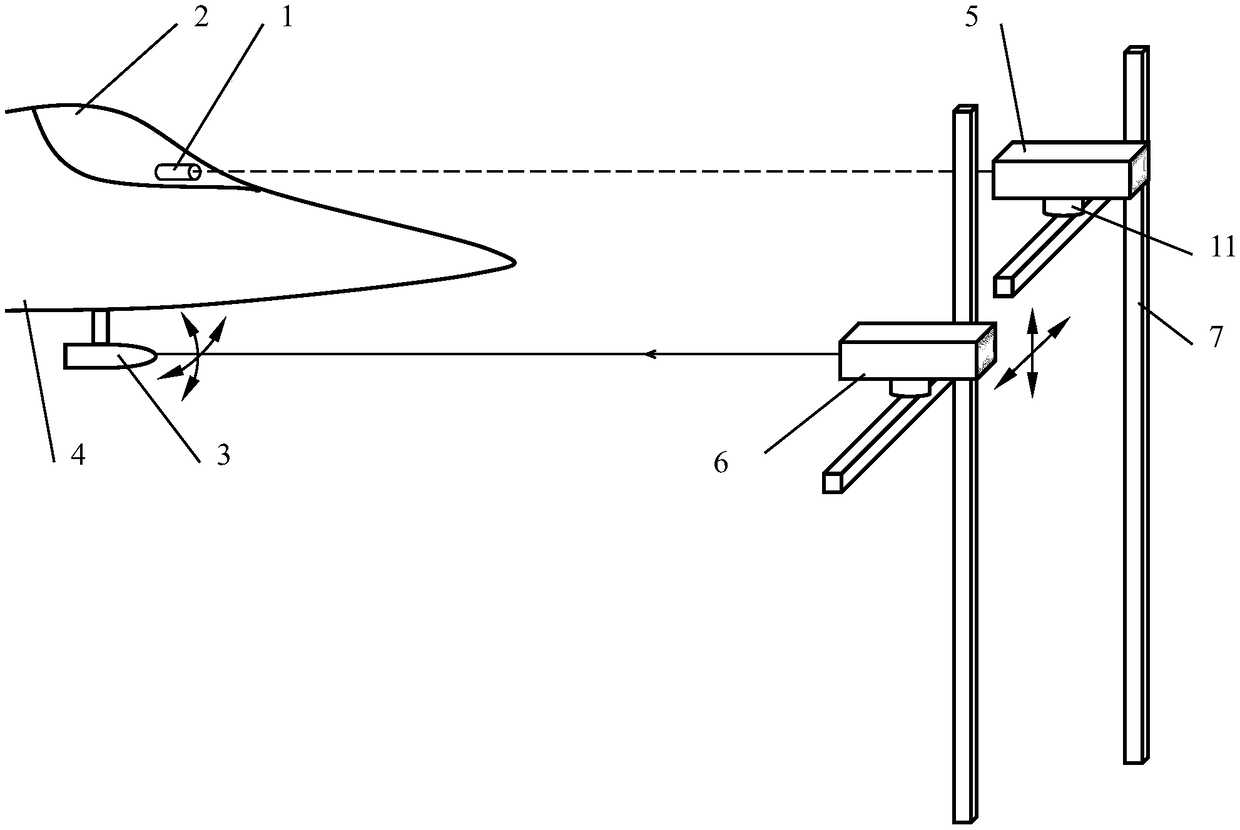

[0019] In the first step, install the main laser autocollimator 5 and the auxiliary laser autocollimator 6 on their respective right-angled two-dimensional slide rails 7, and arrange the main laser autocollimator 5 and the auxiliary laser autocollimator 6 In front of fuselage 4, such as figure 1 As shown, the main laser autocollimator 5 and the auxiliary laser autocollimator 6 adopt a digital high-precision laser autocollimator, and the built-in display can show the true image of the optical target; according to the airborne fire control system sight 1 and the design spatial positional relationship between the photoelectric pod 3, determine the spatial positional relationship between the main laser autocollimator 5 and the secondary laser autocollimator 6, further speaking, according to the airborne fire control system sight 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com