Fixture for end-tooth flange york boring lug hole and vehicle clamp spring groove and machining technology achieved by means of fixture

A flanged fork and end tooth technology is applied in the field of end tooth flanged fork boring ear holes, clamps for car spring grooves and their processing technology, which can solve the problems affecting the initial dynamic balance value of assembly and dynamic balance, and the tolerance of ear hole shape and position. Over-tolerance, uneven distance between spring grooves, etc., to ensure the quality of dynamic balance, ensure the accuracy of parts, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

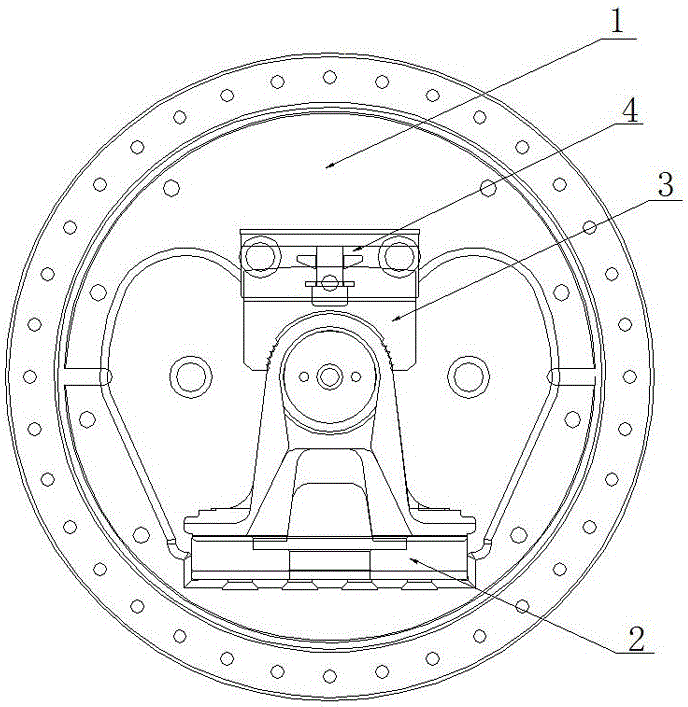

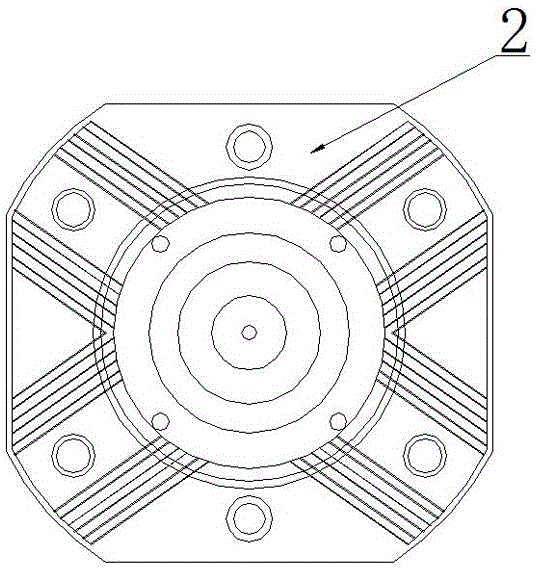

[0015] As shown in the figure, a jig for boring ear holes of end-toothed flange forks, car circlip grooves and its processing technology, the jig includes a jig body 1, a positioning plate 2 and a hydraulic clamping mechanism, and the jig body 1 is a middle axial A cylinder with a through hole, the bottom of the through hole of the clamp body 1 is provided with a groove for installing the positioning disc 2, and the positioning disc 2 for placing the flange fork to be processed is fixed in the groove of the clamp body 1 by screws, The upper surface of the positioning disc 2 is provided with end face teeth adapted to the bottom of the end tooth flange fork. The hydraulic clamping mechanism is arranged on the upper part of the clamp body 1. The hydraulic clamping mechanism includes a hydraulic cylinder 4, a pressure plate and two Floating V-shaped block 3, the lower end surface of the floating V-shaped block is provided with an arc-shaped groove that can cooperate with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com