Machining tool and machining method for adjusting piece of aero-engine

An aero-engine and processing method technology, which is applied in air transportation, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult clamping, accumulation of clamping errors, scattered processes, etc., and achieves low manufacturing cost, reasonable structure, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

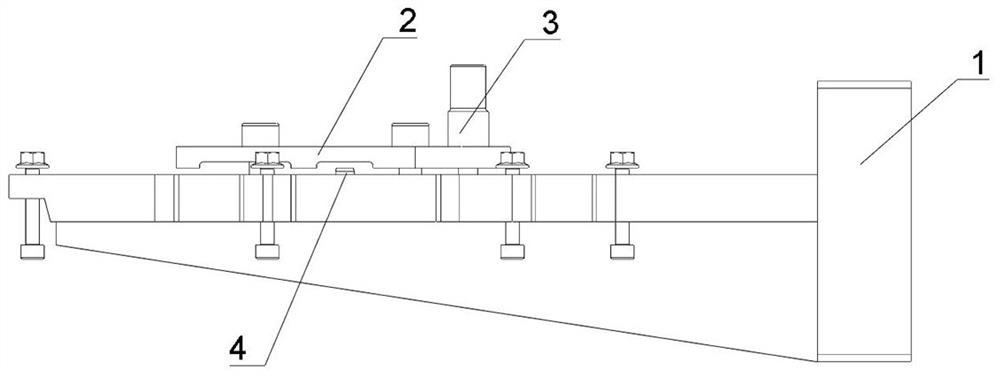

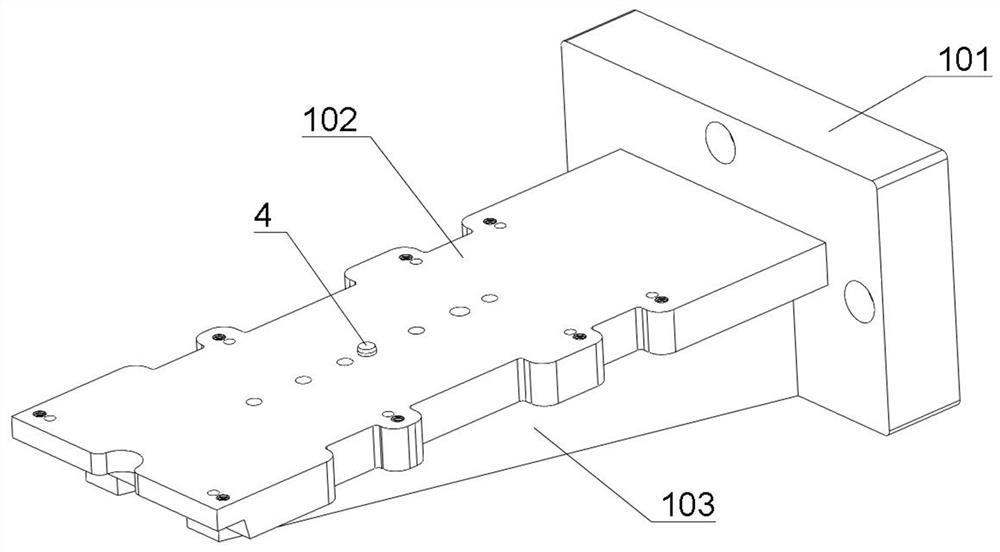

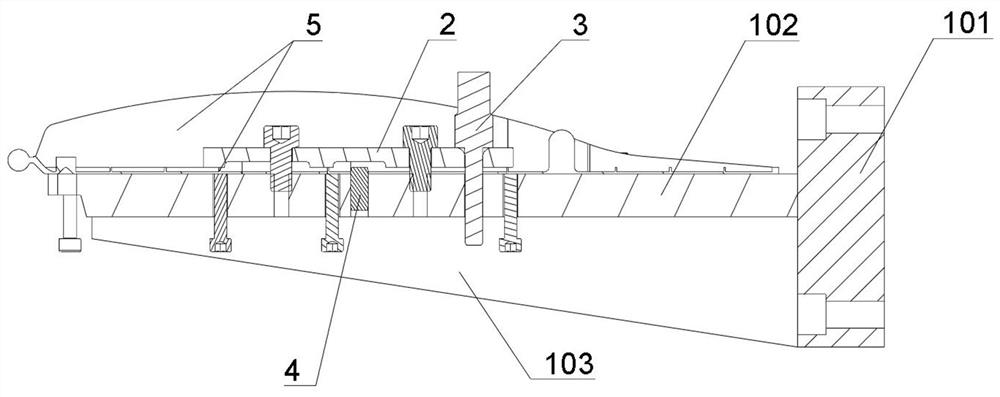

[0046] like Figure 1-Figure 6 shown:

[0047] The present invention provides an aero-engine adjusting piece processing tool, comprising a fixture body 1, a pressing block 2, a taper positioning pin 3 and a cylindrical positioning pin 4, wherein:

[0048] The fixture body 1 includes a fixing plate 101 and a clamping plate 102;

[0049] The fixing plate 101 is vertically arranged at one end of the clamping plate 102;

[0050] The center of the clamping plate 102 is provided with a plurality of screw holes and a plurality of pin holes;

[0051] Both sides of the clamping plate 102 are provided with a plurality of screw holes;

[0052] The cylindrical positioning pin 4 is arranged in the pin hole in the center of the clamping plate 102;

[0053] The pressing block 2 is arranged in the middle of the clamping plate 102;

[0054] The tapered positioning pin 3 passes through the pressing block 2 and the clamping plate 102 at the same time.

[0055] In this embodiment, the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com