Ignition advancer and advance angle control optimization method of oil/CNG double-fuel engine

A dual-fuel engine, ignition advance angle technology, applied in the direction of automatic control, automatic control, electrical automatic control, etc., can solve the problems that cannot be adjusted, the angle is fixed, and cannot be adjusted, so as to improve reliability and eliminate error accumulation , Improve the effect of position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

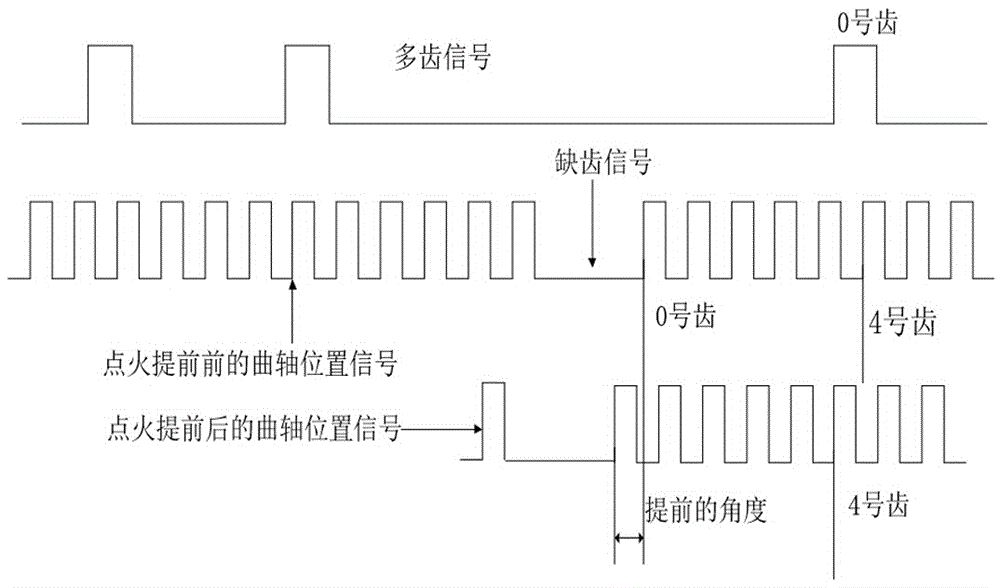

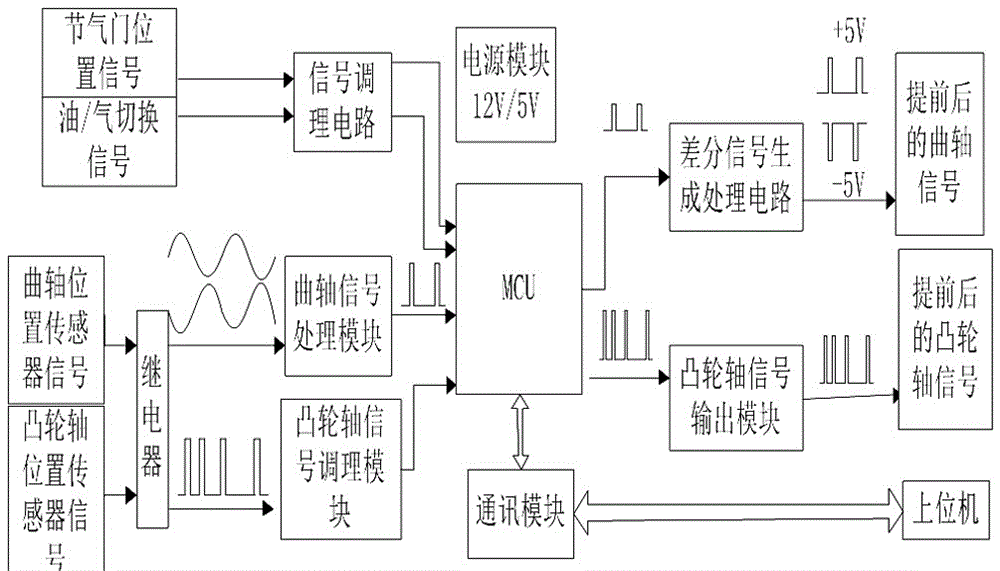

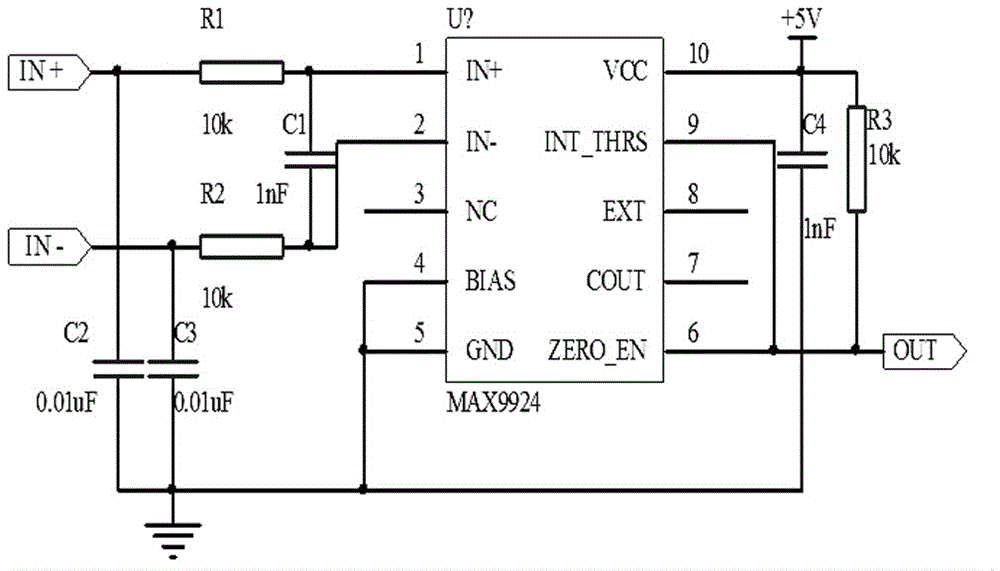

[0032] Attached below figure 1 ~9 and the specific implementation manner further describe the present invention in detail.

[0033] In the prior art, the engine crankshaft position sensor is generally a magnetoelectric sensor, which outputs two sine wave differential signals with different levels and frequencies according to the engine speed; the camshaft position sensor is a Hall sensor, which outputs a 5V TTL signal . When the ECU of the original machine is working, the synchronization is realized according to the characteristic teeth of the camshaft position sensor input signal and the characteristic teeth of the crankshaft position sensor input signal. After synchronization, the ignition advance angle is calculated from the value queried by MAP according to the existing algorithm to trigger ignition at a certain position of the crankshaft signal.

[0034] When the ignition advancer is working, the two crankshaft position signals, throttle position signal, camshaft positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com