Regulation method and device for double-roll thin-strip continuous casting machine fixing roll

A twin-roll thin strip and adjustment method technology, which is applied in the field of thin strip continuous casting equipment, can solve problems such as the need for repeated operations, and achieve the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

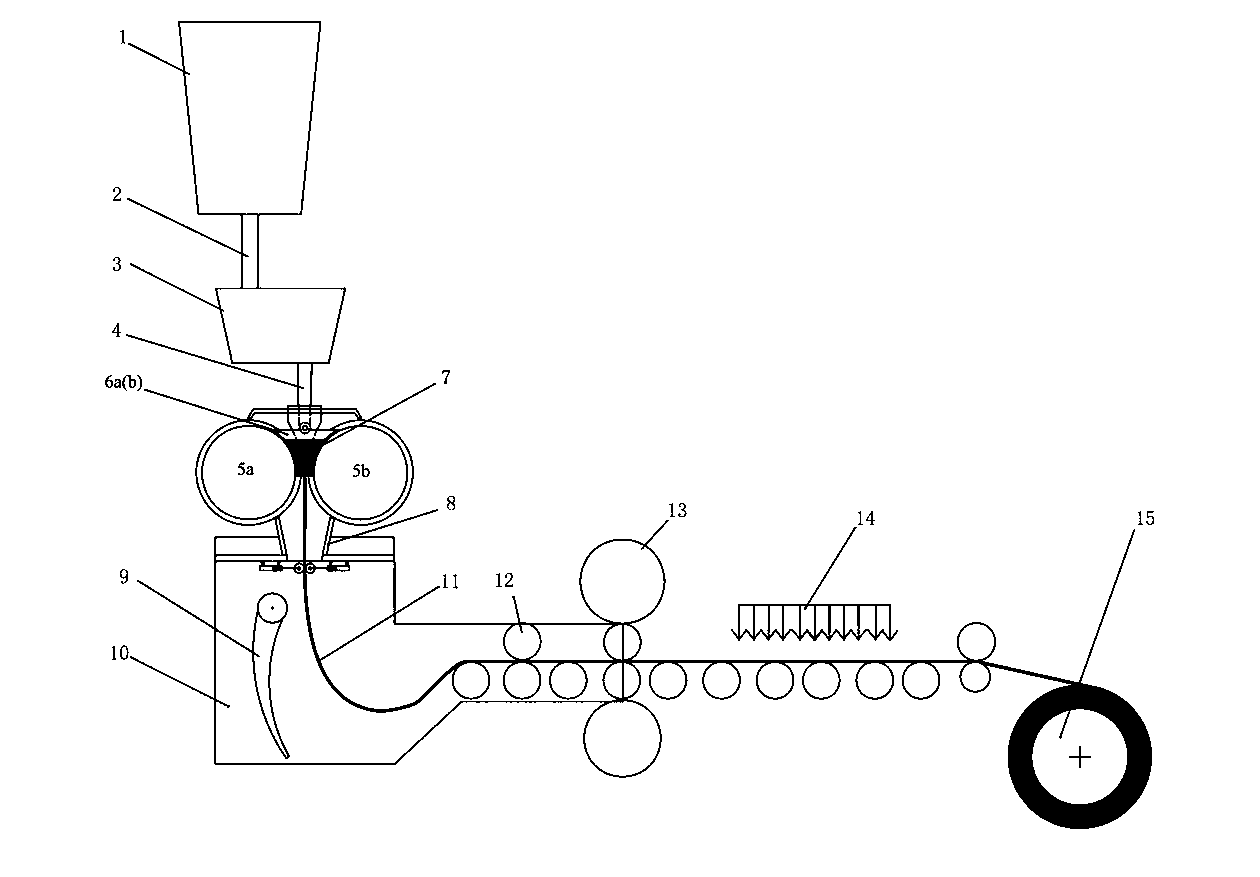

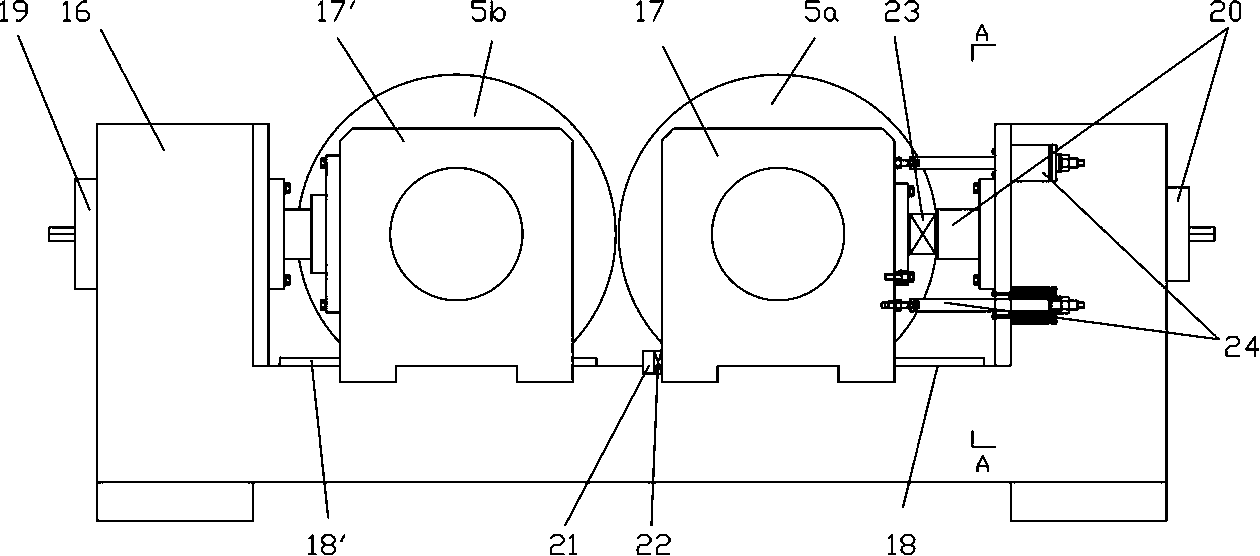

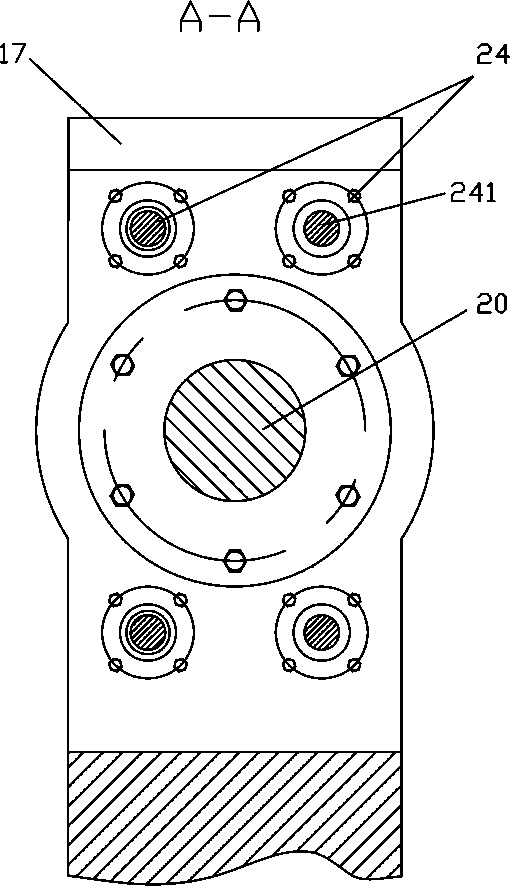

[0025] see Figure 1 ~ Figure 4, the fixed roll adjustment device of the twin-roll strip continuous casting machine of the present invention comprises a hydraulic cylinder 20, which is arranged on the continuous casting machine frame 16 on the side corresponding to the fixed side casting roll 5a, and the piston ends of the hydraulic cylinder 20 are connected to each other. The casting machine frame 16 supports the bearing housing 17 of the fixed-side casting roll 5a; a block 21 is arranged under the other side of the bearing housing 17 of the fixed-side casting roll 5a relative to the hydraulic cylinder 20, and is fixed on the continuous casting machine On the frame 16, a pressure sensor 22 is established between the block 21 and the bearing seat 17; a casting force sensor 23 is arranged between the hydraulic cylinder 20 and the bearing seat 17; Tensioning mechanism, take one set as an example, and the others are the same), installed on the bearing housing 17 supporting the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com