A construction method of space curved rib beam steel structure

A technology for steel structure construction and steel structure, which is applied in building construction, construction, and building materials processing, etc., and can solve the problems of difficult to guarantee processing quality, difficult construction, and inconvenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

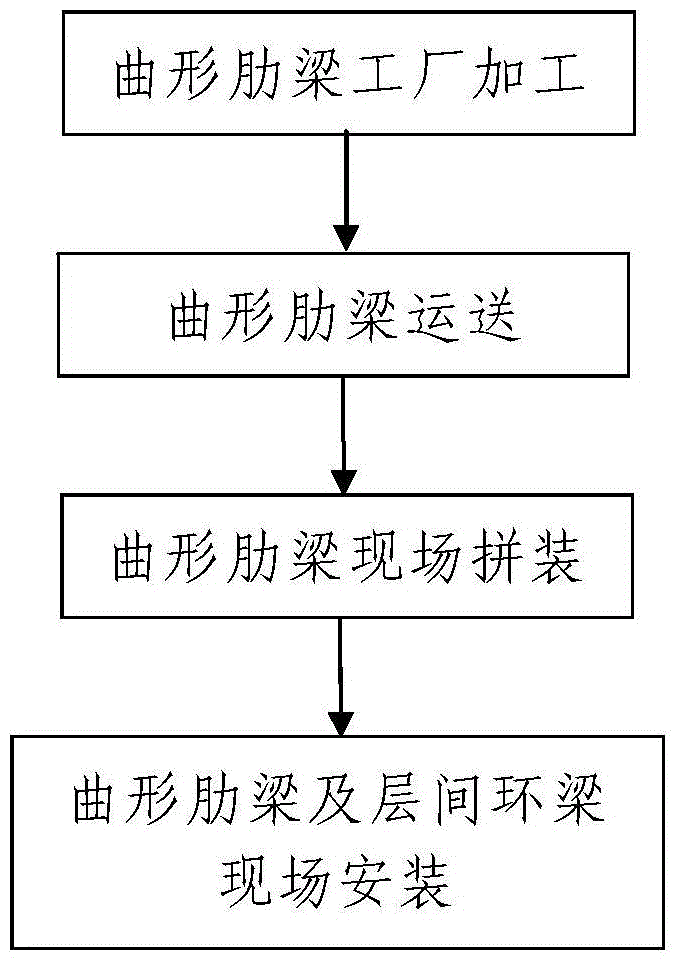

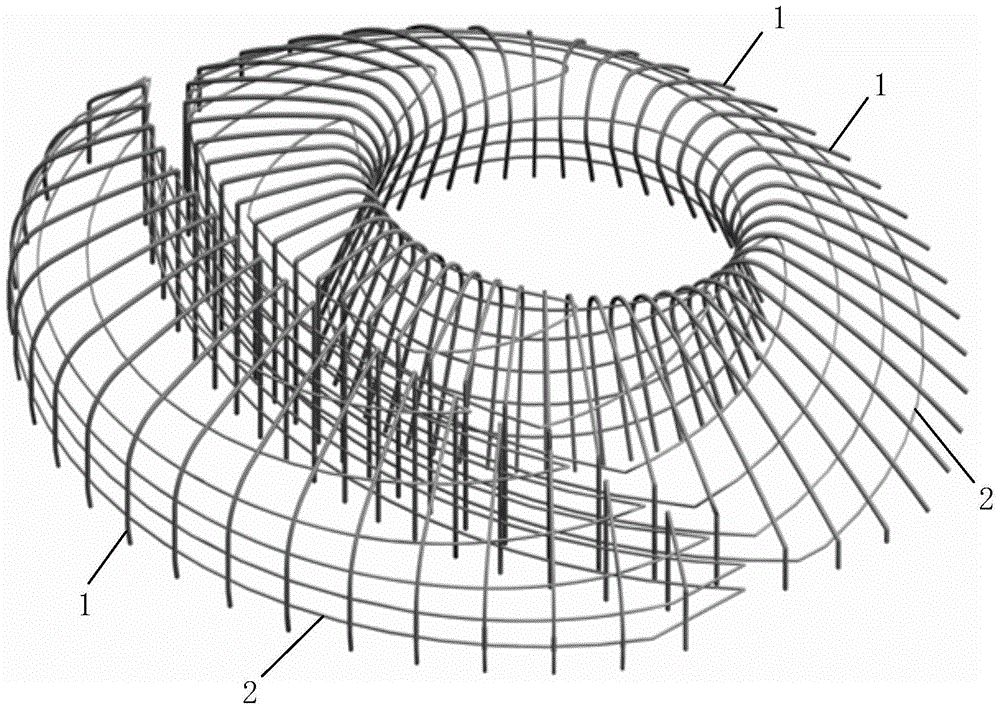

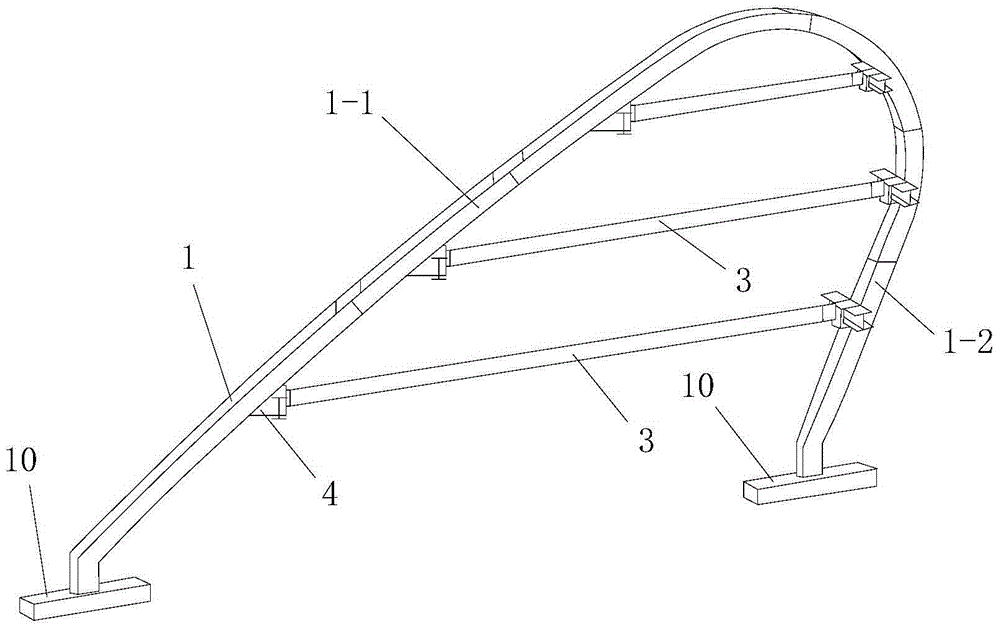

[0097] Such as figure 1 A construction method of a space curved rib beam steel structure is shown. The space curved rib beam steel structure to be constructed includes multiple curved rib beams 1 arranged on a horizontal foundation from front to back, and multiple curved rib beams 1 1 have the same structure, the curved ribbed beam 1 is a curved steel beam and its cross-sectional shape is Japanese-shaped, see figure 2 ; combine image 3 , each said curved rib beam 1 is spliced by the outer beam body 1-1 and the inner beam body 1-2 located inside the outer beam body 1-1, and the outer beam body 1-1 and the inner beam body Between 1-2, the tension beam 3 arranged from top to bottom through M channels is fastened and connected as a whole, and the tension beam 3 is a linear steel beam; the outer beam body 1-1 and the inner beam body 1-2 The bottoms are all supported on the horizontal foundation and the tops of the two are fastened and connected as a whole; the multiple curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com