Cold balance and structure of hot pressing plate and working crossbeam of large-format hot press

A hot-pressing plate, large-format technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increased heat consumption, high difficulty of temperature difference balance control, loss of working accuracy of working beams, etc., to achieve the effect of saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

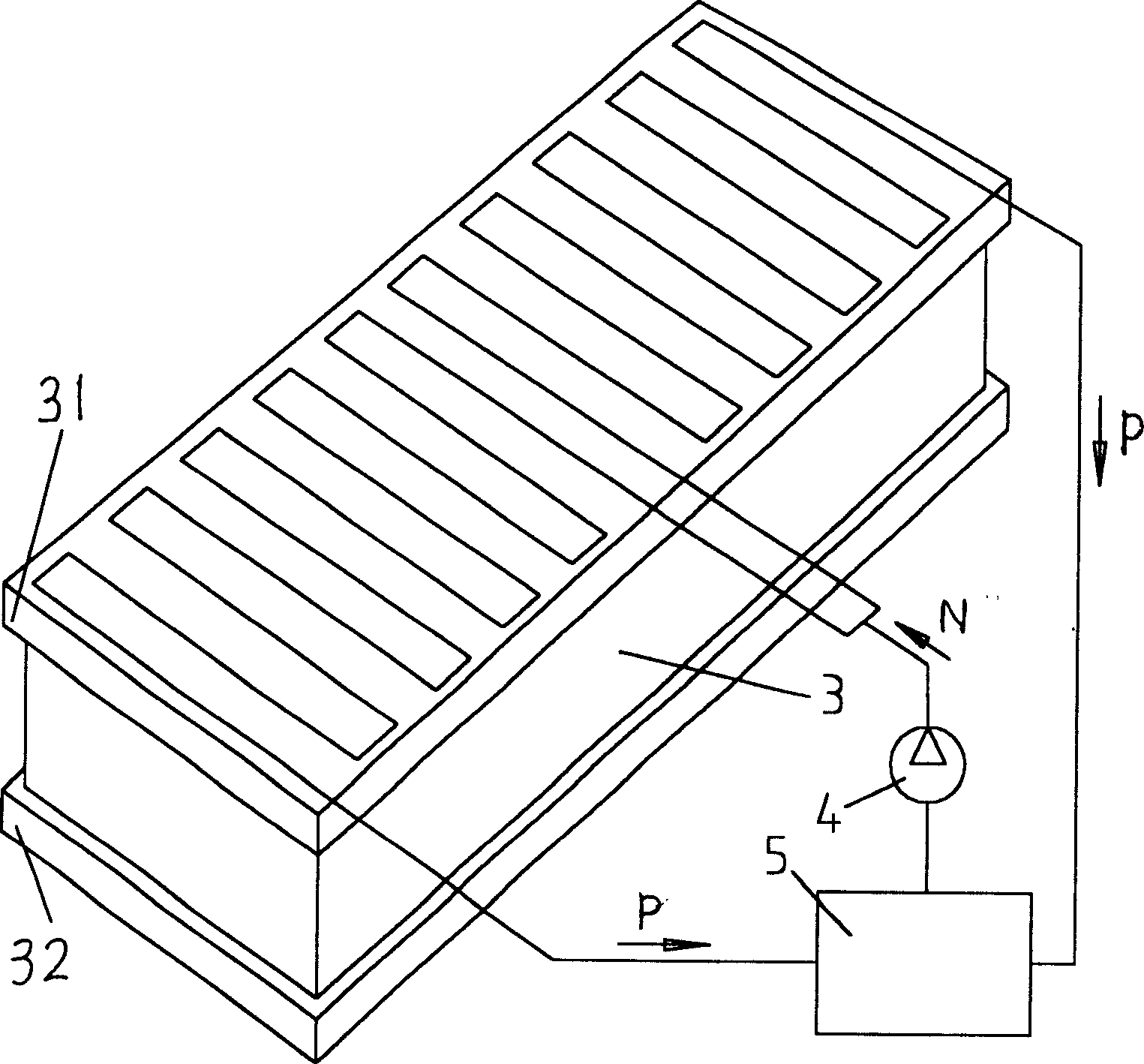

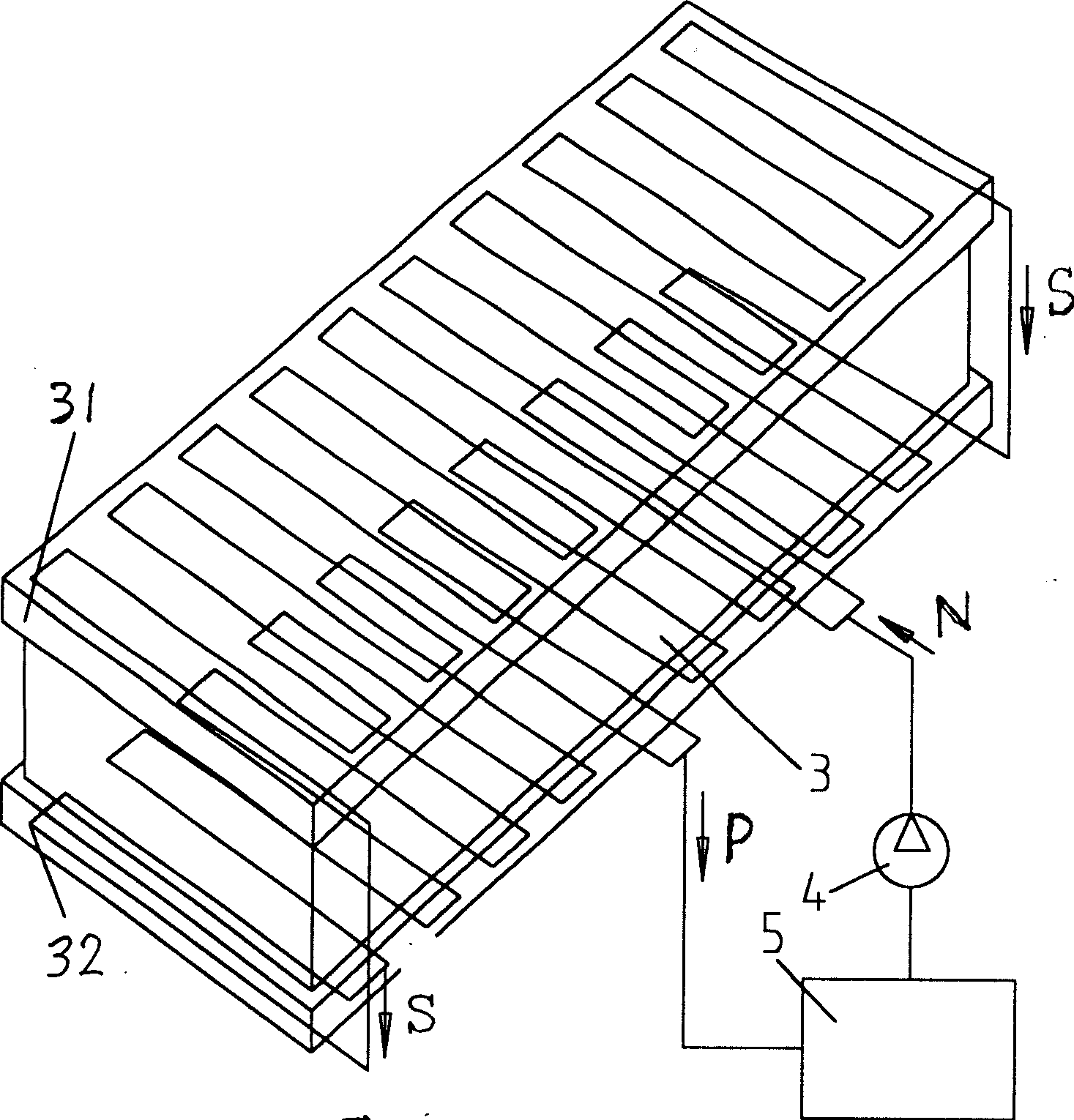

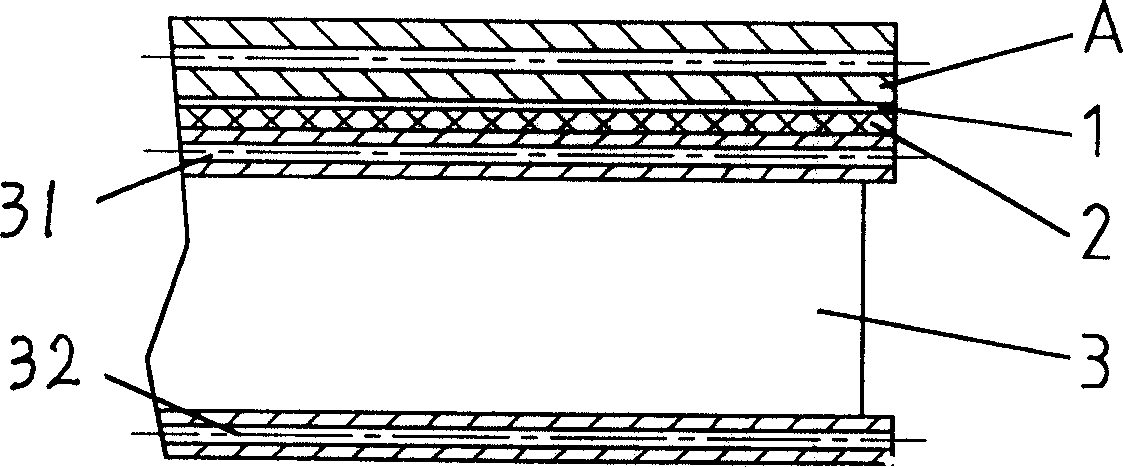

[0011] A thermal insulation structure and cold balance technology of the working beam of a flat vulcanization hot press, the size of the hot pressing plate A (length×width×thickness) is 10,000mm×1,800mm×100mm; the heat reflection material 1 is made of aluminum foil epoxy Resin glass cloth composite paper, the size is 10,000mm×1,800mm×1mm (splicing is allowed), the aluminum foil surface of the composite paper is firmly attached to the hot pressing board; the heat insulation material 2 is epoxy resin glass cloth laminated board, the size is 10,000mm×1,800 mm×20mm (splicing is allowed); the working beam 3 is made of welded steel structure, its size (length×width×thickness) is 10,000mm×1,800mm×650mm, the thickness of the upper 31 and lower 32 panels is 50mm, and the middle thickness is drilled Rows of cooling water through holes with a diameter of 25mm are installed, and the distance between the rows of cooling water through holes is 100mm; in the length direction of 10,000mm, 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com