Device and method for manufacturing staggered cylinder metal card clothing

A technology of metal card clothing and cylinder, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems of uneven tension in the middle rack, 1.5mm, and tolerance control of ±0.02mm, which is difficult to control. Achieve the effects of avoiding wrong teeth and bad teeth, promising application prospects, and eliminating error accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

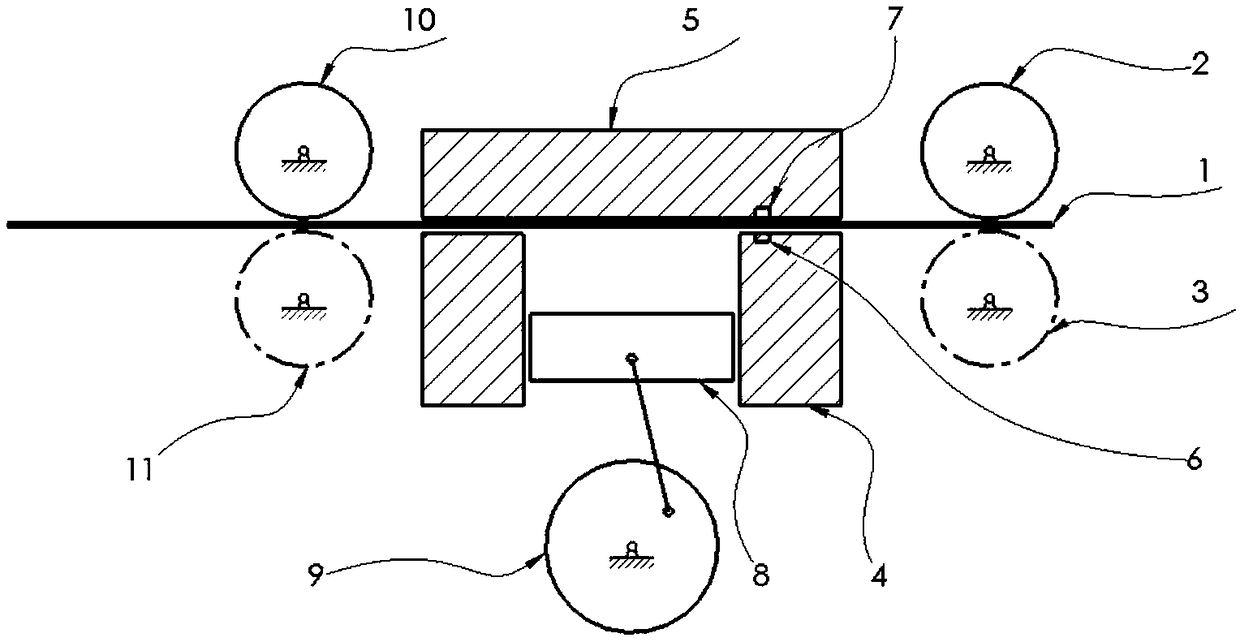

[0040] A device for making misplaced cylinder metal card clothing, such as figure 1 As shown, it includes two pairs of pressure rollers arranged up and down, that is, the rear upper pressure roller 2, the rear lower pressure roller 3, the front upper pressure roller 10 and the front lower pressure roller 11, and the extrusion box between the two pairs of pressure rollers, The extrusion box includes an upper pressing plate 5, a lower pressing plate 8 and a positioning seat 4 arranged under the upper pressing plate 5, and the upper side of the slider part of the crank slider mechanism 9 that drives the lower pressing plate 8 to move up and down is connected with the lower pressing plate 8 through a T-shaped groove. , the positioning seat 4 is located on the side of the lower platen 8 .

[0041] Among the two pairs of pressure rollers, the rear upper pressure roller 2 and the front upper pressure roller 10 are surrounded by stepped grooves that limit the rack 1 in the straight ru...

Embodiment 2

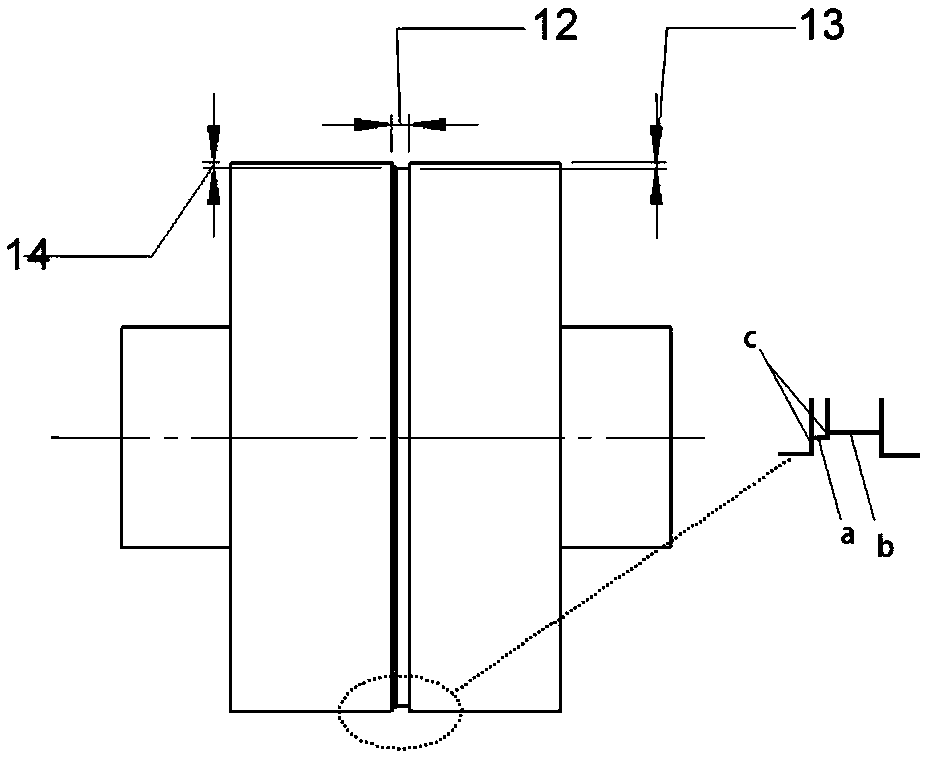

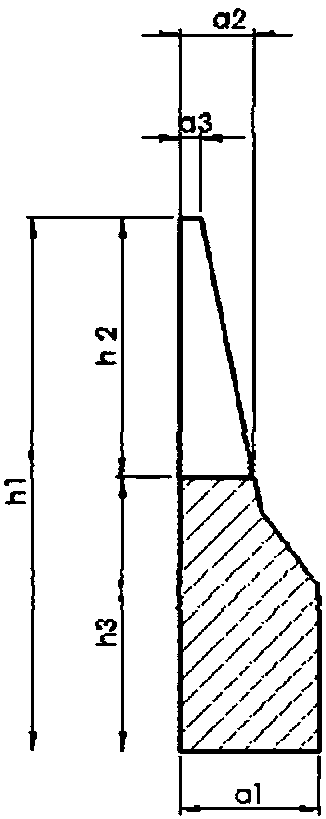

[0048] A device for making dislocated cylinder metal card clothing, the structure of which is basically the same as that of Embodiment 1, the difference is that for (N+1) dislocated cylinder metal card clothing, when the surface of the upper platen 5 opposite to the lower platen 8 is set When groove channel 16 and protruding block 17 are arranged, the height of groove channel 16 in upper pressing plate 5 or lower pressing plate 8 is equal to 1 / 2 of the base width of tooth bar 1, and the width of groove channel 16 is equal to the total of tooth bar 1. Tooth height.

[0049] The total number of raised blocks 17 in the upper pressing plate 5 and the lower pressing plate 8 is an integer multiple of 2N, and every 2N raised blocks 17 is a period, and the arrangement is N raised blocks 17 of the lower pressing plate 8 and the upper pressing plate 5 The N protruding blocks 17 are arranged alternately, and the protruding blocks 17 of the upper platen 5 and the lower platen 8 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com