Thermal-barrier coating and method for making same

A thermal barrier coating and bonding layer technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of cracking, peeling off the thermal barrier coating, sliding, etc. Shear resistance, the effect of alleviating the release of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

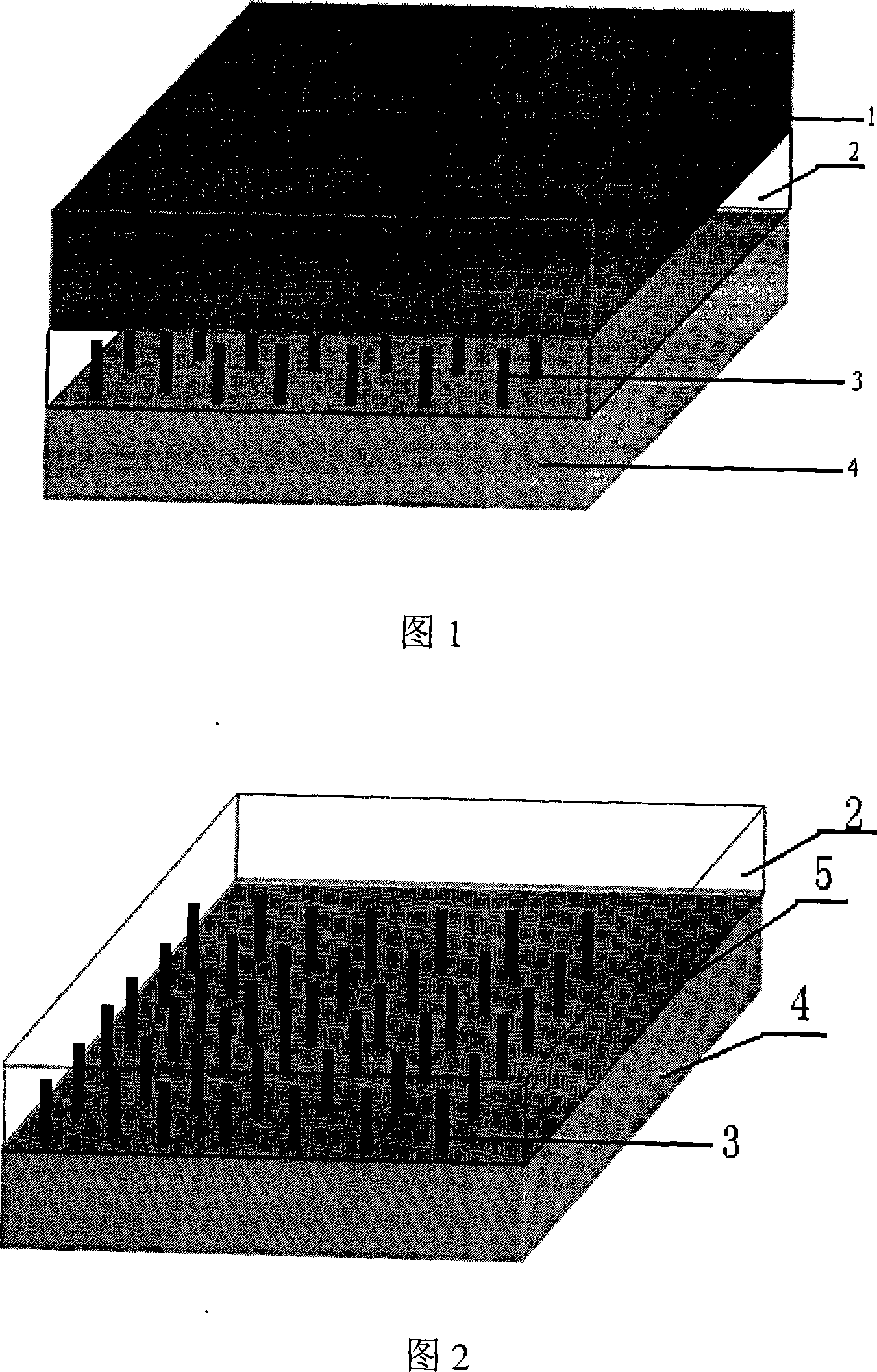

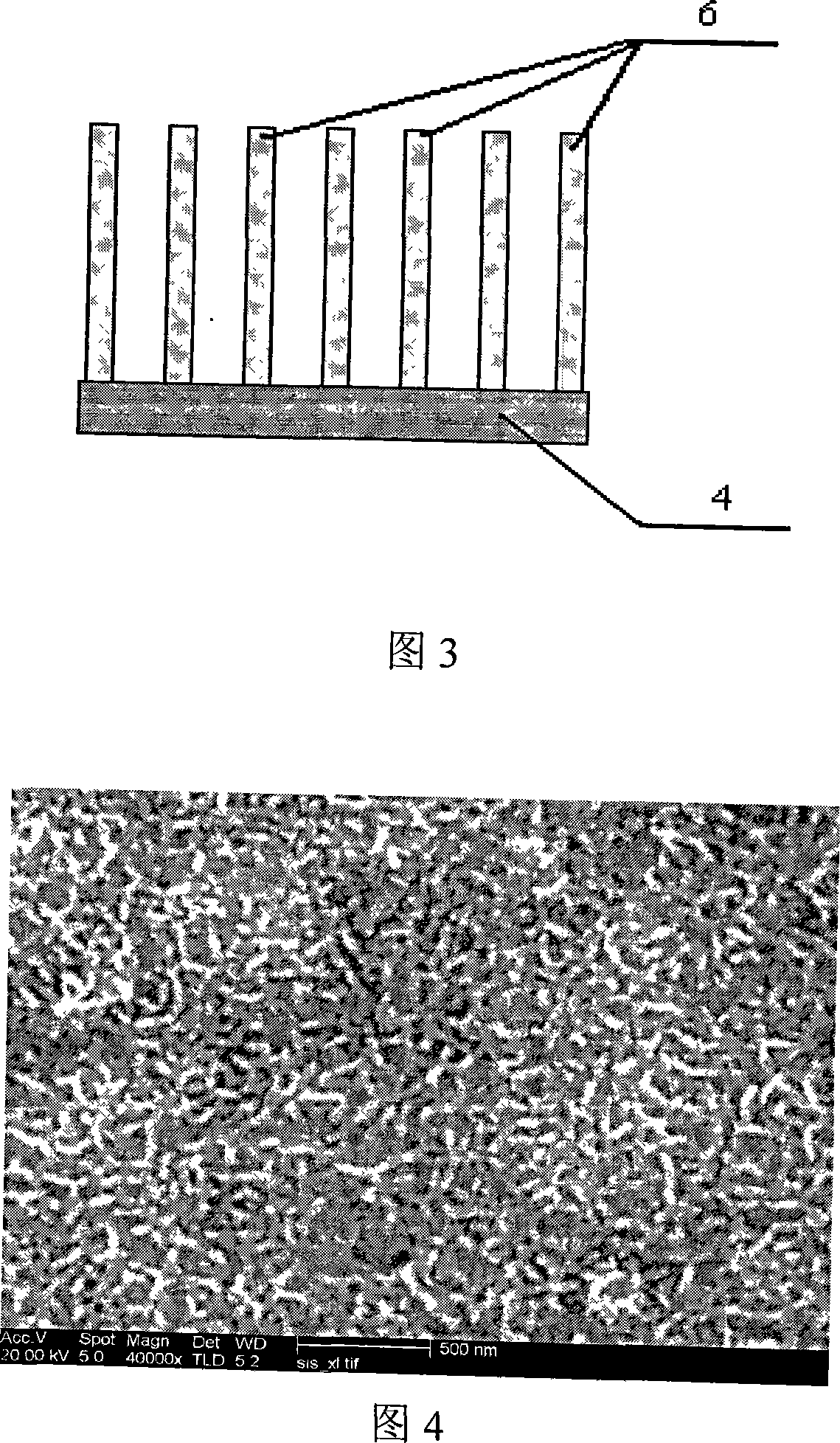

[0008] Embodiment 1: The thermal barrier coating in this embodiment is composed of an outer ceramic layer 1 and an inner bonding layer 5, wherein the inner bonding layer 5 is composed of a nickel-based superalloy layer 4 and a bonding layer connected to the outer surface of the nickel-based superalloy layer 4. The bonding layer 2 is composed of nickel nanowires 3 and yttria-stabilized zirconia.

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that the nickel nanowires 3 in the bonding layer 2 are connected to the outer surface of the nickel-based superalloy 4 by electrodeposition, and the length of the nickel nanowires 3 is 150-200 nm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 in that the nickel nanowires 3 in the bonding layer 2 are connected to the outer surface of the nickel-based superalloy 4 by electrodeposition, and the length of the nickel nanowires 3 is 180 nm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com