Patents

Literature

75results about How to "Eliminate error accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

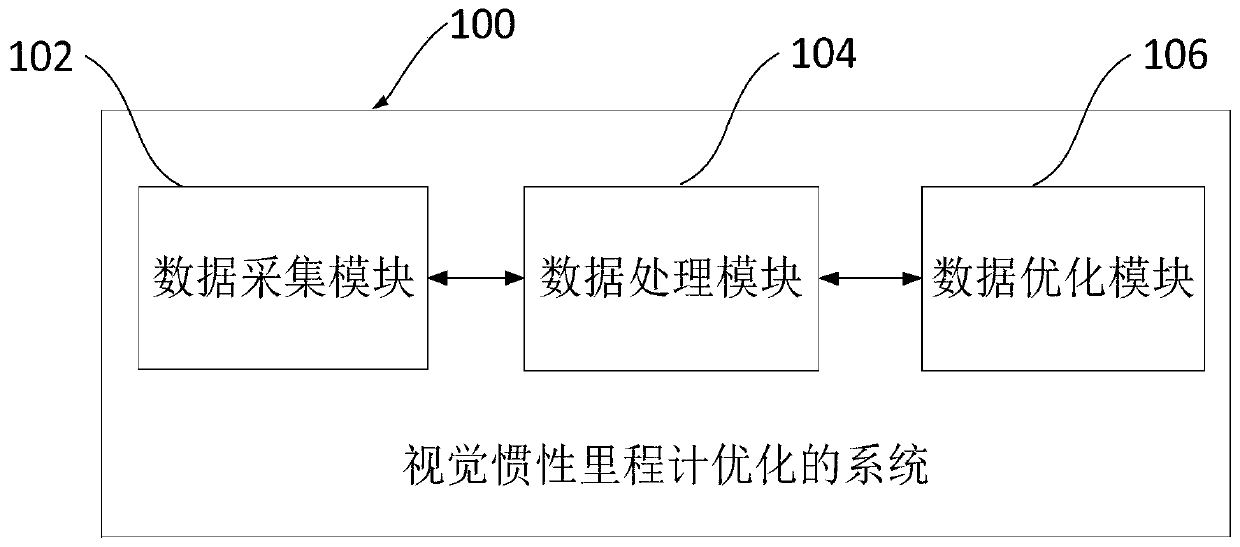

Method and system for optimizing visual inertial speedometer

ActiveCN110763251AEliminate error accumulationImage enhancementImage analysisData ingestionImage estimation

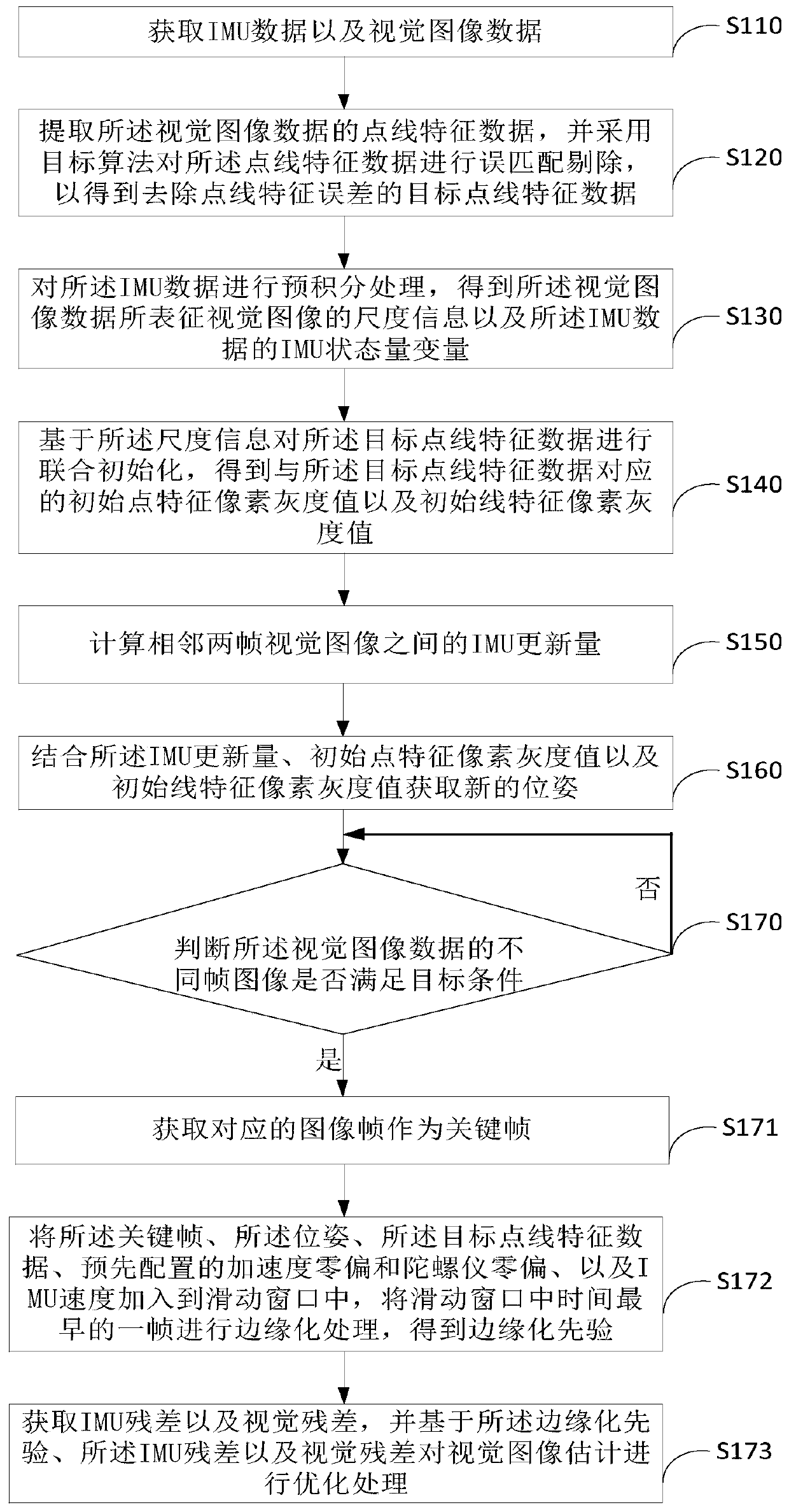

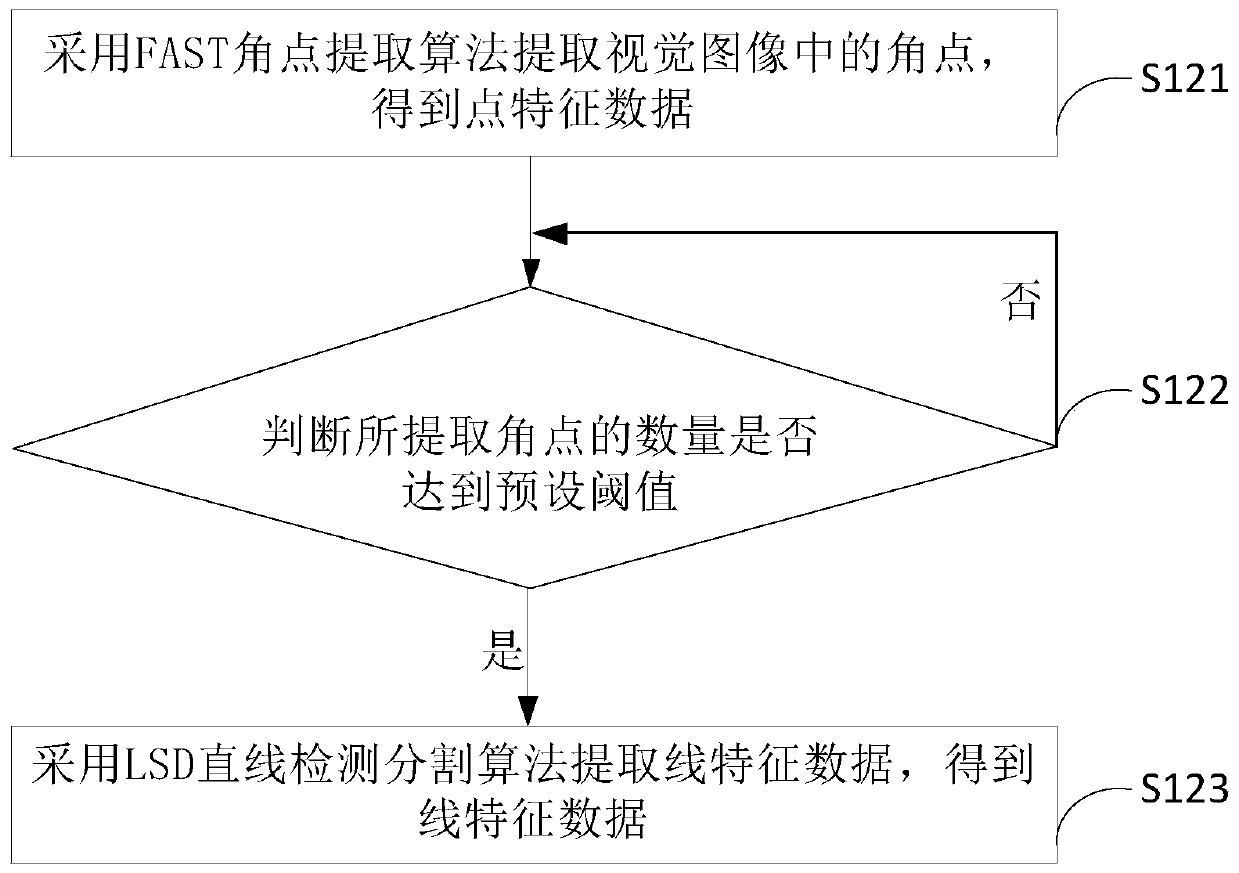

The embodiment of the invention discloses a method and system for optimizing a visual inertial speedometer. The method comprises the steps of obtaining IMU data and visual image data; extracting dotted line feature data of the visual image data; performing pre-integration processing on the IMU data to obtain scale information and IMU variables; performing joint initialization on the dotted line feature data based on the scale information to obtain a dotted line feature pixel gray value; calculating an IMU update amount between two adjacent frames of visual images; combining the IMU update amount to obtain a new pose; judging whether different frames of images meet target conditions or not; if so, obtaining a key frame; adding the key frame, the pose, the target dotted line feature data, pre-configured acceleration zero offset and gyro zero offset and an IMU speed to a sliding window to obtain marginalized prior; and obtaining an IMU residual error and a visual residual error, and performing optimization processing on visual image estimation based on the marginalized prior, the IMU residual and the visual residual error. The accumulation of errors can be eliminated to obtain an optimal trajectory of the visual images.

Owner:EAST CHINA JIAOTONG UNIVERSITY

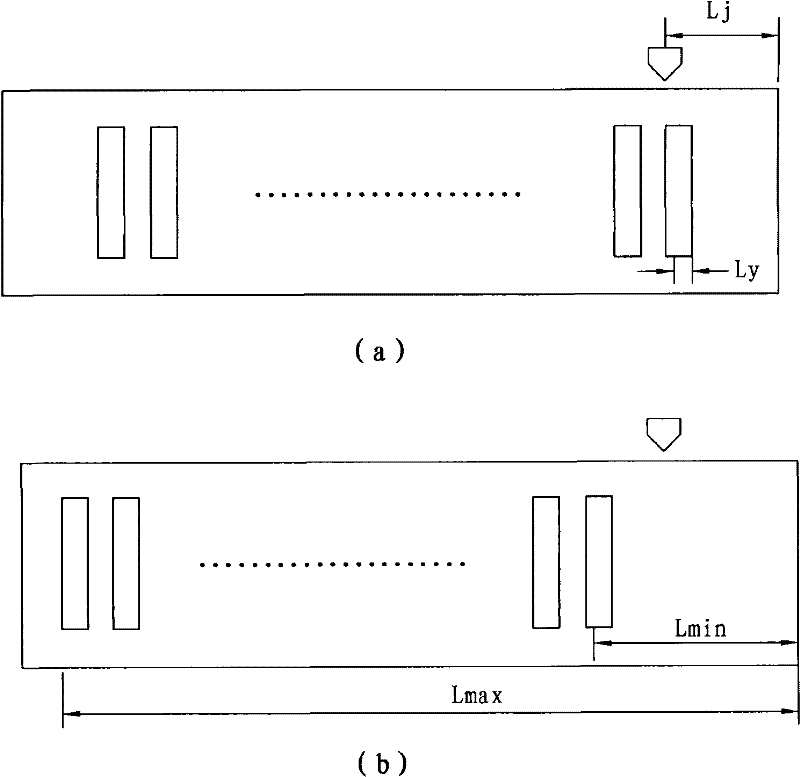

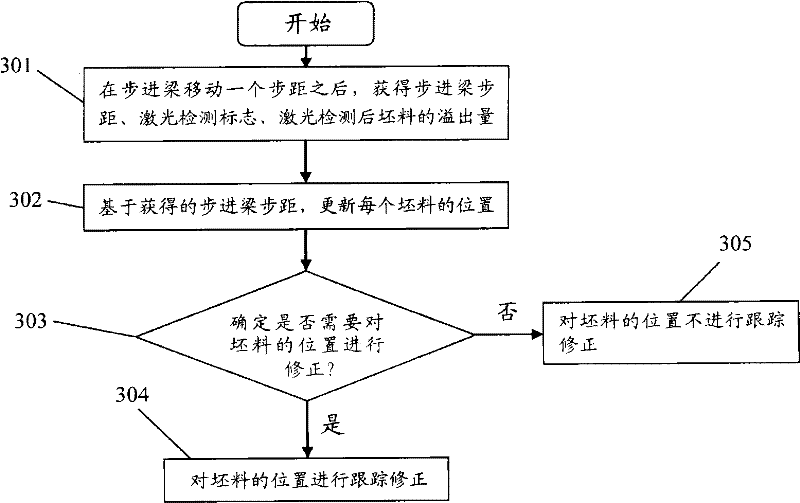

Method for automatically correcting tracking process of heating furnace

ActiveCN102345009AGuaranteed trackingImprove temperature qualityFurnace typesHeat treatment process controlEngineeringHeating furnace

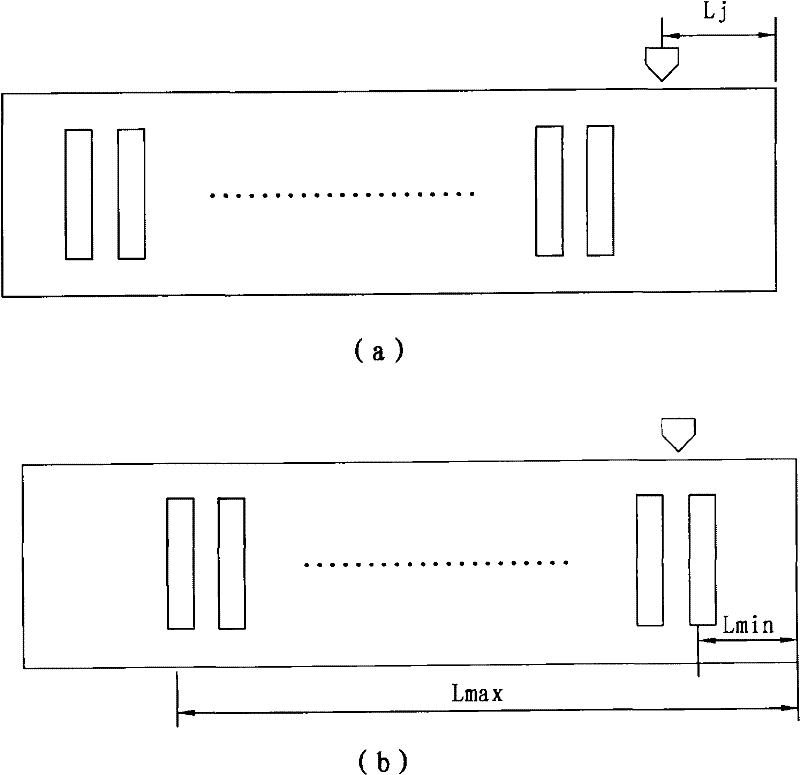

The invention discloses a method for automatically correcting the tracking process of a heating furnace. The method comprises the following steps of: after a walking beam moves by a step pitch, obtaining the step pitch of the walking beam, a laser detection mark and an overflow quantity of blanks after laser detection; on the basis of the obtained step pitch of the walking beam, updating the positions of the blanks in the heating furnace; on the basis of the laser detection mark, the laser detection overflow quantity and the updated blank positions, determining whether the positions of the blanks need to be subjected to tracking correction or not; when the shortest position in a plurality of blanks is less than the position of a targeting laser and the laser detection mark is equal to 0, carrying out advanced tracking correction on the updated positions of the blanks in the heating furnace; and when the shortest position in a plurality of blanks is greater than the position of the targeting laser and the laser detection mark is equal to 1, carrying out lagging tracking correction on the updated positions of the blanks in the heating furnace.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD +1

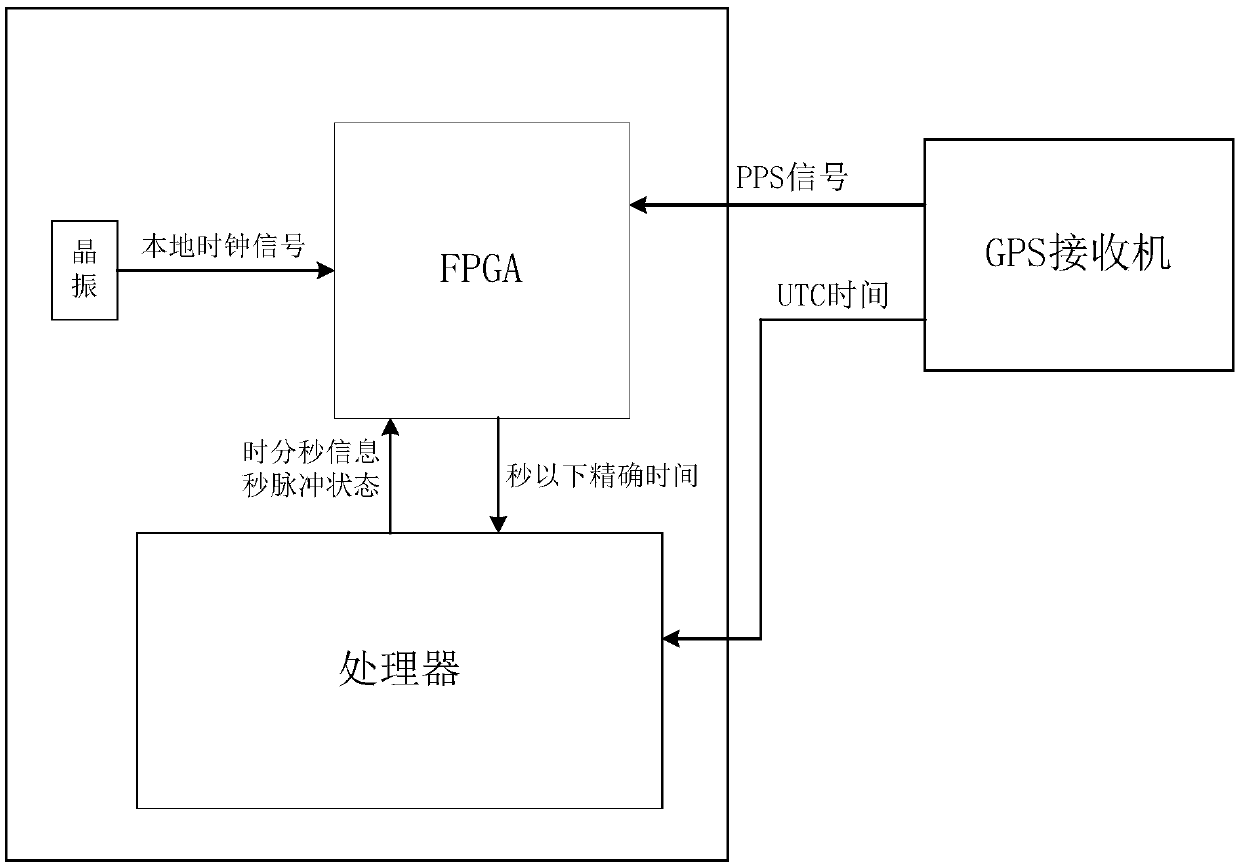

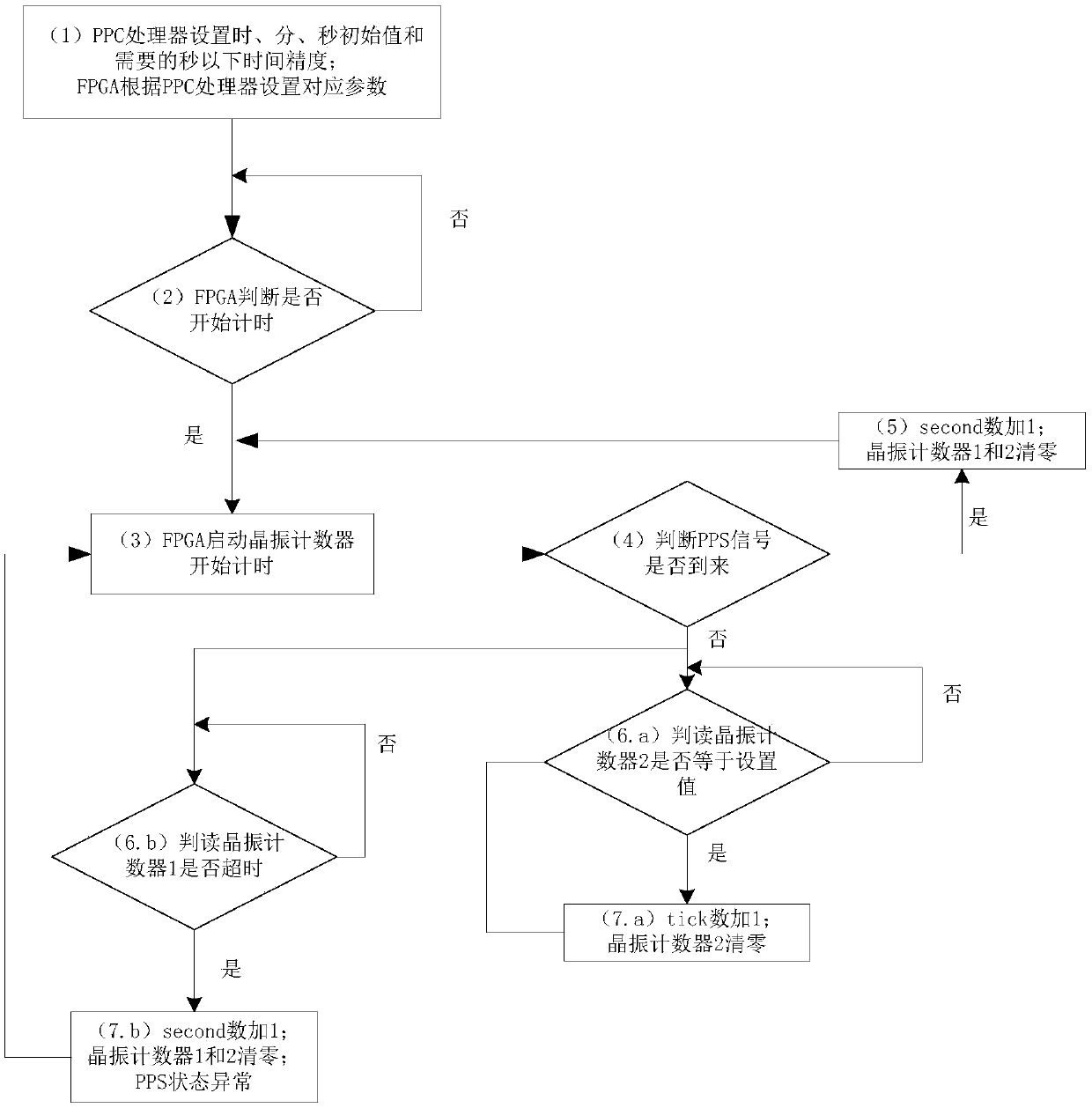

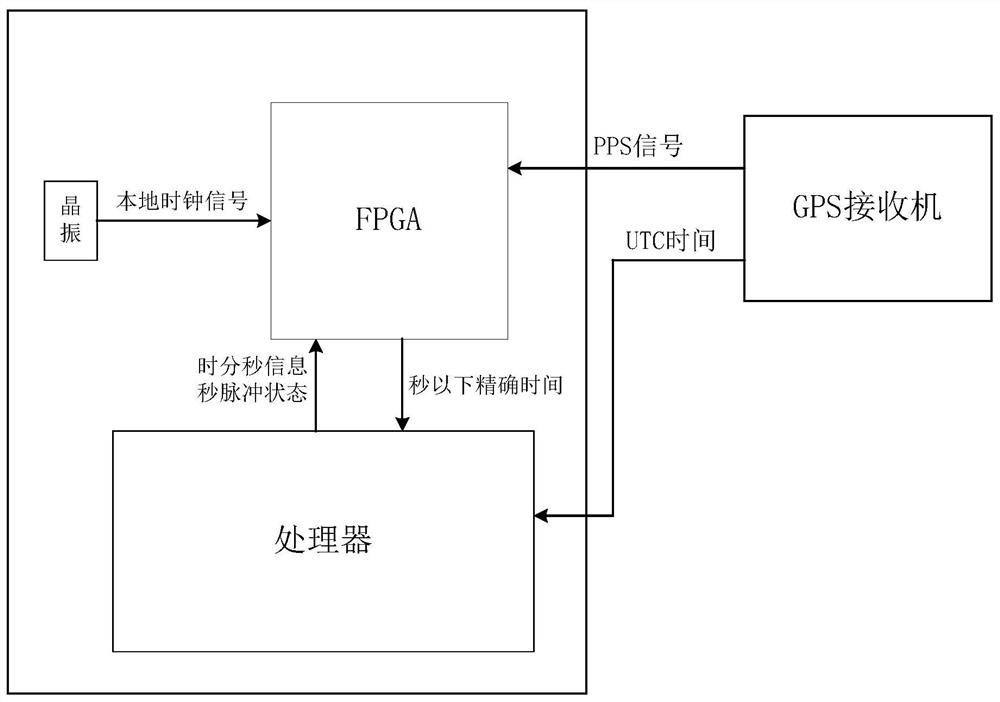

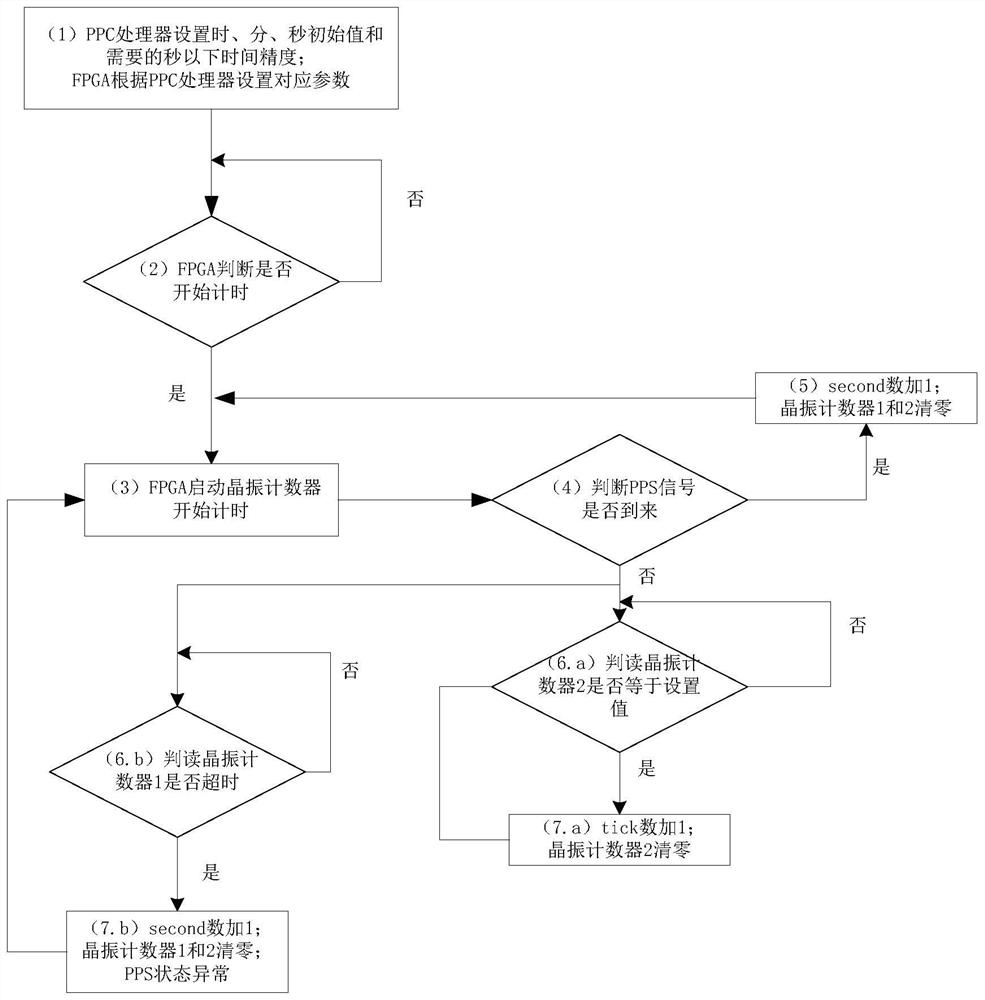

Adjustable-precision time acquisition method based on second pulses

The invention provides an adjustable-precision time acquisition method based on second pulses. The method includes: receiving UTC time information, which is issued by a GPS receiver, by a PPC processor, and obtaining hour, minute and second data, which are synchronized with a GPS, after solution calculation; generating precision information by the PPC processor, and passing the hour, minute, second and less-than-second data obtained after solution calculation and the precision information to an FPGA clock acquisition unit; receiving a local clock signal from a local clock source by the FPGA clock acquisition unit, receiving a PPS signal from the GPS receiver, and calibrating the received hour, minute, second and less-than-second data; and sending back the calibrated hour, minute, second and less-than-second data to the PPC processor by the FPGA clock acquisition unit through an LBC bus to realize calibration of less-than-second data. According to the method, time precision configuringis flexible, and time acquisition precision is high.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

Transmission shaft set assembling technology

ActiveCN101380893AEliminate error accumulationGuarantee the quality of dynamic balanceControl devicesUniversal jointDynamic balance

The invention relates to an assembling process of a drive shaft assembly. The process comprises the following steps: the first step: the assembling of part A: an extruder and a working platform device are adopted to arrange a universal joint on a flange fork and a universal joint fork on the universal joint; the second step: the assembling of part B: an extruder and a working platform device are adopted to arrange a universal joint on a flange fork and a spline shaft fork and a spline hub sub-assembly or a sliding fork and a rear shaft head sub-assembly on the universal joint; the third step: an extruder and a universal clip extrudes and assembles components of part A, components of part B and a shaft tube into a drive shaft assembly; the fourth step: a welding machine and a universal clip are adopted for alignment and welding of the drive shaft assembly; and the fifth step: a dynamic balancer and a universal clip are adopted for the dynamic balance of the drive shaft assembly. Therefore, the invention can increase the assembling precision and product quality of the drive shaft assembly, eliminates the part processing error, improves the labor efficiency, shortens the production period and decreases the production cost and labor intensity.

Owner:XUCHANG YUANDONG DRIVE SHAFT

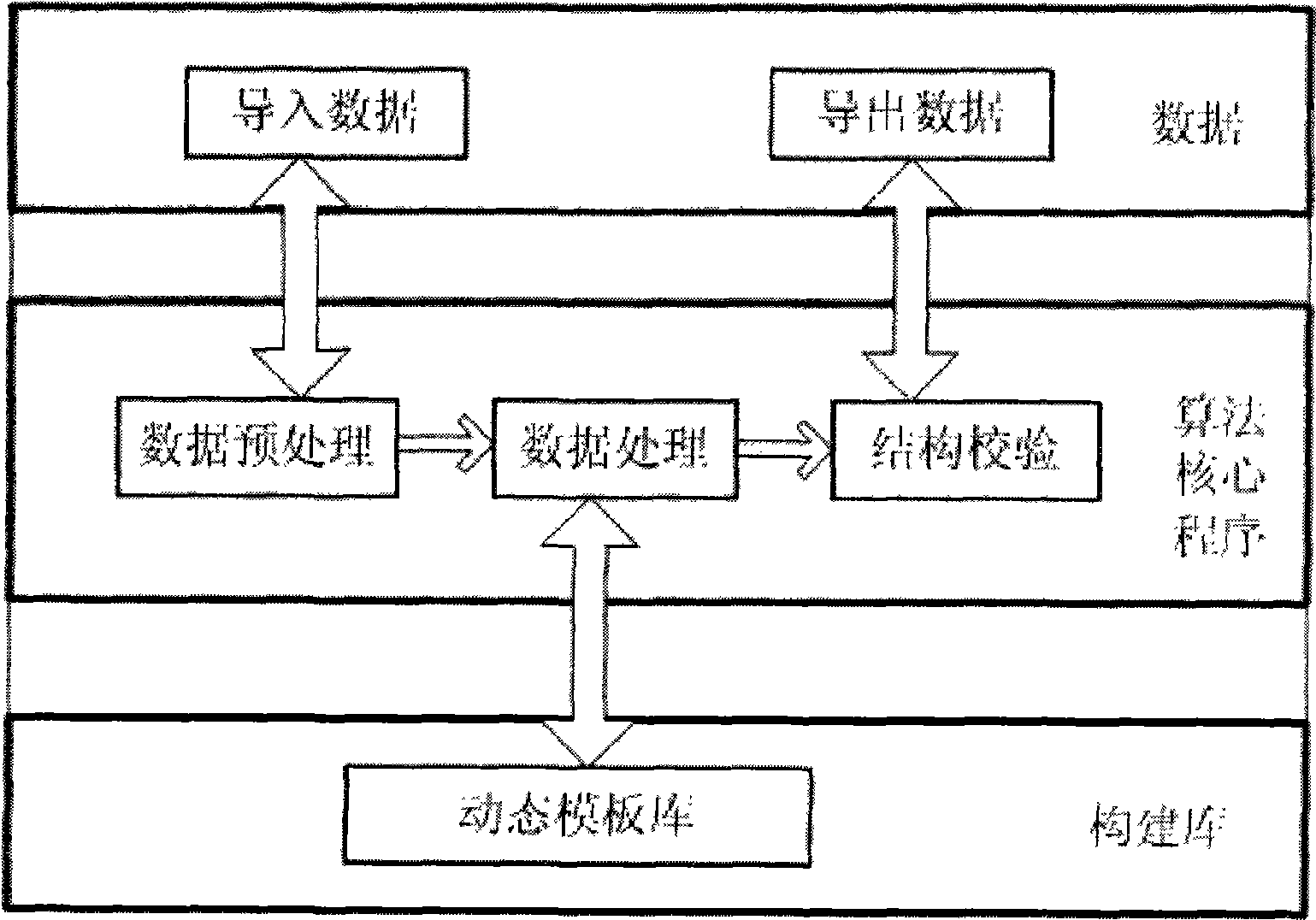

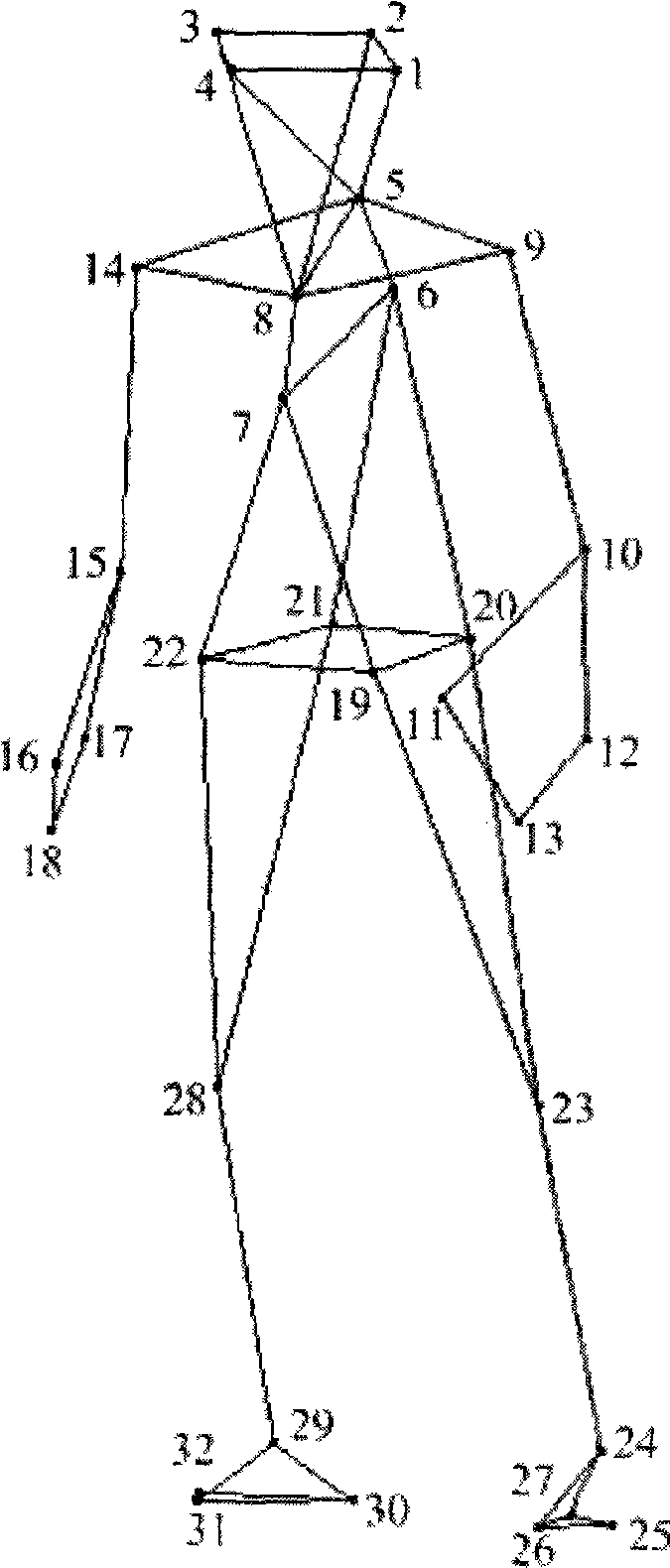

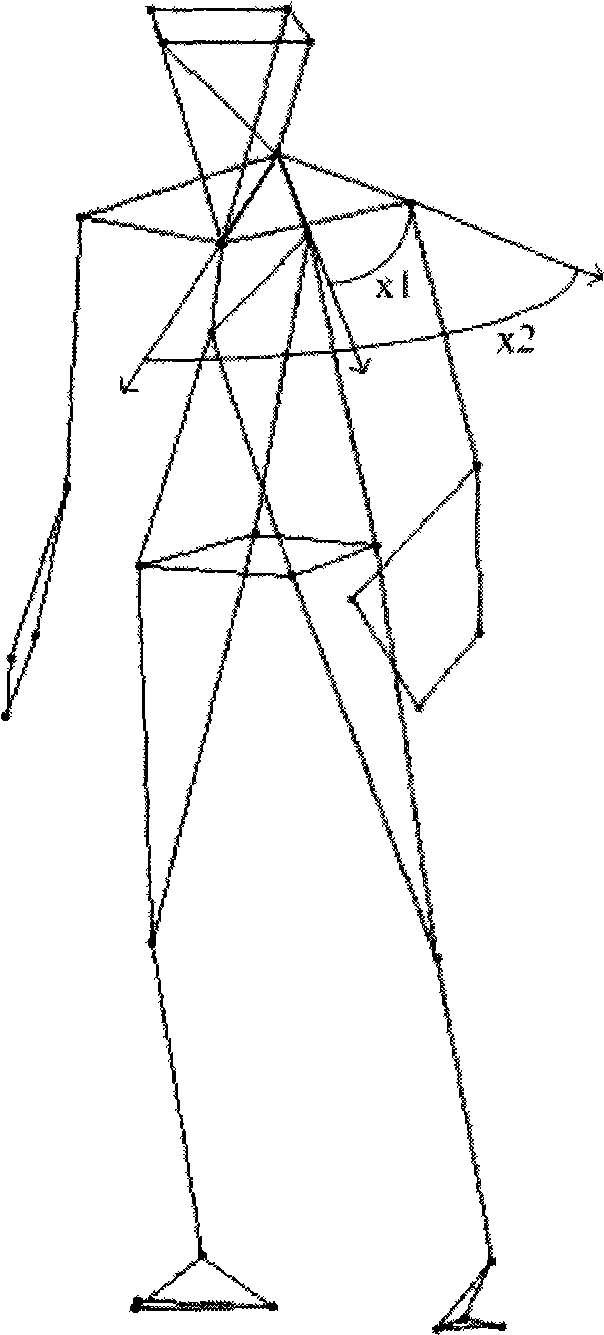

Optical motion capture data processing method based on dynamic template

ActiveCN101533526AAchieve automatic processingEliminate errors3D modellingMotion captureComputer science

The invention discloses an optical motion capture data processing method based on a dynamic template. By establishing a motion characteristic database, an improved optical motion capture data processing method based on a rigid body is provided; and the method stresses on solving the problem that the rigid body structure is damaged during motion, and establishes a dynamic matched template through the motion characteristic database so as to effectively solve the problems of mismatching and error accumulation because the prior rigid body matching only uses a unique match template. By using the information retrieval of the motion characteristic database, the method automatically adjusts length error parameters of each rigid body during tracking and matching, and automatically finishes without manual intervention during processing; and single-frame data processing time consumption meets the real-time requirement of motion capture.

Owner:DALIAN UNIV

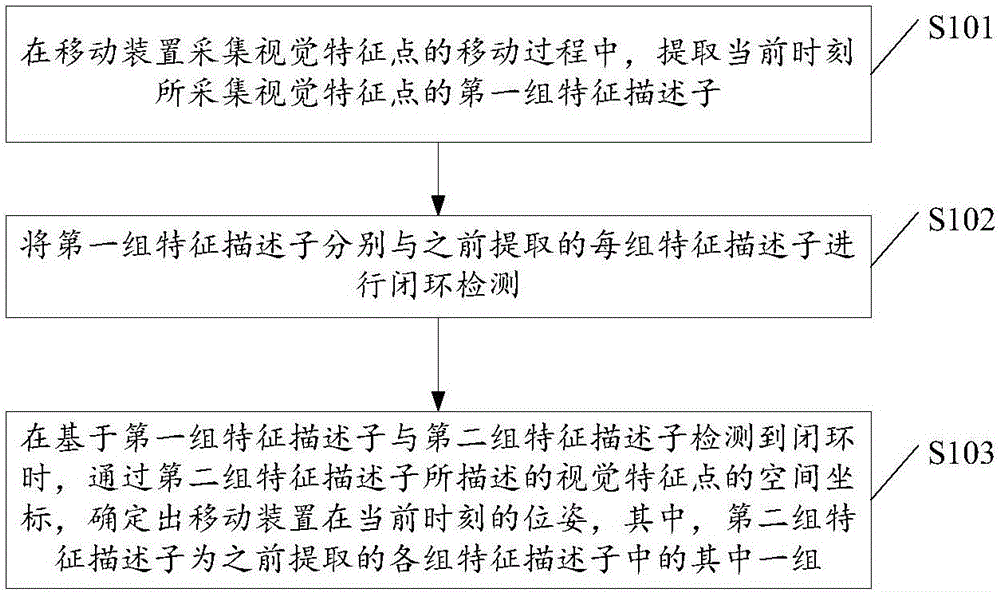

Moving device and positioning method thereof

ActiveCN106352877AEliminate error accumulationSolve technical problems of positioning accuracyNavigational calculation instrumentsClosed loopComputer vision

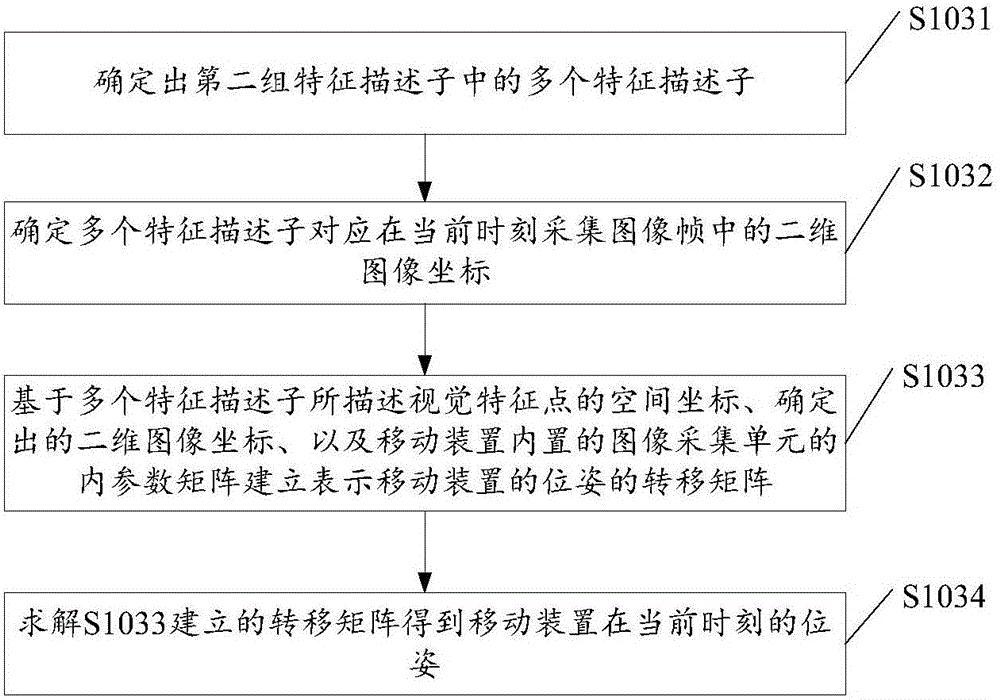

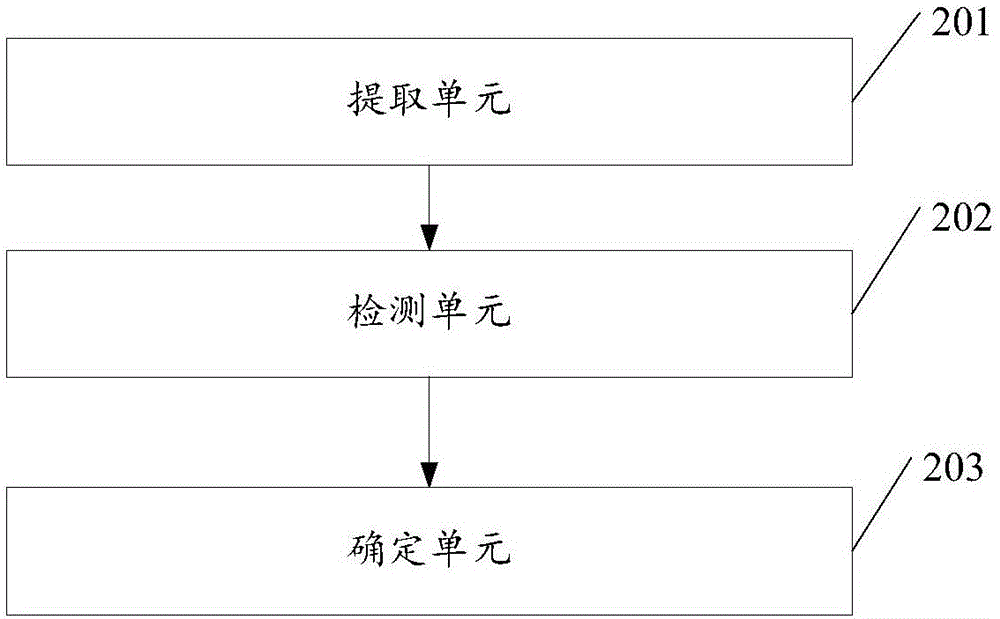

The invention discloses a moving device and a positioning method thereof. The positioning method includes: in the moving process when the moving device collects visual feature points, extracting first feature descriptors of the visual feature points collected at the current moment; performing closed-loop detection on the first feature descriptors and feature descriptors extracted before respectively; when a closed loop is detected on the basis of the first feature descriptors and second feature descriptors, determining pose of the moving device at the current moment through spatial coordinates of the visual feature points described by the second feature descriptors which are one of the feature descriptors extracted before. By the moving device and the positioning method, the technical problem that positioning accuracy is affected seriously by accumulated errors of pose estimation when the moving device moves is solved, and accuracy of positioning based on the moving device is improved.

Owner:WILLAND (BEIJING) TECH CO LTD

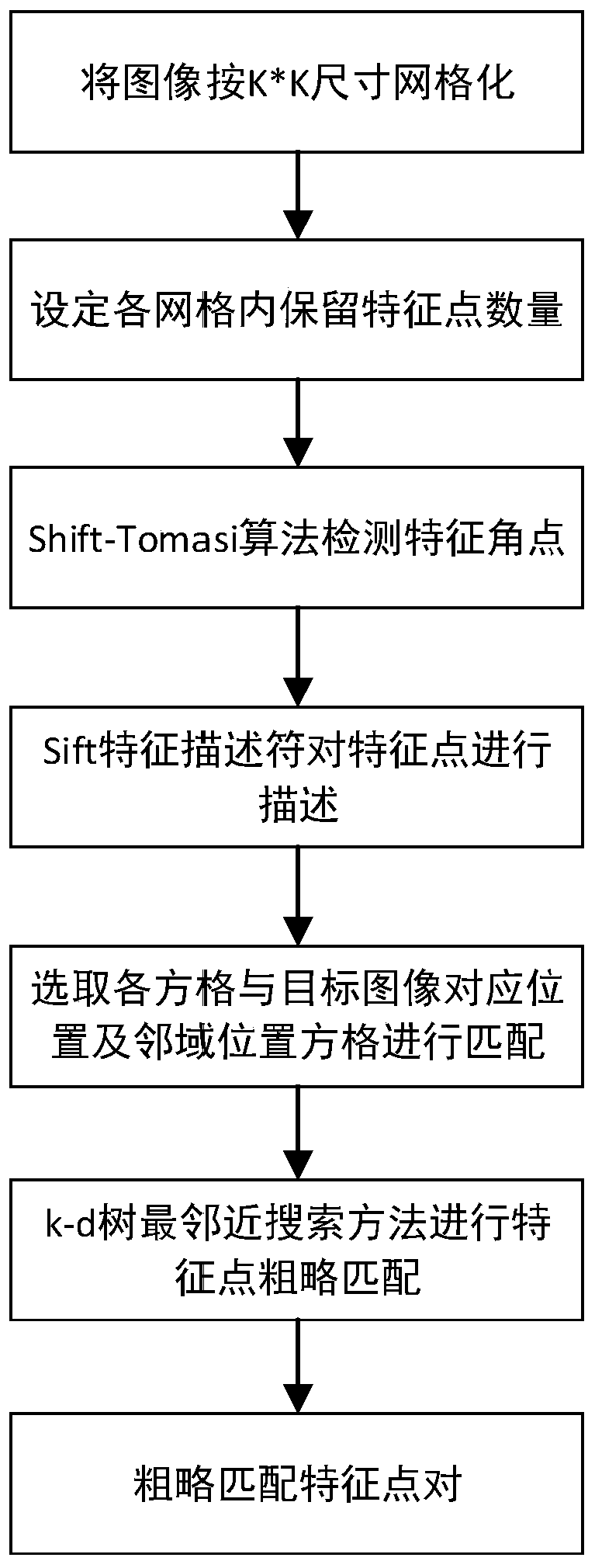

Panoramic image splicing method in airport environment

ActiveCN111127318AImprove display visual effectSolve the problem of automatic panorama stitchingImage enhancementImage analysisNuclear medicineColor difference

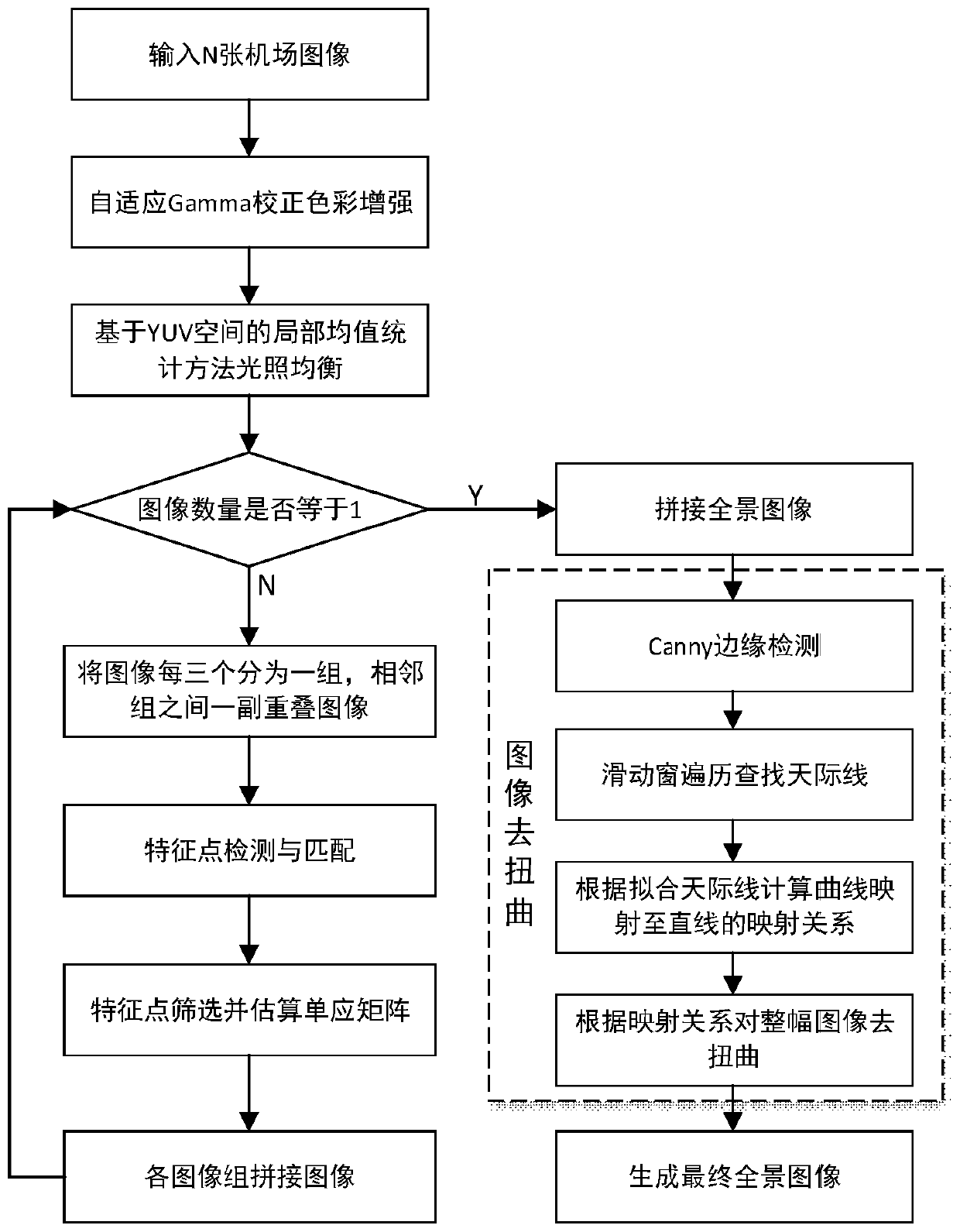

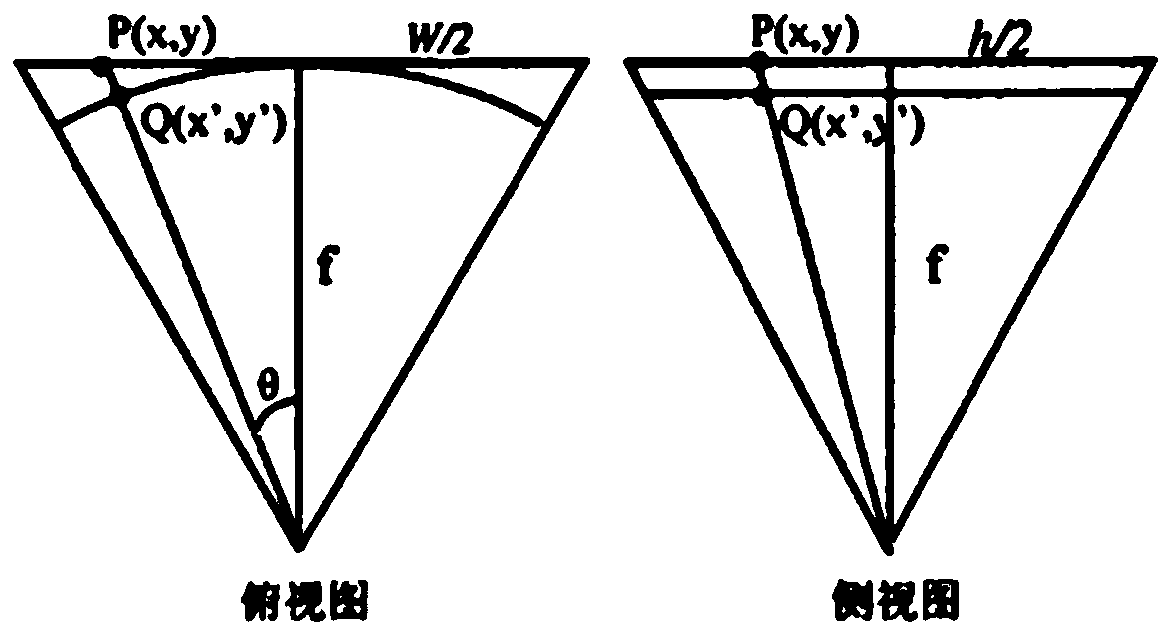

The invention provides a panoramic image splicing method in an airport environment. The panoramic image splicing method comprises the following steps: firstly, preprocessing acquired images; adpotinga color difference correction method based on a YUV space to realize color consistency among multiple cameras; projecting a camera image to a cylindrical plane, and detecting feature points in the image by adopting a feature point detection algorithm for images after cylindrical projection; achieving rough matching of the feature point pairs in adjacent images; removing error feature point pairs through an RANSAC algorithm, calculating an accurate homography matrix between images to achieve uniform transition splicing between registered images through a gradual-in gradual-out fusion technology; carrying out canny edge detection on the panoramic image, selecting the longest line segment as the skyline position, and fitting a skyline smooth curve by using a least square method so that imagedistortion caused by splicing can be eliminated. A grouping iteration splicing method is adopted, error accumulation in the multi-path image splicing process is eliminated, and the splicing success rate and the splicing effect are improved.

Owner:NANJING LES ELECTRONICS EQUIP CO LTD

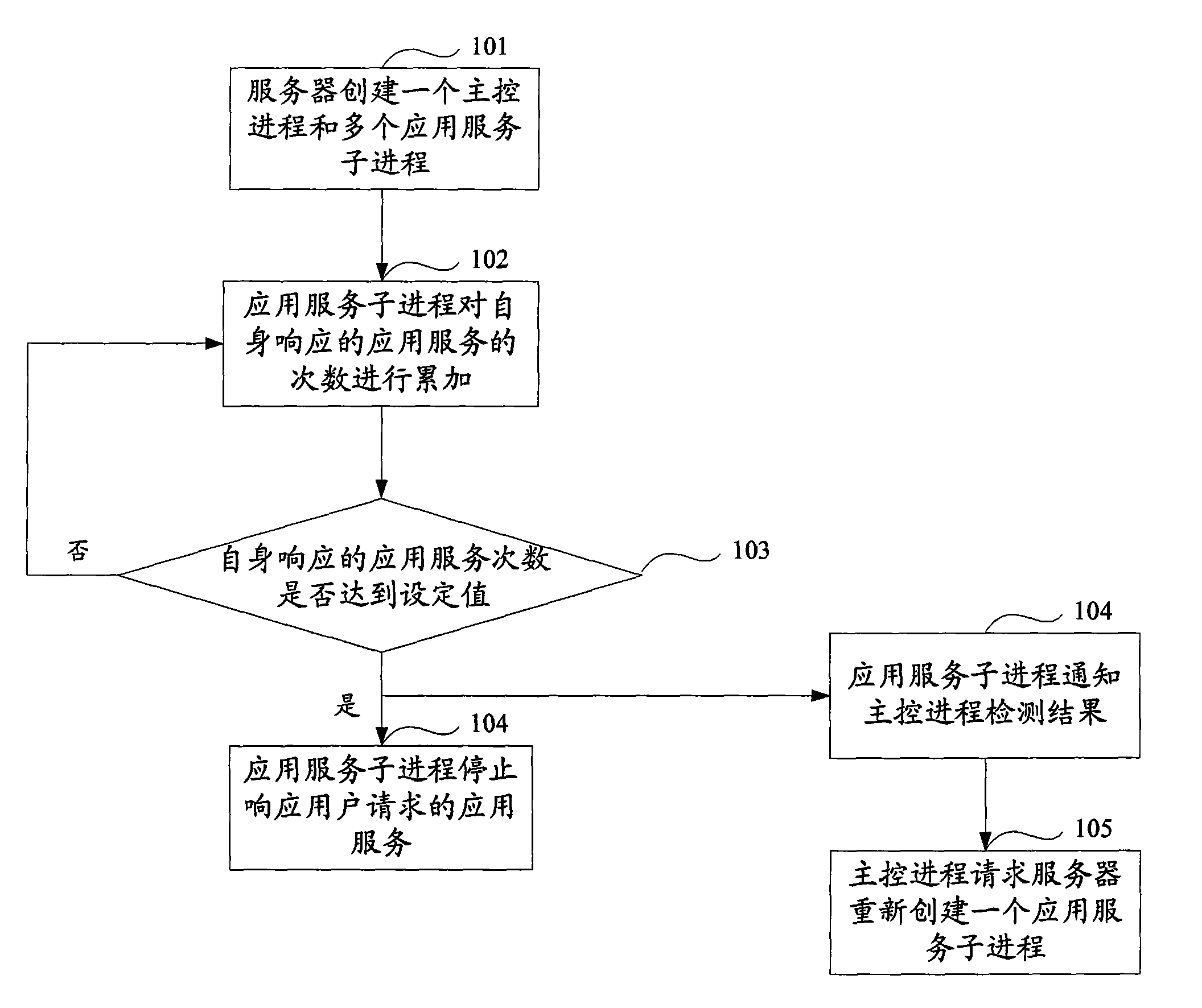

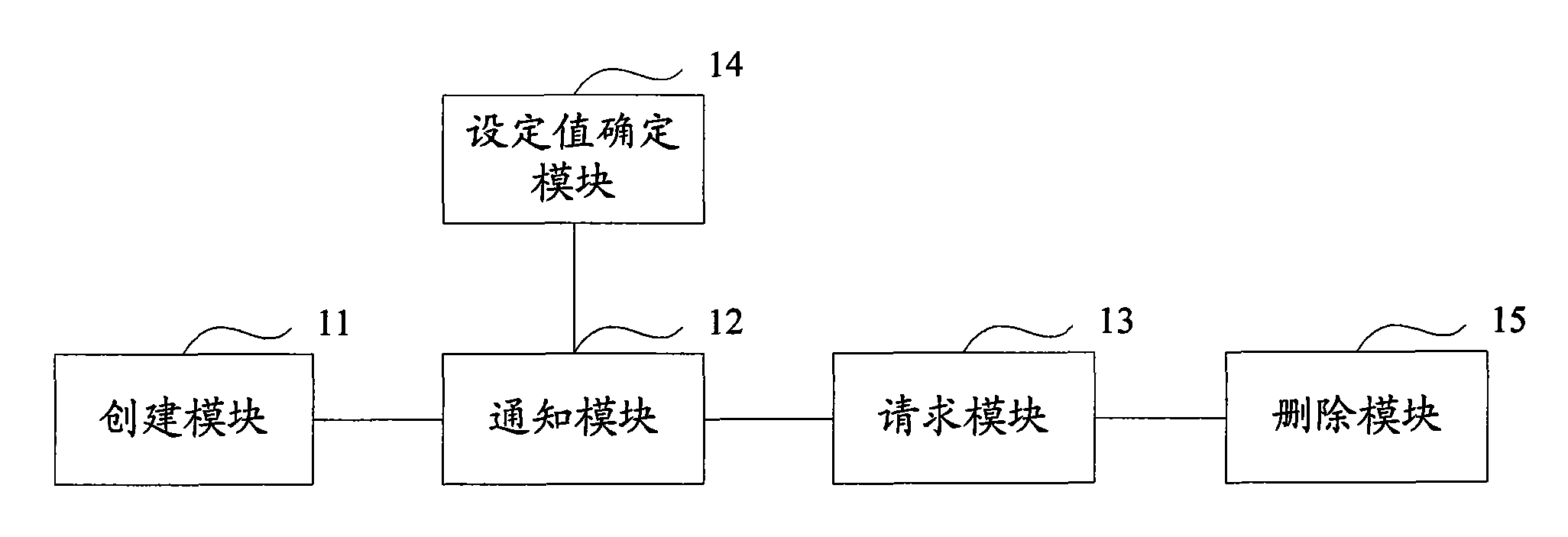

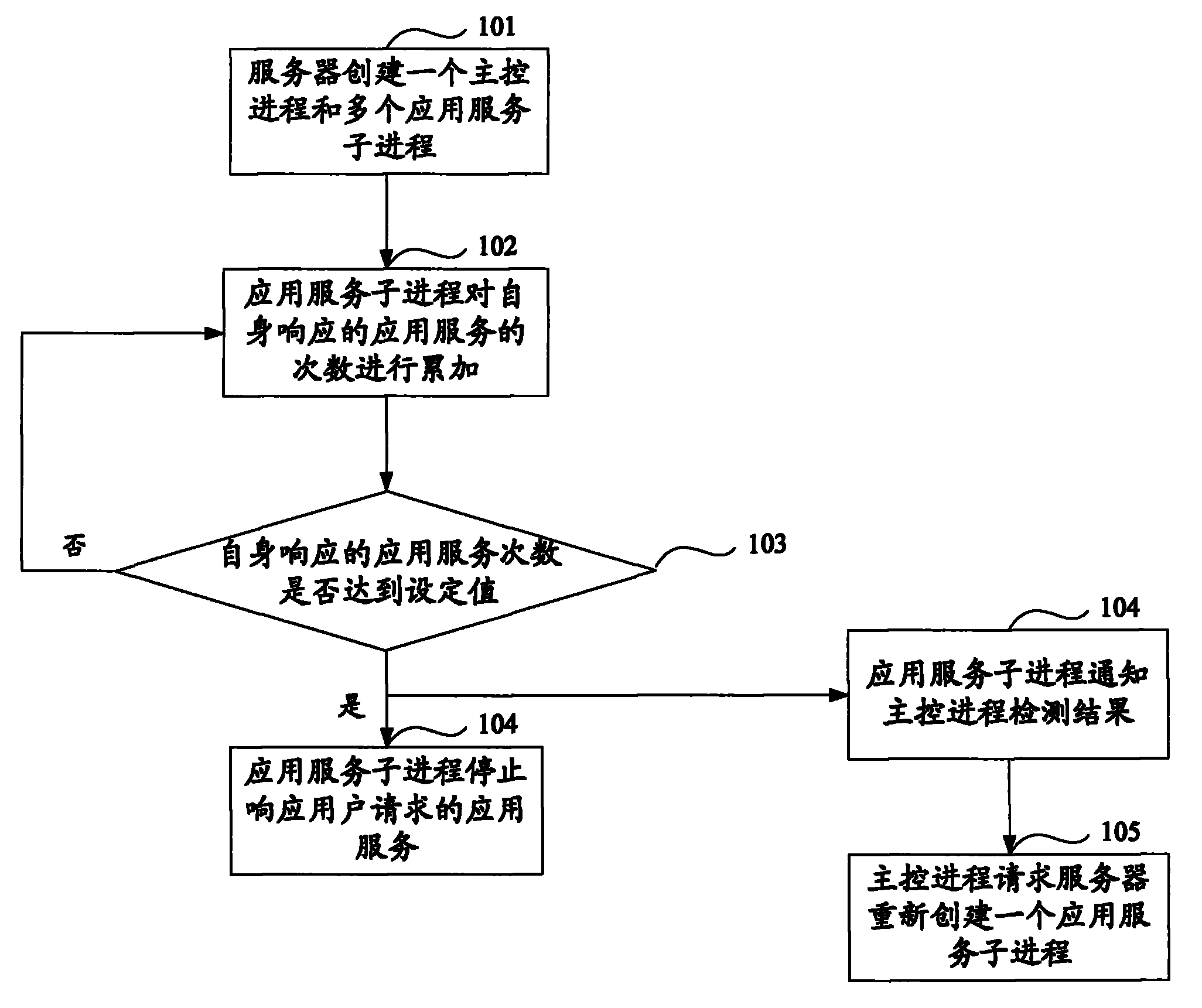

Process survival control method and device

InactiveCN102012836AReduce mistakesImprove long-term stabilityProgram initiation/switchingSoftware engineeringChild process

The invention discloses a process survival control method and device. An application service child process created by a server accumulates the number of application services responded by per se and stops responding the application services requested by application users when the response number reaches a set value, and the disabled application service child process is substituted by the new application service child process re-created by the server, thus error accumulation caused by programming error or run error can be eliminated and error of the application service child process in a running state is ensured to be smaller so as to improve the long-term stability of a server program.

Owner:CHINA MOBILE COMM GRP CO LTD

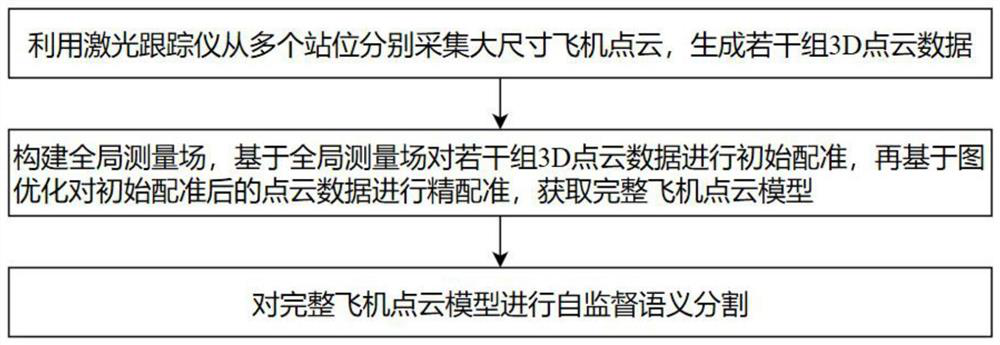

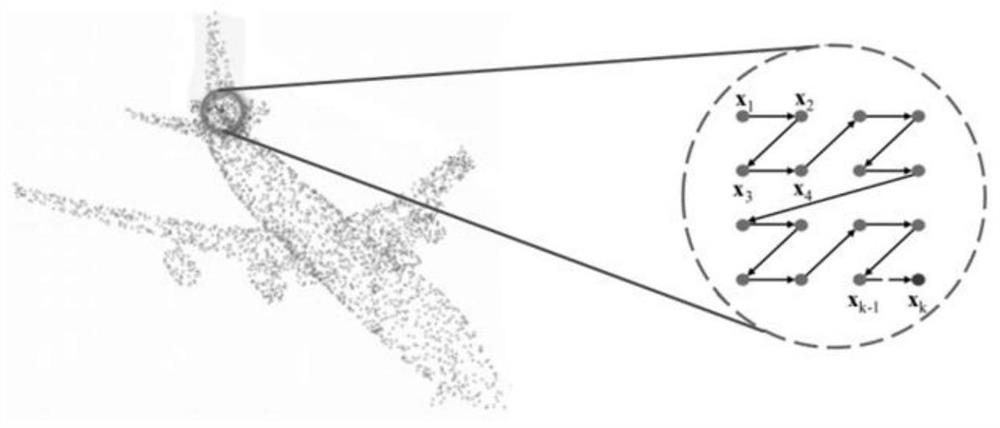

Large aircraft point cloud model self-supervision semantic segmentation method based on deep learning

PendingCN111860520AAccurate and Effective Shape Semantic SegmentationReasonable ideaImage enhancementImage analysisPoint cloudEngineering

The invention discloses a large aircraft point cloud model self-supervision semantic segmentation method based on deep learning, and the method comprises the steps: collecting large-size aircraft point clouds from a plurality of stations through a laser tracker, and generating a plurality of groups of 3D point cloud data; constructing a global measurement field, performing initial registration onthe plurality of groups of 3D point cloud data based on the global measurement field, and performing fine registration on the initially registered point cloud data based on graph optimization to obtain a complete aircraft point cloud model; and carrying out self-supervised semantic segmentation on the complete aircraft point cloud model. According to the invention, an optical three-dimensional detection system measurement technology is utilized to process and analyze acquired 3D data, so that shape semantic segmentation on a large aircraft can be accurately and effectively carried out, the conception is reasonable, and automatic application can be realized in scenes such as aircraft safety inspection and the like in practice.

Owner:南京耘瞳科技有限公司

Transmission shaft spline shaft metal processing technique

The invention discloses a transmission shaft spline shaft metal processing technique. The processing technique comprises the following steps of: performing thermal refining by using a thermal refining automatic line; milling a small end surface by using a milling and drilling machine, and drilling centre bores at two ends; performing fine turning by using a numerically controlled lathe; milling a spline by using a numerical control spline milling machine; removing front points and burr; and performing mid frequency induction hardening by using a mid frequency induction hardening machine. The processing technique can guarantee the part accuracy to the maximum extent, eliminate various errors caused by position reference conversion, shortens the whole metal processing flow, reduce a large number of manpower and material resources, greatly reduce the processing cost, reduce the labor intensity, improve the working efficiency, and save processing cost.

Owner:XUCHANG YUANDONG DRIVE SHAFT

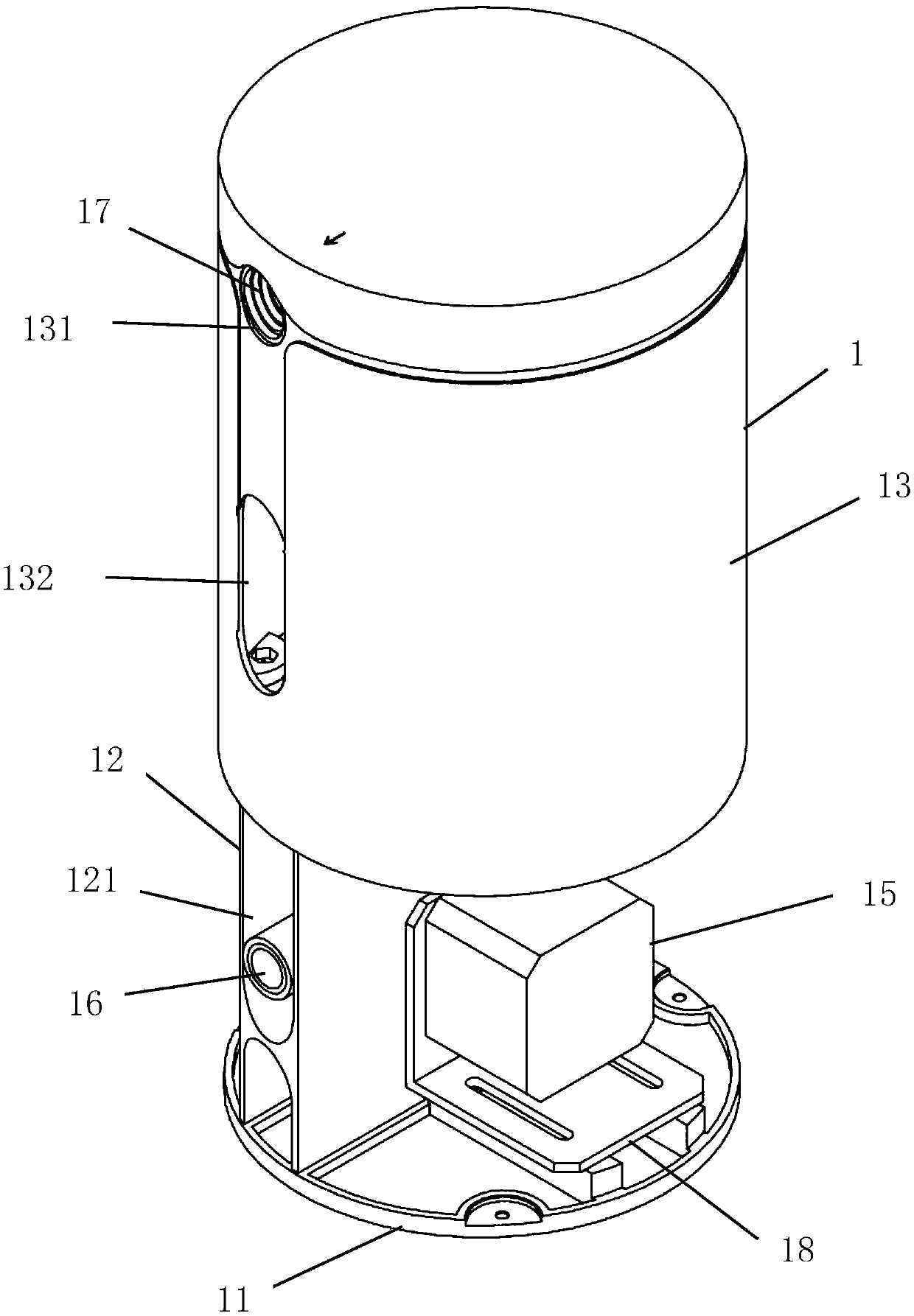

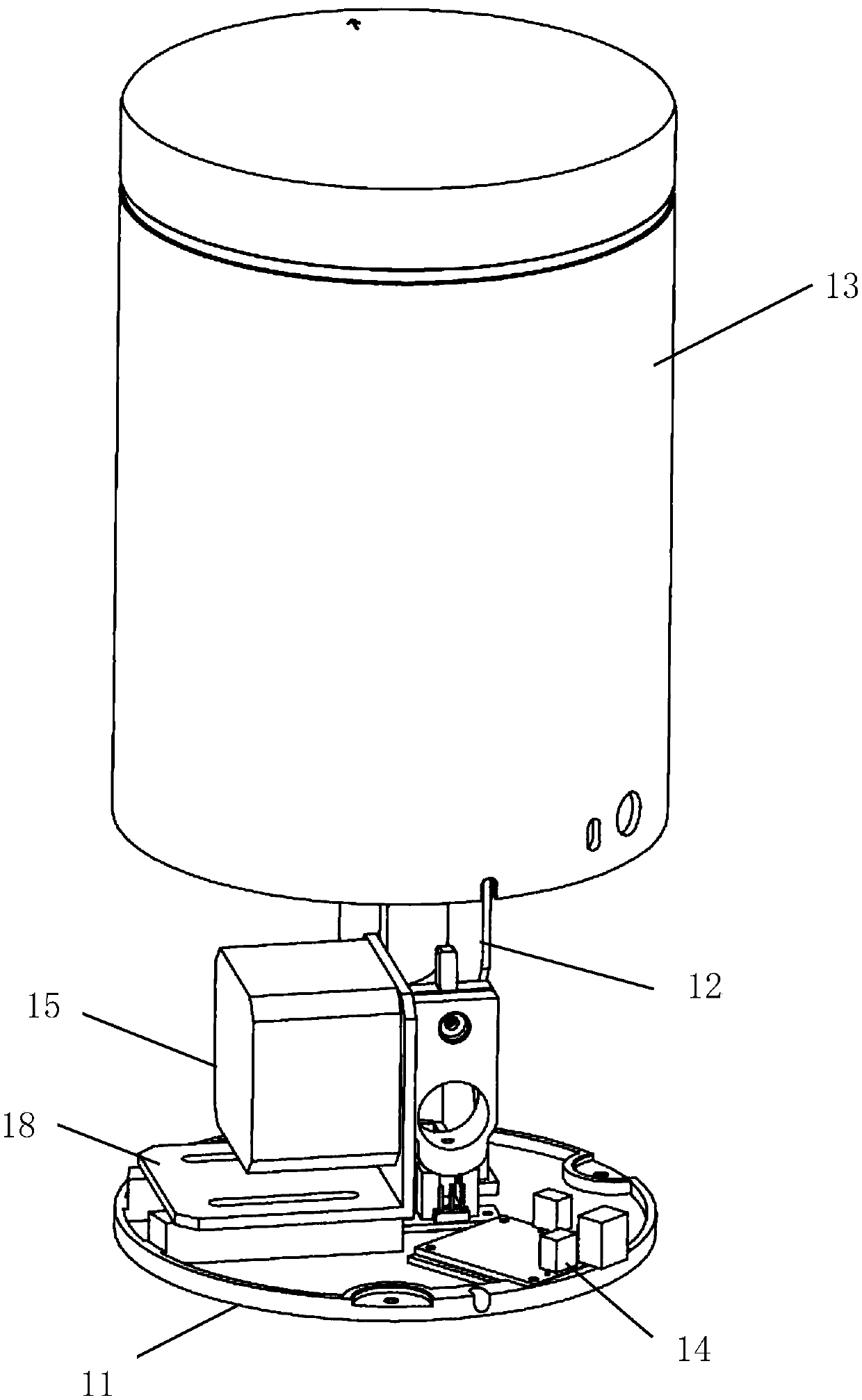

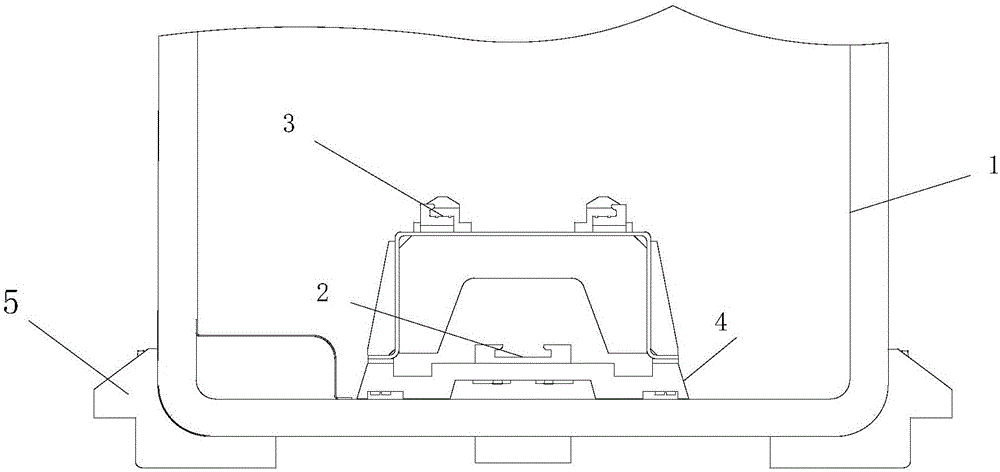

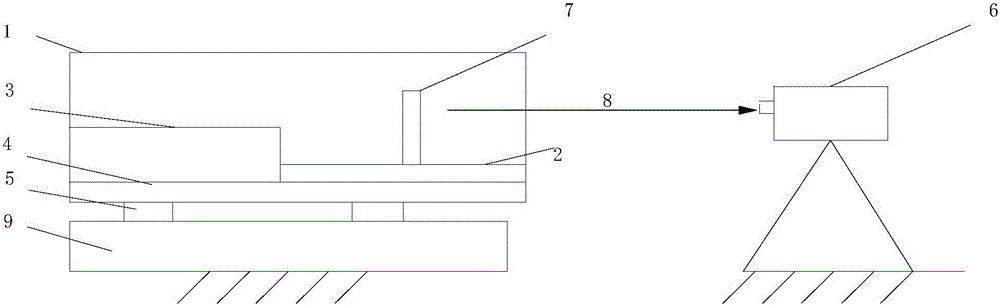

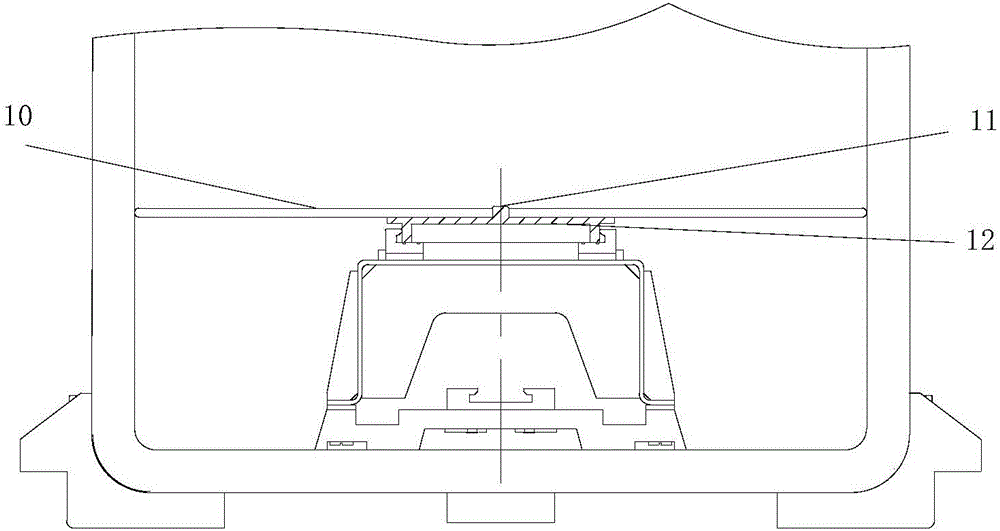

Three-dimensional laser scanner system and use method

PendingCN107869955AReduce configuration requirementsHigh positioning accuracyUsing optical meansPoint cloudLaser scanning

The invention provides a three-dimensional laser scanner system and use method. The three-dimensional laser scanner system comprises a scanner support, a camera component and a backboard, the camera component is mounted on the scanner support, an object to be scanned is placed in the front of the backboard, the camera component is connected with a computer through a USB (universal serial bus) interface, three-dimensional laser scanner software is arranged in the computer, and the camera component aligns the object to be scanned. The three-dimensional laser scanner system has the advantages that by a high-precision coding image backboard spliced algorithm, positioning accuracy is improved, accuracy and reliability of subsequent photography measurement are ensured, a laser scanner is flexible, efficient, easy to use and high in accuracy, point cloud of the surface of the object is acquired by a laser, and the space position of the laser scanner in the working process is determined according to visual image markers.

Owner:华朗三维技术(深圳)有限公司

Guide rail assembling technological method for large composite box

ActiveCN105806192AAchieve high-precision assemblyEliminate error accumulationMechanical measuring arrangementsHeight differenceMechanical engineering

The invention provides a guide rail assembling technological method for a large composite box, and relates to the technical field of guide rail assembling technologies for large composite boxes.The dimension of an inner cavity of the composite box is 8000 mm*1000 mm*1200 mm, a front guide rail and a rear guide rail are installed on the inner surface of the I quadrant of the box through guide rail bases, and the front guide rail and the rear guide rail are connected to the inner wall of the box through the guide rail bases.The guide rail assembling reference of the composite box is determined to adjust related dimensions of bottom corner parts, errors generated by tipping and defection of the composite box are eliminated, and the assembling precision of the guide rails relative to the installation reference is ensured; the inner wall of the box serves as the assembling reference to ensure the symmetry degree of the guide rails relative to the center of the box; a digital level gage is used for conveniently, rapidly and accurately measuring the parallelism and height difference dimensions of the guide rails, and a symmetry degree detection tool is used for achieving quick and effective guide rail precision detection.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

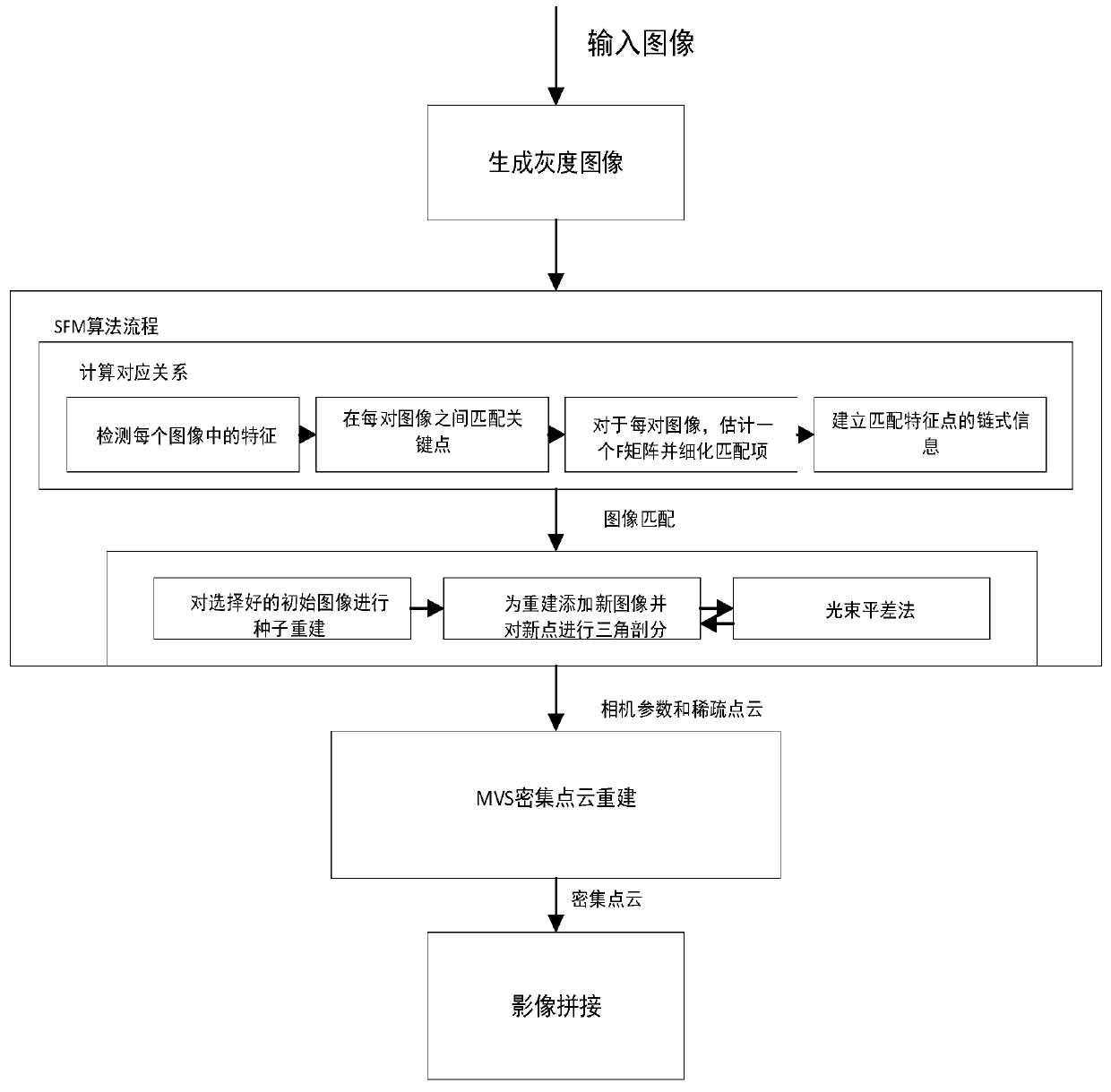

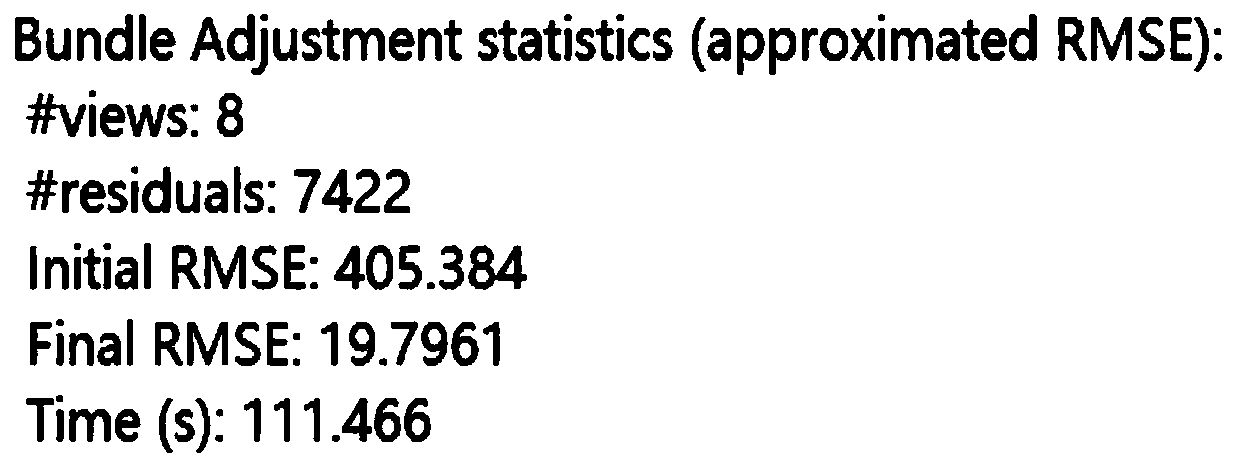

Rapid image splicing method based on optimized three-dimensional reconstruction

ActiveCN111553845AEliminate error accumulationGuaranteed accuracyInternal combustion piston enginesGeometric image transformationPattern recognitionPoint cloud

The invention discloses a rapid image splicing method based on optimized three-dimensional reconstruction, and the method comprises the steps: constructing dense point clouds of a photographing regionthrough employing a motion recovery structure and a multi-view stereo technology, and achieving the splicing of an image through the dense point clouds; optimized feature descriptors are adopted in image feature point extraction to perform optimization adjustment, and when error accumulation is eliminated, an optimization strategy of how to select a next optimal view after initialization is completed is proposed, so that the accuracy of point cloud generation is ensured, and the possibility of failure of a bundle adjustment method is reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

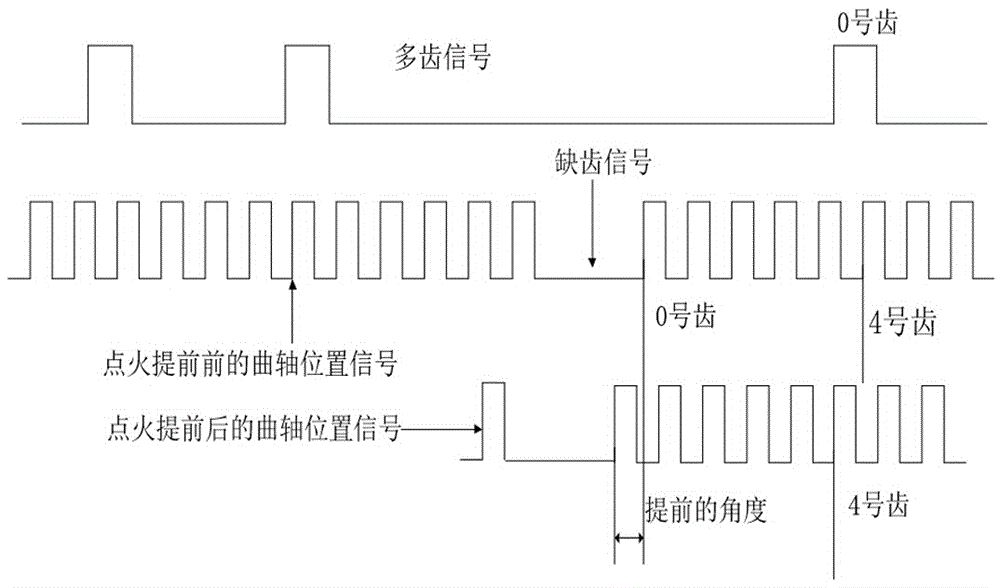

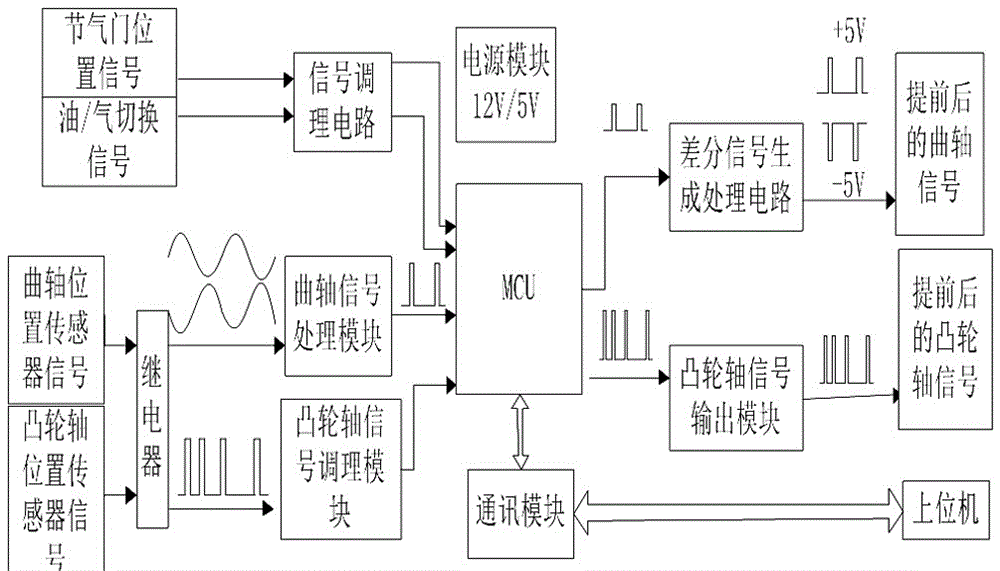

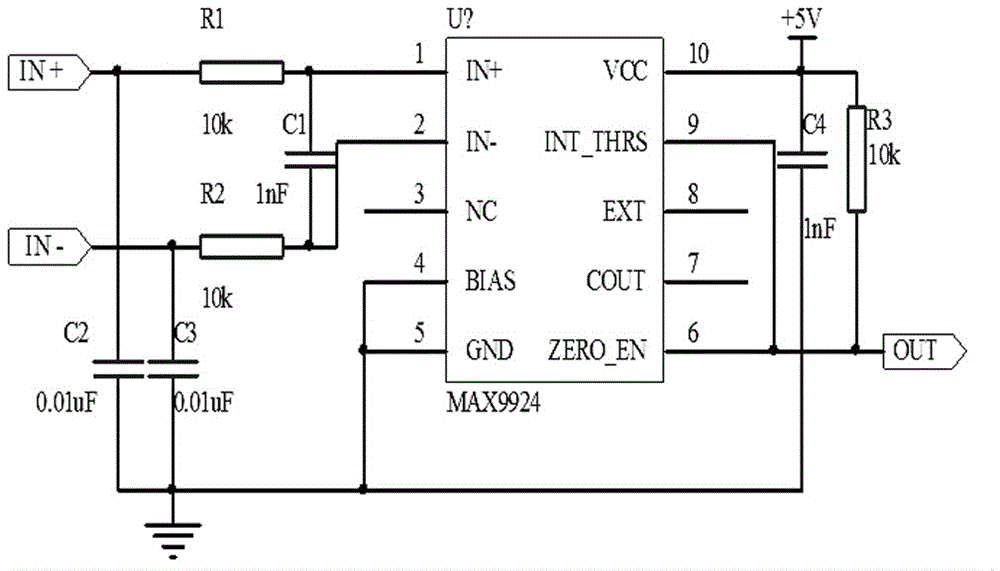

Ignition advancer and advance angle control optimization method of oil/CNG double-fuel engine

InactiveCN106545452AHigh positioning accuracyImprove reliabilityIgnition automatic controlAutomatic controlDifferential signalingMissing tooth

The invention provides an ignition advancer of an oil / CNG double-fuel engine. The ignition advancer of the oil / CNG double-fuel engine comprises an MCU, a differential signal generating and processing circuit, a power supply module and a communication module, wherein the differential signal generating and processing circuit is used for changing a crankshaft position signal transmitted by the MCU into a differential signal output circuit, and the communication module is used for communication between the ignition advancer and an upper computer. The invention further provides an ignition advance angle control optimization method of the oil / CNG double-fuel engine. The ignition advance angle control optimization method of the oil / CNG double-fuel engine comprises the following steps that (STP1), after the crankshaft position signal is acquired by the MCU, missing teeth of a bent shaft are captured; (STP2), the tooth number of one circle of the crankshaft is calculated according to the missing teeth of the crankshaft, and meanwhile, the degrees of rotating angles between the adjacent teeth are calculated; (STP3), through MAP calculation, an ignition advance angle required under the current working condition is calculated; and (STP4), according to the rotating angles, between the adjacent teeth, of the crankshaft and the required advance angle value, the position of analogue output of the next tooth is calculated. According to the ignition advancer of the oil / CNG double-fuel engine, adjusting of the ignition advance angle can be achieved under the full working conditions, and the types of the crankshaft signal and the camshaft signal can be automatically recognized through a system.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

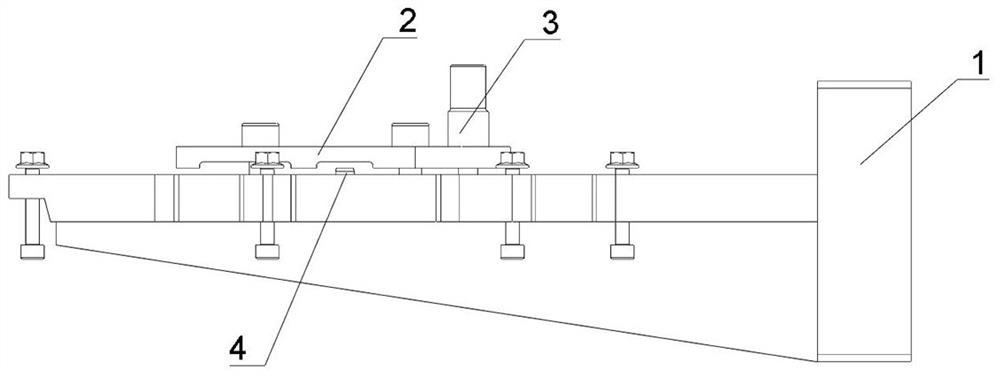

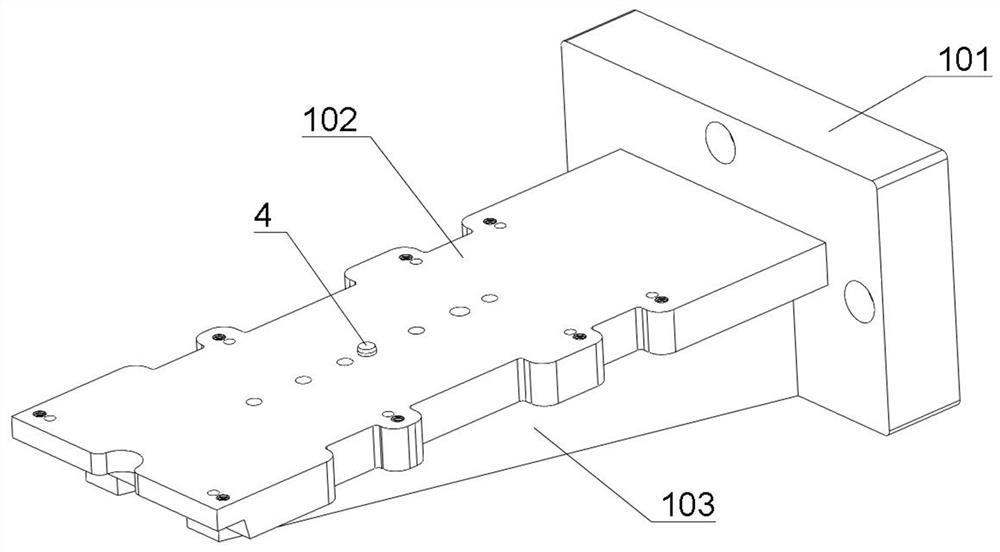

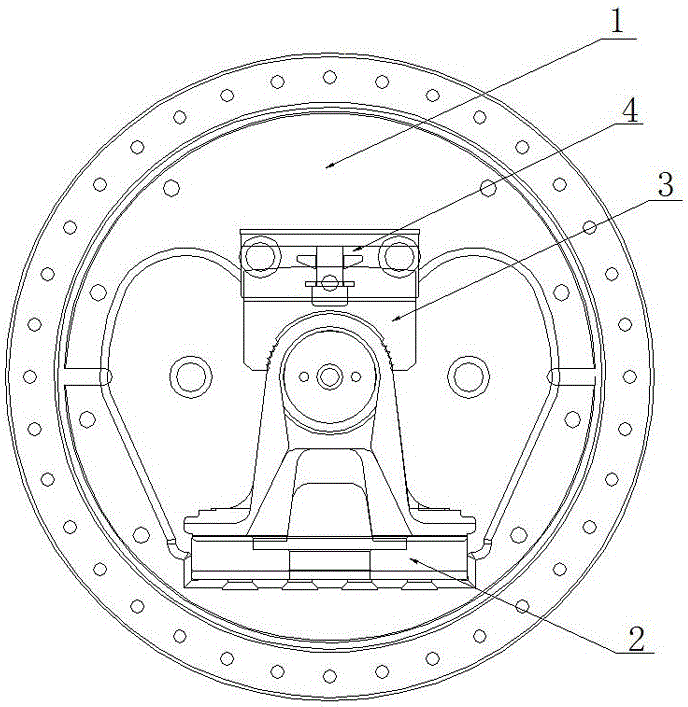

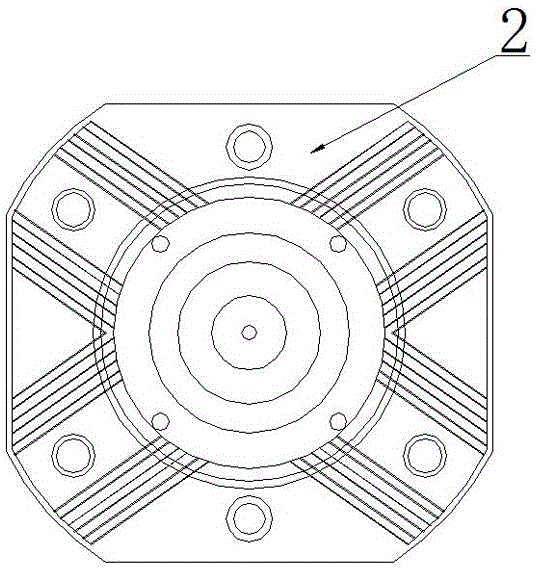

Machining tool and machining method for adjusting piece of aero-engine

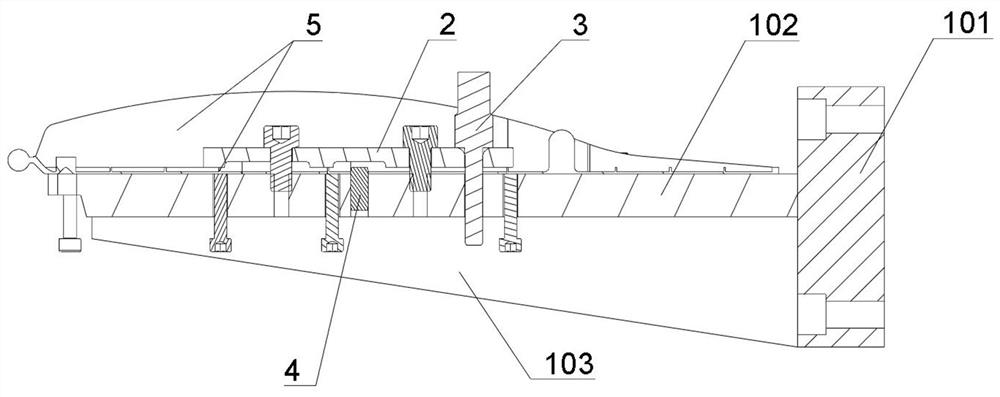

ActiveCN114654278AReasonable structureLow manufacturing costWeight reductionPositioning apparatusPhysicsMachine tool

The invention provides an aero-engine adjusting sheet machining tool and method, and relates to the technical field of machining. The machining tool comprises a clamp body (1), a pressing block (2), a taper positioning pin (3) and a cylindrical positioning pin (4), and a plurality of screw holes and a plurality of pin holes are formed in the center of the clamp body (1); the cylindrical positioning pin (4) is arranged in the pin hole; the pressing block (2) is arranged in the middle of the clamp body (1). The taper positioning pin (3) penetrates through the pressing block (2) and the clamping plate (102) at the same time. By means of the machining tool, the problems that machining procedures of the aviation adjusting piece are scattered, clamping is difficult, and machining efficiency is low are solved. The machining method is convenient to operate, the machining precision can be effectively improved, and the product machining quality is improved.

Owner:CHENGDU HOLY AVIATION SCI & TECH

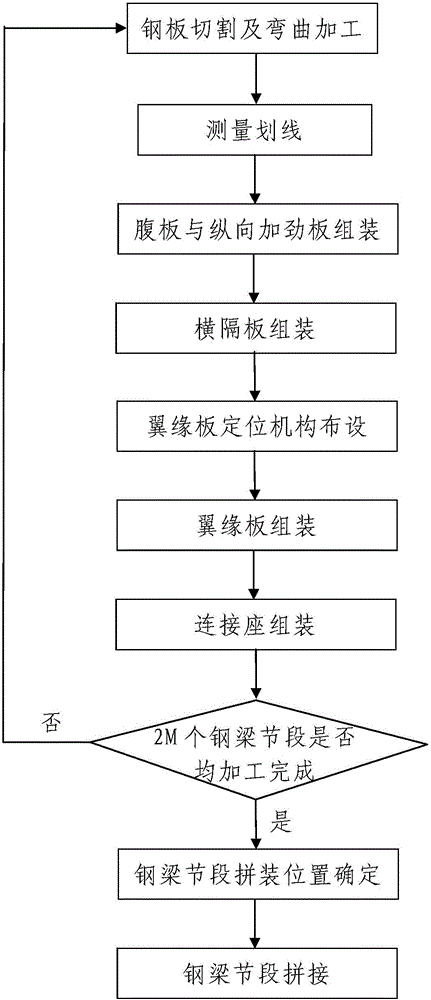

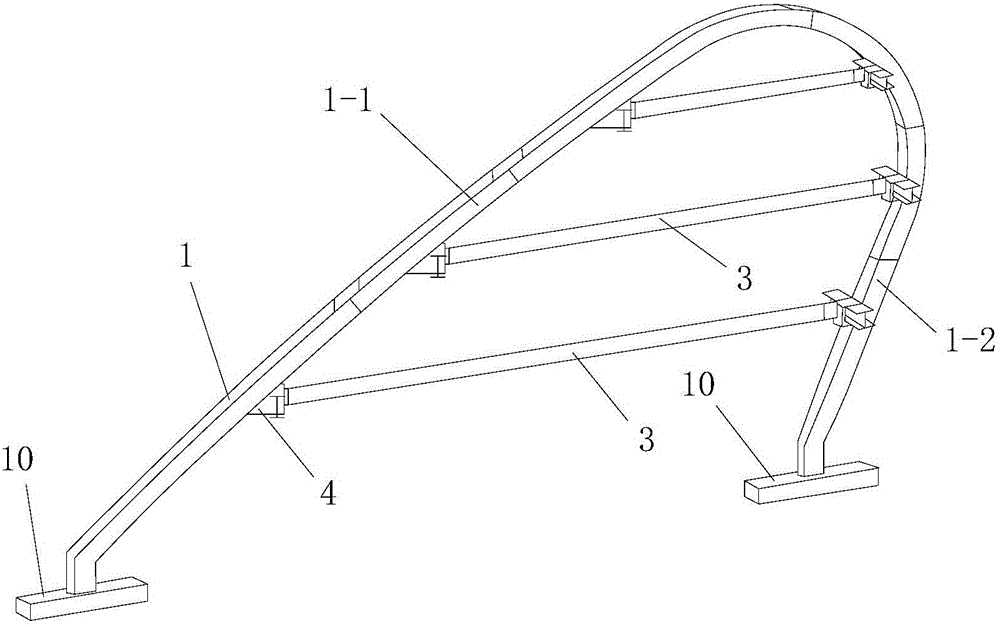

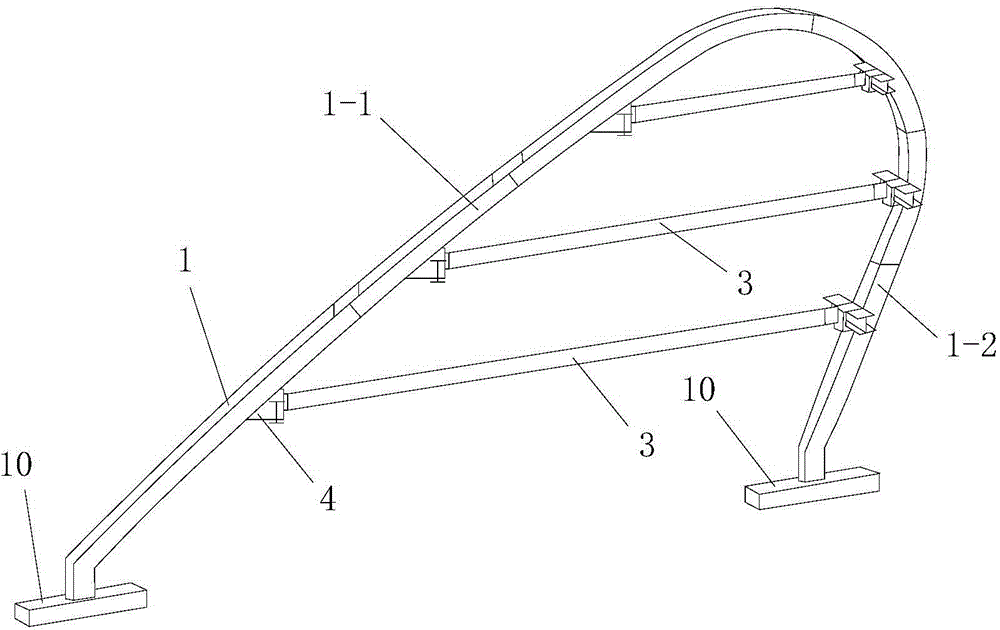

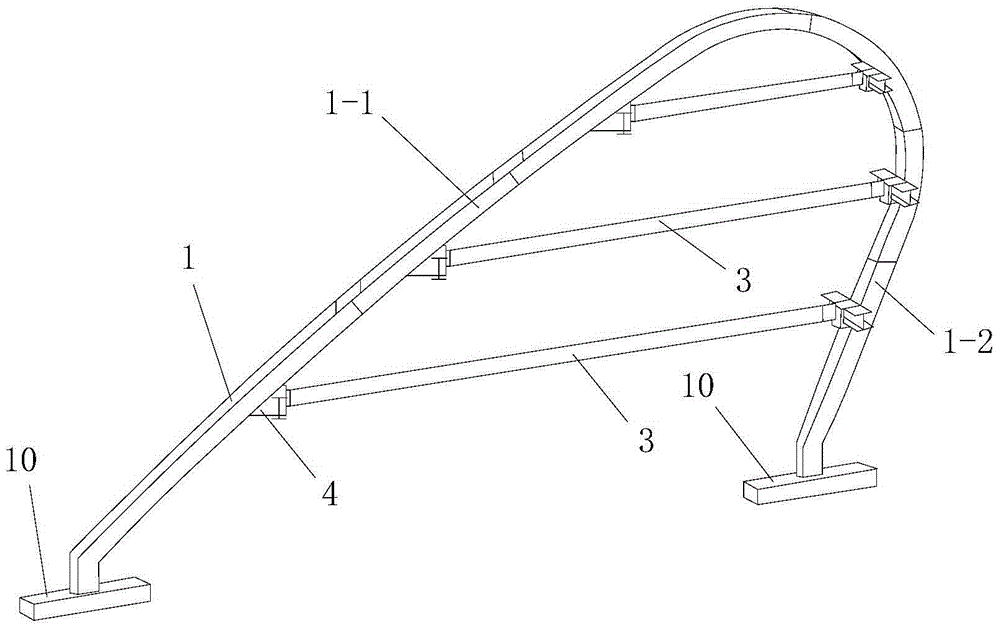

Curved ribbed beam processing and assembling construction process

ActiveCN104989107AThe process steps are simpleReasonable designBuilding roofsBuilding material handlingSteel platesFlange

The invention discloses a curved ribbed beam processing and assembling construction process. A processed curved ribbed beam is a curved steel beam, the cross-section of the curved steel beam is in the shape of a Chinese character ri, an outer side beam body and an inner side beam body of the curved ribbed beam are connected with each other through straining beams, and each of the outer side beam body and the inner side beam body is spliced by a number M of steel beam sections, each steel beam section comprises a top flange plate, a bottom flange plate, two webs and a vertical stiffening plate, and each steel beam section is provided with a connecting base. The curved ribbed beam processing and assembling construction process comprises steps of (1) processing the steel beam sections in a factory, cutting steel plates, carrying out bending processing to the steel plates, carrying out measuring and scribing processes, assembling the webs and the vertical stiffening plate, assembling diaphragm plates, laying flange plate positioning mechanisms, assembling the flange plates and assembling the connecting bases; and (2) assembling the curved ribbed beam, determining the splicing positions of the steel beam sections, and splicing the steel beam sections. The curved ribbed beam processing and assembling construction process has simple steps, and is reasonable in design, convenient to implement and good in usage effect, and the processing and assembling construction process of the curved ribbed beam steel structure can be completed simply and quickly in high quality.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

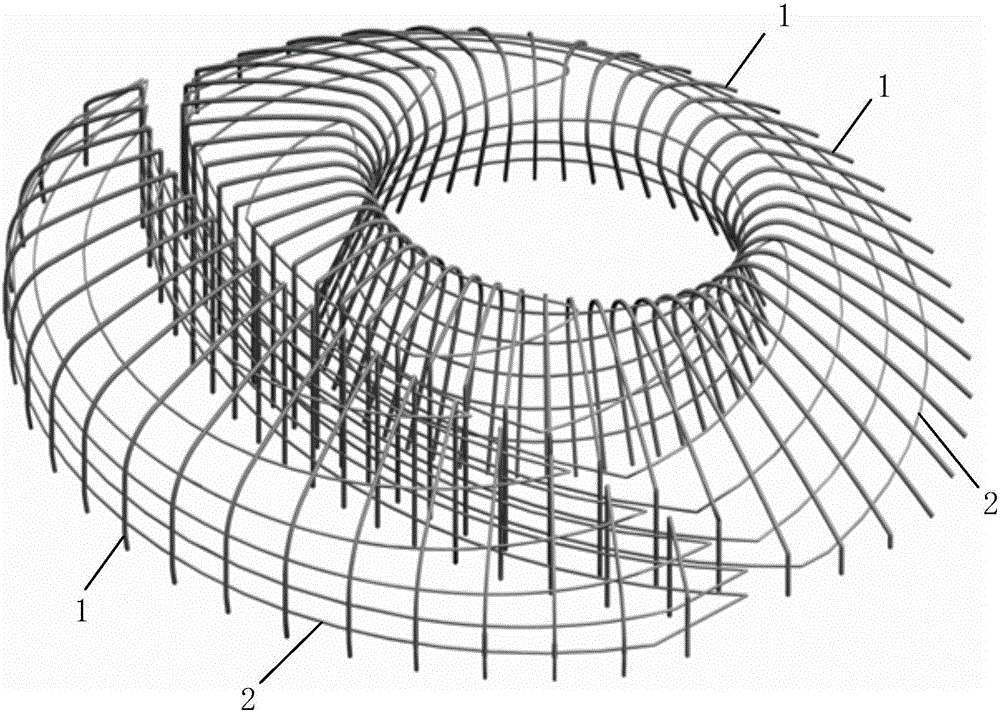

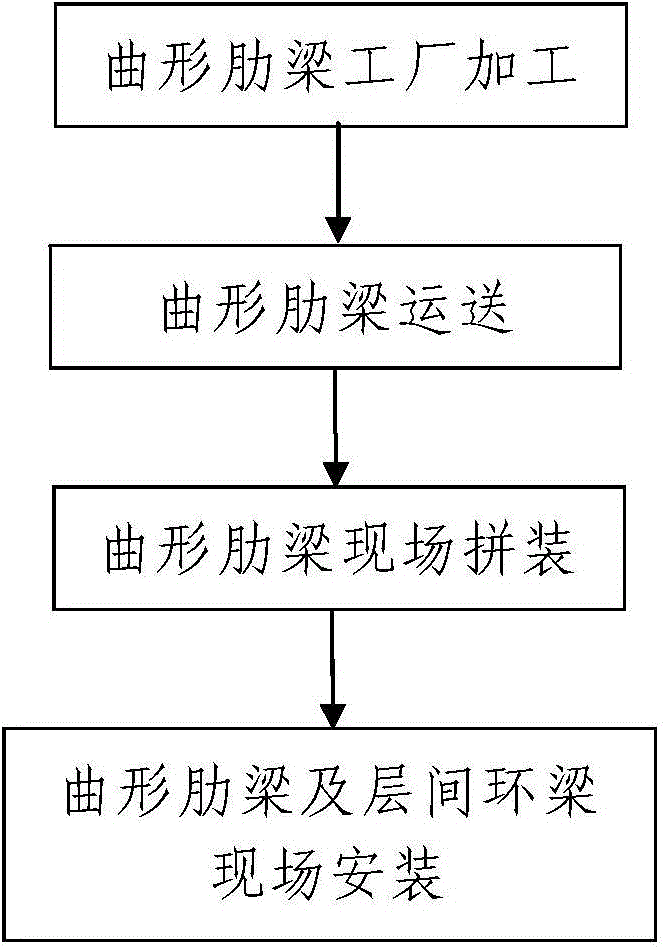

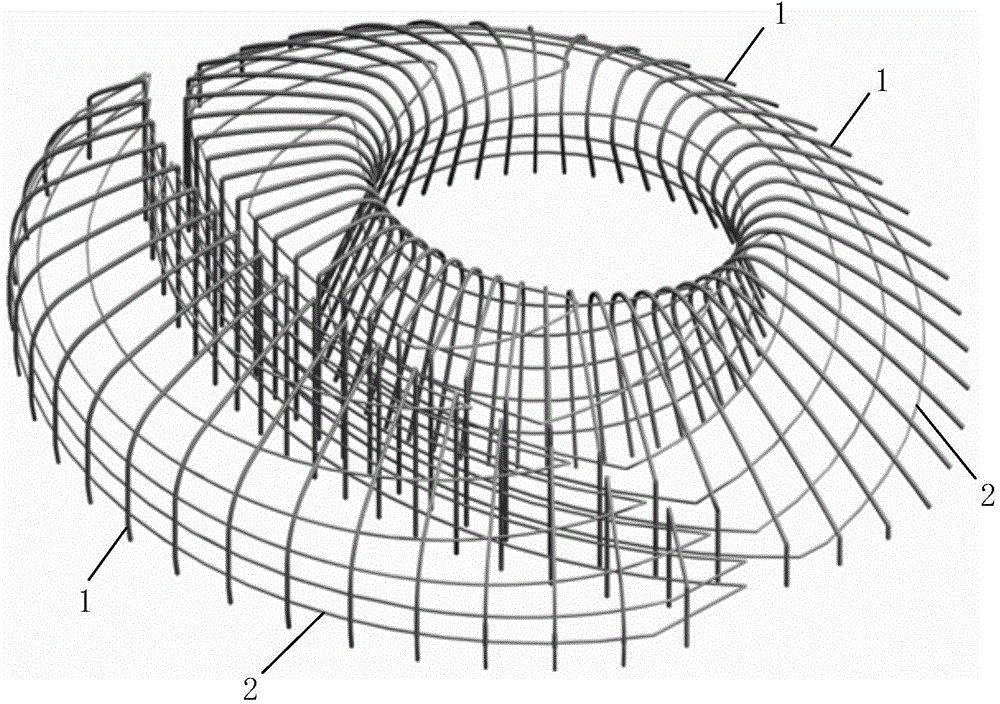

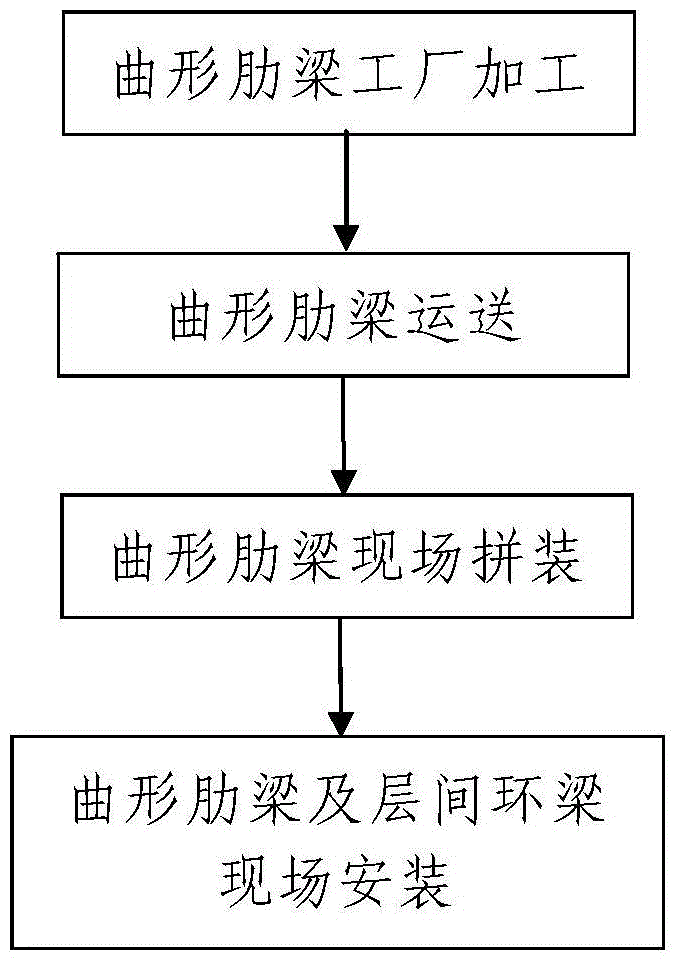

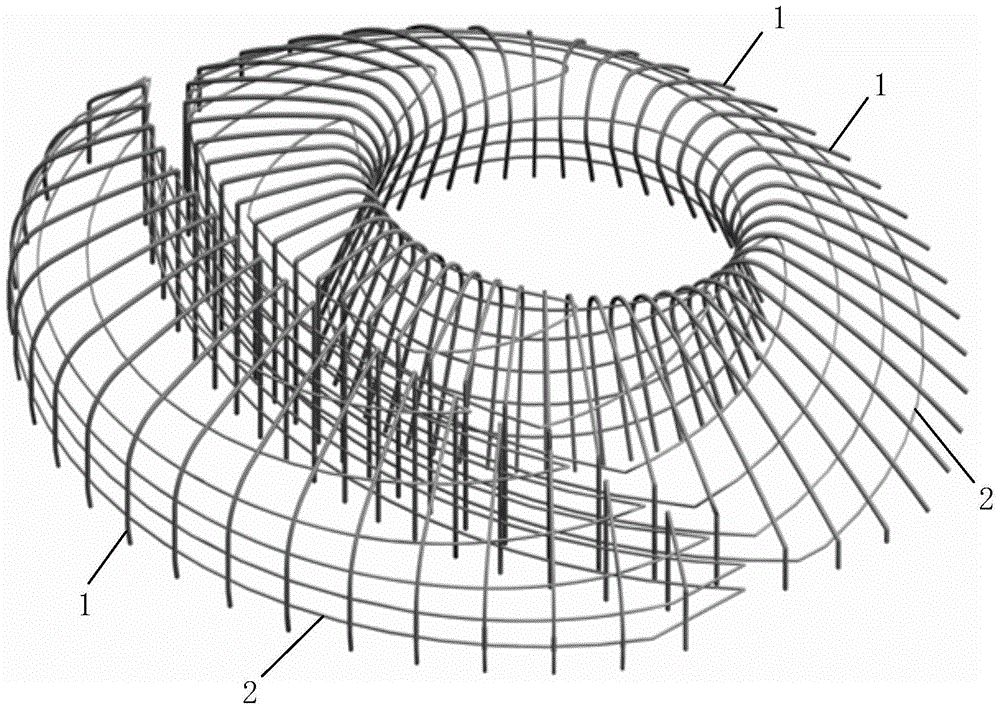

Construction method for space curved rib girder steel structure

ActiveCN104818849AThe method steps are simpleReasonable designBuilding material handlingFlangeBox girder

The invention discloses a construction method for a space curved rib girder steel structure. The constructed space curved rib girder steel structure comprises several curved rib girders distributed on a horizontal foundation from front to back; the cross section of the curved rib girders is H-shaped and its outer girder body and inner girder body are formed by splicing M steel girder sections; several curved rib girders are integrally connected by interlayer ring beams; the steel girder section comprises an upper flange plate, a lower flange plate, two webs and a longitudinal stiffening plate; and each steel girder section is provided with a connecting base. The construction process of the space curved rib girder steel structure comprises the steps: firstly, curved rib girder factory processing, processing each steel girder section of the curved rib girder; secondly, curved rib girder conveying; thirdly, curved rib girder field splicing; and fourthly, curved rib girder and interlayer ring beam field installation. The process is simple, the design is rational, the construction is convenient, and the using effect is good. The construction process of the space curved rib girder steel structure can be simply and conveniently completed, the construction process is safe and the construction period is short.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

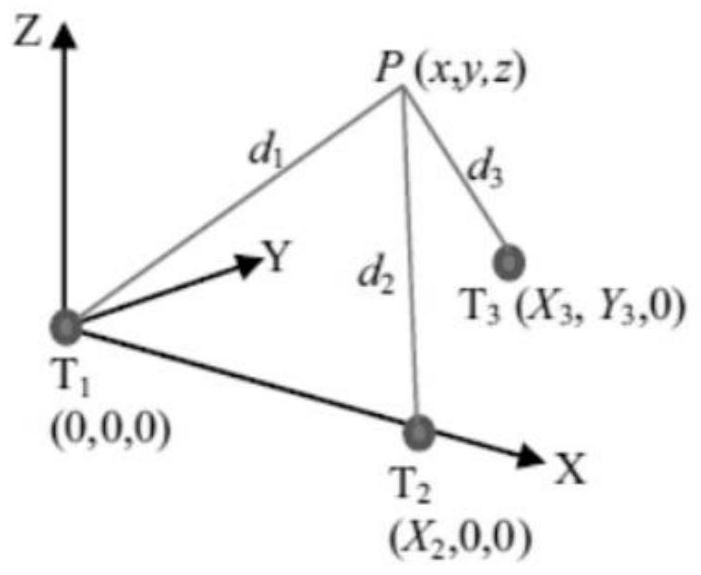

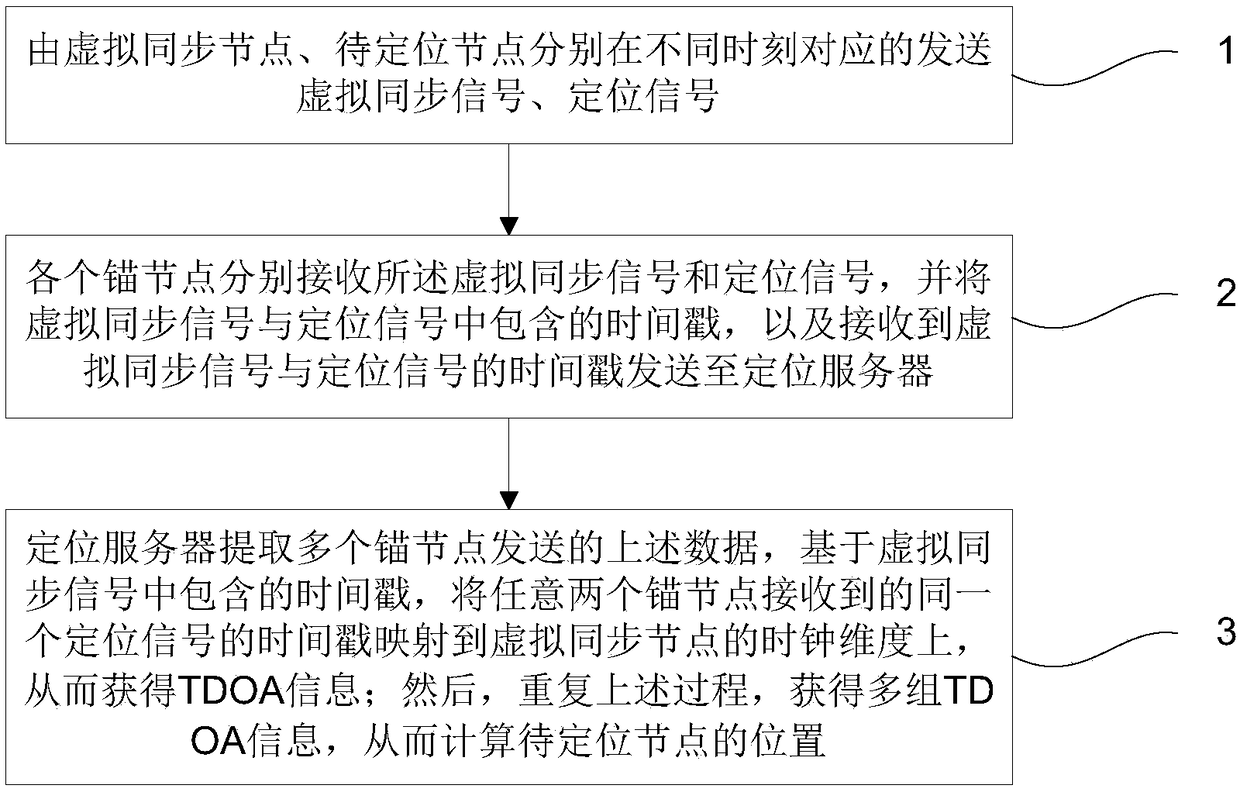

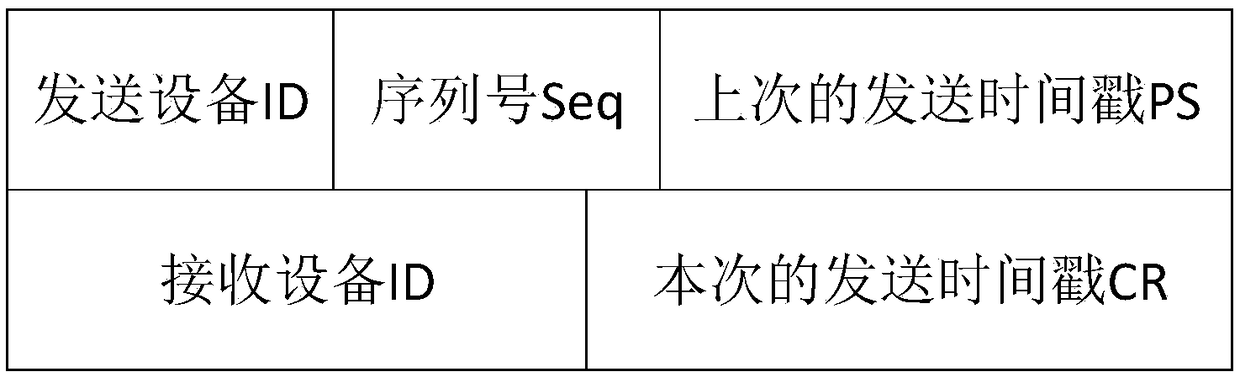

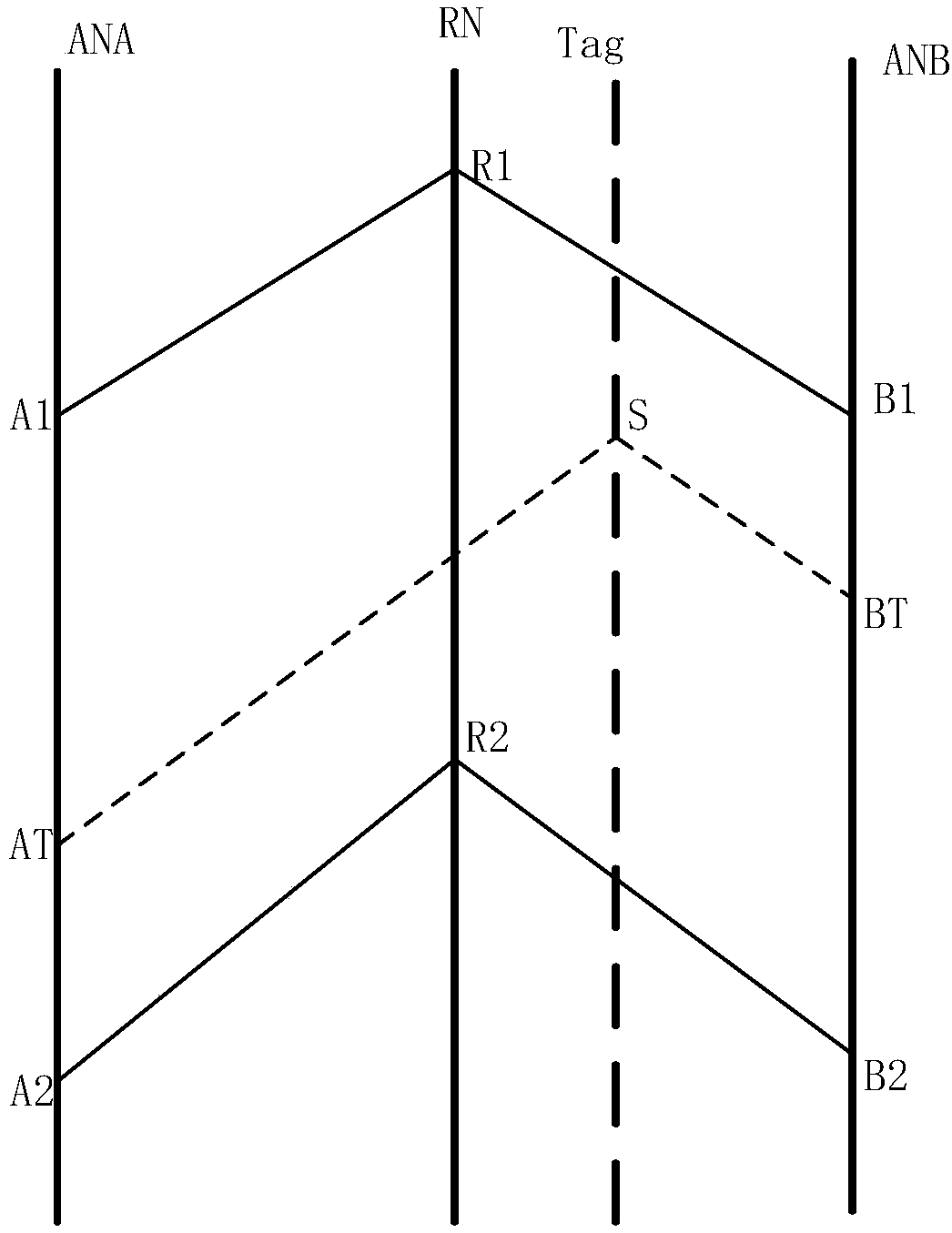

Method and system for realizing indoor positioning by using virtual time synchronization

ActiveCN108093474ASave network resourcesEliminate error accumulationSynchronisation arrangementTime-division multiplexVirtual synchronyReal-time computing

The invention discloses a method and a system for realizing indoor positioning by using virtual time synchronization. According to the invention, when positioning is carried out, hardware synchronization between anchor nodes is not needed, which saves network resources; since each time of virtual synchronization is a new start, synchronization error accumulation is eliminated, and the accuracy ofindoor positioning is improved; in addition, when virtual time synchronization is carried out, no additional equipment is required; the complexity and computational complexity of a traditional TDOA method are greatly reduced; and the cost is reduced.

Owner:重庆脉实智能制造有限公司 +1

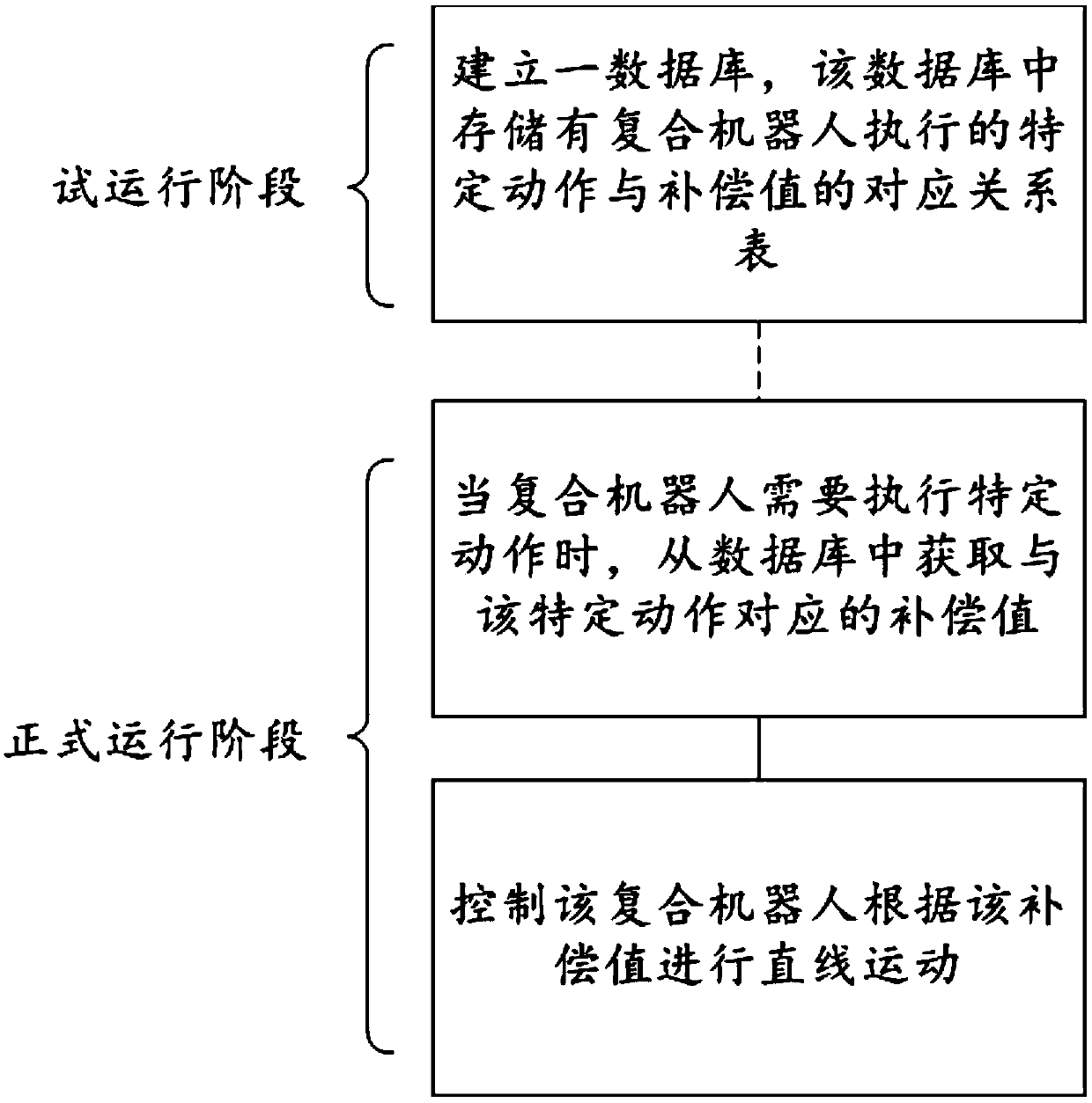

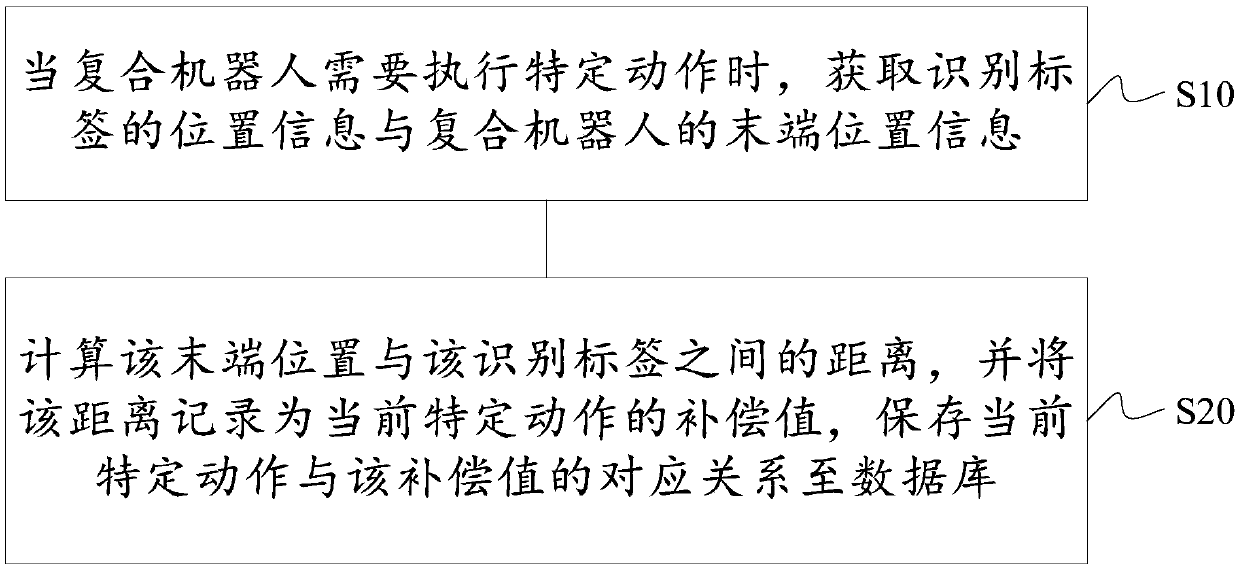

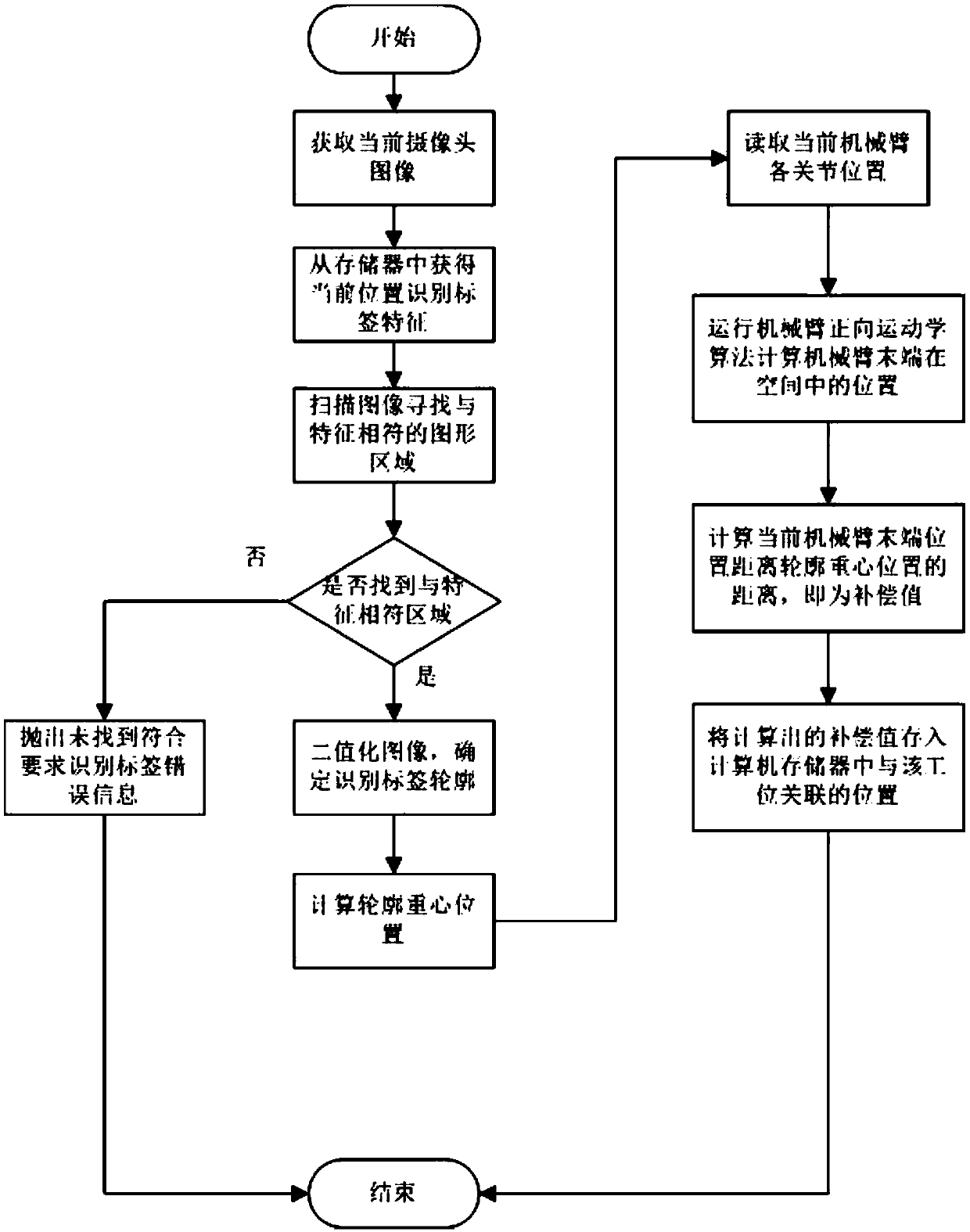

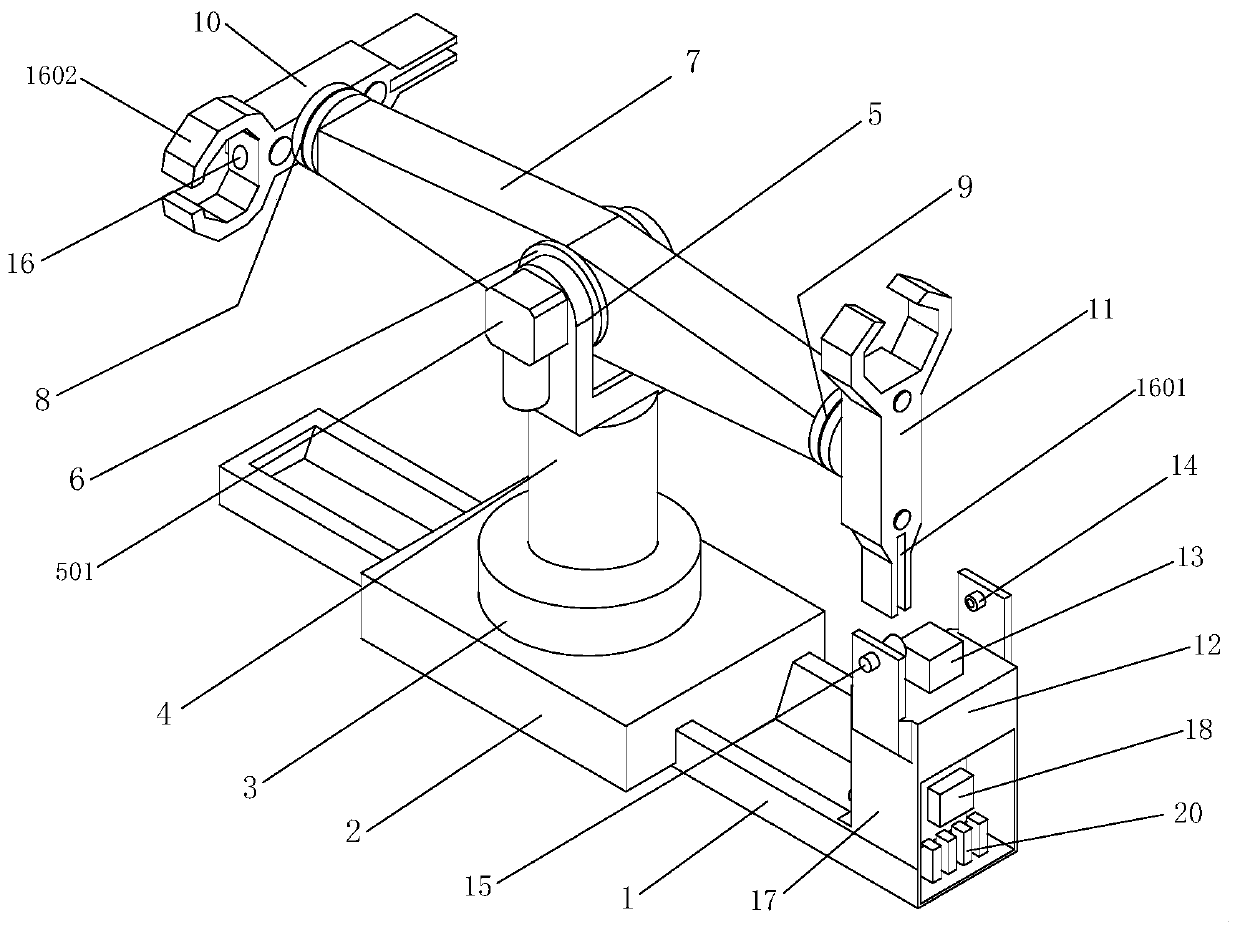

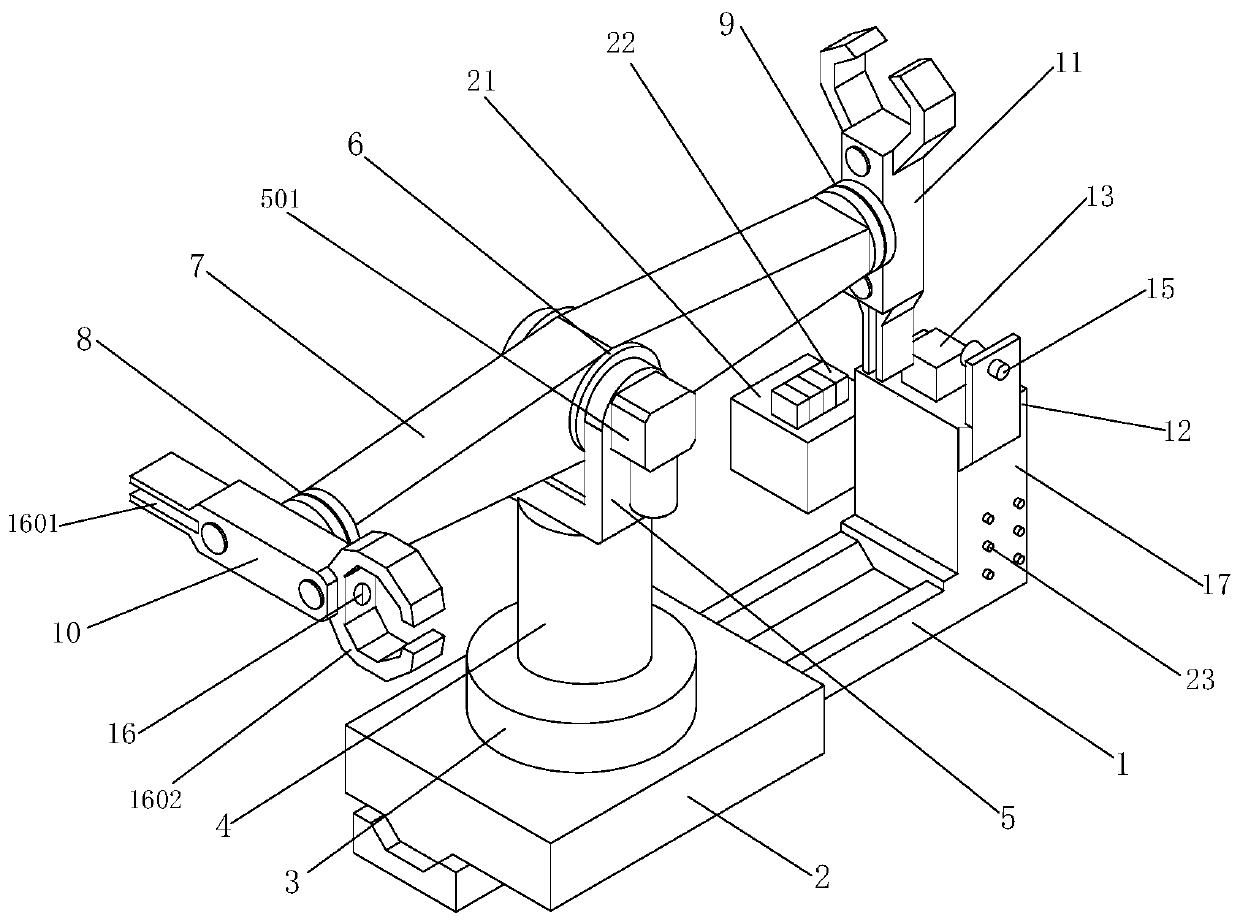

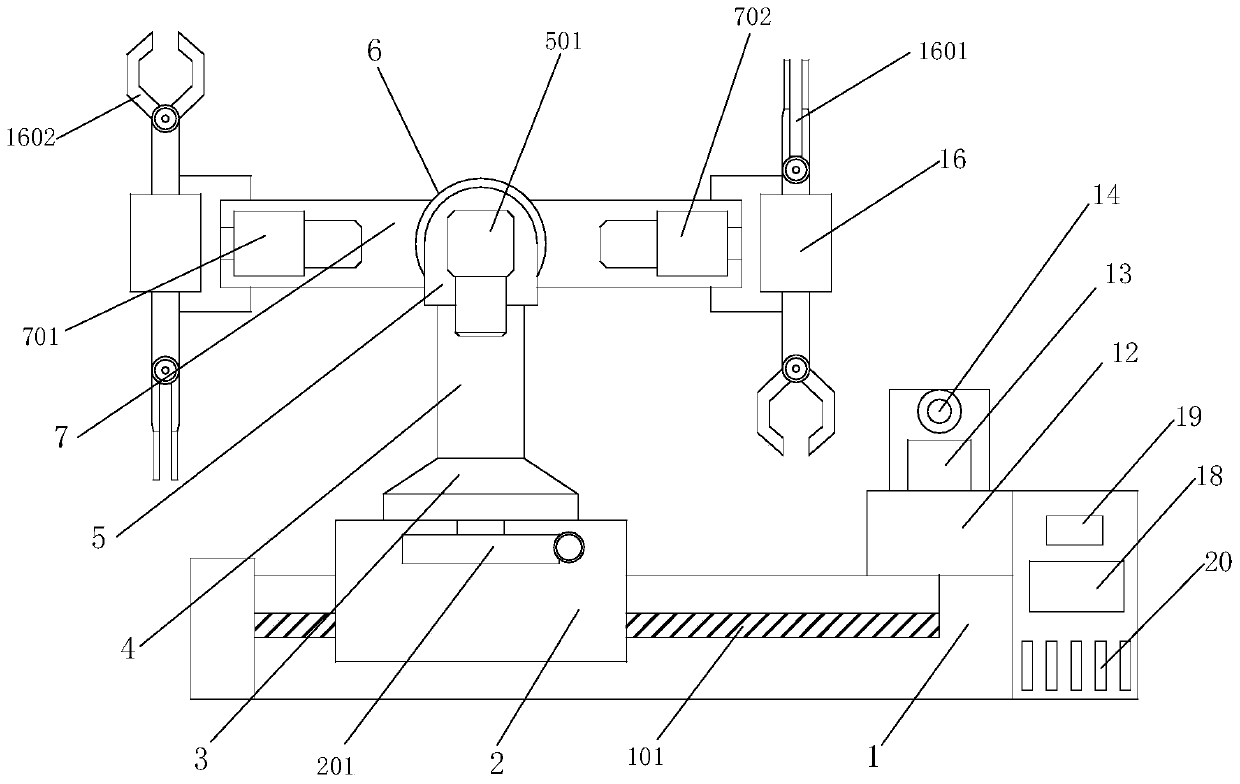

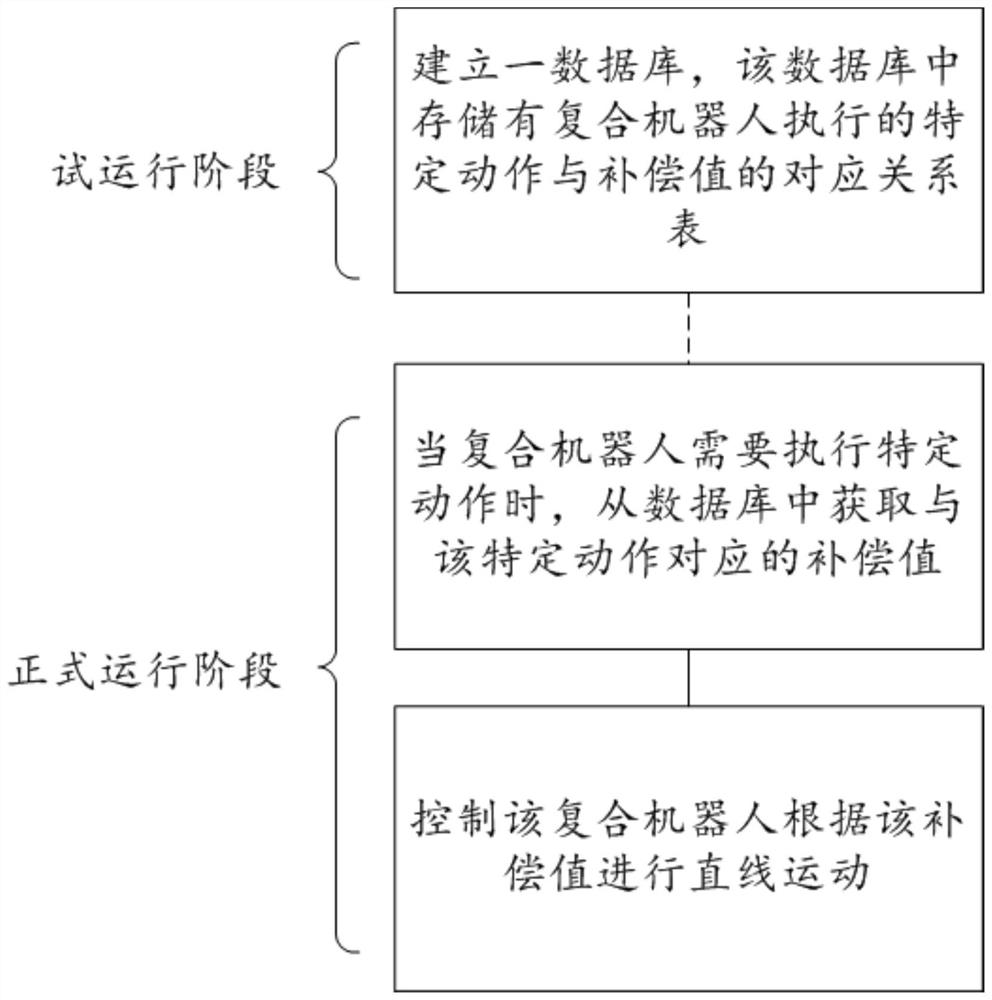

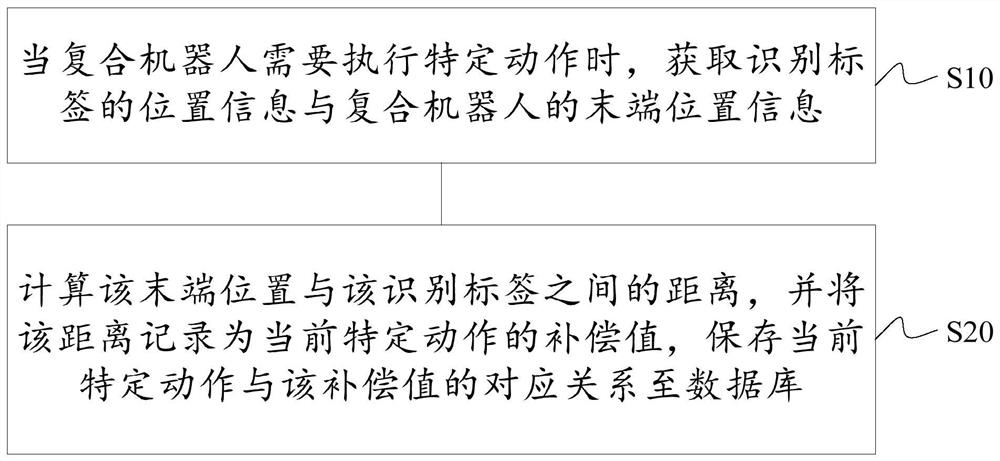

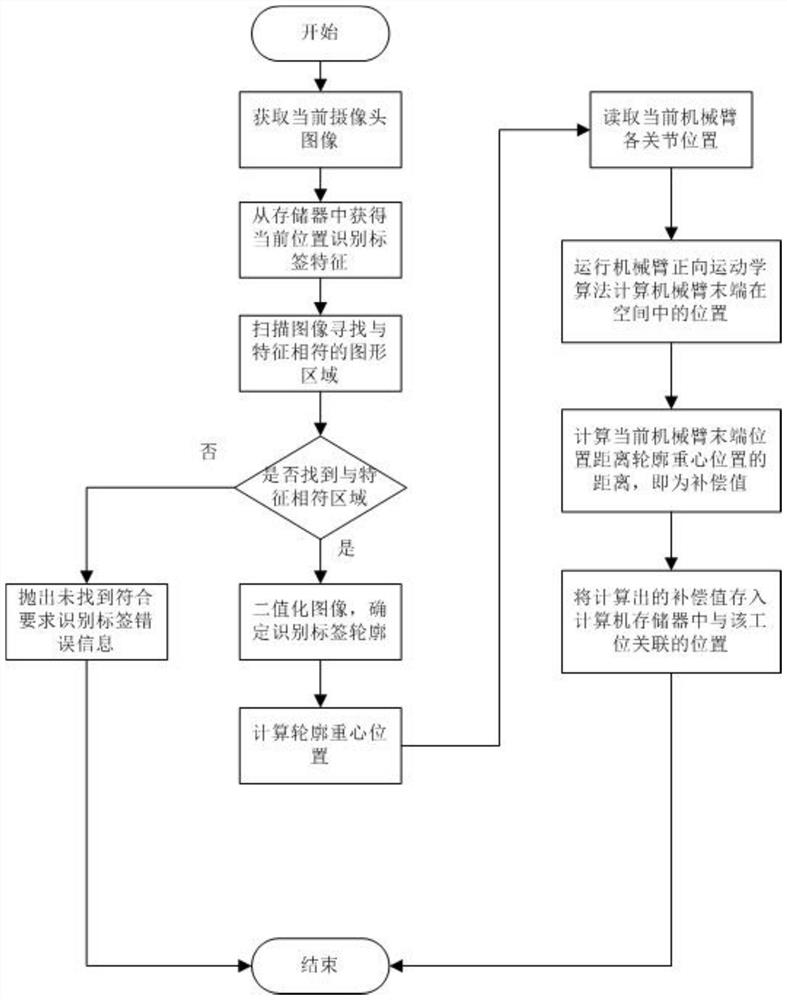

Hybrid robot working accuracy compensation method and system, and storage medium

ActiveCN109591051AEliminate error accumulationGuarantee working accuracyProgramme-controlled manipulatorEngineeringFormal verification

The invention discloses a hybrid robot working accuracy compensation method and system, and a storage medium. The method comprises two stages of trial operation and formal operation: in the trial operation stage, the method comprises the step of establishing a database, wherein a corresponding relation table between the specific actions executed by the hybrid robot and the compensation value is stored in the database; and in the formal operation stage, the method comprises the steps of acquiring a compensation value corresponding to the specific action from the database when the hybrid robot needs to perform the specific action, and controlling the hybrid robot to move linearly according to the compensation value. The accumulate error of mechanical arms caused by the sliding of an AGV baseof the hybrid robot can be overcome, and the working accuracy of the hybrid robot can be guaranteed.

Owner:上海英医达医疗器械用品有限公司

Industrial robot with self-failure detection function

ActiveCN110370318AQuick liftFacilitate modular productionProgramme-controlled manipulatorRemote controlEngineering

The invention belongs to the technical field of an industrial robot and particularly relates to an industrial robot with a self-failure detection function. The industrial robot with the self-failure detection function comprises a fixed pedestal and a horizontal swing arm; the top end of the fixed pedestal is in embedded connection with a movable sliding platform; a horizontal rotating disk is fixedly arranged at the top end of the movable sliding platform; an upright column is vertically fixed on the middle part of the top end of the horizontal rotating disk; a groove-shaped bracket is arranged at the top end of the upright column; the groove-shaped bracket is connected with the middle part of the horizontal swing arm through a clamping connection disk in the groove-shaped bracket; a firsttorsion disk and a second torsion disk are symmetrically fixed at the two ends of the horizontal swing arm; and a first work arm is fixed on the first torsion disk. An original point detection blockis provided and performs contact detection on a working part, so that error accumulation generated by the industrial robot during work is eliminated timely; meanwhile, a video recorder is provided andshoots corresponding self-detection pictures, a flaw detection machine is provided and performs flow detection operation on the internal structure of the working part, and the self-detection result is transmitted to a remote control terminal to perform real-time monitoring.

Owner:NANJING YUSHENG ROBOT CO LTD

Drive shaft assembly assembling method

InactiveCN104476103AEliminate error accumulationGuarantee the quality of dynamic balanceMetal working apparatusBalancing machineDrive shaft

The invention relates to a drive shaft assembly assembling method. The drive shaft assembly assembling method includes of step 1, assembling of a subassembly A by mounting a universal joint on a flange yoke by an extruder and workbench equipment, and mounting a universal joint yoke on the universal joint; step 2, assembling of a subassembly B by mounting a universal joint on a flange yoke by the extruder and the workbench equipment, and mounting a spline shaft yoke and a splined hub subassembly or a slide yoke and a rear shaft head subassembly on the universal joint; step 3, assembling the subassembly A, the subassembly B and a shaft tube into a drive shaft assembly by means of extrusion by the extruder and a universal fixture; step 4, straightening and welding the drive shaft assembly by a special welding machine and the universal fixture; step 5, subjecting the drive shaft assembly to dynamic balance by a balance machine and the universal fixture. By the drive shaft assembly assembling method, assembling precision and product quality of the drive shaft assembly can be improved, processing errors of parts are eliminated, labor efficiency is improved, production cycle is shortened and production cost and labor intensity are lowered.

Owner:柳州市恒力传动轴有限责任公司

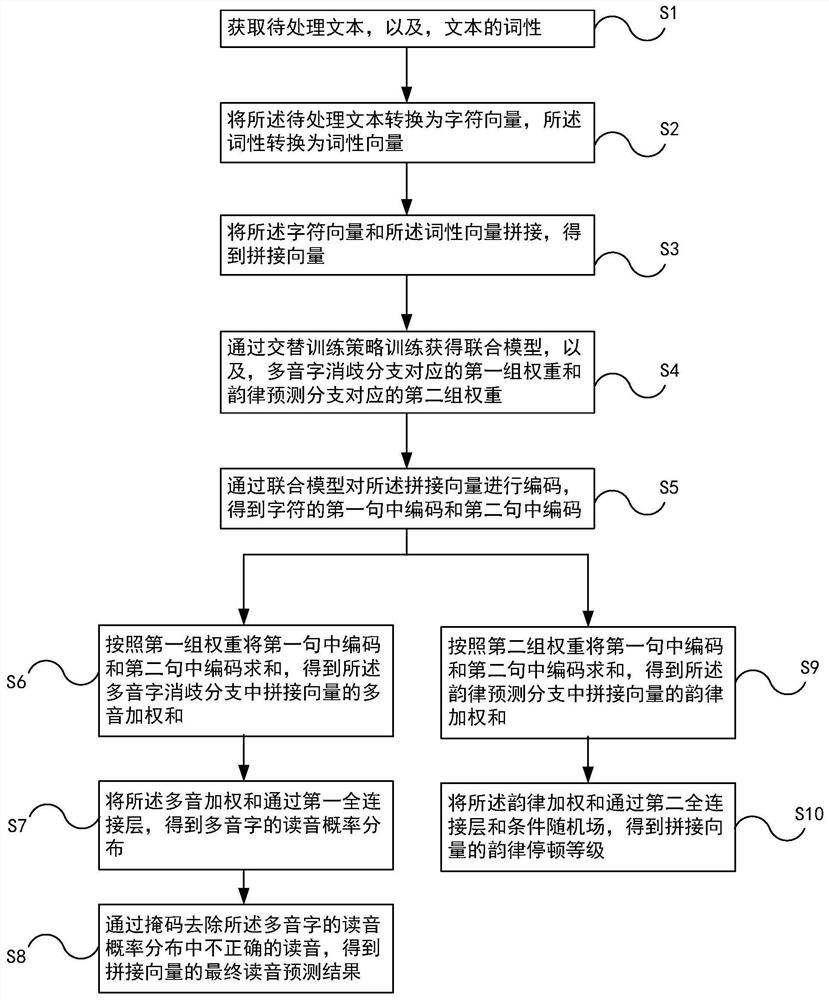

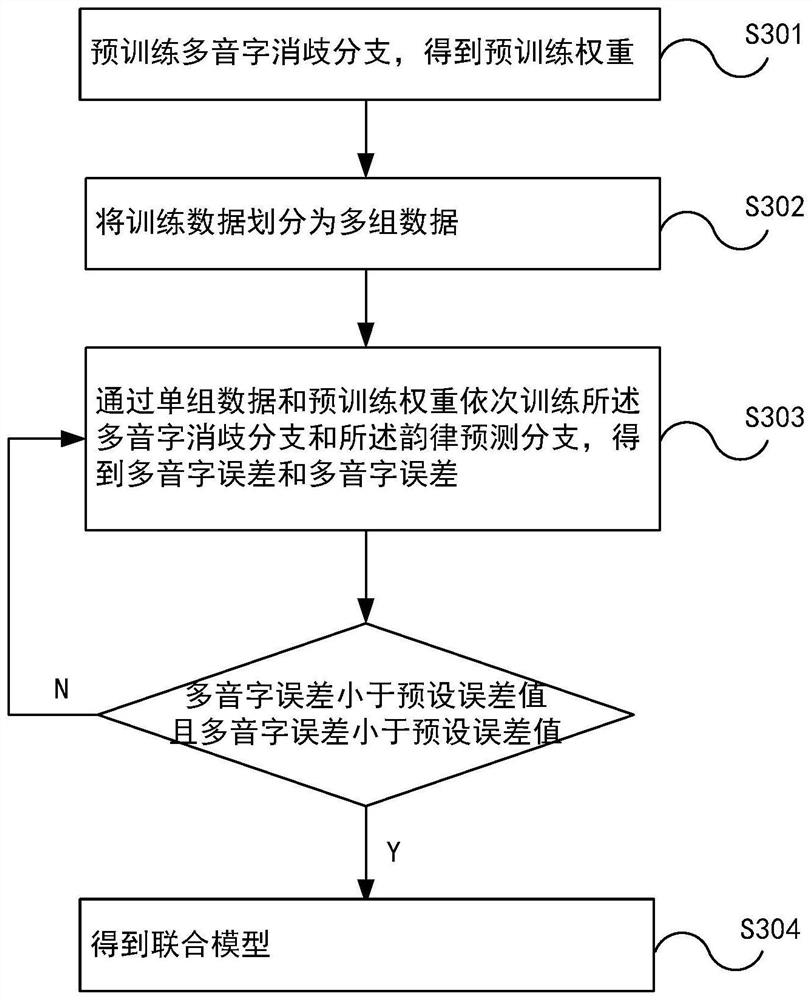

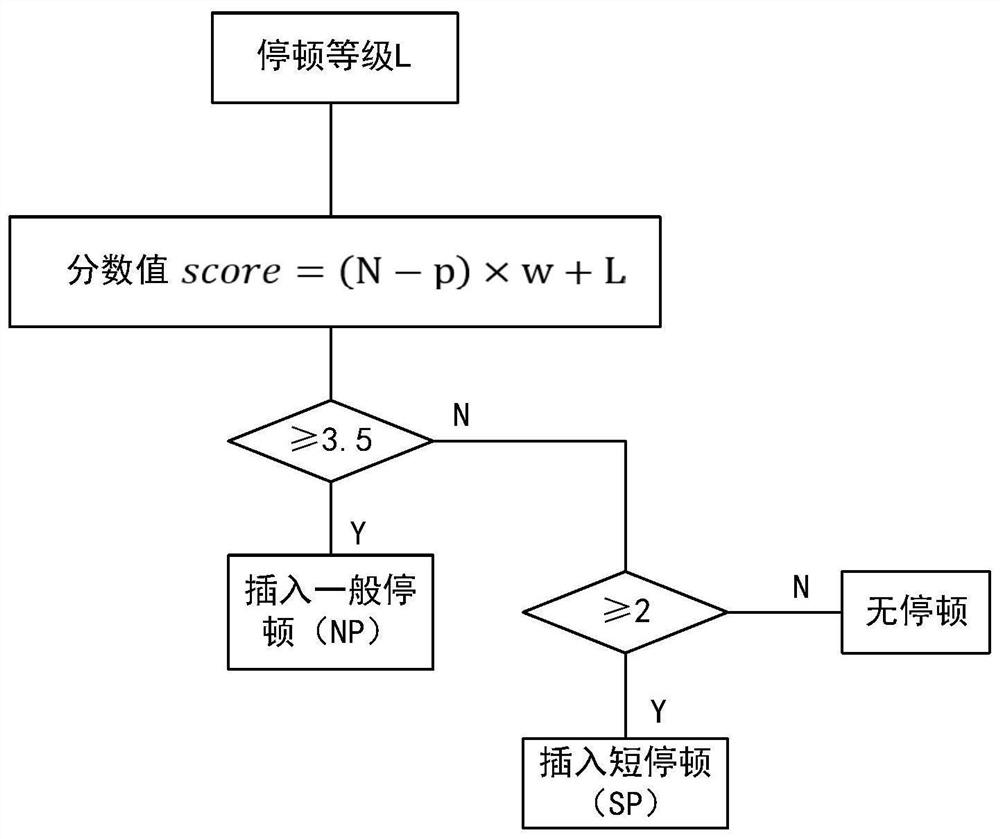

Polyphone disambiguation and rhythm control combined method and system and electronic equipment

ActiveCN113191143ACalculation speedEliminate error accumulationNatural language translationNeural architecturesConditional random fieldPart of speech

The invention provides a polyphone disambiguation and rhythm control combined method, a polyphone disambiguation and rhythm control combined system and electronic equipment. The method comprises the steps of: obtaining a to-be-processed text and part-of-speech thereof, converting the to-be-processed text and the part-of-speech thereof into a character vector and a part-of-speech vector, and splicing to obtain a spliced vector; training through an alternate training strategy to obtain a joint model, a first group of weights and a second group of weights, wherein the joint model comprises a first neural network and a second neural network, and encoding the splicing vector through the joint model to obtain a first in-sentence code and a second in-sentence code of the character; obtaining a polyphone weighted sum according to the first group of weights, and obtaining pronunciation probability distribution of polyphones through a first full connection layer; removing incorrect pronunciation in the pronunciation probability distribution of the polyphone through masks, and obtaining final pronunciation prediction; and obtaining a rhythm weighted sum according to the second group of weights, and obtaining a rhythm pause level through a second full connection layer and a conditional random field. Error accumulation caused by stream structure processing is eliminated, and the calculation speed of text-to-speech conversion is improved.

Owner:HISENSE VISUAL TECH CO LTD

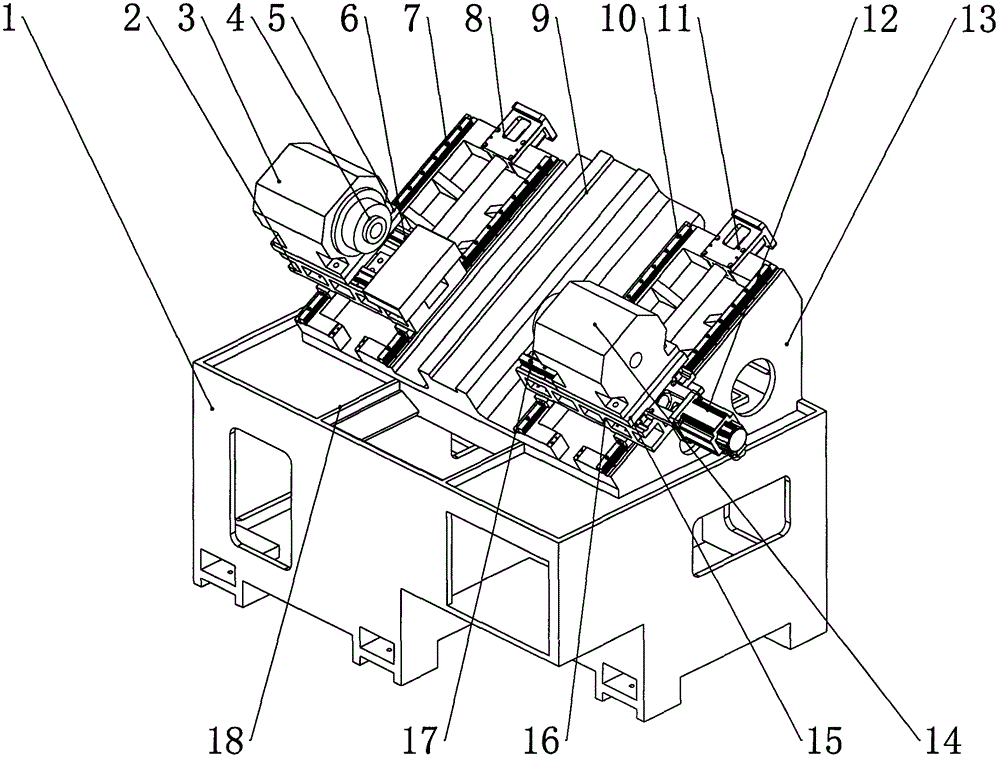

Numerically-controlled machine tool provided with double moving spindles

InactiveCN106238755AEfficient separationSave time at workLarge fixed membersMaintainance and safety accessoriesNumerical controlMachine tool

The invention relates to a numerically-controlled machine tool provided with double moving spindles. The numerically-controlled machine tool comprises a base and a tool body, wherein a spindle box and an auxiliary spindle box which are oppositely arranged are arranged on two sides of the base; a spindle is arranged on the spindle box; an auxiliary spindle is arranged on the auxiliary spindle box; the spindle box can move in the axial direction and the radial direction of the spindle on the tool body; the auxiliary spindle box can move in the axial direction and the radial direction of the auxiliary spindle on the tool body. The machine tool provided with the double spindles is adopted, the spindle box and the auxiliary spindle box which are oppositely arranged are arranged at two ends of the base, an auxiliary device or manual turning for clamping is not required, working time consumed for clamping is shortened in the aspect, and the working efficiency is improved; meanwhile, error accumulation caused by repeated clamping is eliminated, and the machining accuracy is improved; besides, both the spindle box and the auxiliary spindle box can move freely in the axial direction and the radial direction, the time for moving between the spindles is shortened, and the machining efficiency is further improved. The machine tool is suitable for large-scale popularization.

Owner:钟胜

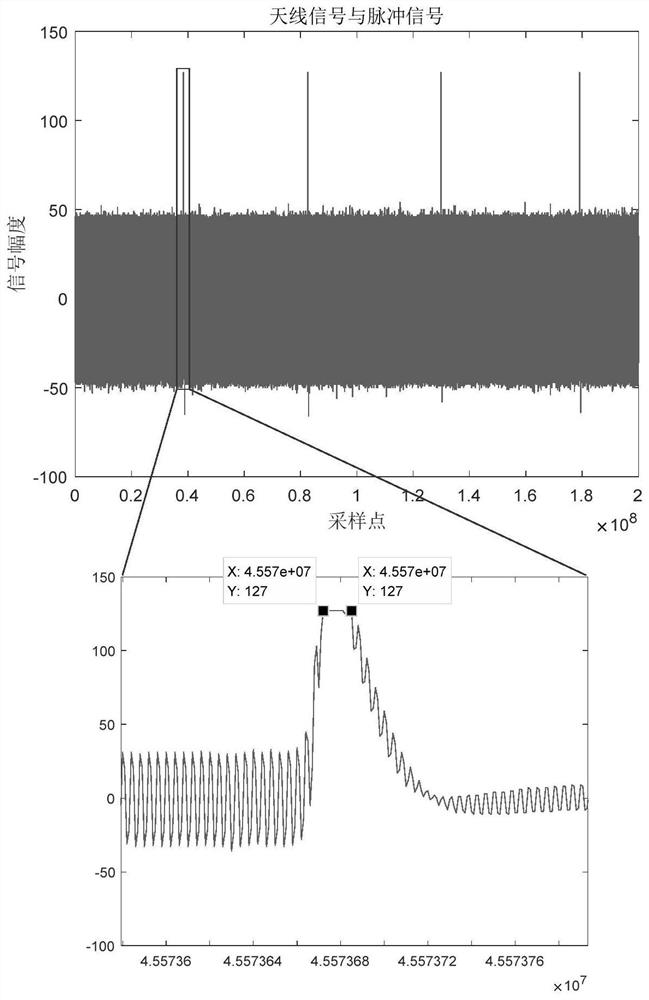

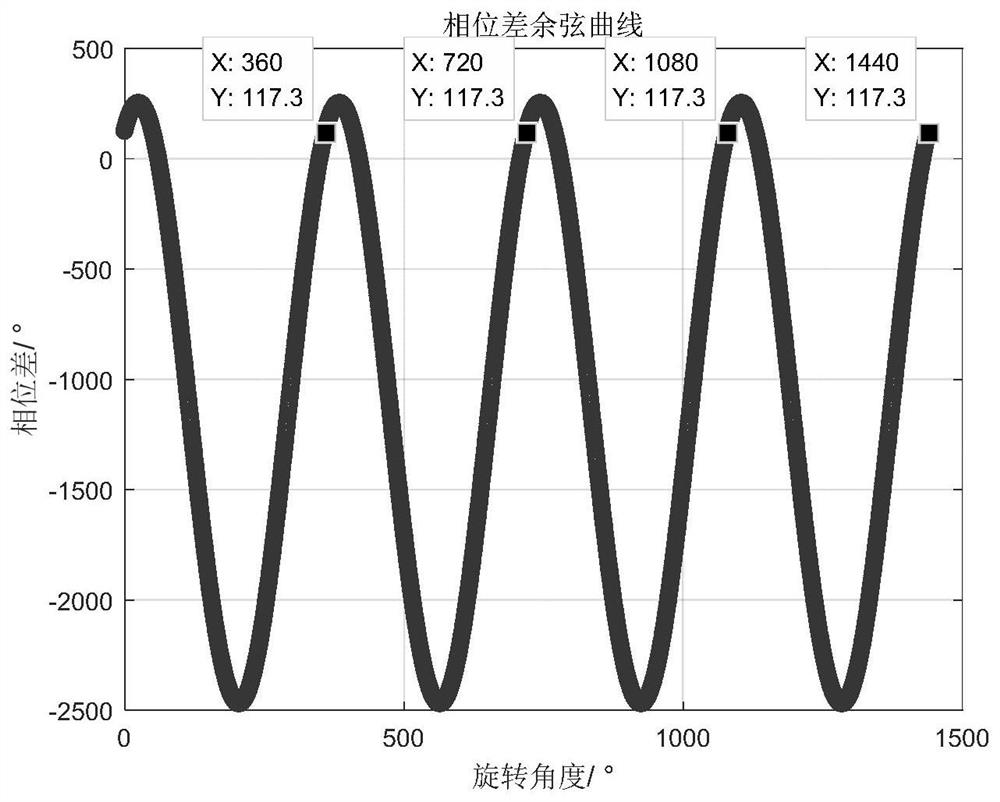

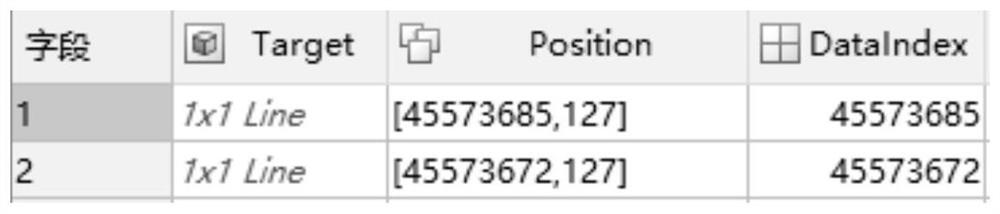

Pulse signal-based rotating baseline interferometer phase calibration method

ActiveCN113552534AEliminate error accumulationEliminate Azimuth OffsetRadio wave direction/deviation determination systemsData acquisitionPhysics

According to the pulse signal-based rotating baseline interferometer phase calibration method provided by the invention, angle measurement error accumulation can be eliminated, the system angle measurement accuracy is improved, and the minimum error of an angle measurement result is ensured. Under the condition that the baseline rotation speed is set to be one circle per second, aiming at the problem that error accumulation is easily caused by a traditional method that data are continuously collected after a pulse signal is searched for the first time, angle measurement error accumulation is eliminated by searching the pulse signal of the rotating baseline phase interferometer once every two seconds, and the angle measurement accuracy of a system is improved; and aiming at the problem of angle measurement errors caused by the fact that the initial time of data acquisition is possibly in the middle of pulse signals when the pulse signals are searched for each time in the traditional method of acquiring data in one second when the pulse signals are searched for each time, azimuth angle deviation is eliminated by searching the pulse signals of the rotating baseline phase interferometer once every two seconds, and the minimum error of an angle measurement result is ensured.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Compensation method, system and storage medium for compound robot operation accuracy

ActiveCN109591051BEliminate error accumulationGuaranteed working accuracyProgramme-controlled manipulatorSimulationControl theory

The invention discloses a compound robot operation accuracy compensation method, system and storage medium, wherein the method includes two stages of trial operation and formal operation: in the trial operation stage, it includes: establishing a database, the database stores the Correspondence table between the specific actions performed by the compound robot and the compensation values; in the formal operation stage, including: when the compound robot needs to perform a specific action, obtain the compensation value corresponding to the specific action from the database; control the compound robot to perform a straight line according to the compensation value sports. The invention can overcome the error accumulation of the mechanical arm caused by the sliding of the AGV base of the composite robot, and ensure the operation accuracy of the composite robot.

Owner:上海英医达医疗器械用品有限公司

A construction method of space curved rib beam steel structure

ActiveCN104818849BThe method steps are simpleReasonable designBuilding material handlingFlangeBuilding construction

The invention discloses a construction method for a space curved rib girder steel structure. The constructed space curved rib girder steel structure comprises several curved rib girders distributed on a horizontal foundation from front to back; the cross section of the curved rib girders is H-shaped and its outer girder body and inner girder body are formed by splicing M steel girder sections; several curved rib girders are integrally connected by interlayer ring beams; the steel girder section comprises an upper flange plate, a lower flange plate, two webs and a longitudinal stiffening plate; and each steel girder section is provided with a connecting base. The construction process of the space curved rib girder steel structure comprises the steps: firstly, curved rib girder factory processing, processing each steel girder section of the curved rib girder; secondly, curved rib girder conveying; thirdly, curved rib girder field splicing; and fourthly, curved rib girder and interlayer ring beam field installation. The process is simple, the design is rational, the construction is convenient, and the using effect is good. The construction process of the space curved rib girder steel structure can be simply and conveniently completed, the construction process is safe and the construction period is short.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Fixture for end-tooth flange york boring lug hole and vehicle clamp spring groove and machining technology achieved by means of fixture

ActiveCN106736652AHigh dimensional accuracyGuaranteed accuracyWork clamping meansPositioning apparatusDrive shaftEngineering

The invention discloses a fixture for an end-tooth flange york boring lug hole and a vehicle clamp spring groove and a machining technology achieved by means of the fixture. The fixture comprises a fixture body, a positioning disc and a hydraulic clamping mechanism; the machining technology comprises the step that the machining procedures of the end-tooth flange york boring lug hole and the vehicle clamp spring groove are both positioned through end face teeth arranged on the bottom face of an end-tooth flange york and end face teeth of the fixture positioning disc. Accordingly, in the machining process of the end-tooth flange york lug hole of a transmission shaft, two original tedious positioning steps are reduced into one precise positioning process, two machining machine tools are reduced into one machine tool, therefore, the production efficiency is improved, and the production cost is reduced.

Owner:XUCHANG YUANDONG DRIVE SHAFT

A Time Acquisition Method with Adjustable Precision Based on Second Pulse

ActiveCN109617641BEliminate error accumulationTime-division multiplexComputer hardwareTime information

A method for obtaining time with adjustable precision based on second pulses is provided, wherein: the PPC processor receives the UTC time information sent by the GPS receiver, and obtains the hour, minute, and second data synchronized with the GPS after solving; the PPC processor Generate accuracy information, and pass the data and accuracy information obtained after the calculation to the FPGA clock acquisition unit; the FPGA clock acquisition unit receives the local clock signal from the local clock source and the PPS signal from the GPS receiver. Calibrate the received data of hours, minutes, seconds and seconds; the FPGA clock acquisition unit sends the calibrated data of hours, minutes, seconds and seconds back to the PPC processor through the LBC bus to realize the calibration of data below seconds. The time precision configuration of this method is flexible, and the acquisition time precision is high.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

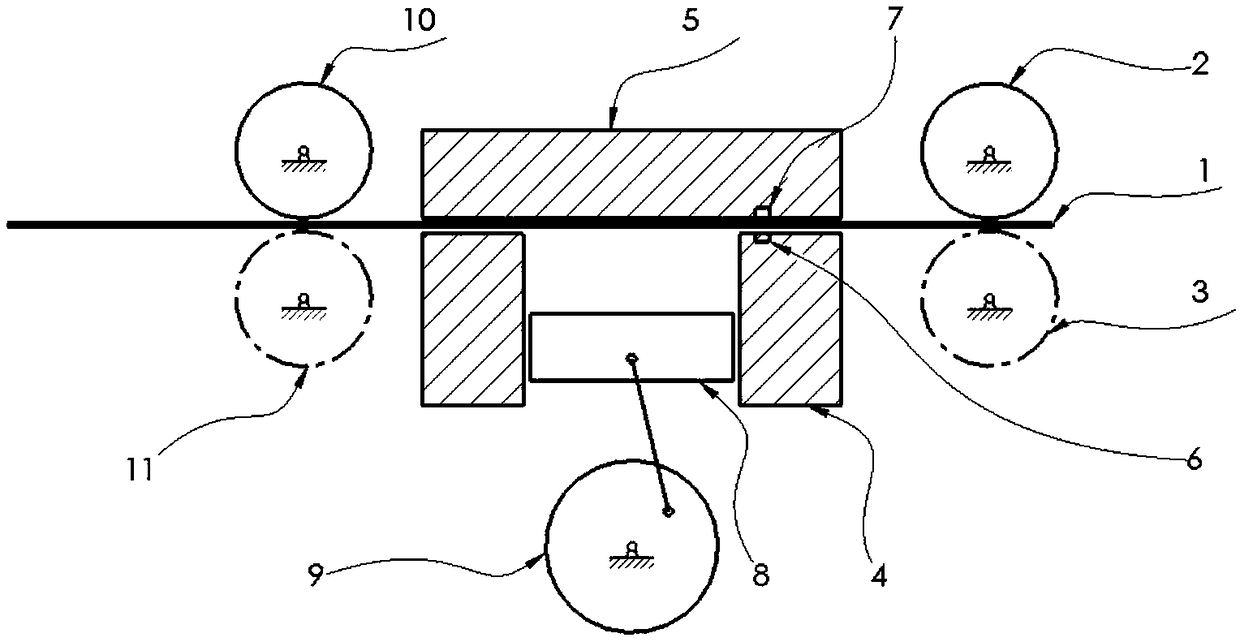

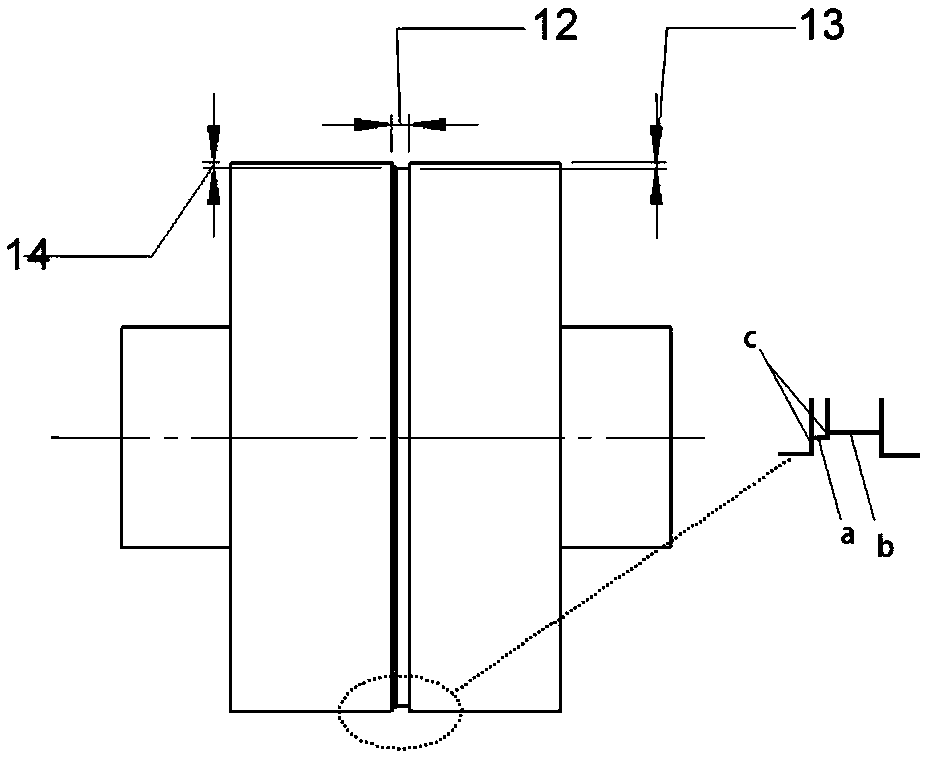

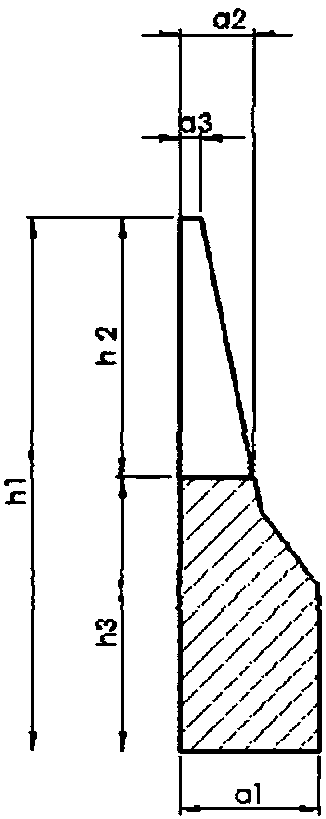

Device and method for manufacturing staggered cylinder metal card clothing

ActiveCN108221095AEliminate error accumulationAvoid misalignment and bad teeth phenomenonCarding machinesElectronic control unitMechanical engineering

The invention discloses a device and method for manufacturing staggered cylinder metal card clothing. The device comprises two pairs of vertically distributed pressing rollers and a squeezing box located between the two pairs of pressing rollers. The squeezing box comprises an upper pressing plate, a lower pressing plate and a positioning base. Grooves are formed around the circumferences of the upper pressing rollers of the two pairs of pressing rollers. A groove channel is formed in the lower pressing plate and internally provided with a plurality of protruding blocks for squeezing needle teeth. The opposite faces of the upper pressing plate and the positioning base are provided with a transmitting end and a receiving end of a photoelectric sensor respectively. A counter is installed inthe positioning base. The counter, the two pairs of pressing rollers and a mechanism which is used for driving the lower pressing plate to move up and down are connected with an electronic control unit. The manufacturing method includes the step that after being fed from one pair of vertically distributed pressing rollers into the squeezing box for staggered rolling, a rack is output by the otherpair of vertically distributed pressing rollers to prepare the staggered cylinder metal card clothing. By means of the device and method, the error accumulation of the pitch of teeth is eliminated, tooth staggering and breakage phenomena are effectively avoided, and the produced card clothing is excellent in quality and has great application prospects.

Owner:DONGHUA UNIV +1

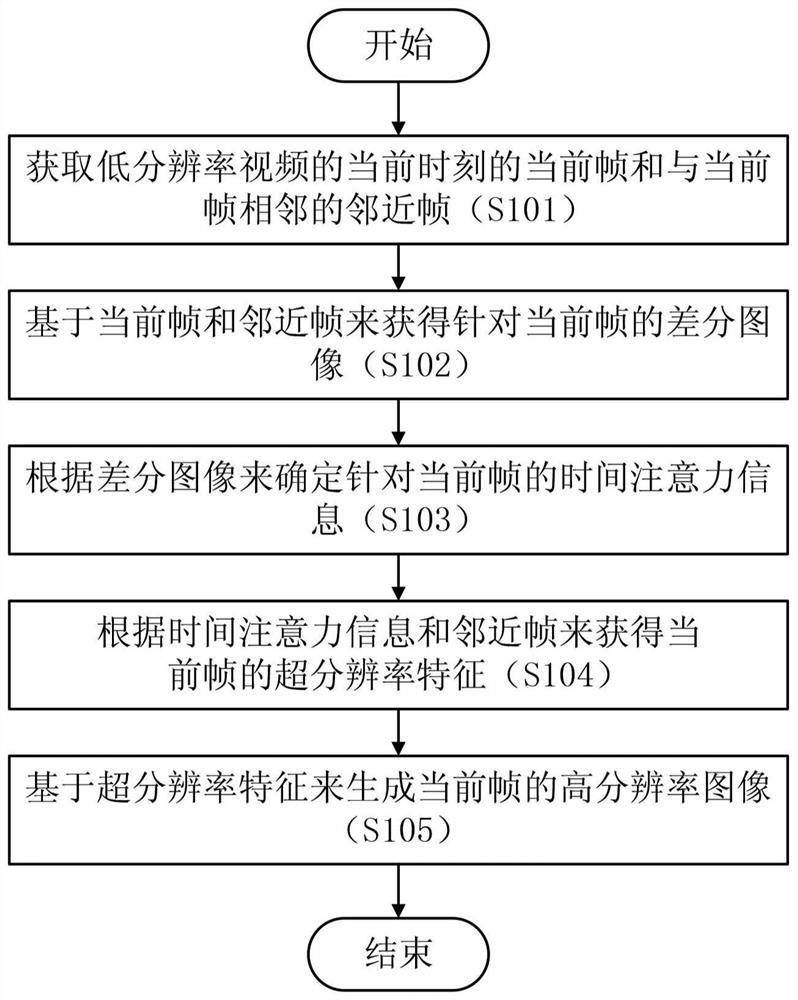

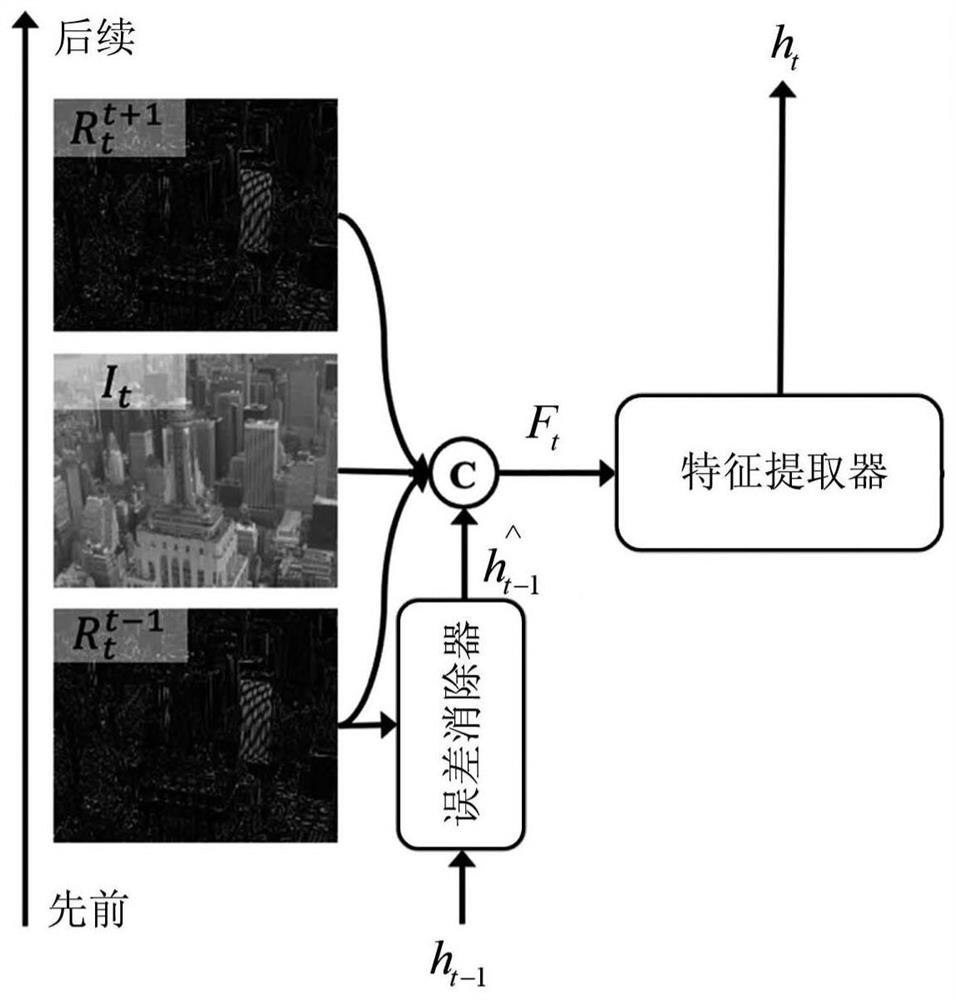

Video processing method and video processing device

PendingCN113610031AEfficient extractionEliminate error accumulationGeometric image transformationCharacter and pattern recognitionComputer graphics (images)Image resolution

The invention provides a video processing method and a video processing device. The video processing method comprises the following steps: acquiring a current frame of a low-resolution video at a current moment and an adjacent frame adjacent to the current frame; obtaining a difference image for the current frame based on the current frame and the adjacent frame; determining time attention information for the current frame according to the difference image, wherein the time attention information represents image feature information concerned by the current frame relative to the adjacent frame; obtaining super-resolution characteristics of the current frame according to the time attention information and the adjacent frame; and generating a high-resolution image of the current frame based on the super-resolution feature.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com