Patents

Literature

103 results about "Pitch error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A positioning method and device

InactiveCN102281629AHigh precisionAvoid low positioning accuracyWireless communicationInterference factorArrival time

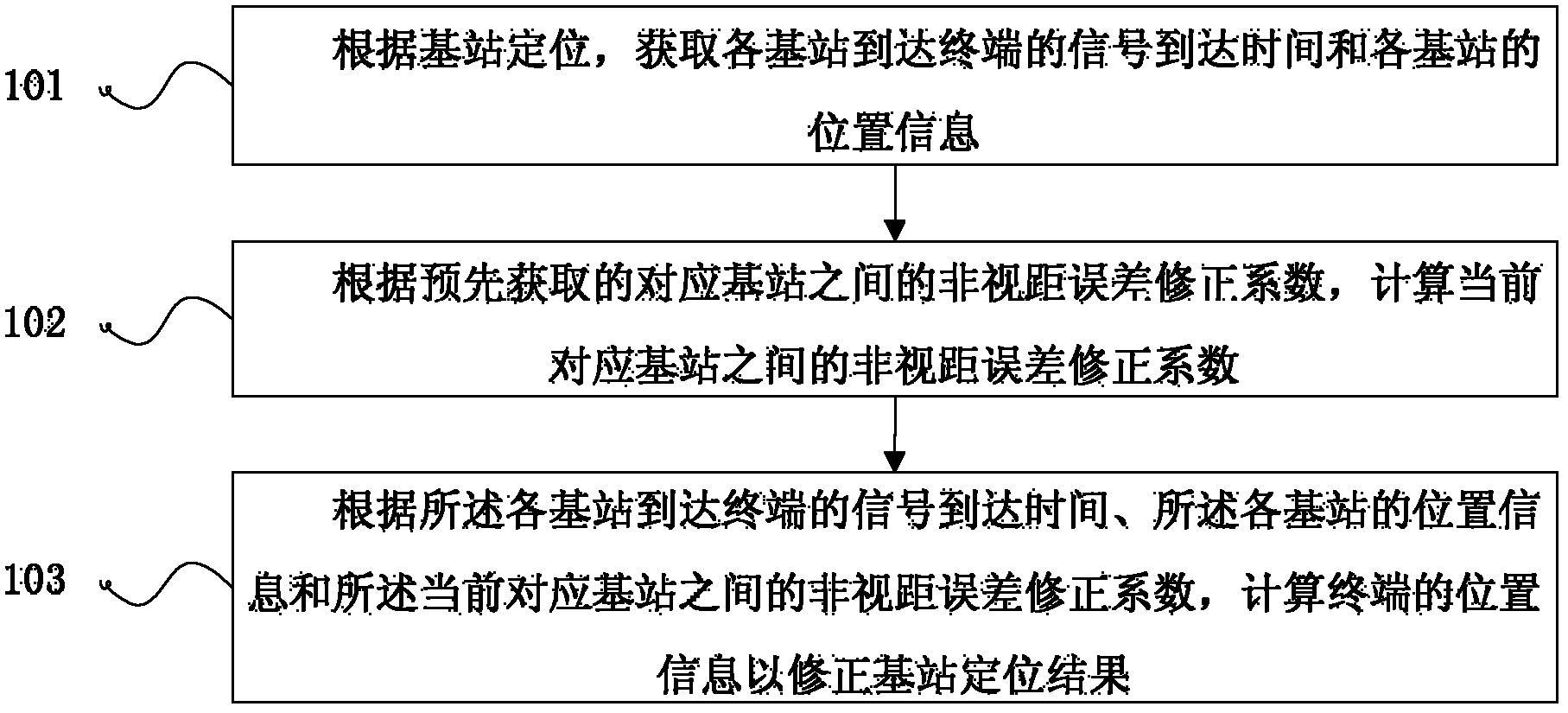

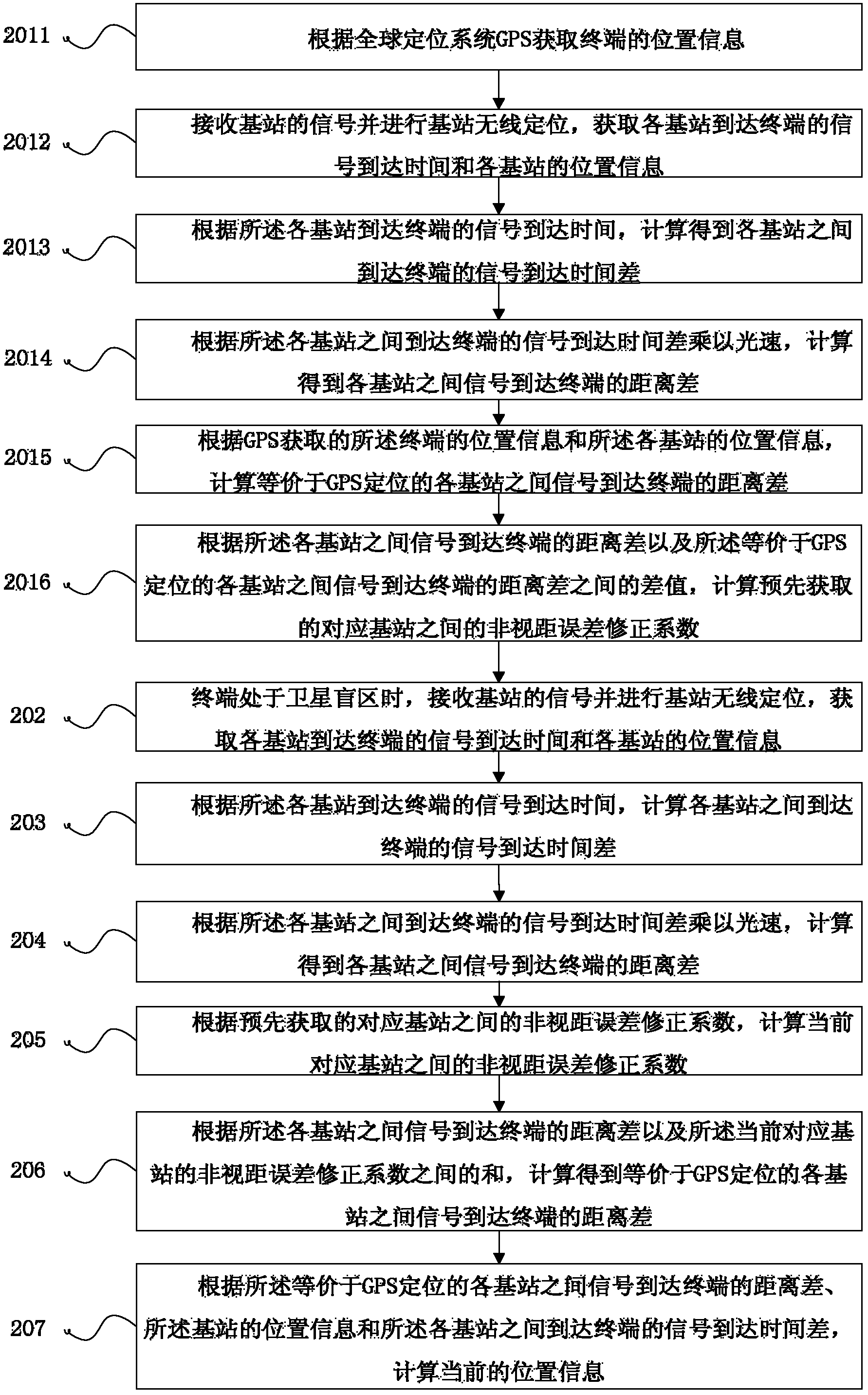

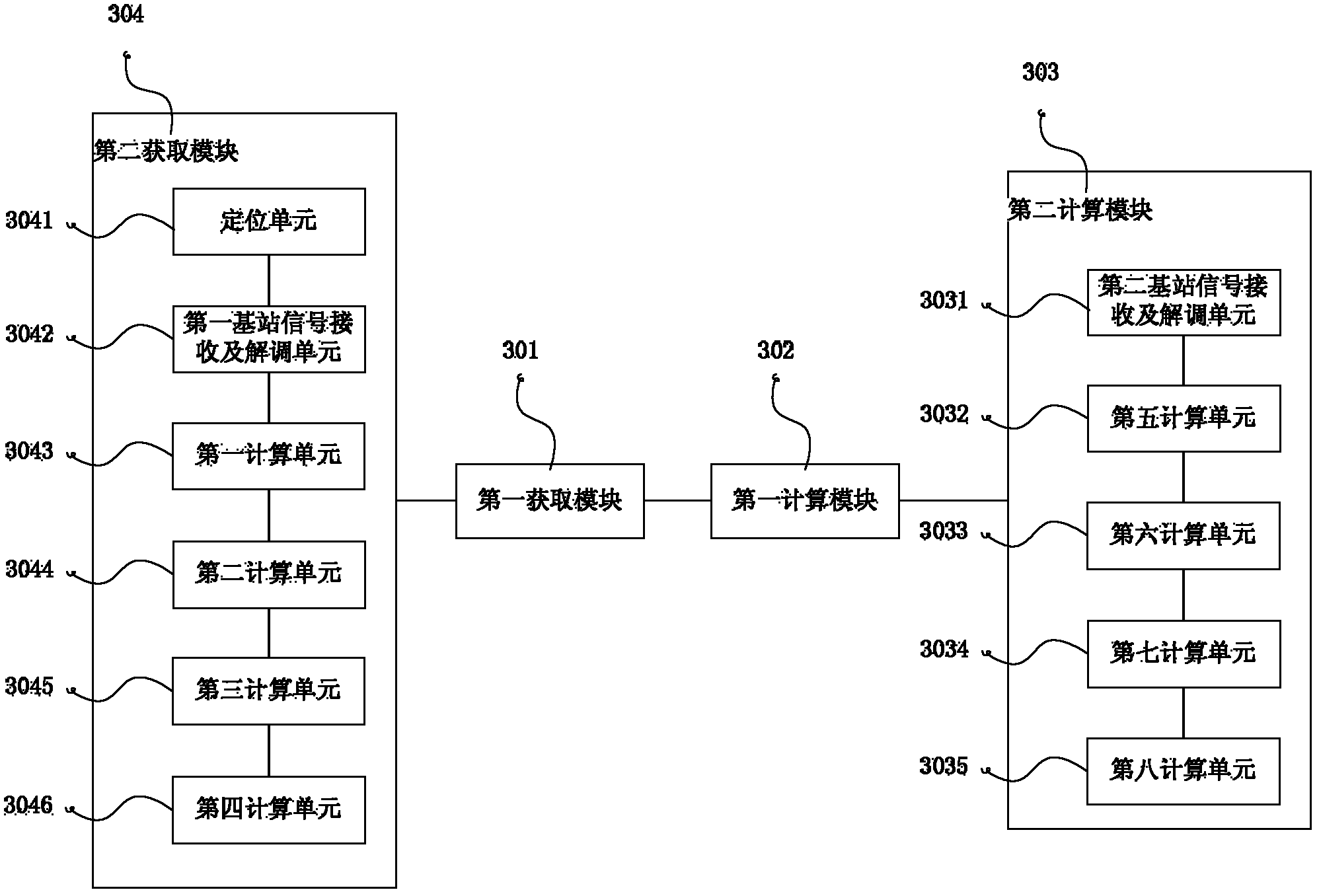

The embodiment of the invention discloses a positioning method and device, belonging to the field of positioning. The method includes: according to the positioning of the base stations, obtaining the signal arrival time of each base station arriving at the terminal and the position information of each base station; Distance error correction coefficient: calculate the position information of the terminal to correct the base station positioning result according to the arrival time of the signals from the base stations to the terminal, the position information of the base stations, and the non-line-of-sight error correction coefficient between the current corresponding base stations . In the embodiment of the present invention, the base station positioning error in the satellite blind area is calculated by a seamless positioning method of the satellite blind area of the fusion satellite and the base station. This makes it possible to obtain higher-precision terminal location information only through base station positioning when satellite signals cannot be received, avoiding positioning in a cellular network environment and the situation of low positioning accuracy caused by various interference factors.

Owner:BEIJING UNIV OF POSTS & TELECOMM

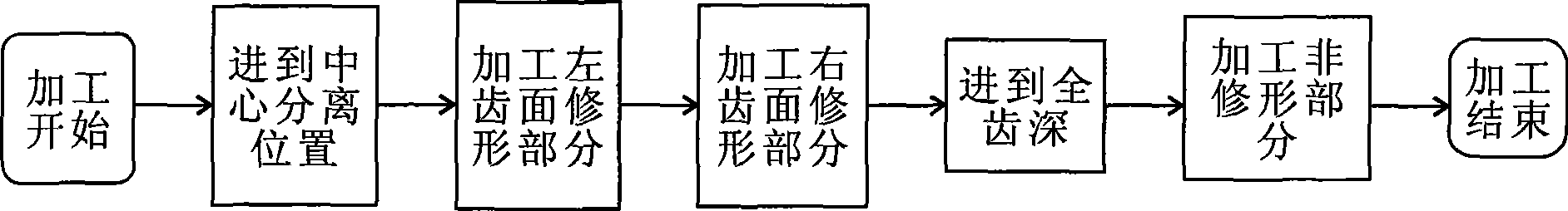

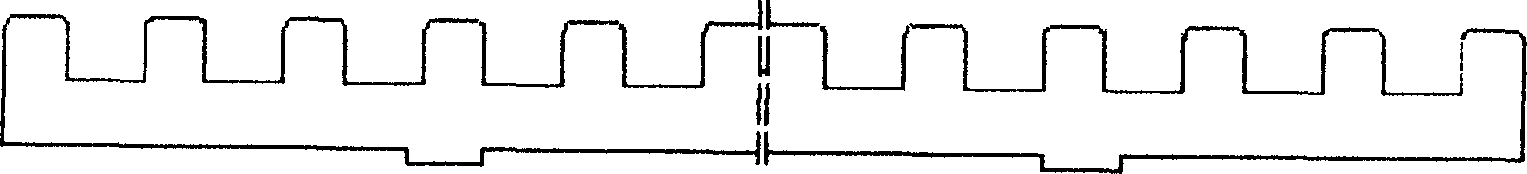

Numerical control gear shaping error compensation and gear profile modification method

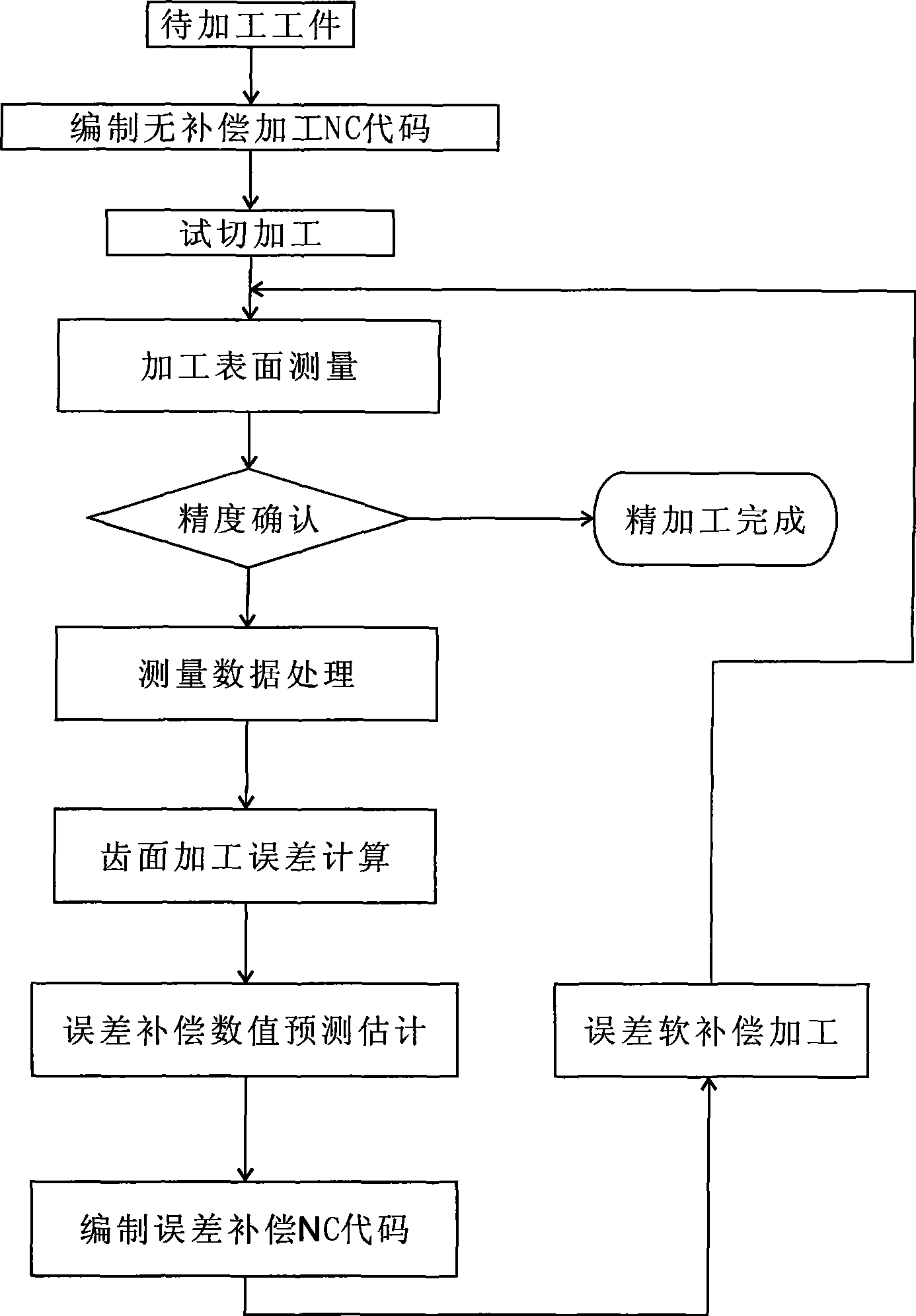

The invention discloses a numerical control gear shaping error compensation and gear profile modification method. The profile error compensation, the pitch error compensation, the tooth pitch accumulative error compensation and the integer accumulative error compensation numerical control processing codes or the profile modification processing code are generated automatically through software, a gear shaper cutter and a workpiece are controlled via a numerical control system so as not to rotate at a speed strictly, and according to the requirement of the compensation procedure, the instantaneous transmission ratio of the gear shaper cutter to the workpiece is adjusted in real time, and the machining precision of the workpiece can be improved by one to two grades on the premise that the precision of the gear shaper cutter and the transmission accuracy of the machine tool are not improved. Especially, when the structural accuracy of the machine tool is naturally lowered after years of use, the accuracy life of the machine tool can be prolonged by using the provided method.

Owner:宜昌长机科技有限责任公司

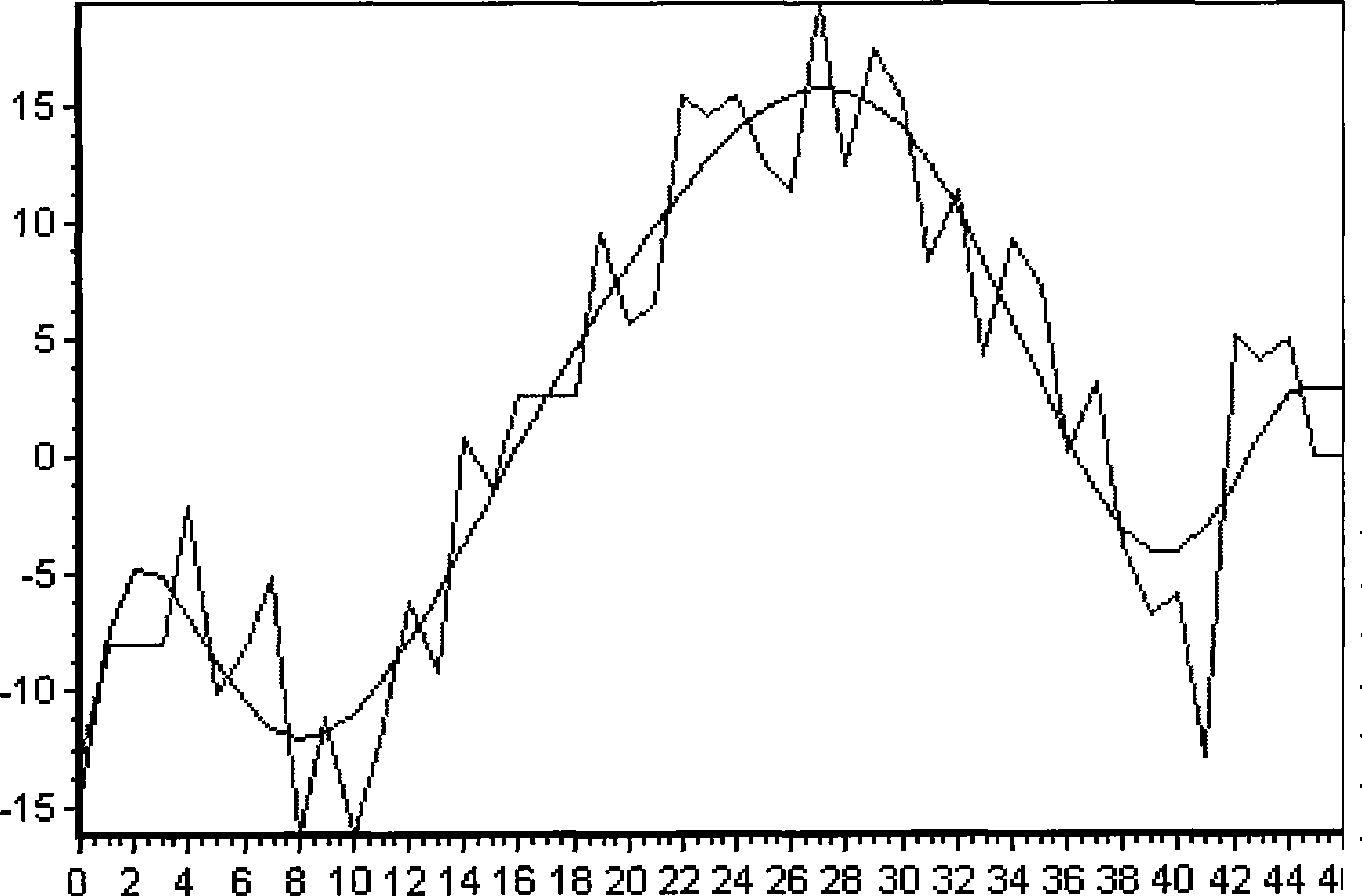

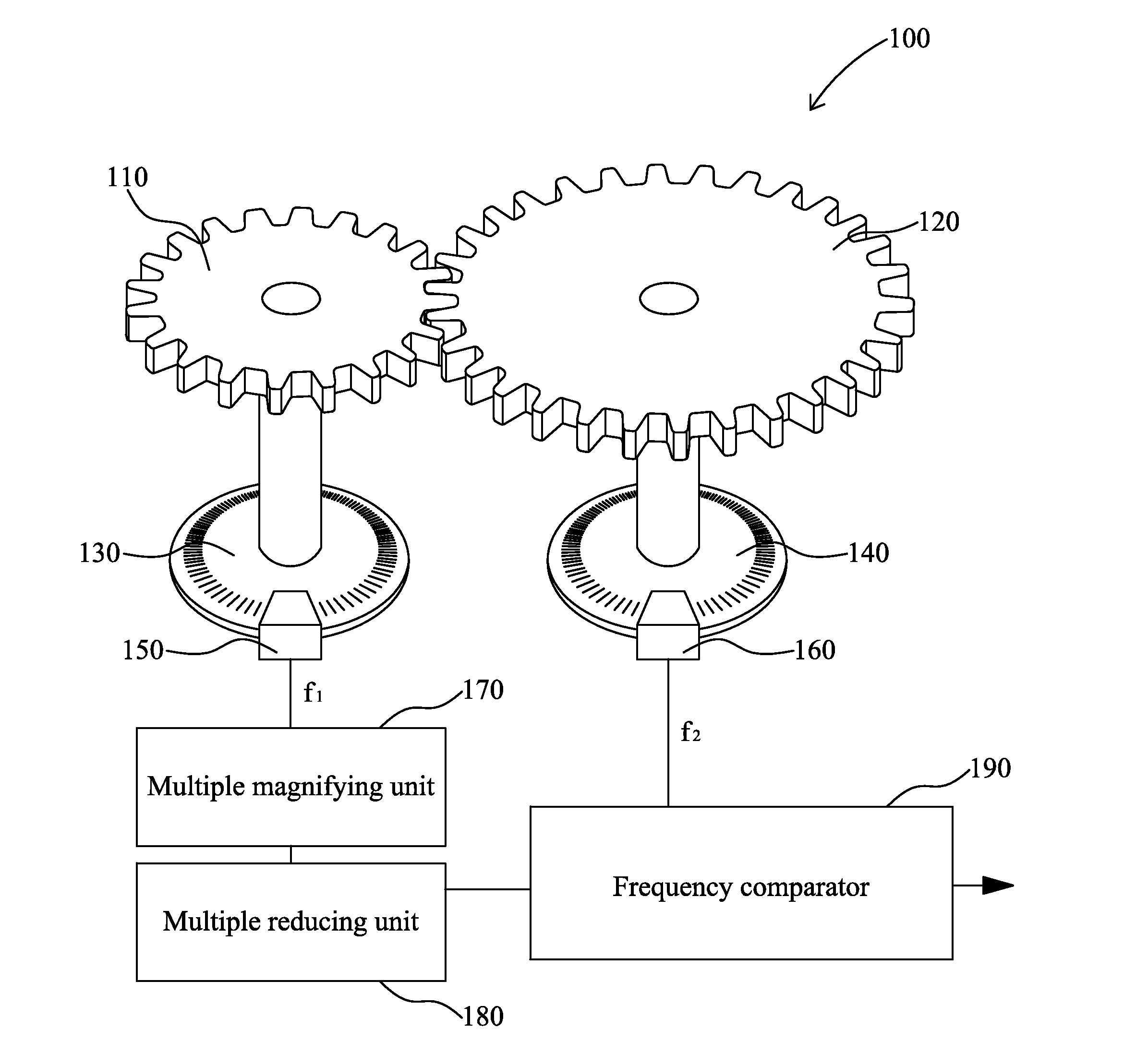

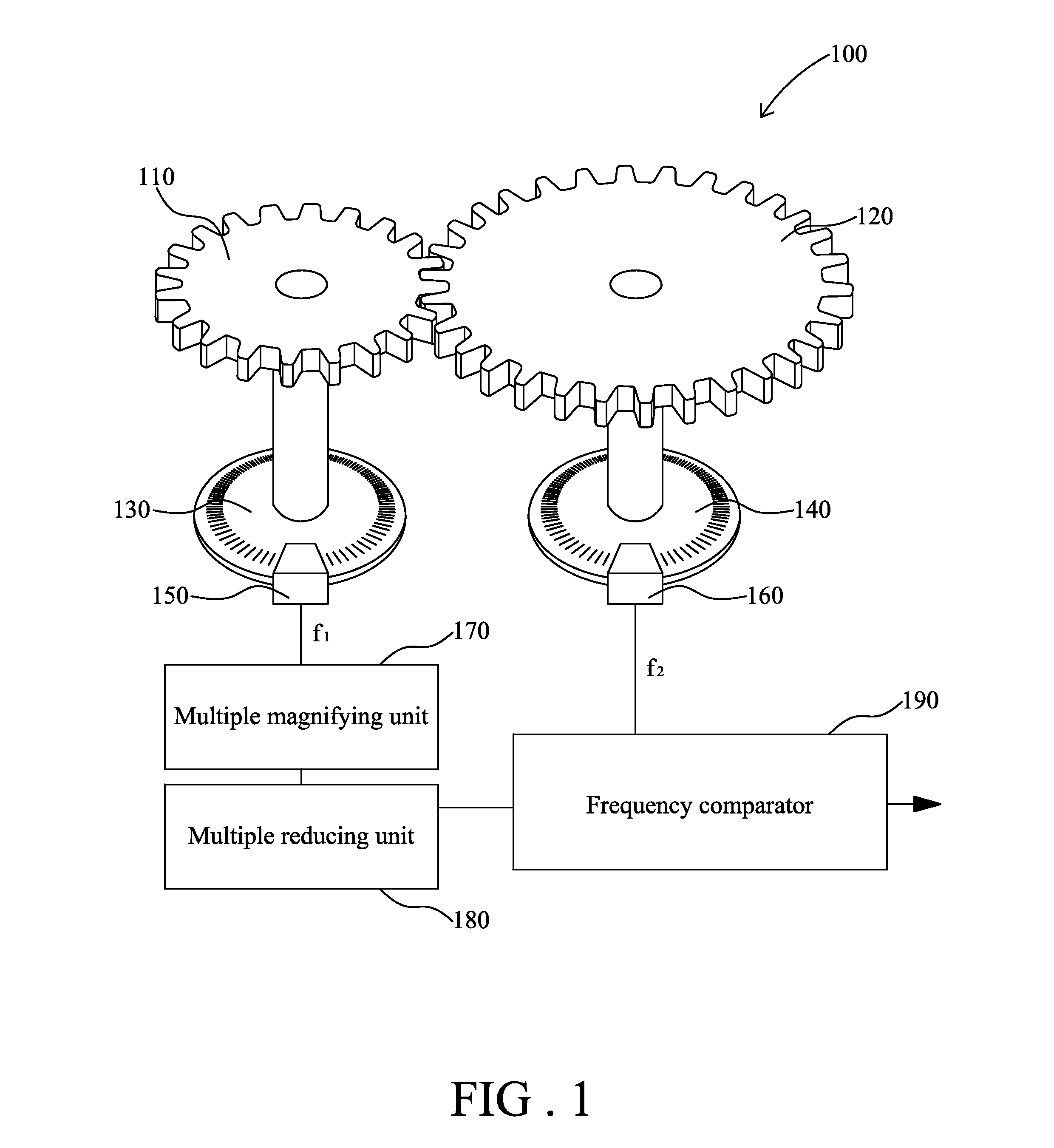

Error measuring method of gear

ActiveUS20150066390A1Machine gearing/transmission testingSpecial data processing applicationsAlgorithmComputer science

An error measuring method of gear includes: performing the single gear flank testing to the gear pair in order to produce a testing signal graph; the operation unit decomposing the testing signal graph by Empirical Mode Decomposition (EMD) to generate a plurality of intrinsic-mode-function graphs (IMFs), the intrinsic-mode-function graph (IMF) having a first function graph with a first range and a second function graph with a second range, the first range is greater than the second range; the operation unit selecting a plurality of third function graph from the intrinsic-mode-function graphs (IMFs), wherein the third range is greater than the second range but not greater than the first range; the operation unit combining the third function graphs to produce a graph of superposing function; the operation unit computing out a plurality of single pitch error, a plurality of adjacent pitch error and an accumulated pitch error.

Owner:NAT CENT UNIV

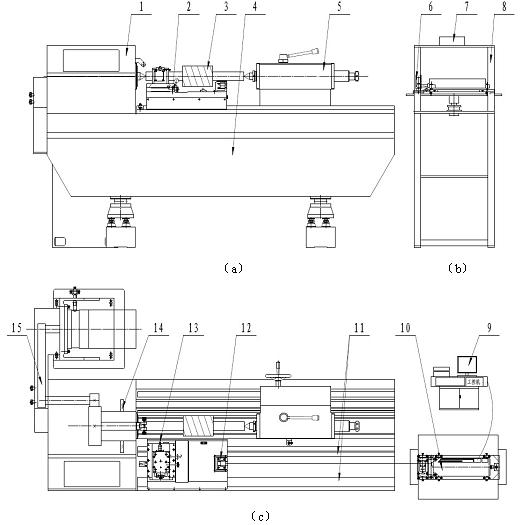

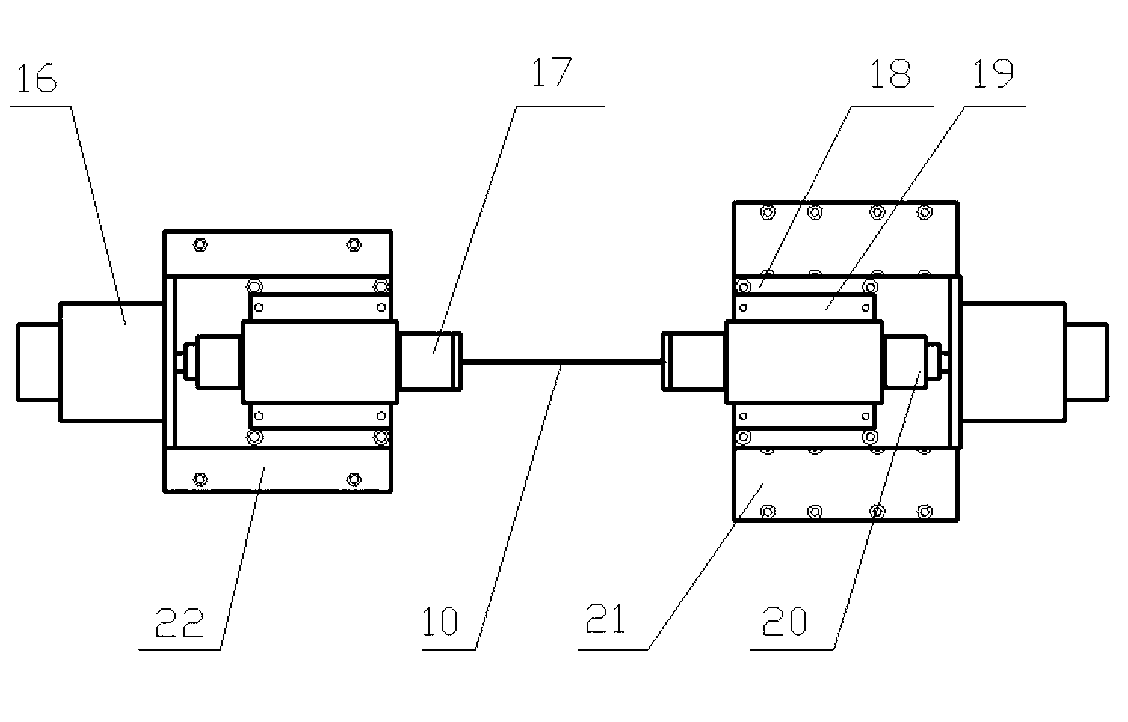

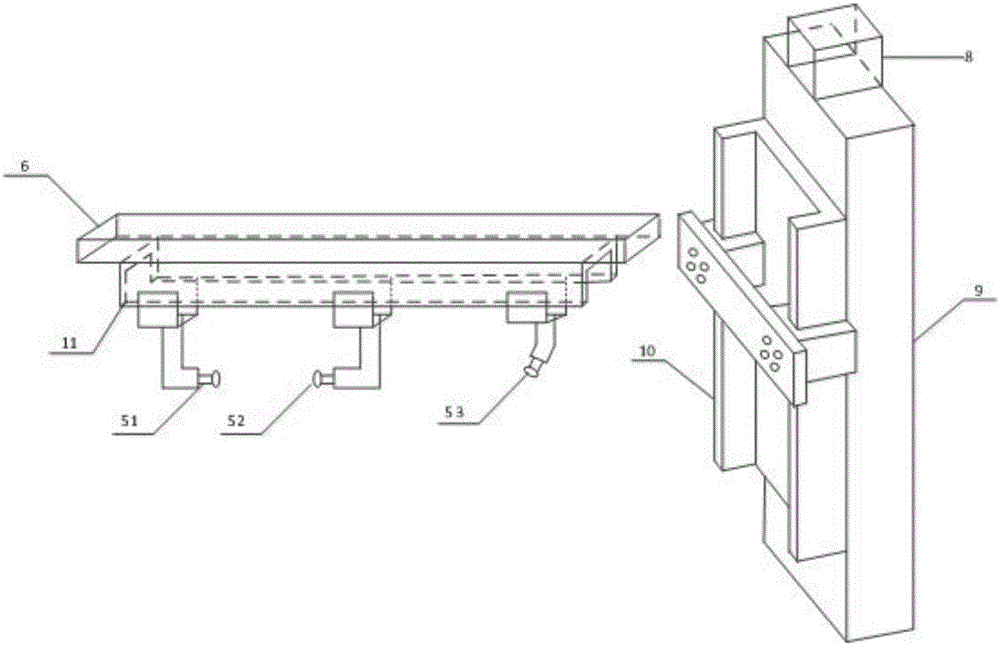

Dynamic measuring device for worm helix error and pitch error

InactiveCN102322824AStrong self-resetting abilityIncrease stiffnessUsing optical meansHelical lineGrating

The invention discloses a dynamic measuring device for worm helix errors and pitch errors, which comprises a headstock, a measuring table, a worm to be measured, a machine bed, a tailstock, an interference mirror, a compensator, a laser support, a computer, a laser head, a flat-V-shaped guide rail, a movable pyramid reflecting mirror, a measuring head, a circular grating system, an axial feed transmission assembly and the like. The circular grating system in the headstock and the worm to be measured are driven by the axial feed transmission assembly to realize synchronous rotation. When the worm to be measured rotates, the measuring table is dragged to move on the guide rail through the measuring head. The laser support supports the laser head, the interference mirror and the compensator. The movable pyramid reflecting mirror is fixedly arranged on the measuring table and moves along with the measuring table relative to the laser support. Since the entire instrument is provided with compensation units for temperature, environment and the like, the measuring accuracy is further improved. By using the measuring device, the automatic and dynamic high-accuracy measurement of the helix errors, pitch deviations and accumulated pitch errors of the worm with precision being or above third grade can be realized.

Owner:NANJING UNIV OF SCI & TECH

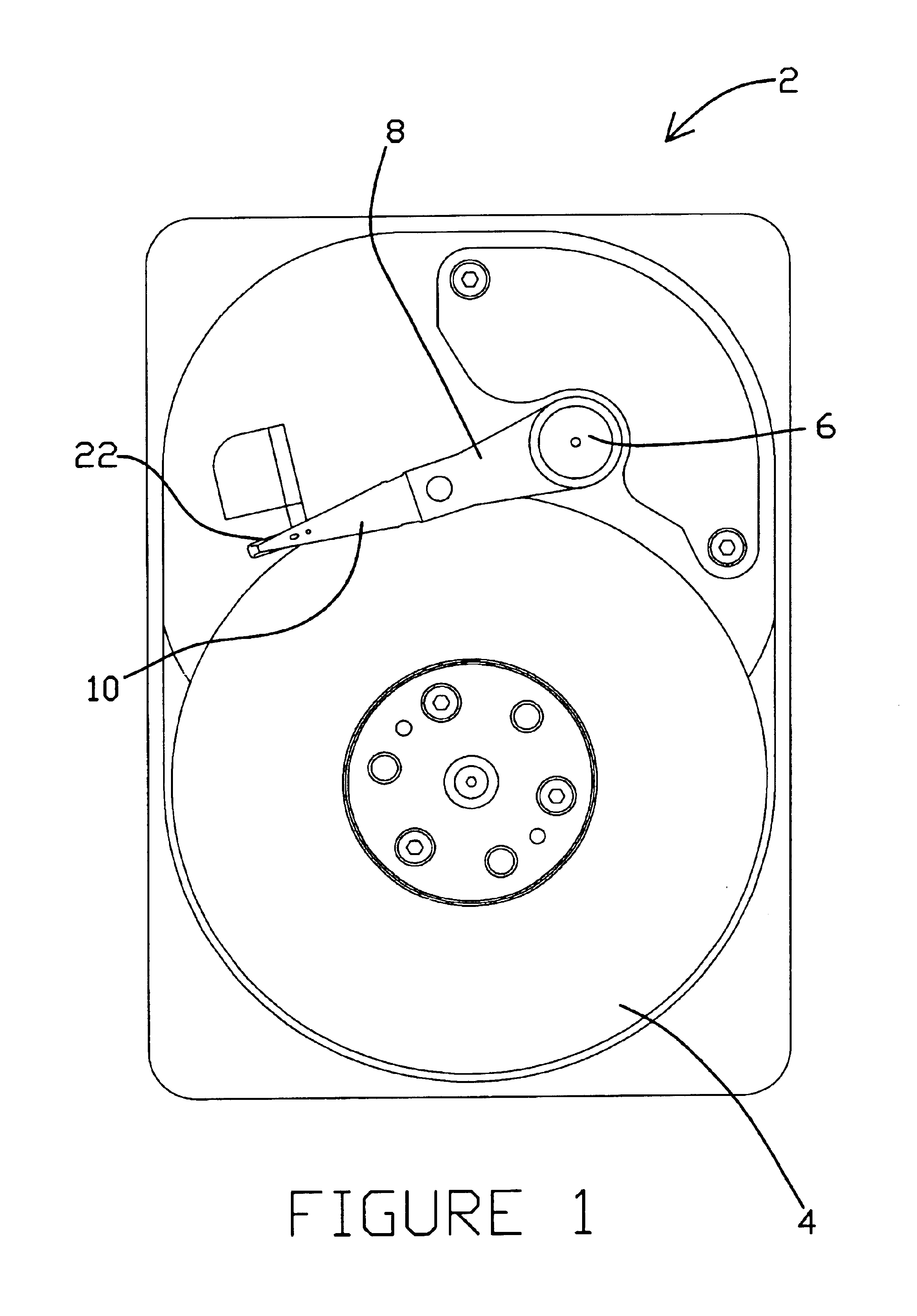

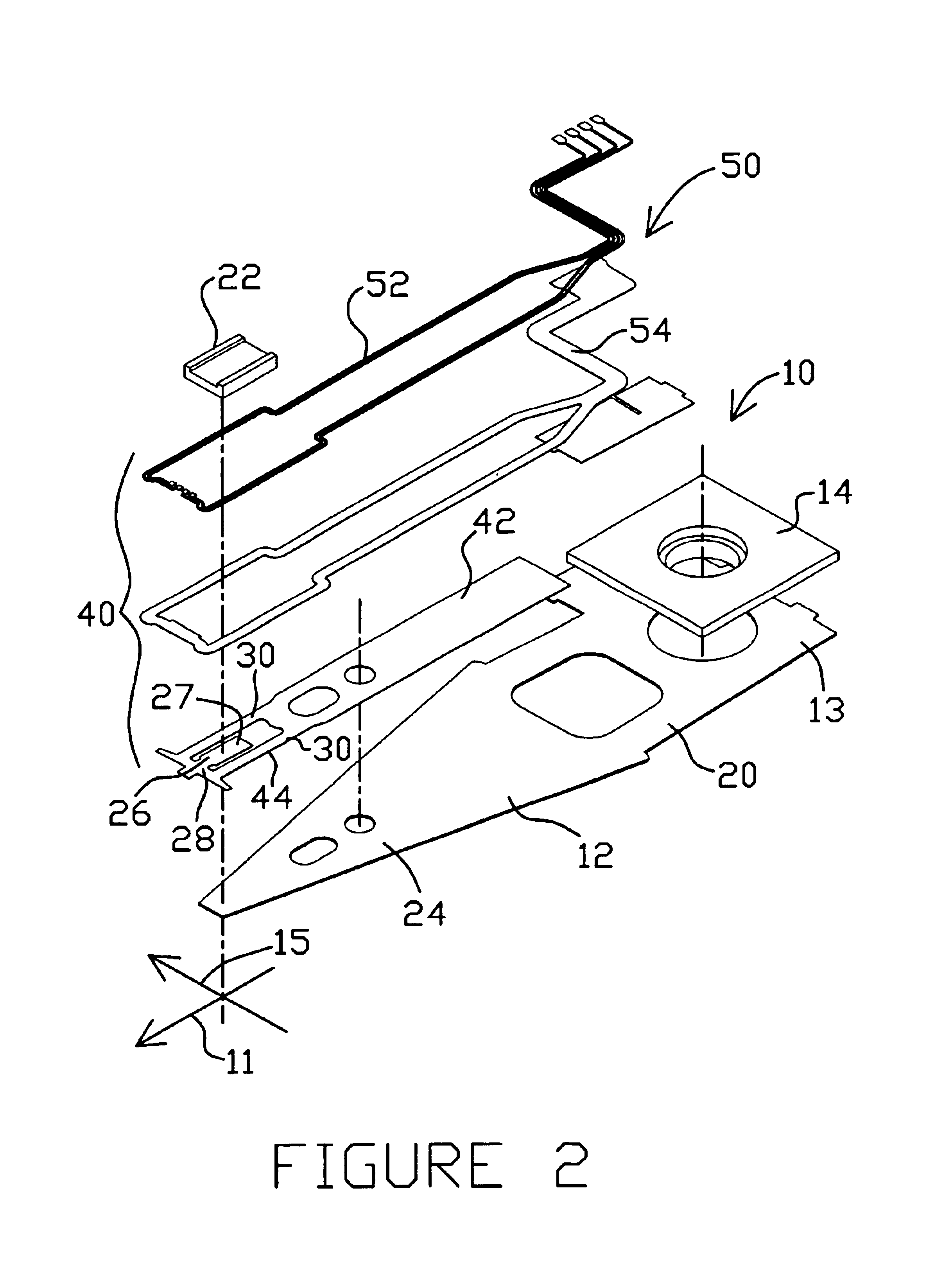

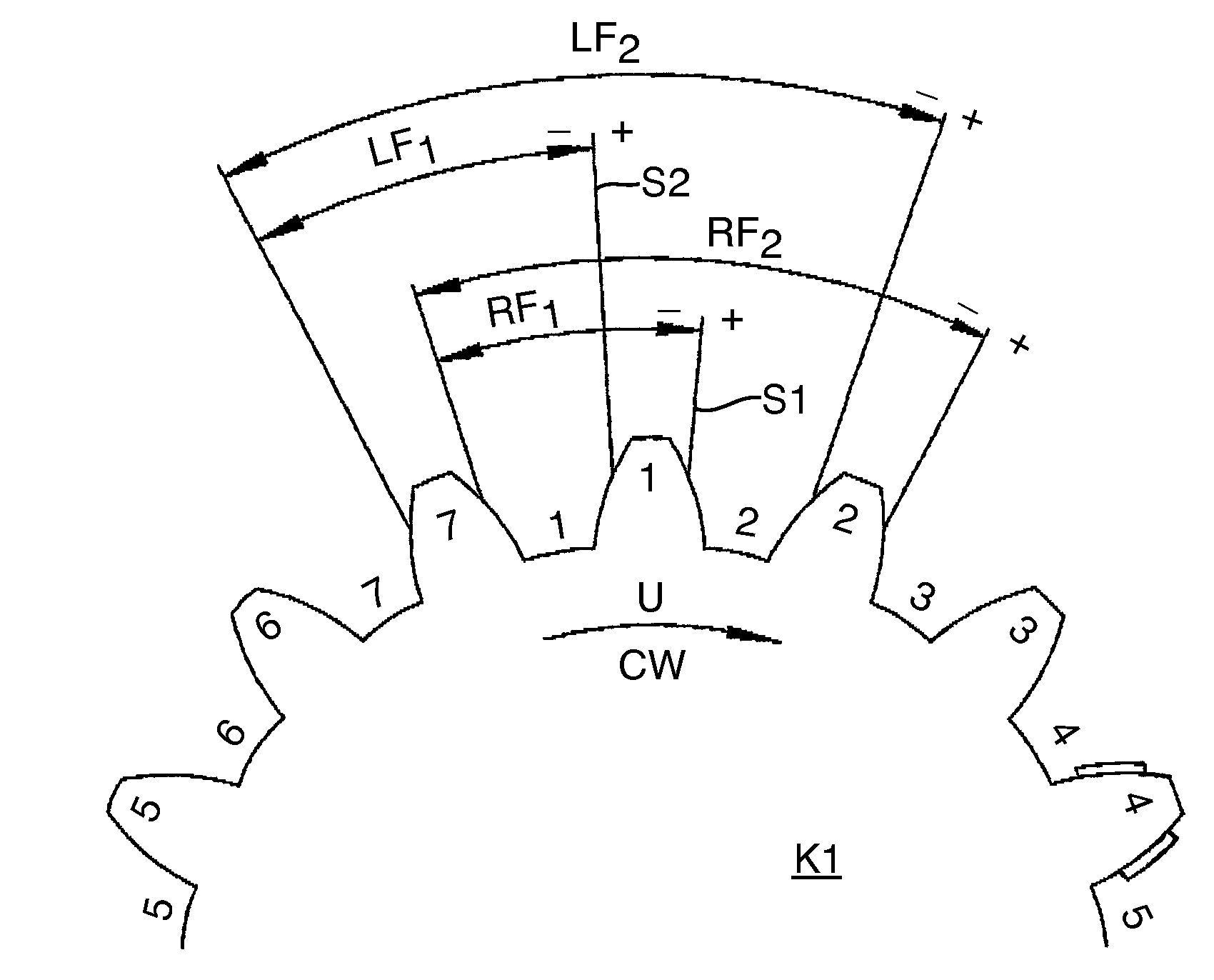

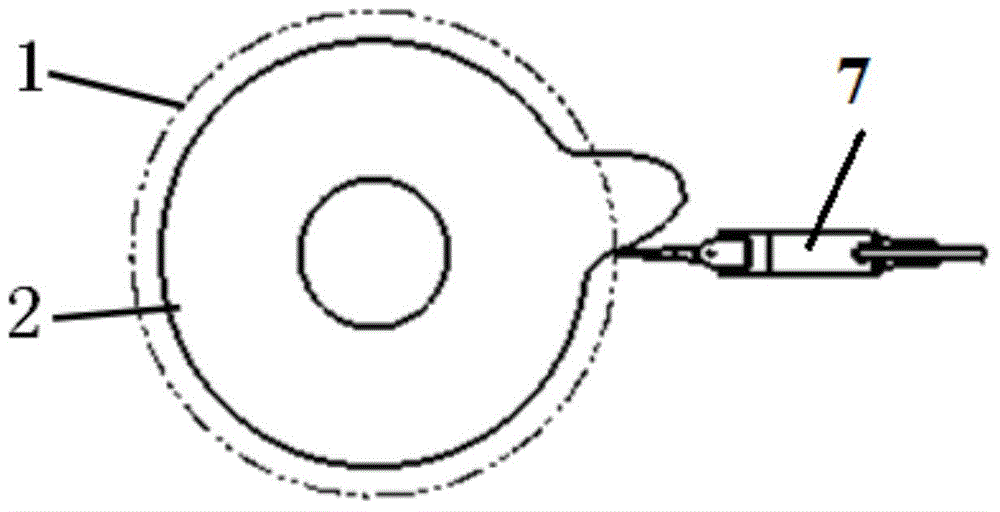

Method for adjusting a head suspension parameter

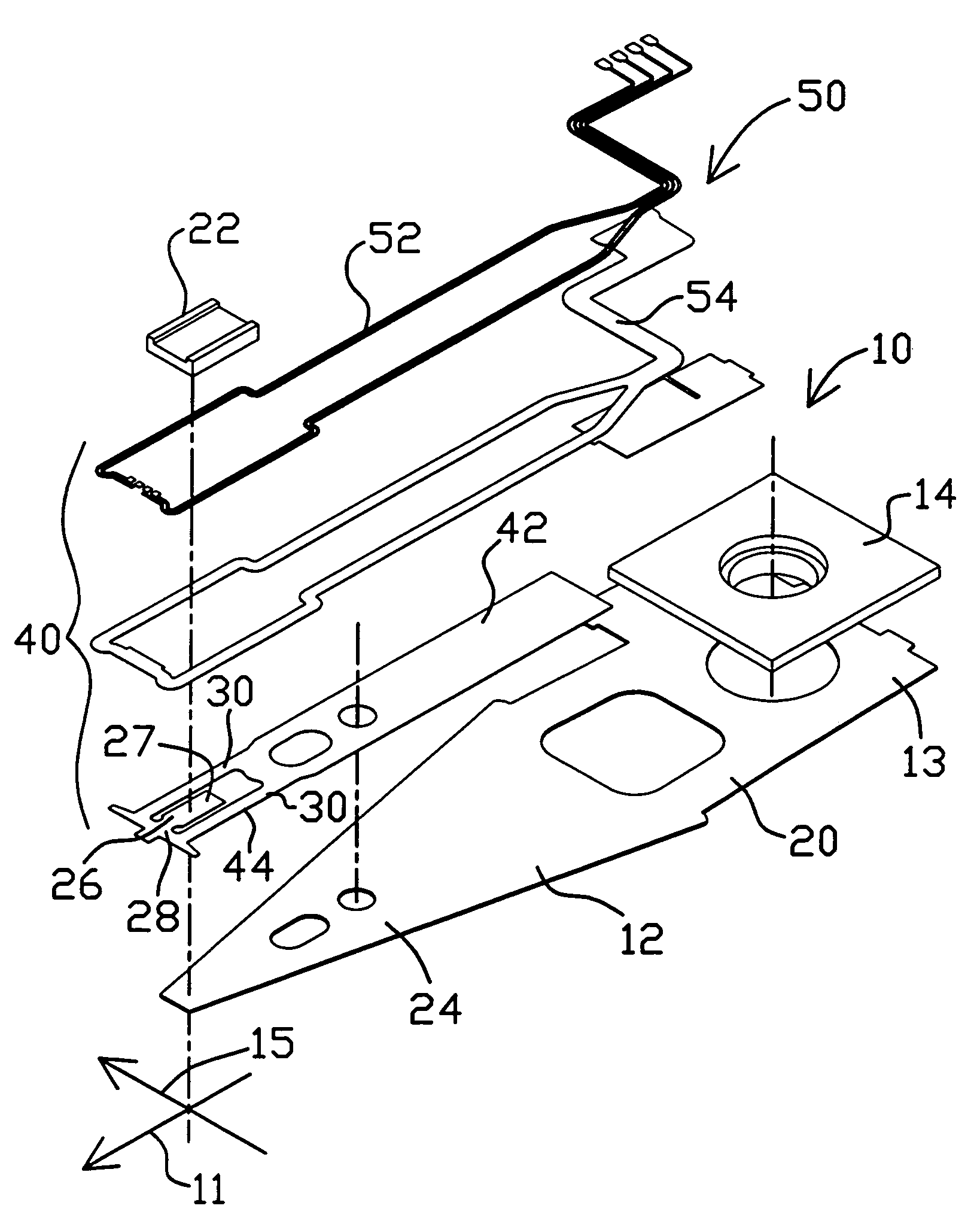

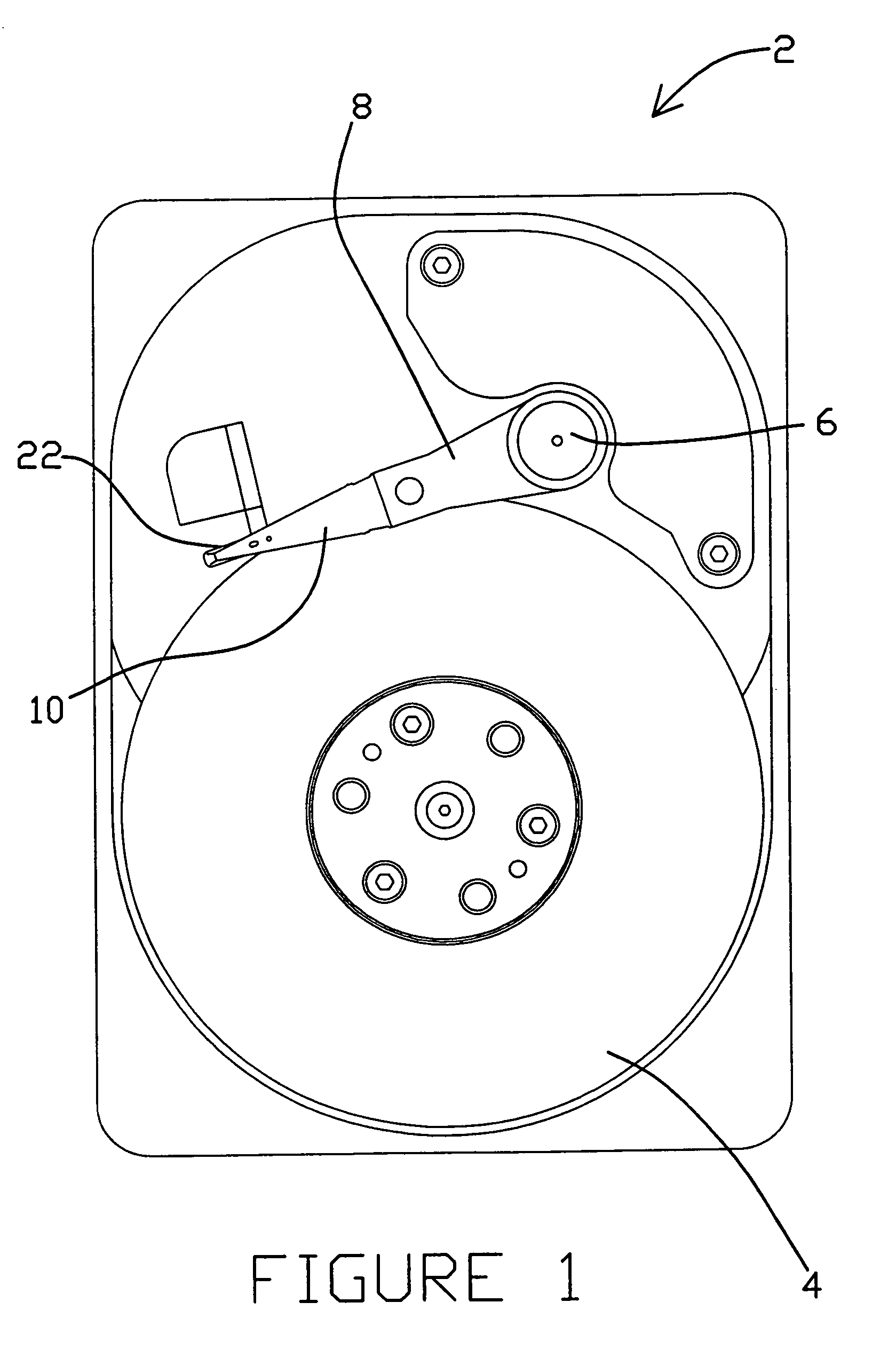

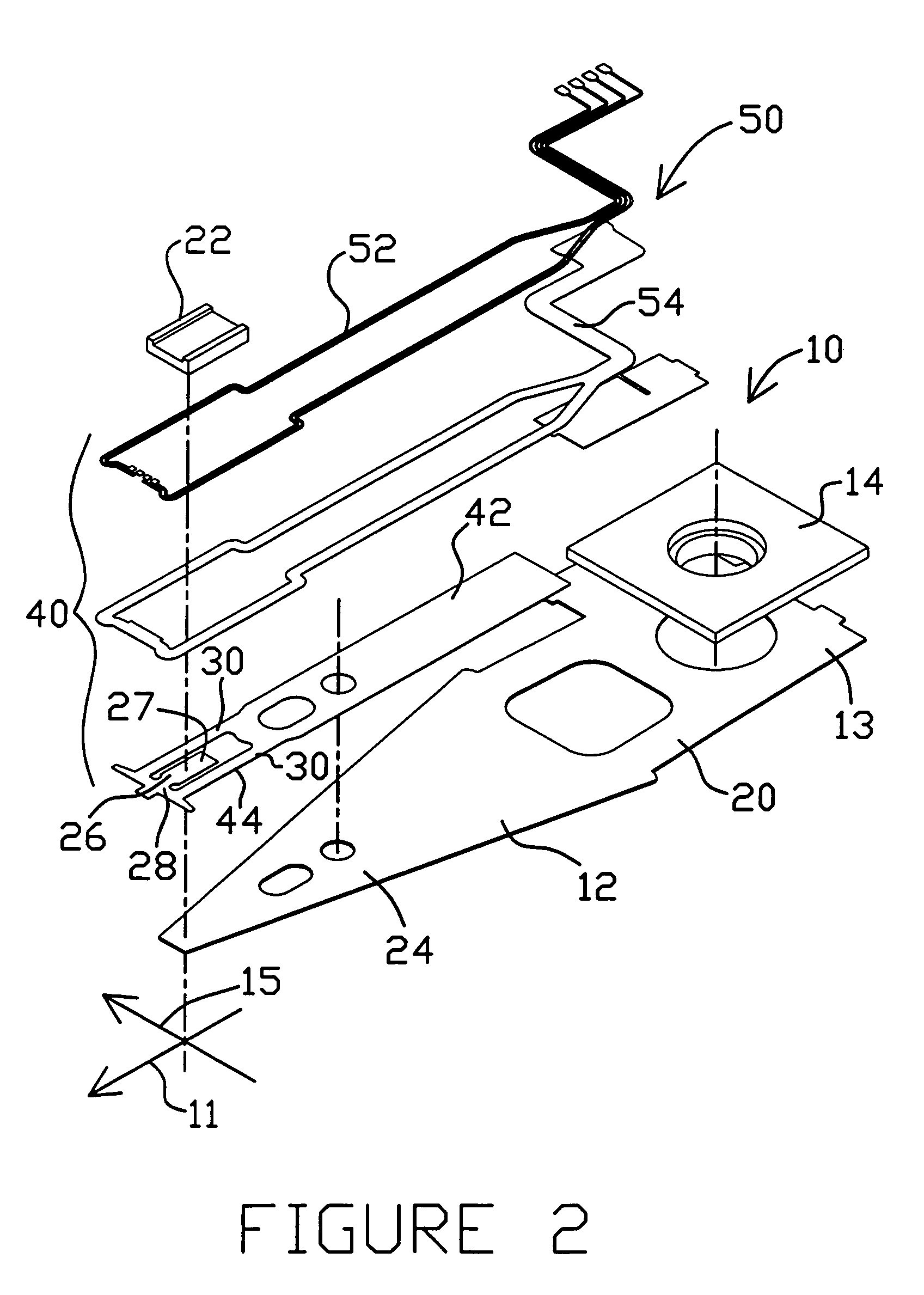

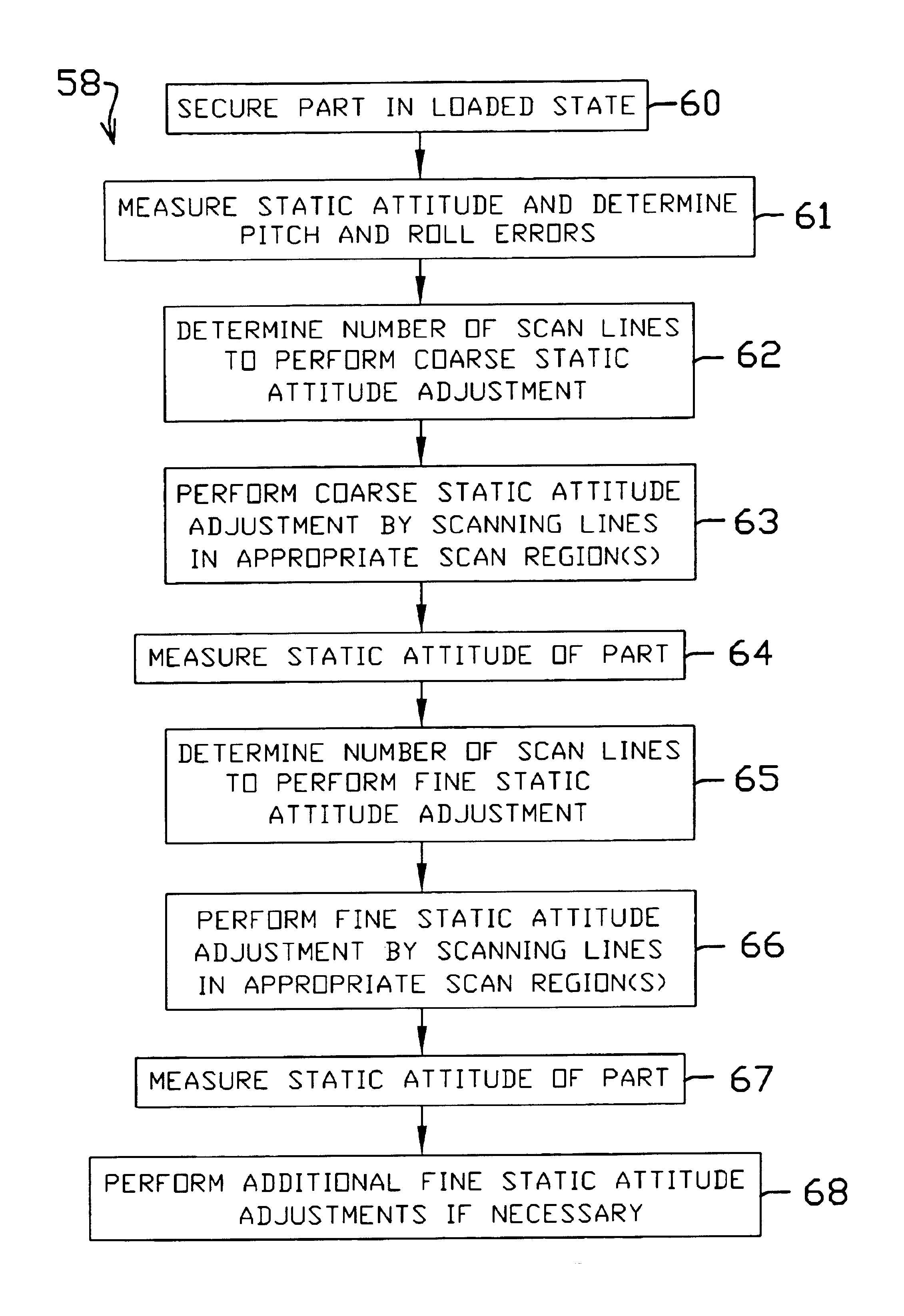

InactiveUS7021097B1Control impactAccurate correctionShaping toolsElectrical transducersAir bearingLaser scanning

Owner:HUTCHINSON TECH

Method for adjusting a head suspension parameter

InactiveUS6837092B1Control impactAccurate correctionShaping toolsMounting/attachment of transducer headAir bearingLaser scanning

A method for adjusting the static attitude of a head suspension by scanning a region of the head suspension with a laser. A head suspension having a gimbal region is provided that permits a head slider attached thereto to gimbal about pitch and roll axes in response to fluctuations in an air bearing over which the head slider flies. One or more predetermined regions of the head suspension are irradiated by a laser beam by scanning the laser beam across the head suspension regions to affect the static attitude of the head suspension. In a preferred embodiment, a plurality of parallel spaced apart lines are scanned on the leaf spring arms of a flexure with the laser to correct pitch errors in static attitude, and a plurality of parallel spaced apart lines are scanned with the laser in the cross section attached to the leaf spring arms to correct roll errors in static attitude. One or both sides of the head suspension can be scanned to create a desired pitch and / or roll correction. In addition, the predetermined scan regions can be scanned with a second plurality of lines to provide a precise static attitude adjustment.

Owner:HUTCHINSON TECH

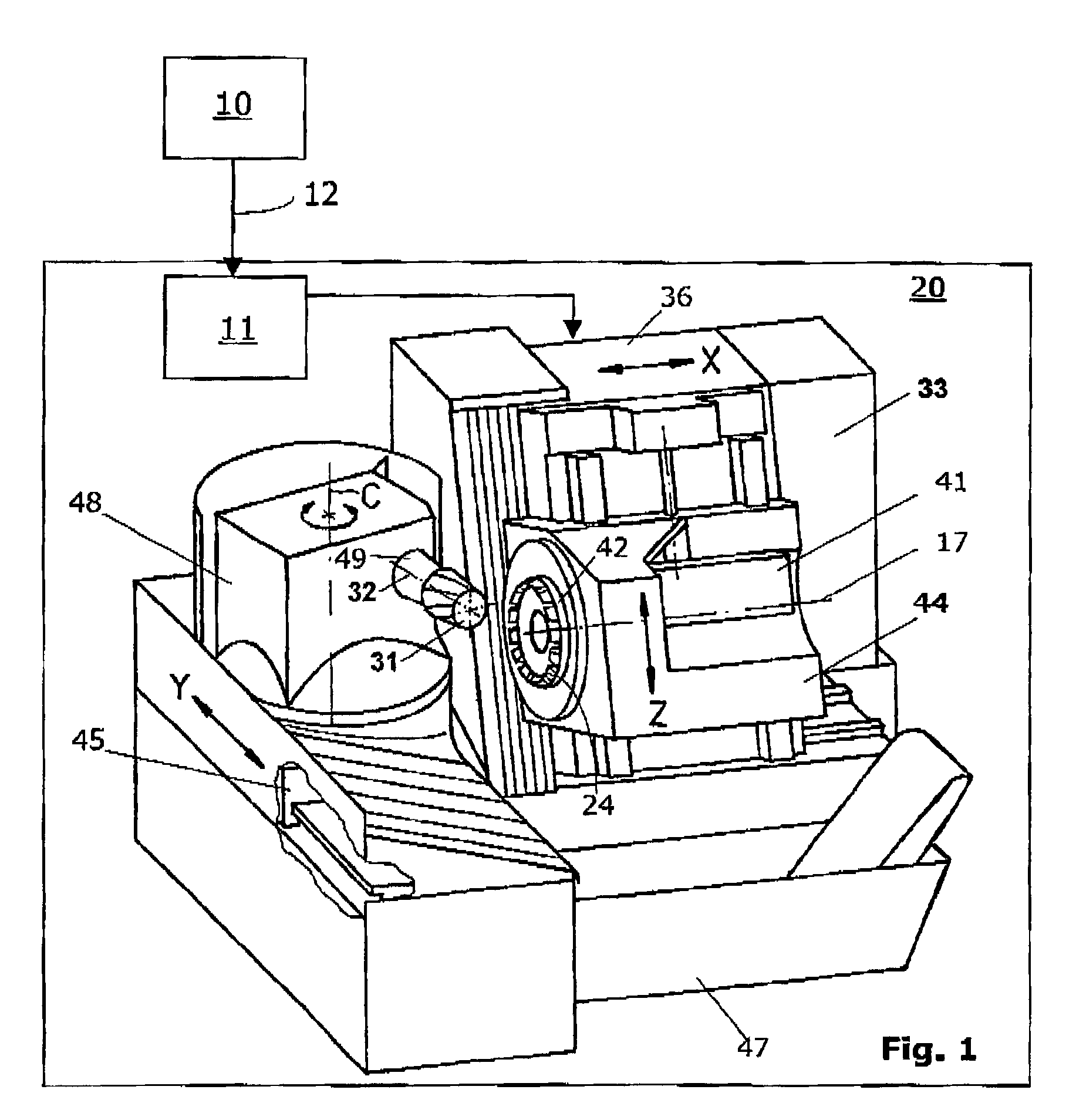

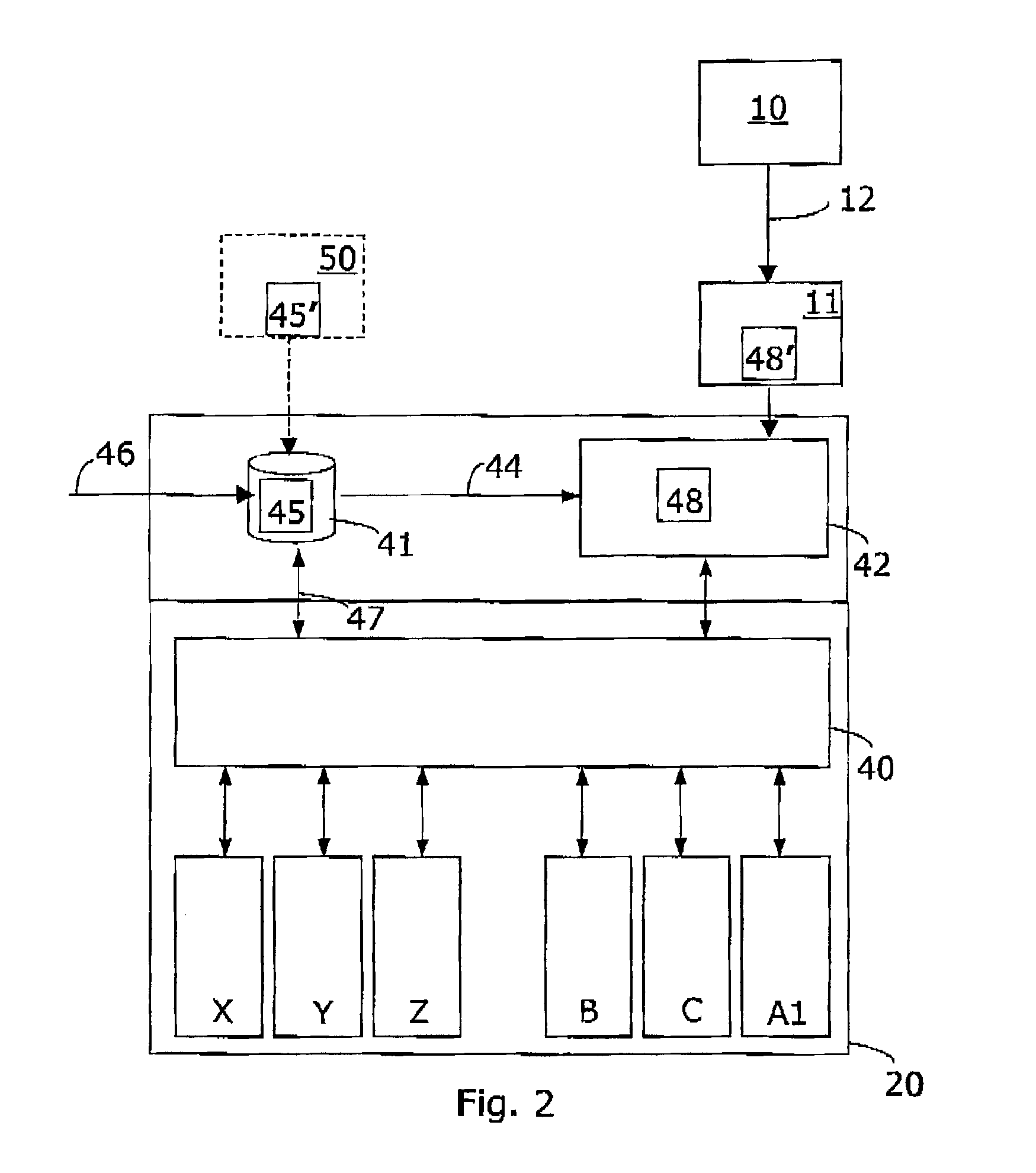

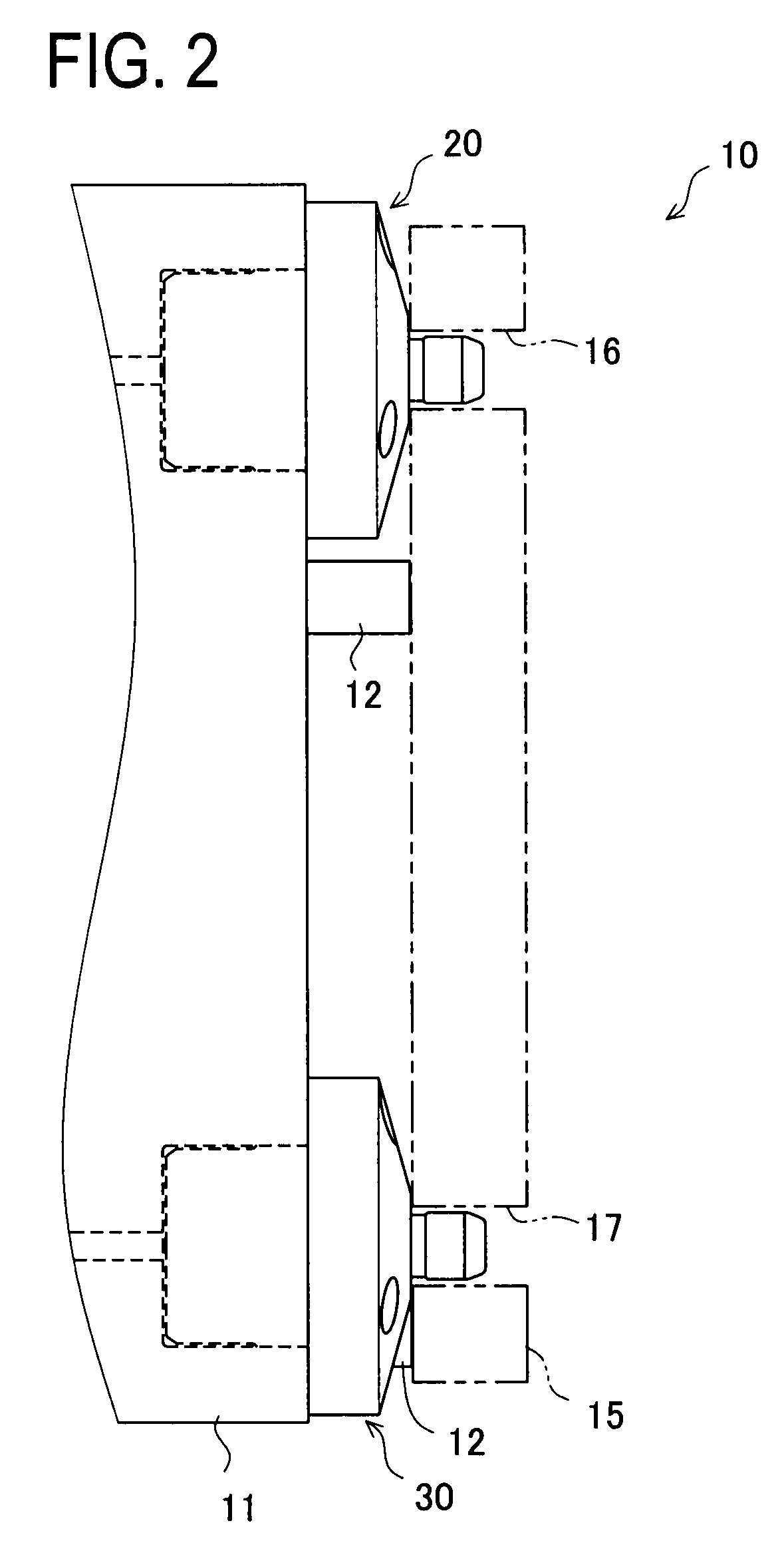

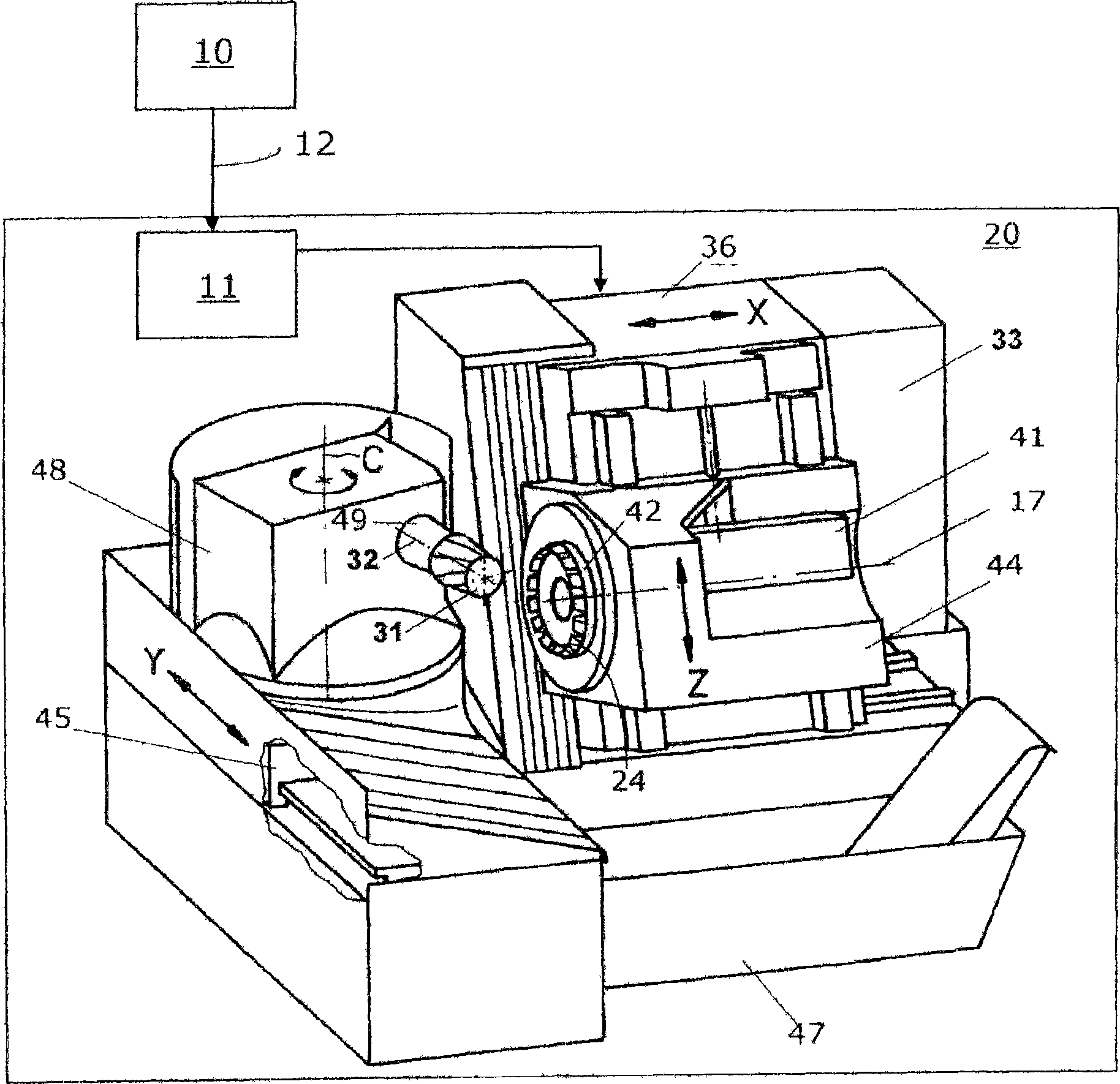

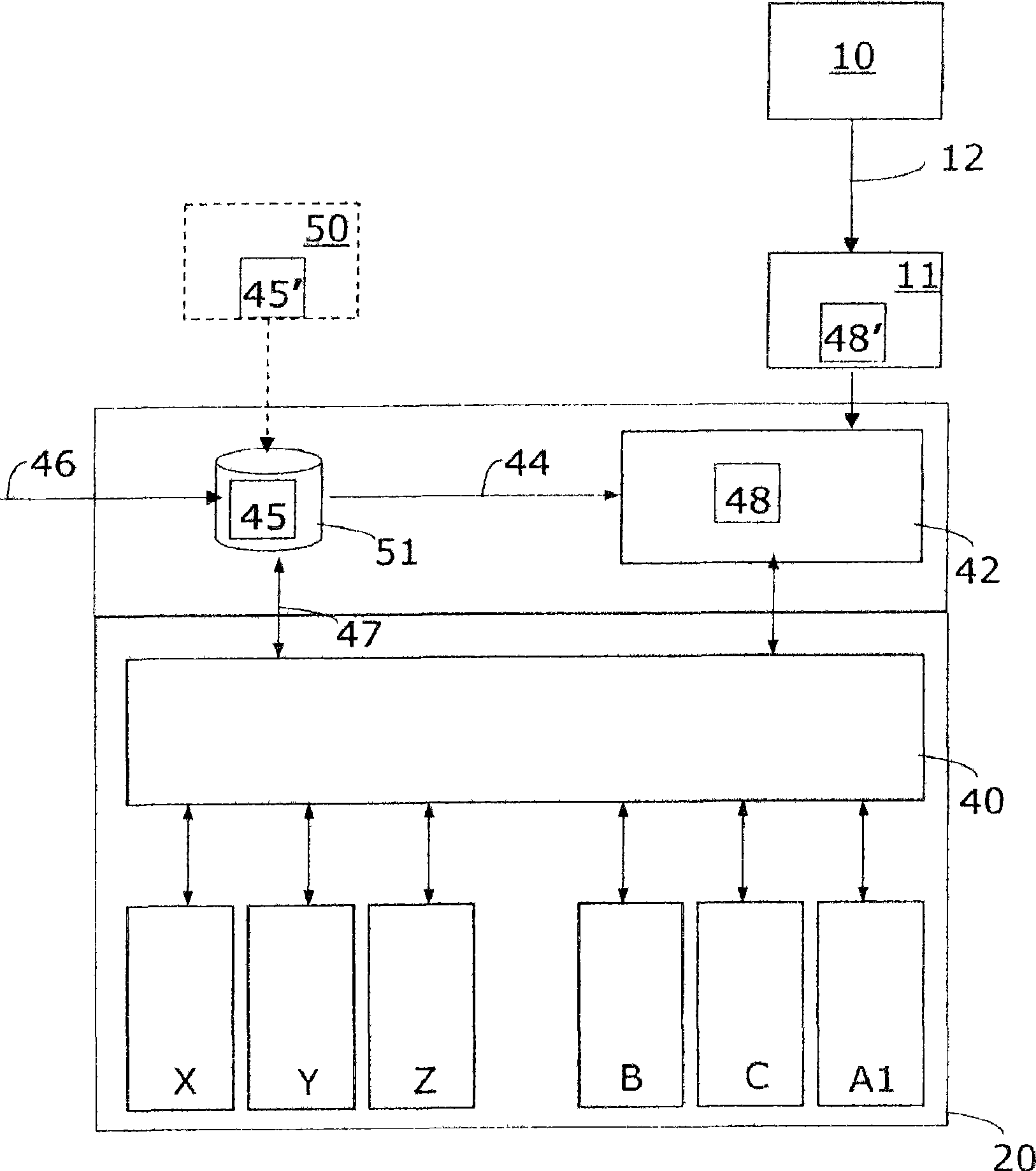

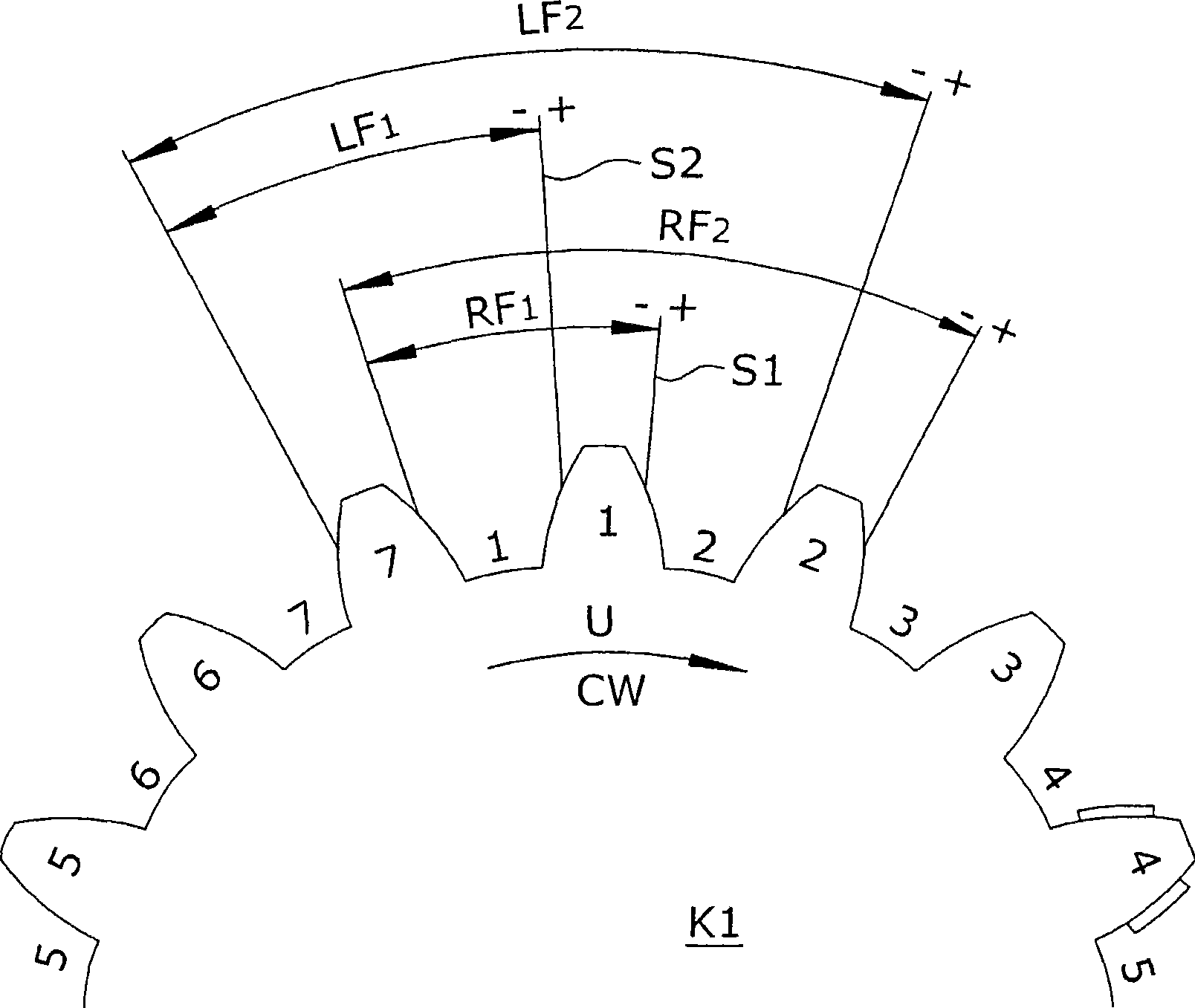

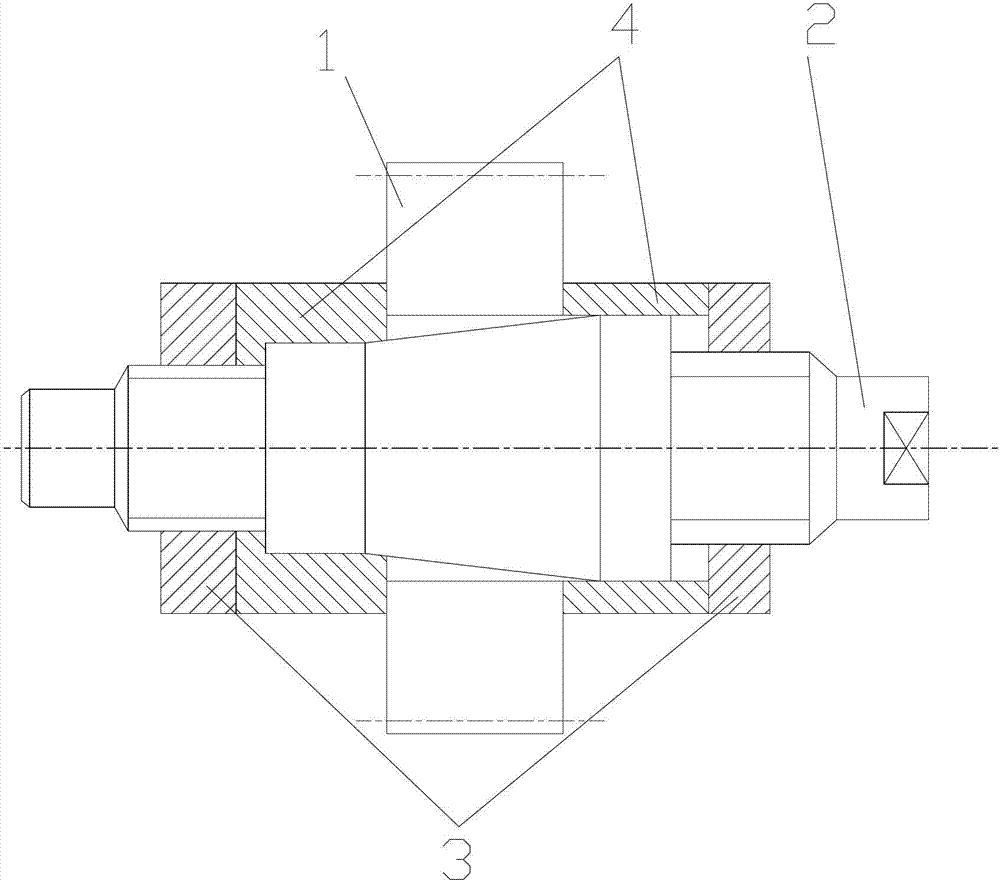

Device and method for machining bevel gears in the indexing method having complete indexing error compensation

The invention relates to an apparatus for machining bevel gears in an indexing method and method for machining the pitch of gears, wherein the production-related pitch error is compensated. The apparatus (20) comprises an interface (11, 12) and can be connected to a measurement system (10) by means of this interface (11, 12). The interface is designed such that the apparatus (20) can take correction values or correction factors from the measurement system (10) in a form in order to be able to adapt master data or neutral data. The data, which was originally present in a memory (51) of the apparatus (20), is corrected on the basis of these correction values or correction factors before production of one or more bevel gears (31) is initiated on the apparatus (20).

Owner:KLINGELNBERG AG

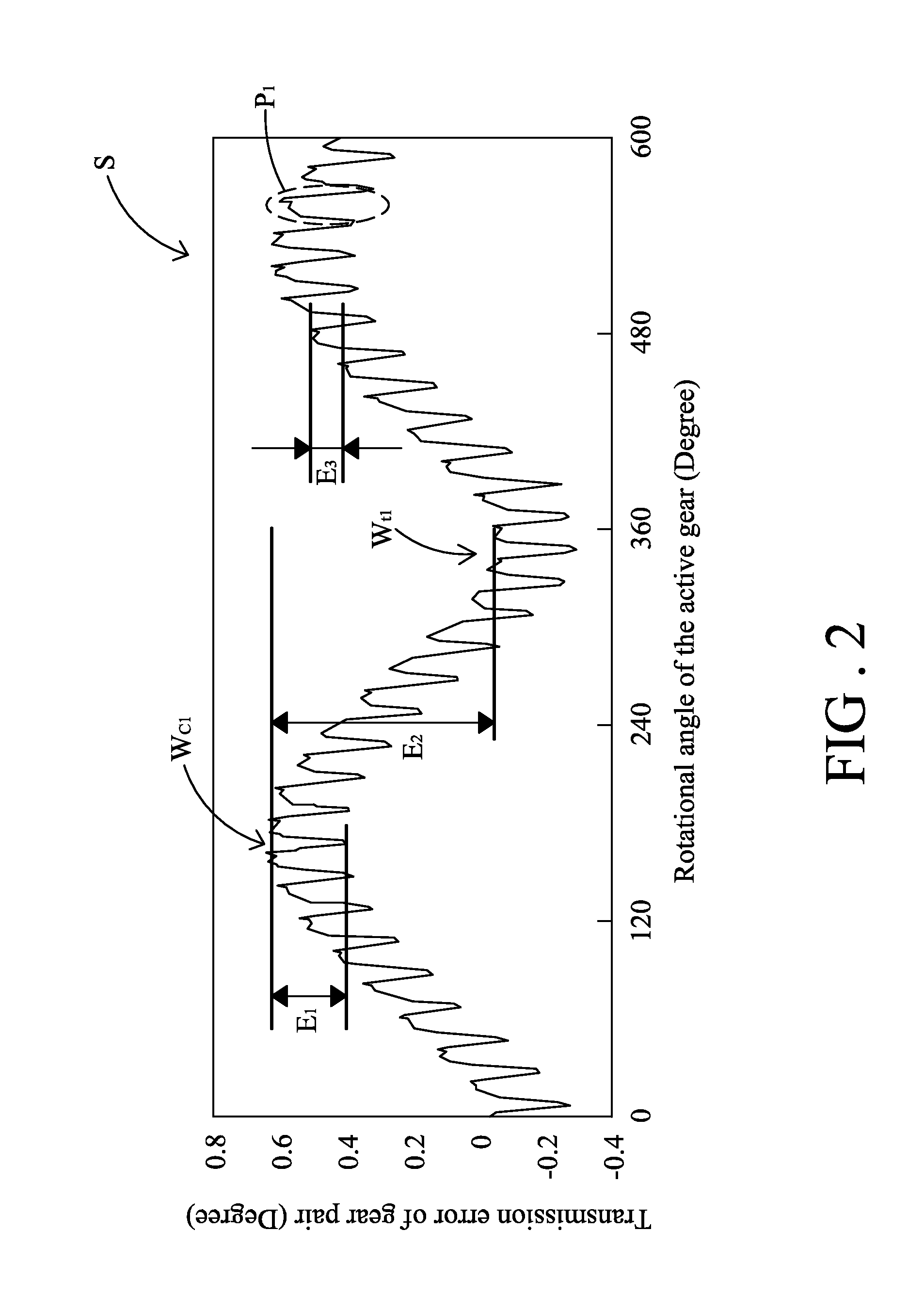

Method for determining the precision of gears

InactiveUS20140088891A1Less susceptible to noiseThe solution cannot be accurately determinedVibration measurement in solidsMachine part testingAlgorithmPitch error

A method for determining the precision of gears includes steps of providing a gear pair; performing a single flank test for the gear pair, to generate a testing signal graph; decomposing the testing signal graph into a plurality of intrinsic-mode-function graphs; selecting a first function graph and a second function graph from the intrinsic-mode-function graphs; measuring the amplitude of vibration of the first function graph, to get a profile error of gear; combining the first and second function graphs to form a graph of function combination; calculating an adjacent pitch error and an accumulated pitch error by means of the graph of function combination; and defining the gear precision for one of the gear pair according to the profile error of gear, the adjacent pitch error and the accumulated pitch error.

Owner:NAT CENT UNIV

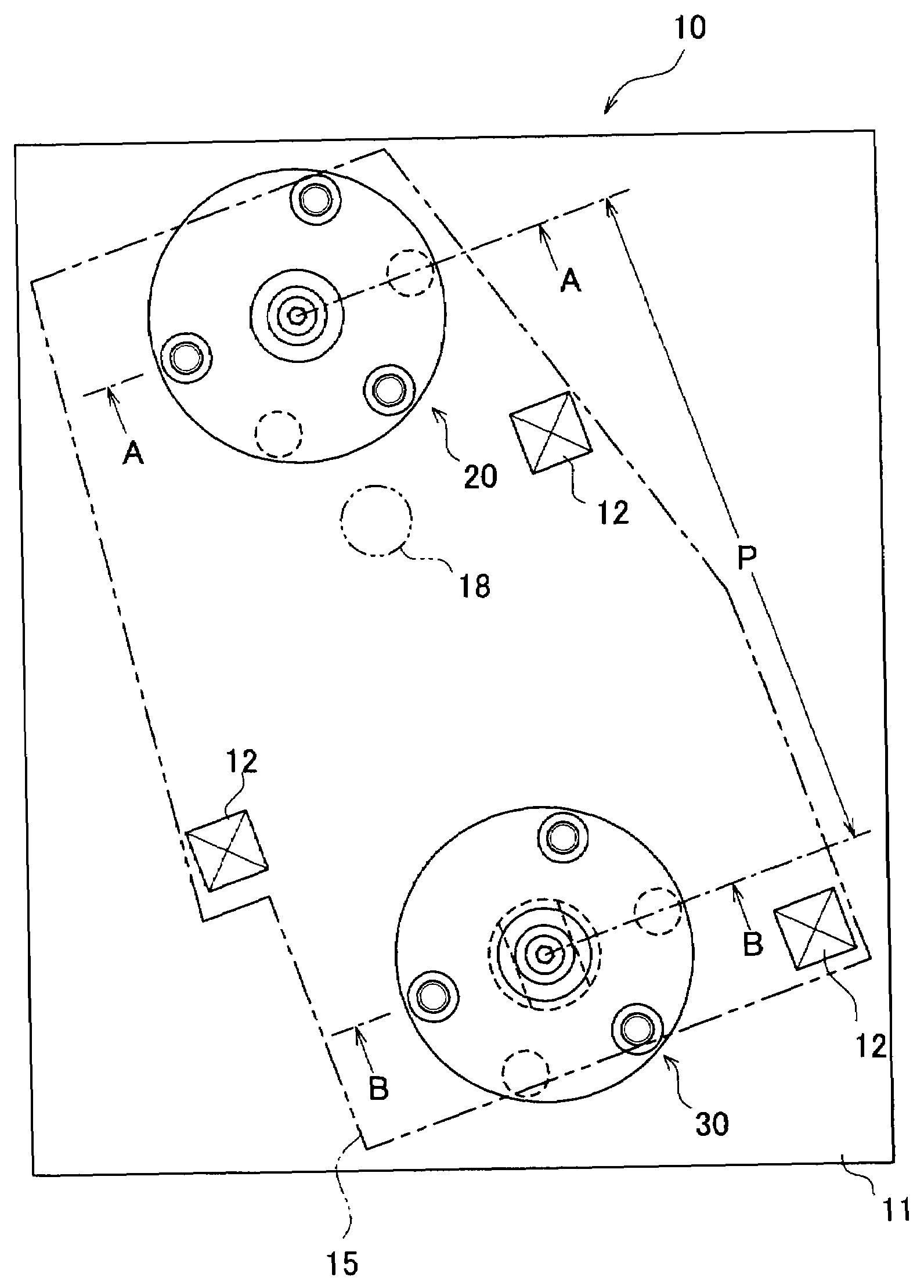

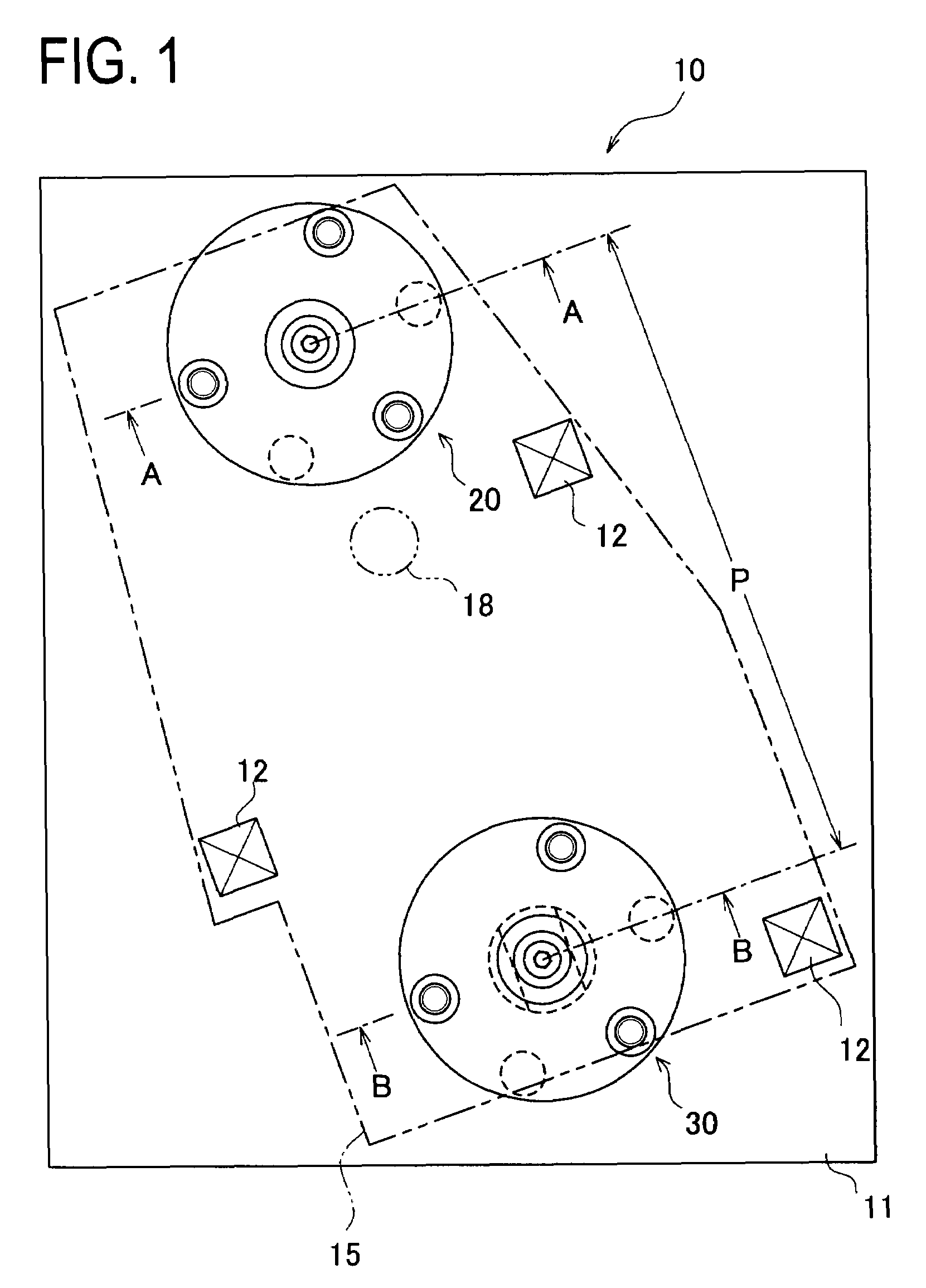

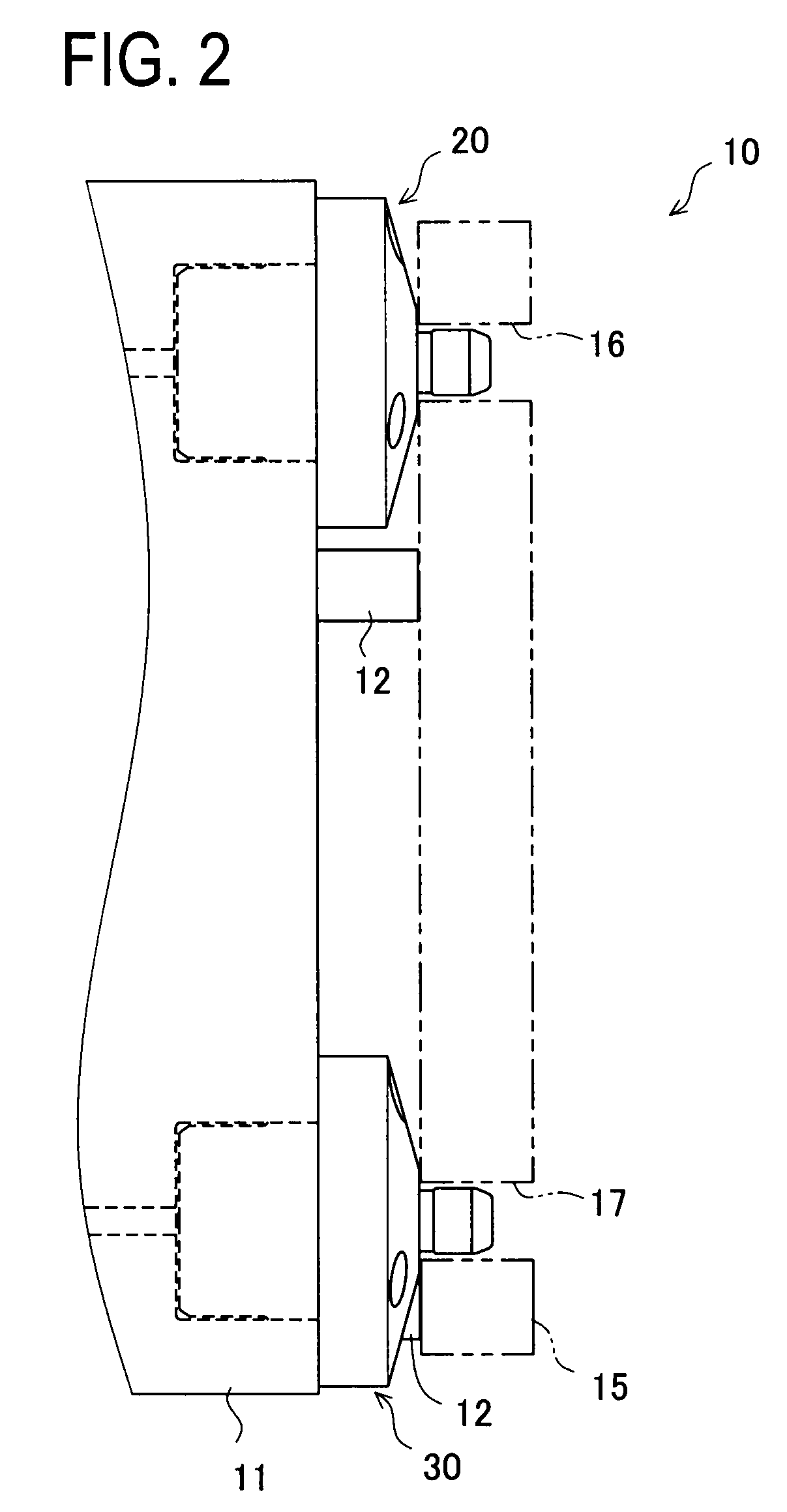

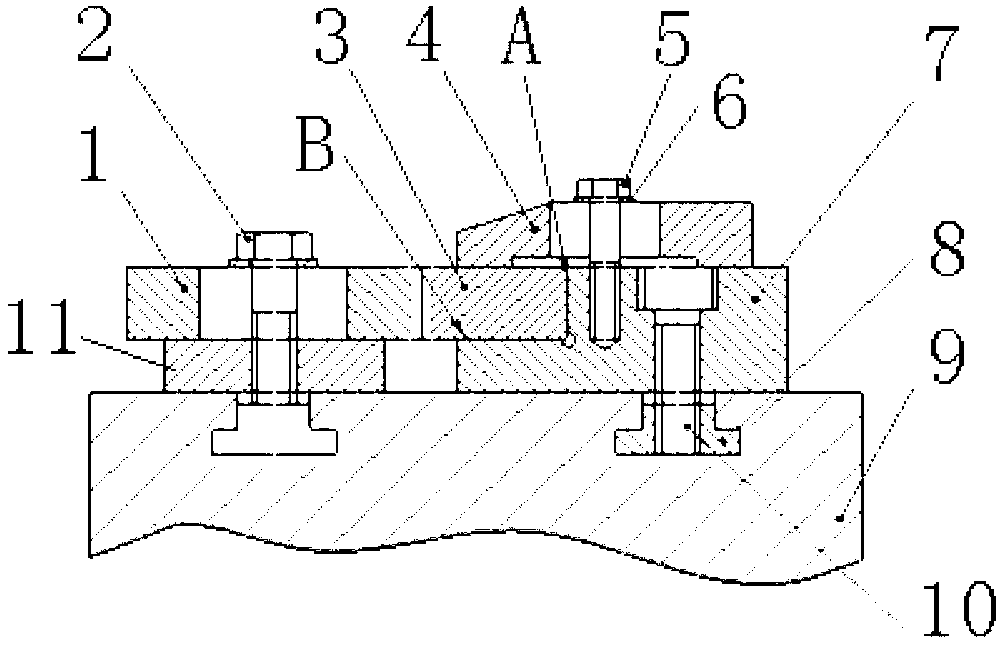

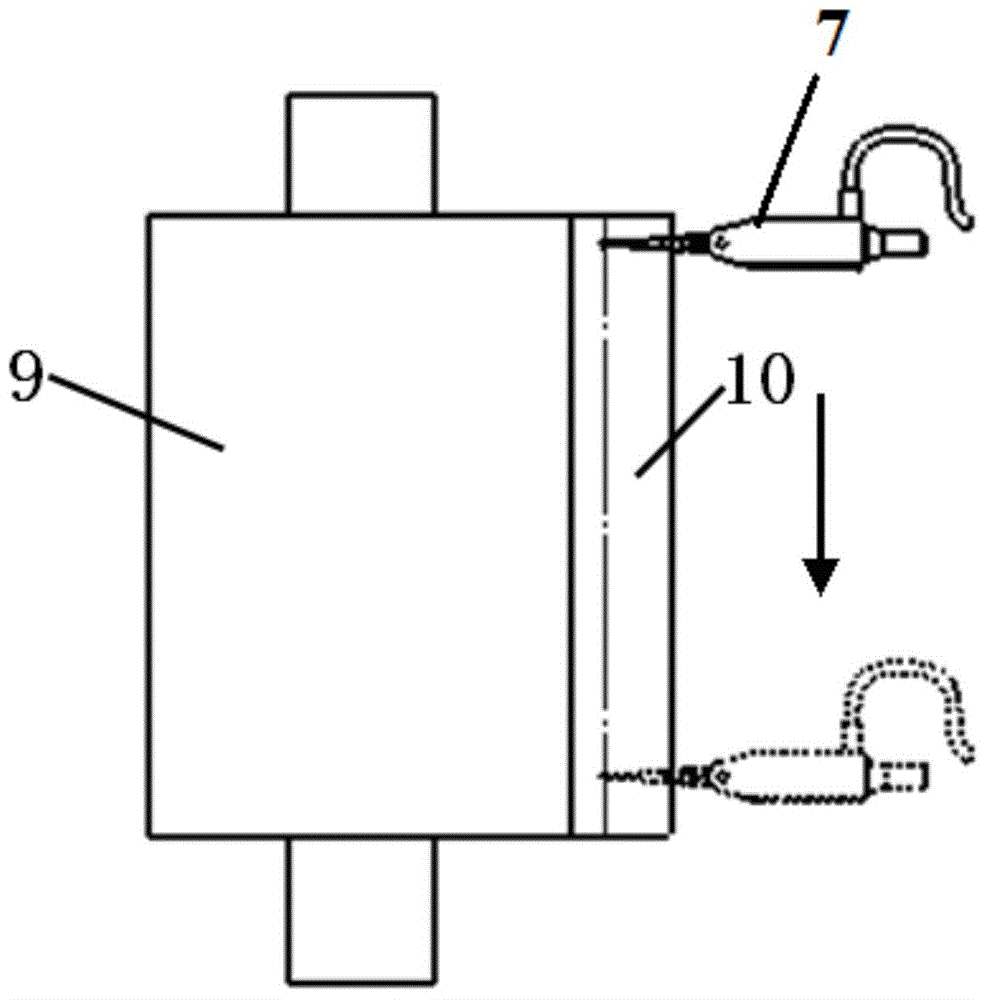

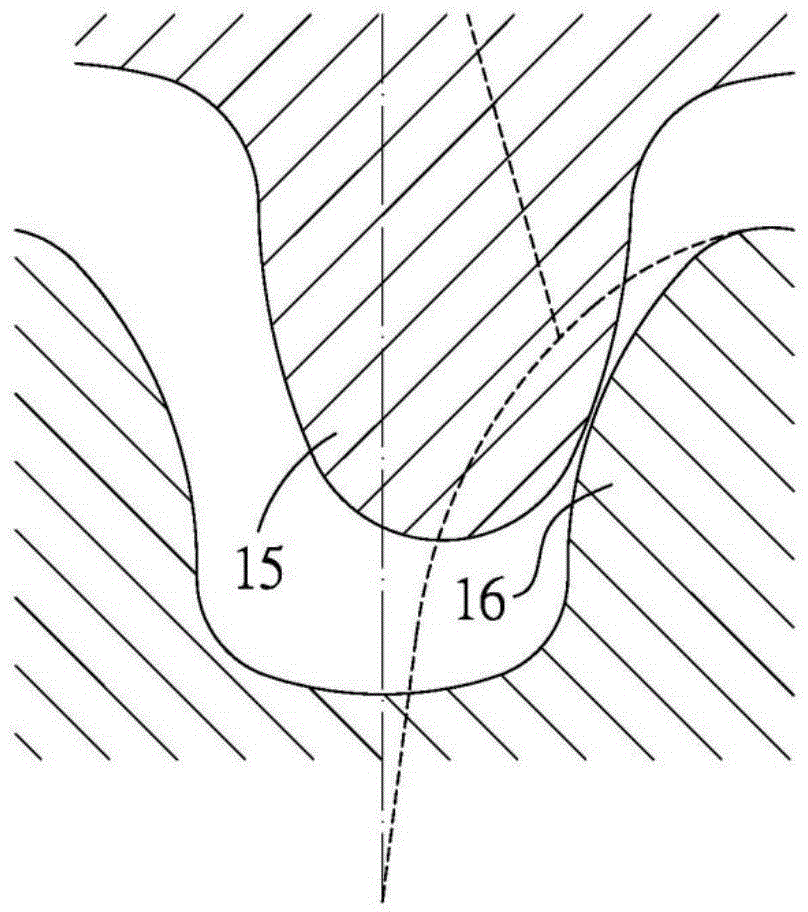

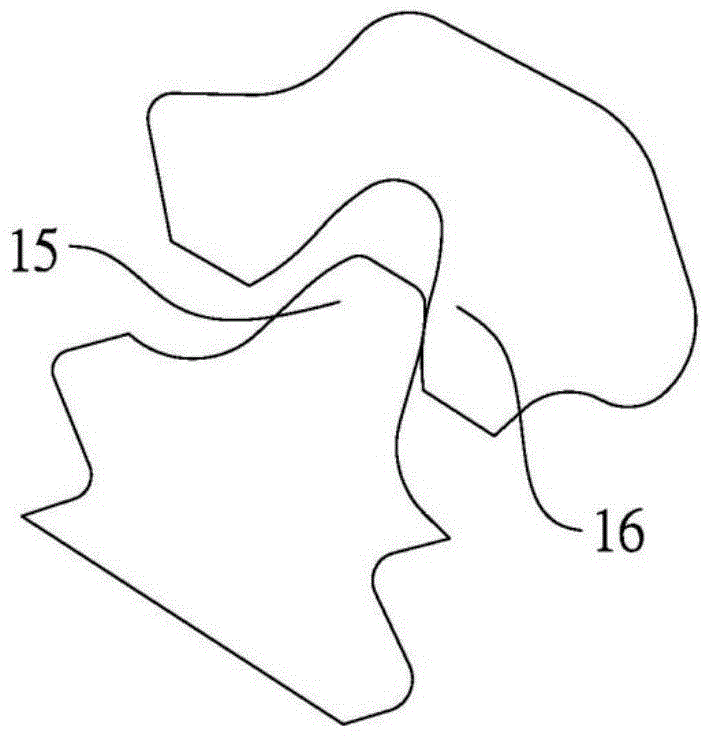

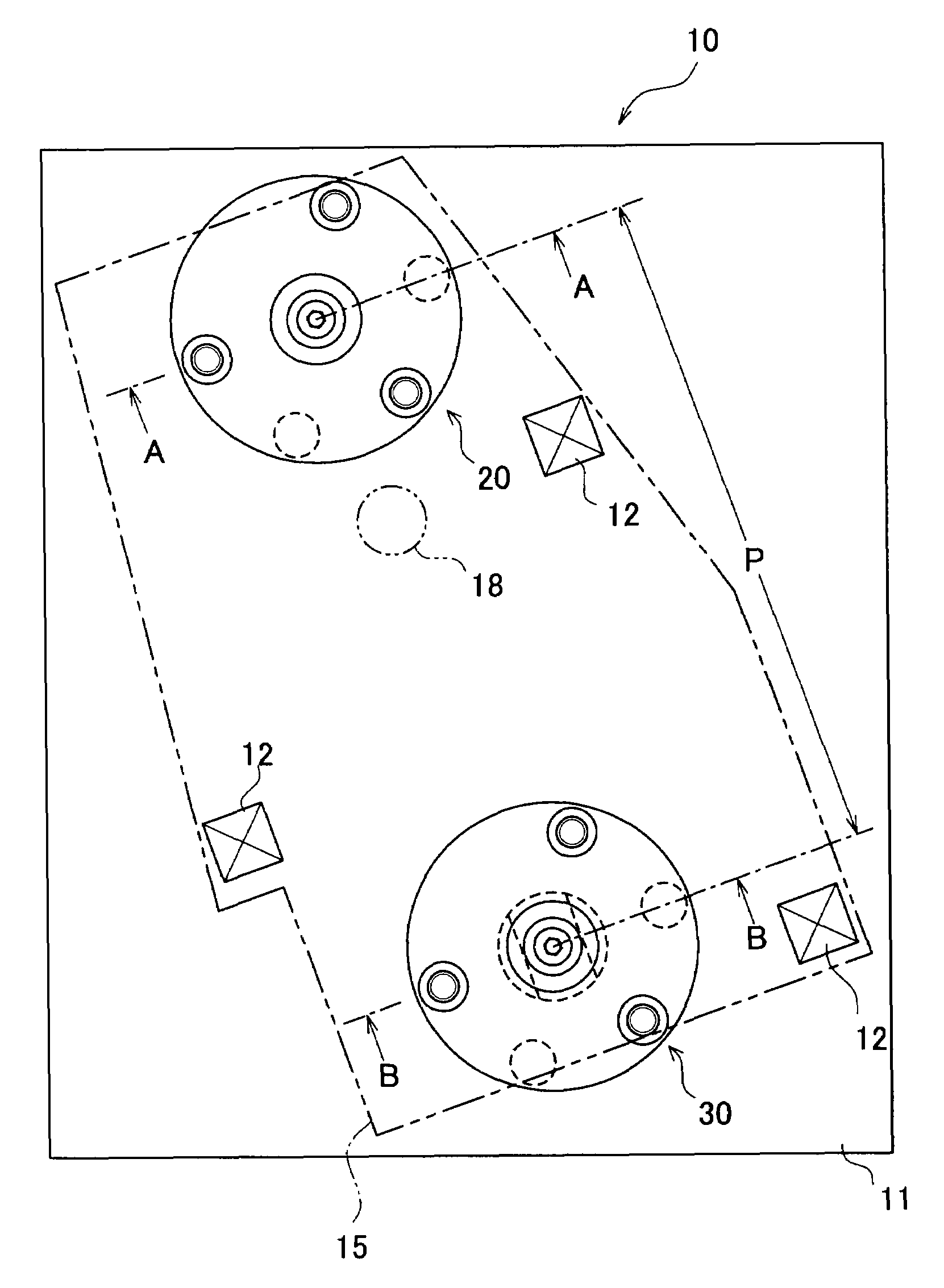

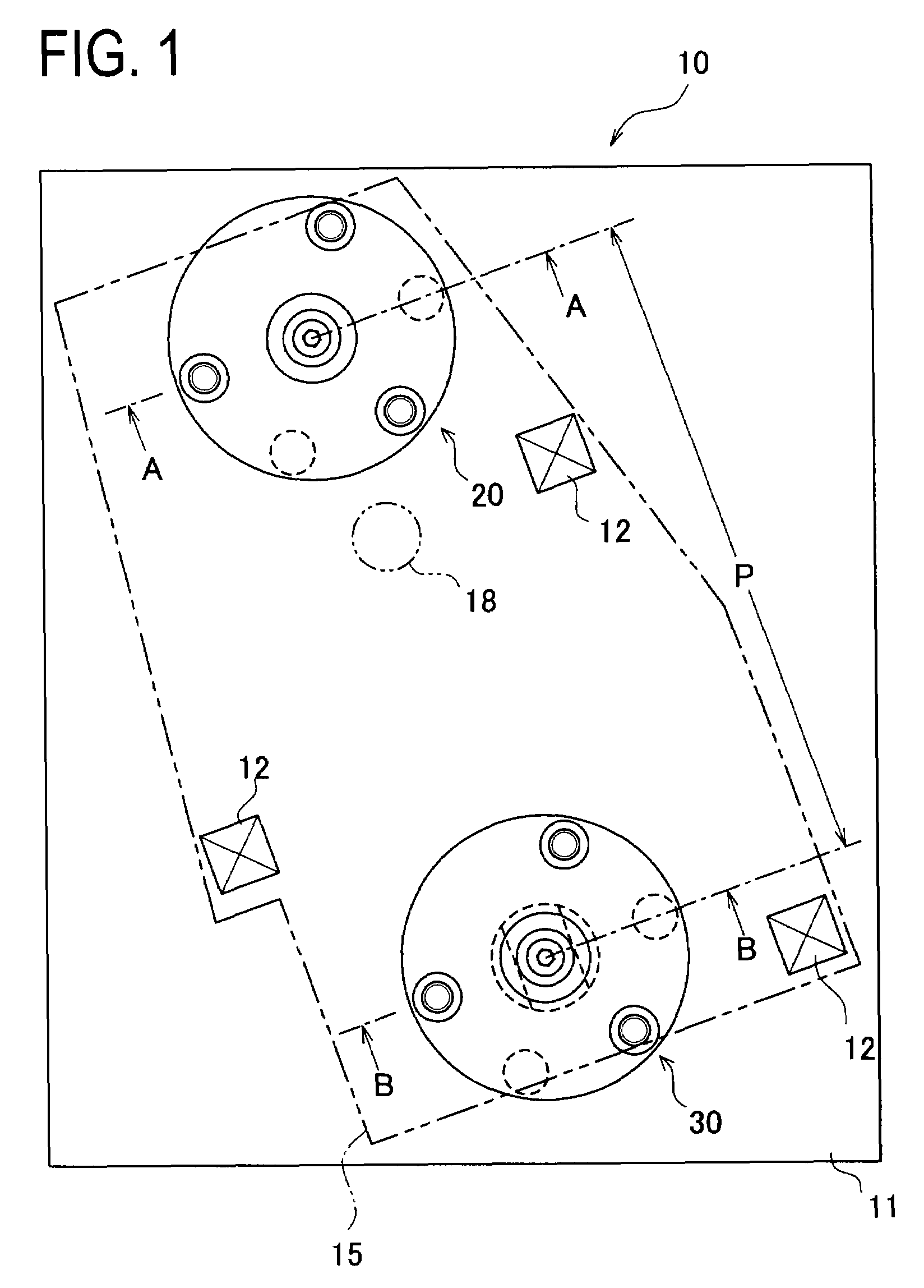

Work positioning method, and positioning device

ActiveUS20090267281A1High positioning accuracyImprove accuracyLarge fixed membersPositioning apparatusEngineeringFlange

Intended is to provide a method for positioning a work (15), which is adapted for a knock hole of a small diameter and which can absorb a pitch error between a main positioning hole (16) and an auxiliary positioning hole (17) of the work (15). An insert shaft (21) of main positioning means 820) is inserted into the main positioning hole (16). Auxiliary positioning means (30) includes a base lower block (36) having a parallel slide holding surface (36e), a sliding flange (34b) having a sliding surface (34c), and an insert shaft (31) disposed above the sliding flange (34b). The sliding flange (34b) of the auxiliary positioning means (30) is guided and moved by the slide holding surface (36e), and is inserted, while absorbing the pitch error, into the auxiliary positioning hole (17), thereby to position the work (15).

Owner:TOYOTA JIDOSHA KK +1

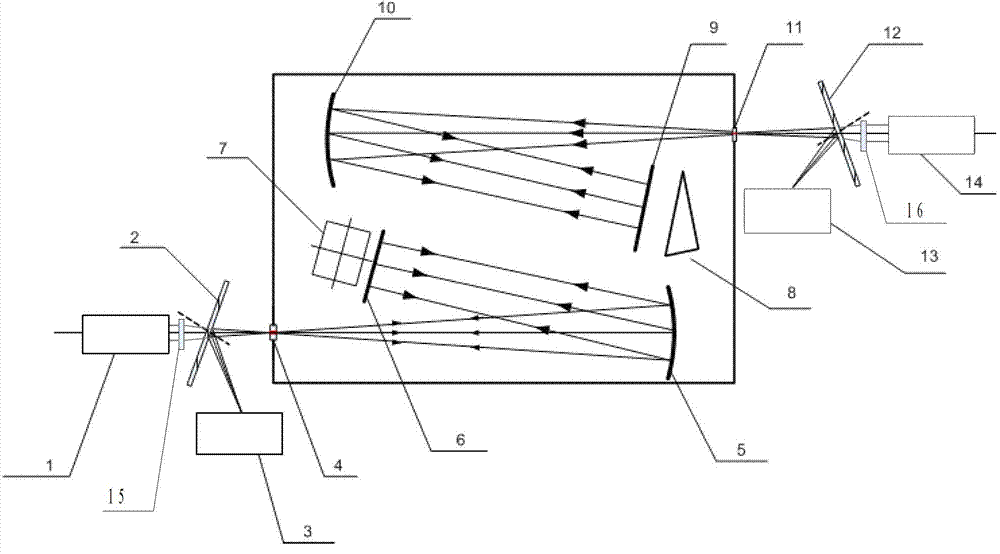

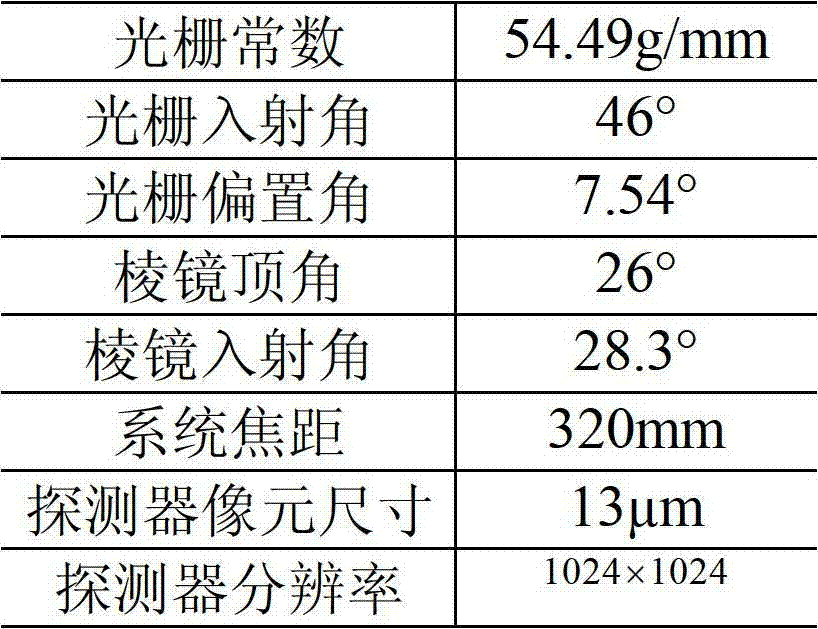

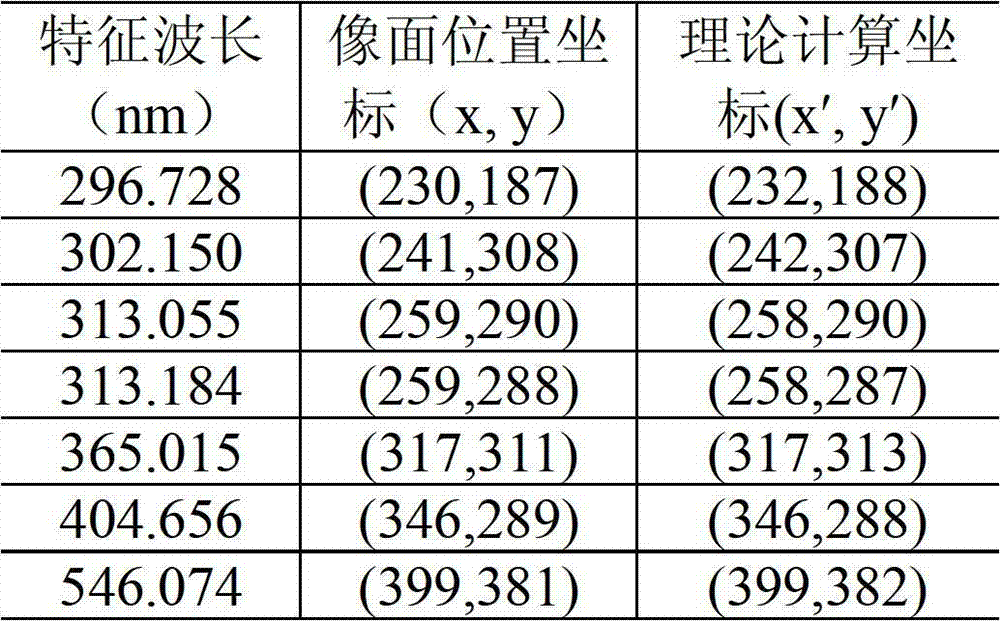

Method for adjusting small echelle grating spectrometer

The invention relates to a method for adjusting a small echelle grating spectrometer. The method comprises the following steps of: fixedly arranging a first incidence pinhole and enabling laser light of a first visible laser device to be incident into the first incidence pinhole; adjusting the position and the angle of a collimating lens so that the collimating lens works in the optimum state; eliminating rolling errors and pitching errors of a crossed dispersion prism; adjusting the position and the angle of a focus lens so that the focus lens works in the optimum state; arranging and adjusting echelle grating and preliminarily adjusting the incidence angle of the echelle grating; adjusting the position of an image plane of an area-array detector and rolling errors of the image plane; and precisely adjusting the incidence angle of the echelle grating and the incidence angle of the crossed dispersion prism. Required professional auxiliary devices are few, the method is an accurate adjusting method which is simple and convenient to operate and easy to apply, and is beneficial for realizing spectrum analysis, with high resolution, wide spectrum range and a transient full-spectrum direct-reading function, of the echelle grating spectrometer.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

High-precision spiral wire winding machine

InactiveCN103317063AEasy to transformDeformation reachesMetal-working feeding devicesPositioning devicesWinding machineClosed loop feedback

The invention discloses a high-precision spiral wire winding machine. By coordinated movement of a wire winding mechanism, a wire guiding mechanism, a wire discharging mechanism with a torque motor and a magnetic powder brake in combined action, a working table driving mechanism, a locking mechanism with a mandrel tension adjusting device, a position detection system used for accurately controlling working table movement and detecting and monitoring the closed loop feedback position and an electrical control system, a wire or a strip spiral wire is wound at a high precision, the spiral wire types comprise equal screw pitch, gradual change screw pitch, jumping screw pitch and mixed screw pitch of the wire or a strip and edgewise winding of the strip, and the screw pitch error is smaller than 2 mu m. The high-precision spiral wire winding machine is further provided with a heating device for the wire or the strip, the wire or the strip which is hard is deformed easily by heating before wound on a mandrel, and the goal of winding is achieved. The spiral wire winding machine is low in cost and meets the multi-mode high-precision spiral wire production requirements of communication enterprises and national defense industries.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

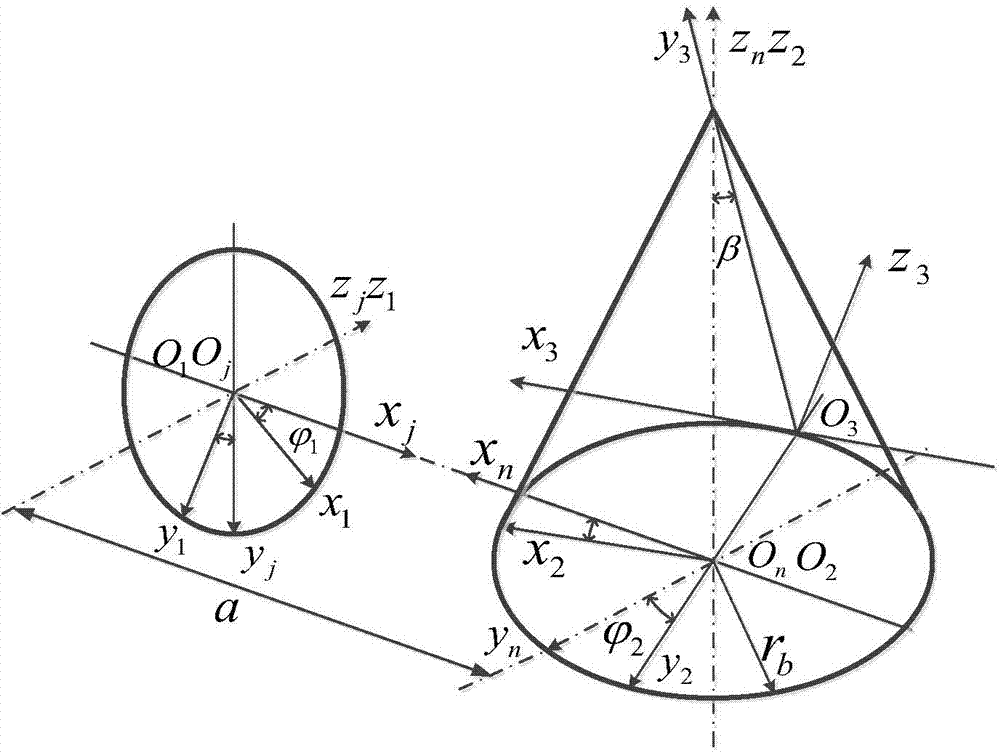

Method for measuring plane secondary enveloping ring surface hobbing cutter

ActiveCN103791869AImprove machining accuracyImprove product qualityMeasurement devicesHobbingMathematical model

The invention relates to a method for measuring a plane secondary enveloping ring surface hobbing cutter, and belongs to the fields of the precision testing technology and instrument, the mechanical transmission technology and metal cutting tools. According to the method, numerical models of various errors of the hobbing cutter are built based on the gear space meshing mechanism and a corresponding worm tooth surface equation according to the definitions of the various errors of the hobbing cutter, coordinate conversion is carried out on the numerical models, the numerical models are resolved into motions of three axes of a measuring machine, and a numerical value solving method is adopted for obtaining numerical solutions of three coordinates. A computer conducts sampling route planning according to the numerical solution, the coordinate values are input into a numerical control system to control the motions of the three axes of the measuring machine, a data collecting system synchronously collects three-axis grating values and measuring head data, the collected data are processed, and the high-precision measurement on cutting edge spiral line errors, edge opening tooth shaped errors and scrap containing groove circular pitch errors of the plane secondary enveloping ring surface hobbing cutter is accordingly achieved.

Owner:BEIJING UNIV OF TECH

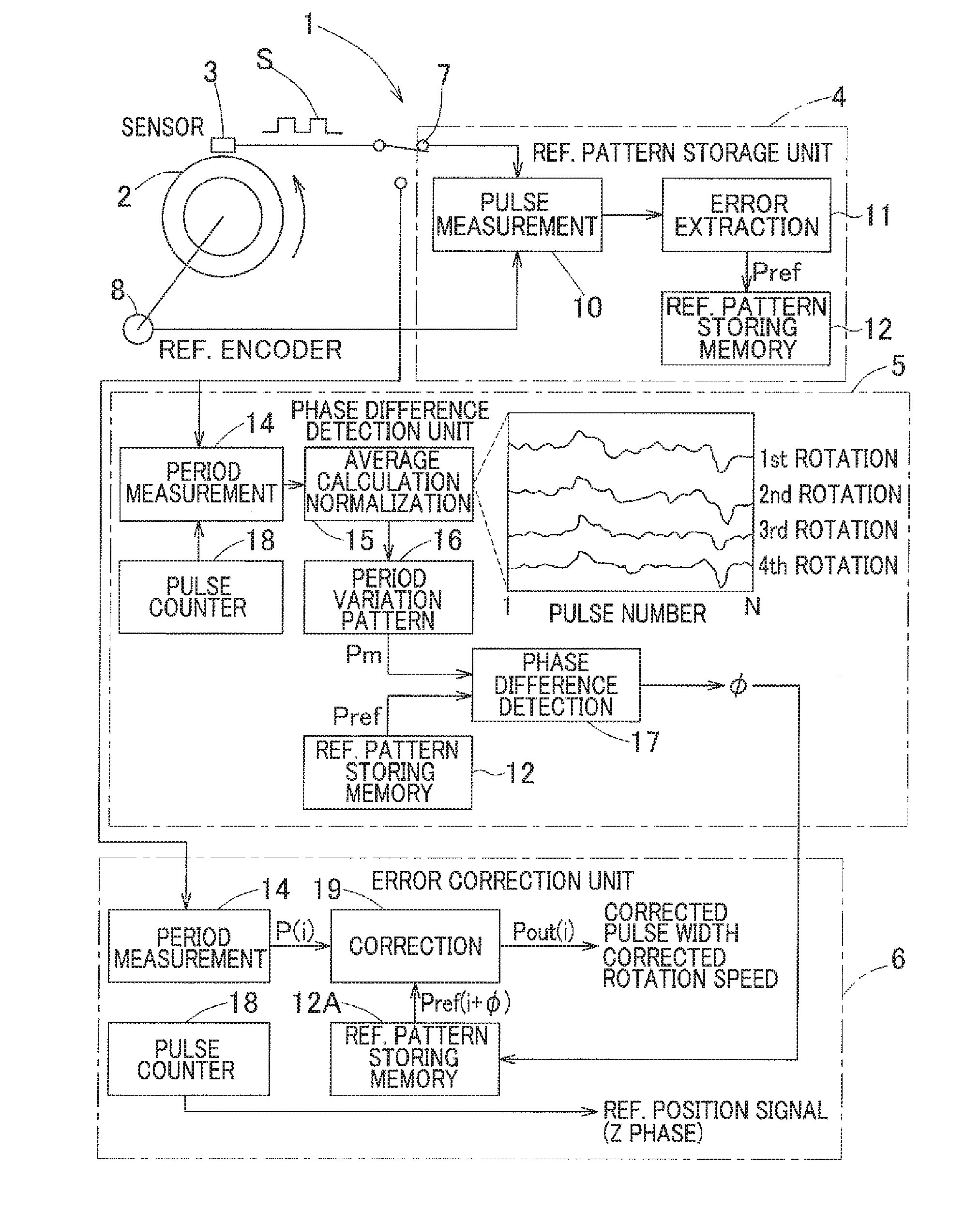

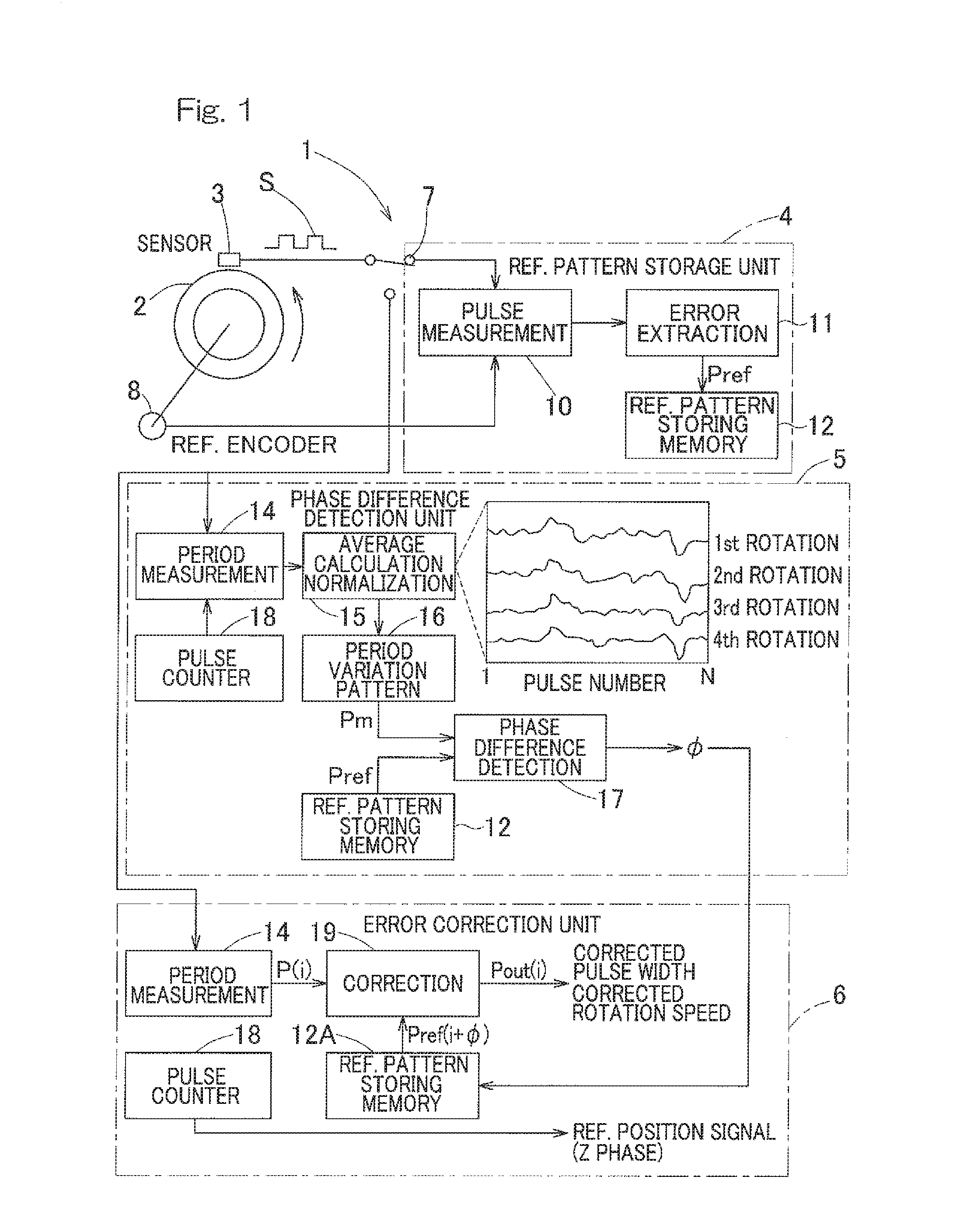

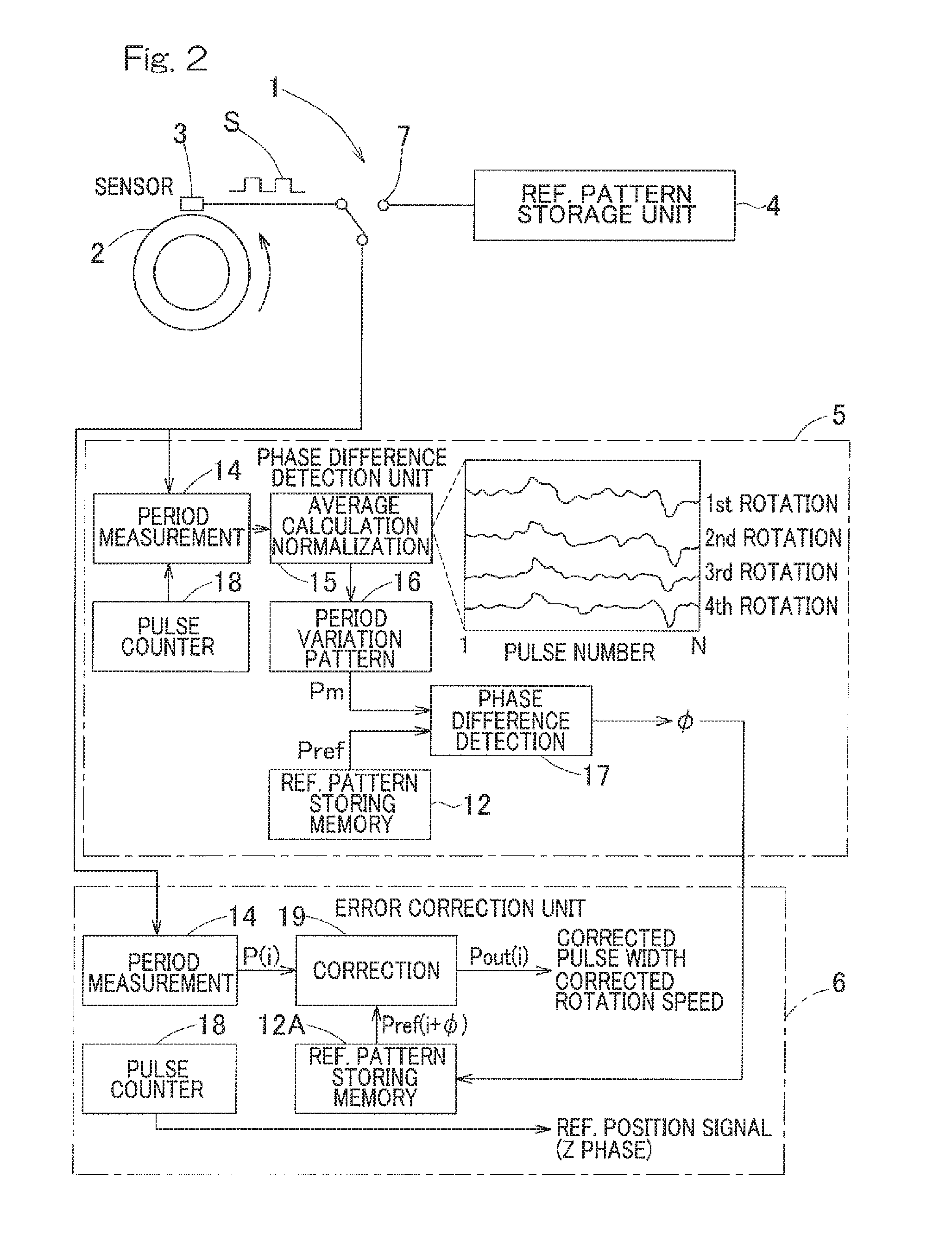

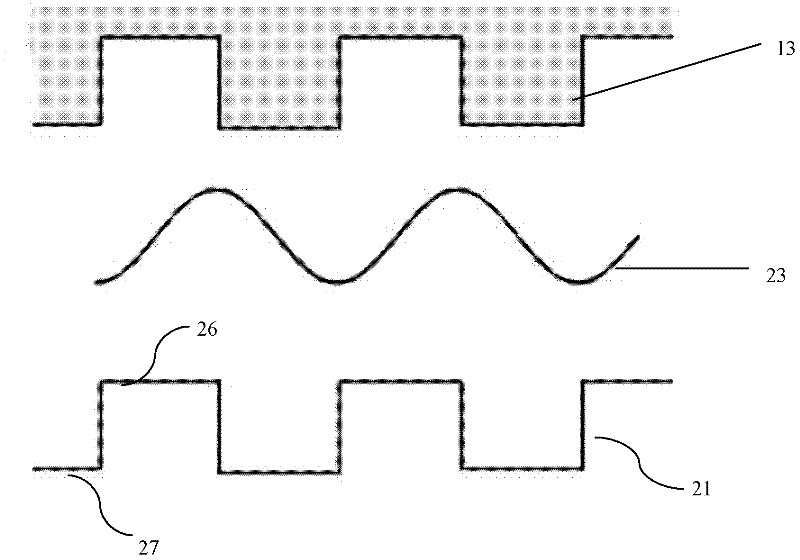

Rotation detection device and bearing unit equipped with rotation detection device

ActiveUS20160138942A1Improve accuracyDetect positionUsing electrical meansStray field compensationRelative phasePhase difference

The rotation detection device includes: an encoder having to-be-detected patterns cyclically arranged in the circumferential direction; and a sensor configured to detect the to-be-detected patterns to generate pulses. The device further includes a reference pattern storage unit, a phase difference detection unit, and an error correction unit. The reference pattern storage unit measures pitch errors in the to-be-detected patterns prior to operation and stores the pitch errors as a reference pattern Pref. The phase difference detection unit determines a pitch error pattern Pm corresponding to one rotation of the to-be-detected patterns from rotation signals representing a plurality of rotations detected during operation, and performs comparison with a reference pattern Pref to determine a relative phase difference φ. Based on the phase difference φ obtained by the phase difference detection unit, the error correction unit corrects errors included in the rotation signals detected by the sensor.

Owner:NTN CORP

Tooth alignment clamp for ultra-long rack and positioning machining method for tooth alignment thereof

InactiveCN103008797AGuaranteed Cumulative ErrorNo changeGear-cutting machinesGear teethEngineeringInverted-T shape

The invention discloses a tooth alignment clamp for an ultra-long rack. The tooth alignment clamp comprises two parallel inverted T-shaped slots which are arranged vertically on a workbench of a rack machining machine, an inverted T-shaped fixing block is arranged in every inverted T-shaped slot, and the upper edges of the two inverted T-shaped slots are respectively provided with a positioning seat and a clamp body; tooth alignment blocks are arranged on the positioning seats; and the clamp bodies are fixedly connected with the other inverted T-shaped fixing block under the corresponding clamp body and are provided with a step with the same height as the tooth alignment blocks in a position facing the tooth alignment blocks, and the steps are used for arrangement of a toothed blank to be machined, and a pressure plate is arranged on the upper surface of the toothed blank. The invention also discloses a positioning machining method for tooth alignment during machining of the ultra-long rack on a gear shaping machine, and positioning machining for tooth alignment of the ultra-long rack is completed through a plurality of steps. The structure of the device is simple, the process of the method is also simple, assembly and disassembly can be performed conveniently, and the pitch and the cumulative pitch error can be ensured for teeth cut later only by ensuring that the positions of the teeth of the rack are not changed relative to the workbench.

Owner:MCC SFRE HEAVY IND EQUIP

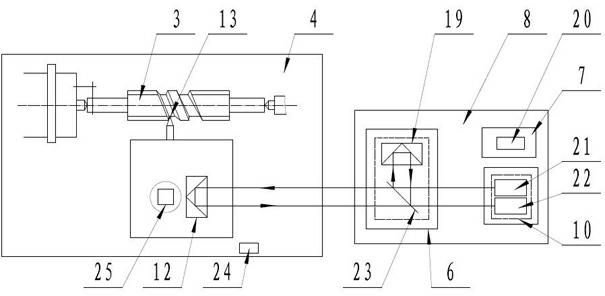

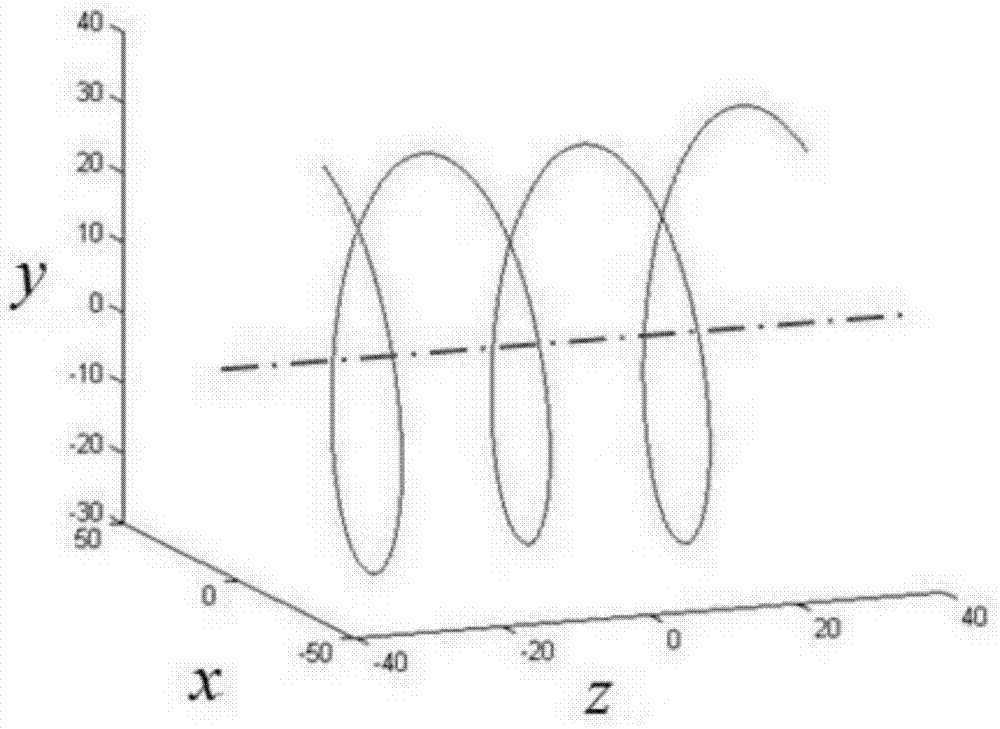

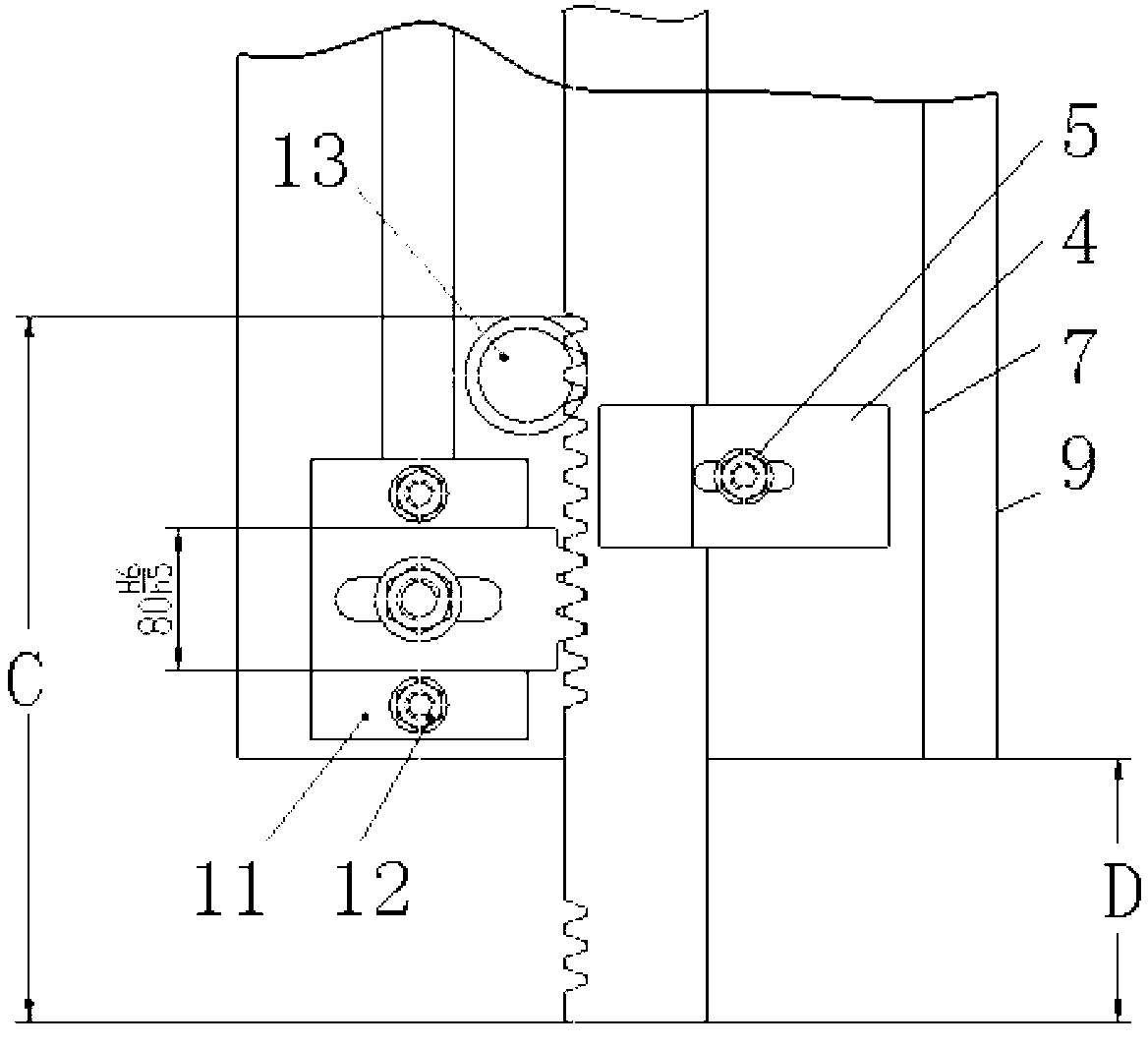

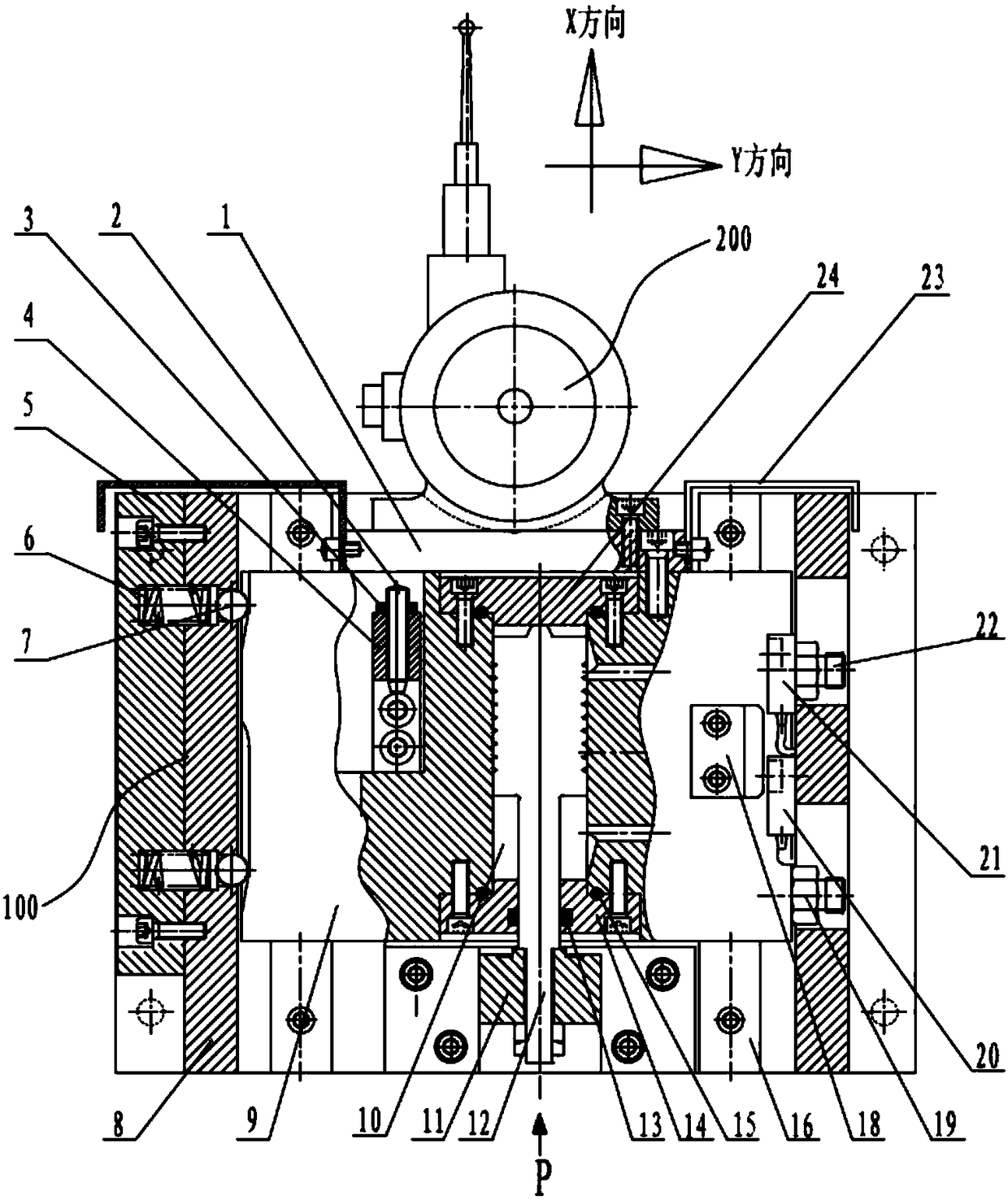

Three-axis linkage-based complicated part accurate measurement central path planning realizing method and device

ActiveCN104154849ARealize stepless adjustmentEasy to detectUsing electrical meansUsing optical meansCircular discElectric sense

The invention provides a three-axis linkage-based complicated part accurate measurement central path planning realizing method and a device. the device comprises a base, a workpiece vertical column, and a measurement vertical column, wherein the measurement vertical column is provided with an electric sensing head capable of moving vertically and horizontally. Horizontal movement of the measurement vertical column is used for contotrlling the distance between the measuring head and the center of a spindle rotating shaft system, stepless adjustment of a basic circle can be realized, a series of basic circle discs do not need to assist measurement of a gear, the detection process is simplified, and detection errors due to wear of the basic circle discs can be solved. Through controlling vertical movement, horizontal movement of the measuring head and linkage of the spindle rotating shaft system, control of the measuring trajectory of the measuring head can be realized respectively, and helix, tooth profile and pitch error of the gear with any base circle radius value within the measuring range can be fully automatically measured. In addition, path planning of an eccentric gear can be realized, and full-automatic measurement on helix, tooth profile and pitch error of the eccentric gear can be realized.

Owner:西安秦川思源测量仪器有限公司

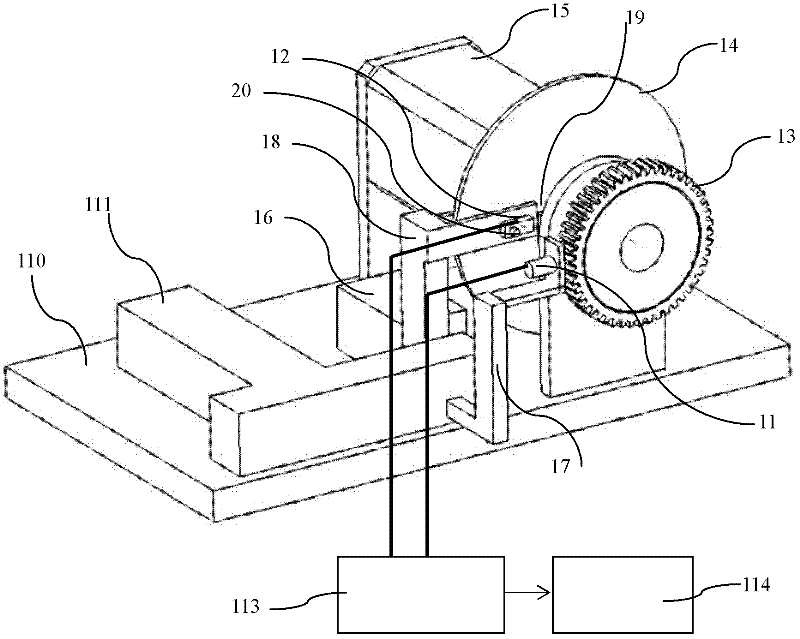

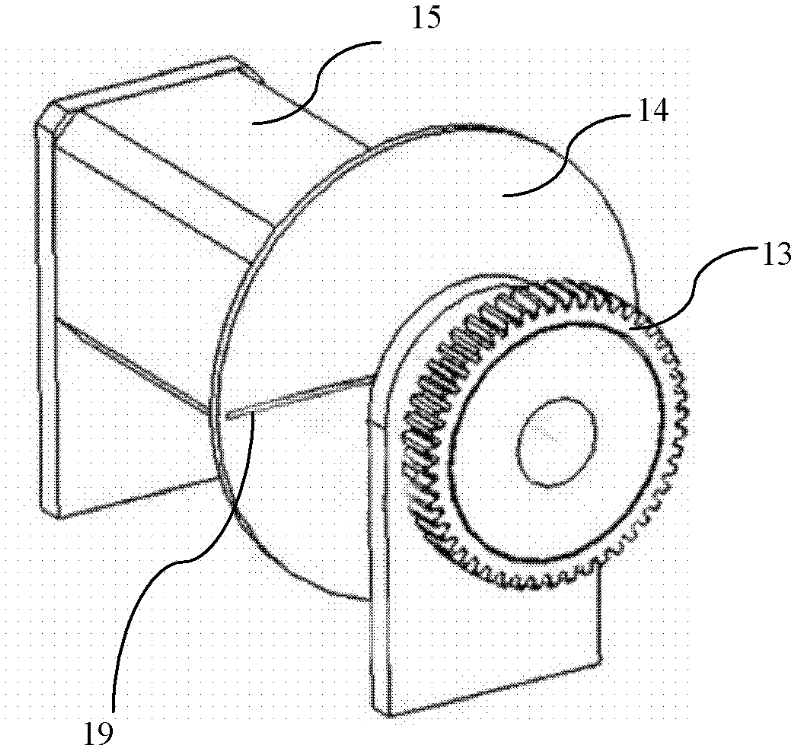

Method for detecting pitch error of ABS gear ring by magnetic induction

ActiveCN102359755AAvoid False Test ResultsIncrease credibilityUsing electrical meansContact testEngineering

The invention discloses a method for detecting a pitch error of an ABS gear ring by magnetic induction. The method is characterized in that the method comprises a detection step, a signal collection step and an error calculation step. Besides, an apparatus for detecting a pitch error of an ABS gear ring by magnetic induction is utilized in the invention and a non-contact test is employed; therefore, no surface damage on a to-be-detected ABS gear ring will be caused. According to the invention, a test process is carried out automatically; an additional error caused by unstable selection of test points and a subjective factor can be avoided, wherein the additional error exists during manual measurement; and when a pitch error of a gear ring is evaluated, out-of-tolerance gear localization can be carried out simultaneously, so that an analytic base of improvement of a corresponded production method and a flow is provided for ABS gear ring manufacturers on the condition that product qualities have problems and are unstable.

Owner:上海龙感汽车电子有限公司

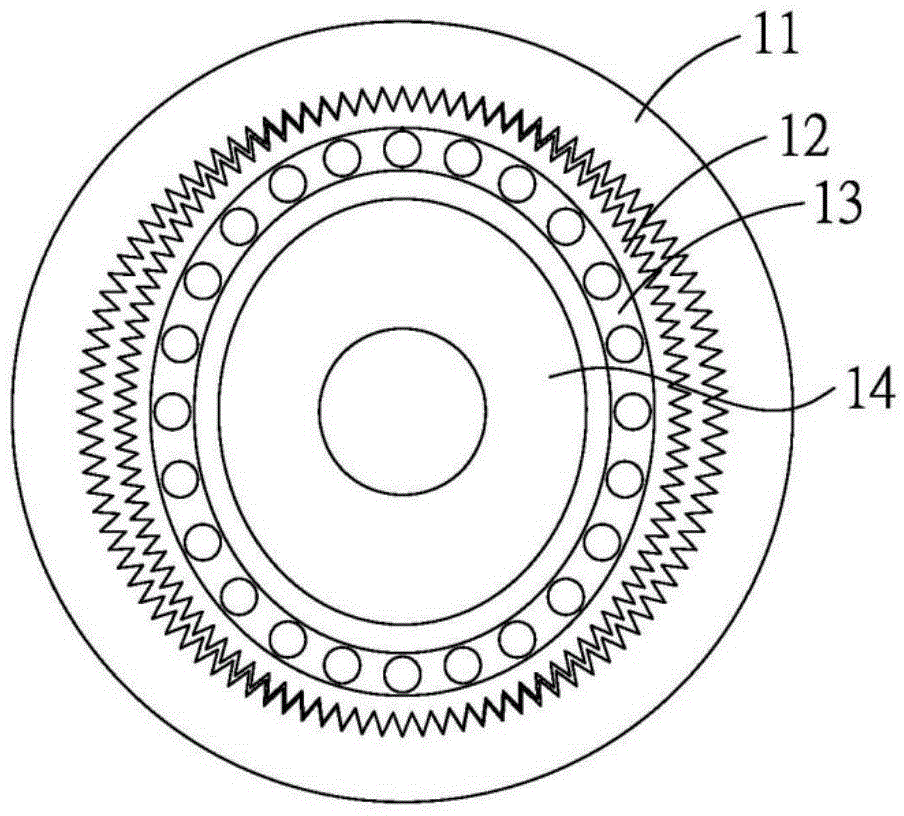

Harmonic type reducing mechanism

InactiveCN104565219AIncrease the number of teethPitch error reductionPortable liftingToothed gearingsTooth numberEngineering

The invention discloses a harmonic type reducing mechanism. The harmonic type reducing mechanism comprises an inner rigid gear with a tooth number of 2(n+1), an outer flexible gear with the tooth number of 2n, a flexible bearing and a wave generation wheel, wherein the outer flexible gear is arranged in the inner rigid gear in a penetrating manner, and the outer flexible gear has a modulus m which is identical to that of the inner rigid gear; the flexible bearing is arranged in the flexible outer bearing in a penetrating manner; the wave generation wheel is arranged in the flexible bearing in a penetrating manner. By increasing the meshed gear teeth, so that a pitch error of each tooth is reduced by average, the transmission precision is improved, the transmission torque is increased, and the flexible bearing is ensured to rotate smoothly.

Owner:HIWIN TECH

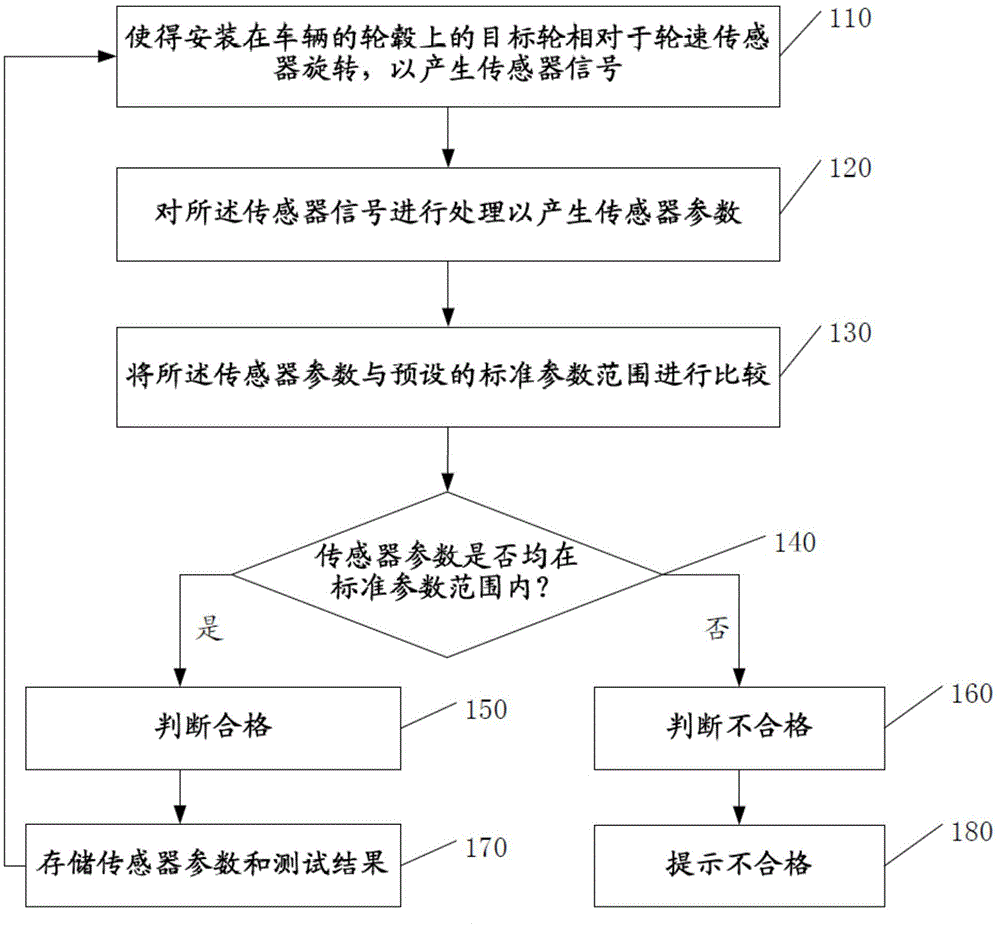

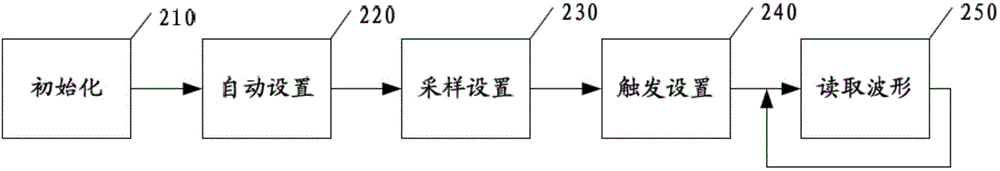

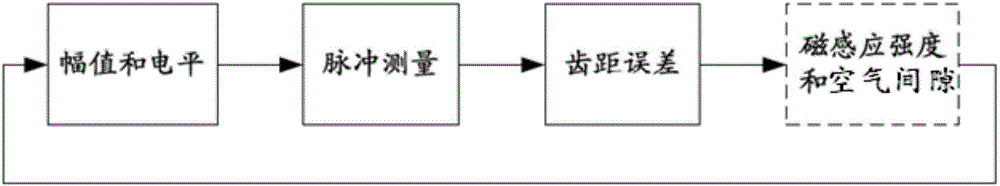

Matching testing method and system used for wheel speed sensor and target wheel

ActiveCN104090129AEasy to knowQuick to knowTesting/calibration of speed/acceleration/shock measurement devicesWheel speed sensorLow voltage

The invention provides a matching testing method and system for a wheel speed sensor and a target wheel. The method includes the steps that the target wheel installed on a hub of a vehicle is made to rotate relative to the wheel speed sensor to generate a sensor signal; the sensor signal is processed to generate sensor parameters including high voltage, low voltage, a duty ratio, a period, positive pulse width, negative pulse width and a pitch error; the sensor parameters are compared with a preset standard parameter range; if the sensor parameters are within the standard parameter range, the sensor parameters are judged to be qualified, and otherwise the sensor parameters are judged to be unqualified. In this way, labor and time needed for testing can be saved, and accuracy of a testing result can be improved.

Owner:CONTINENTAL AUTOMOTIVE CORP LIANYUNGANG CO LTD

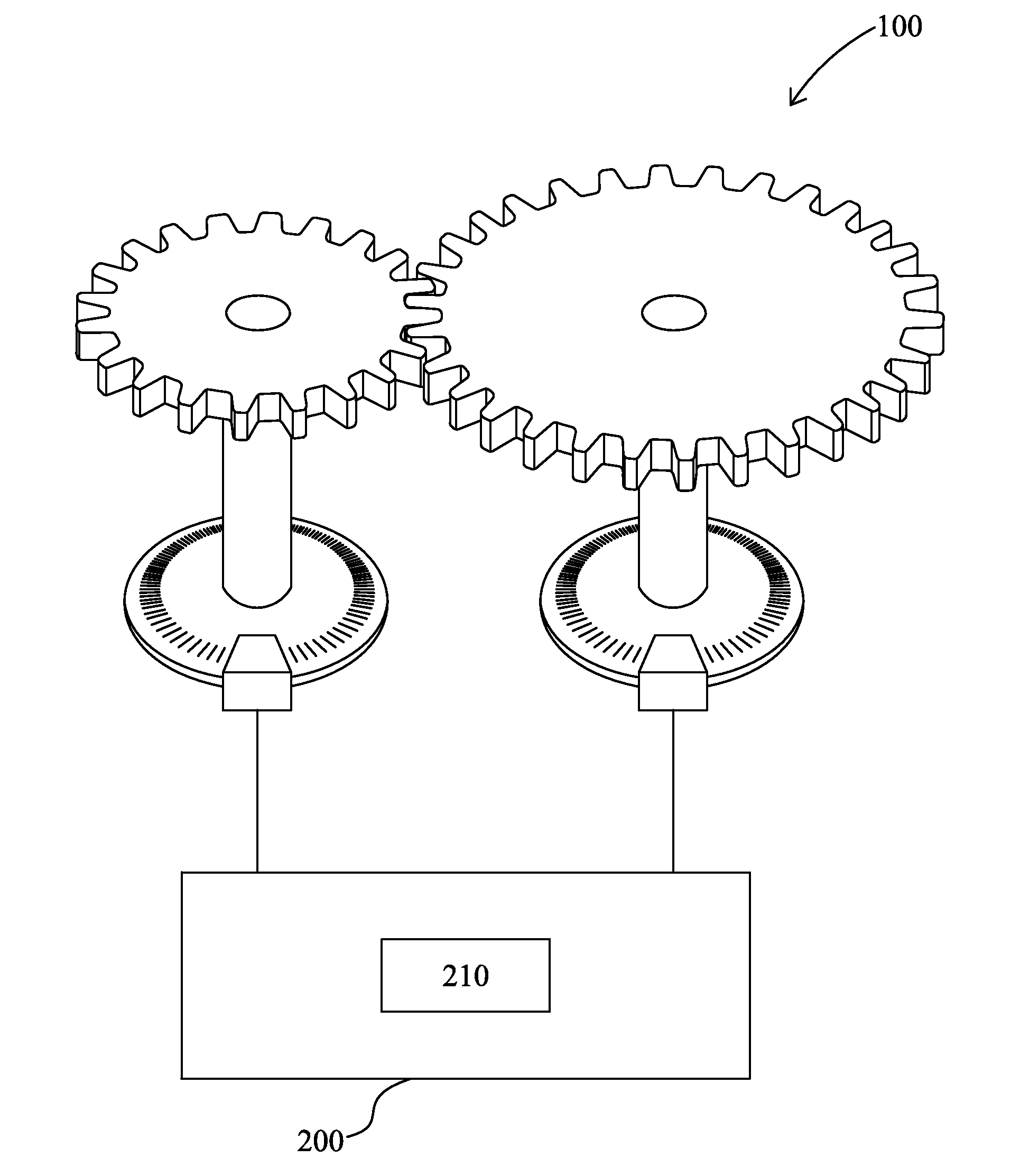

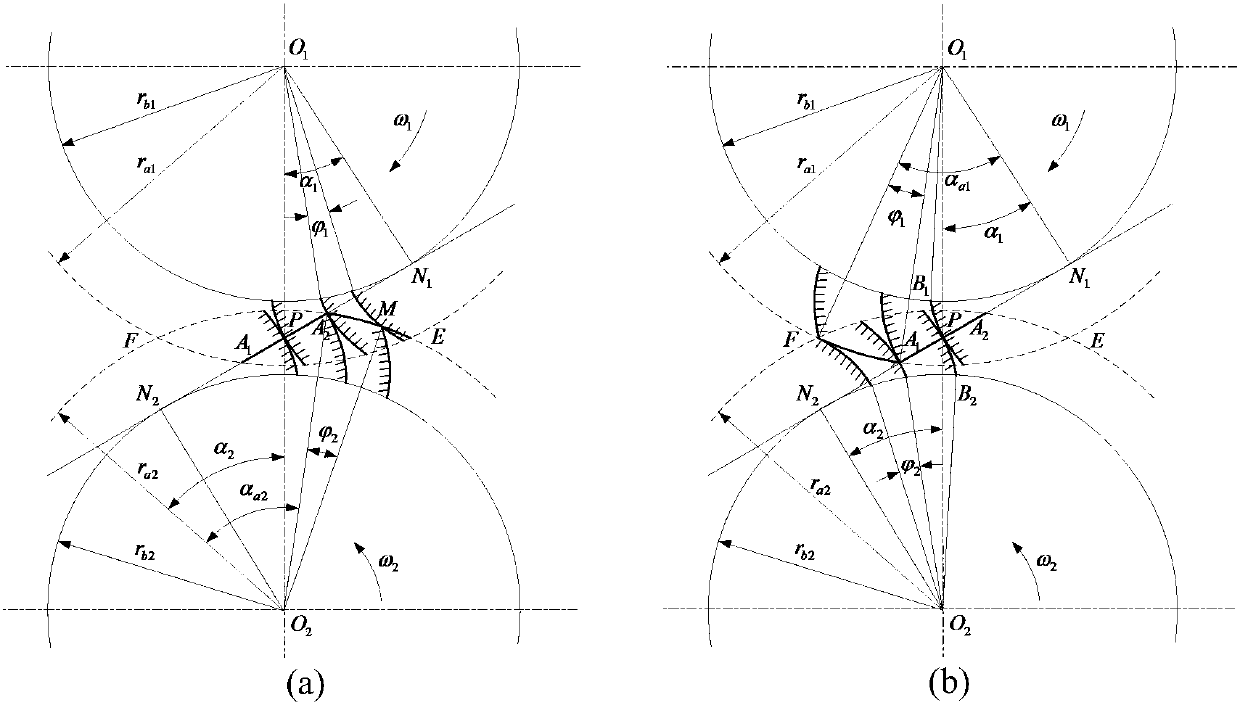

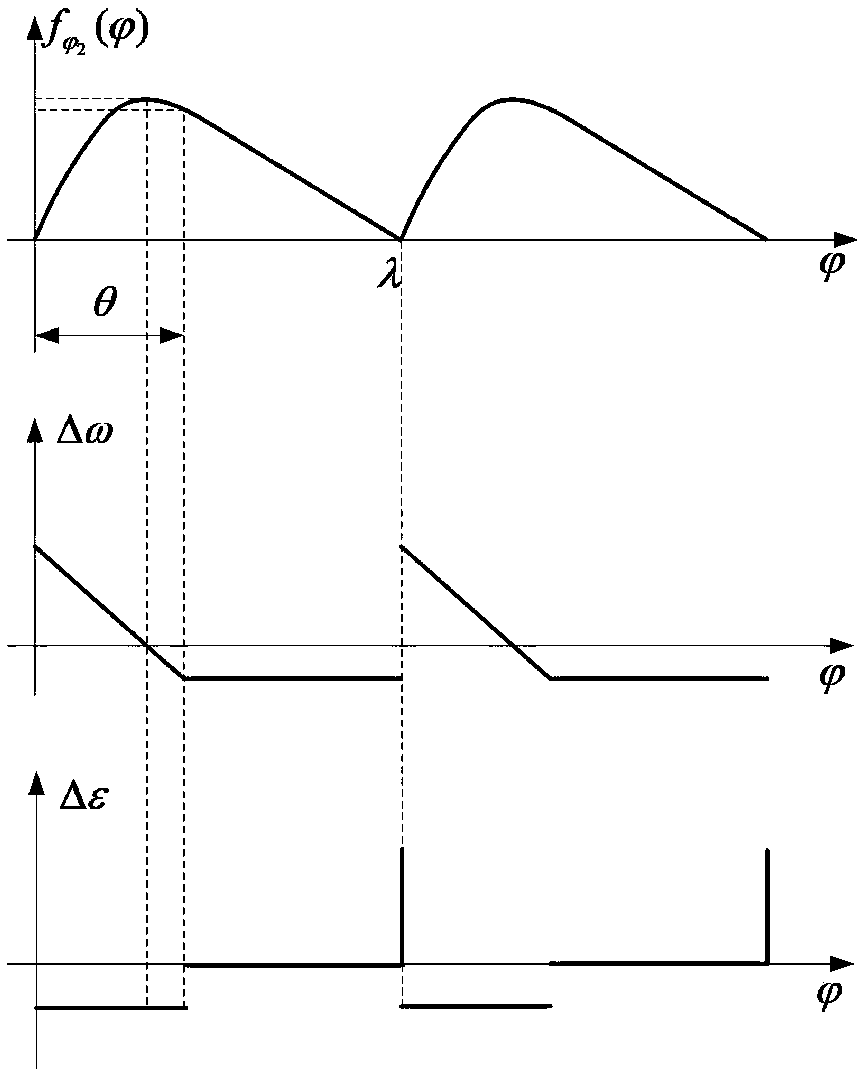

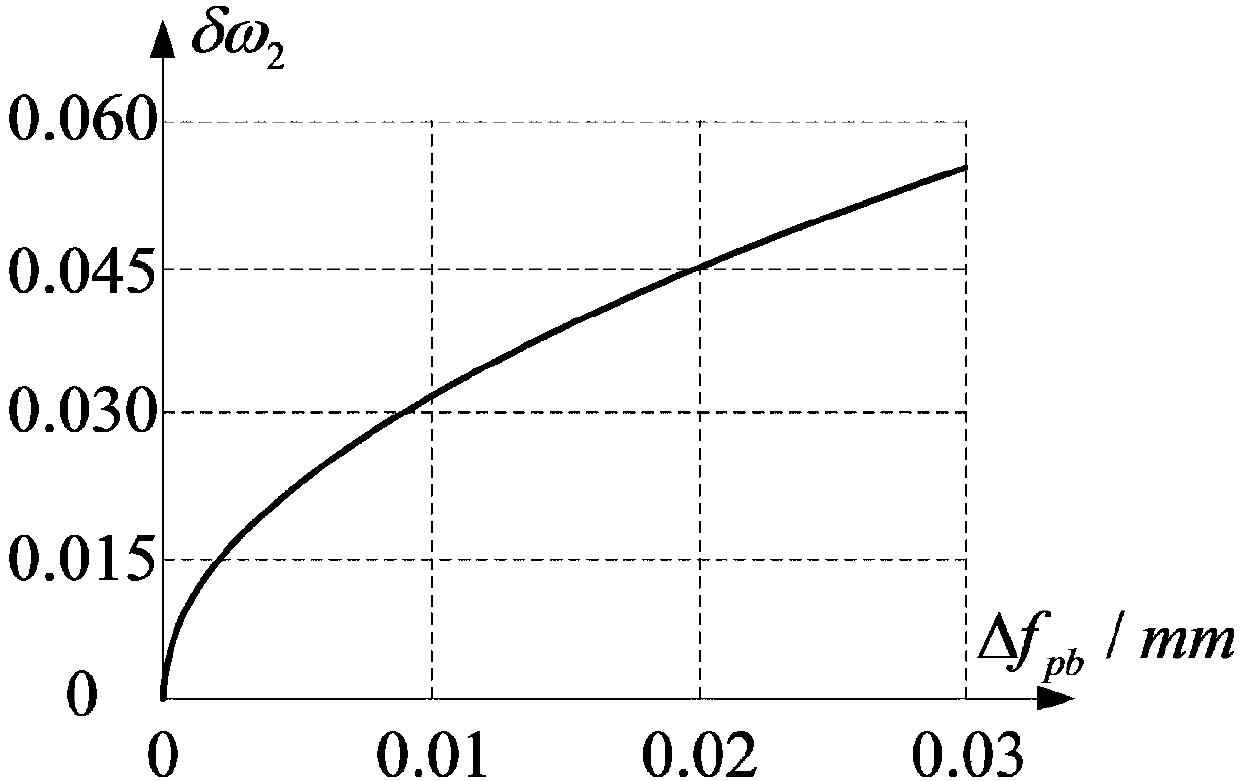

Meshing impact model with base pitch error

The invention provides a gear meshing impact model with a base pitch error, which belongs to the technical field of mechanical transmissions. The base pitch error of a gear can lead out-of-line meshing of a gear pair. In an out-of-line meshing section, a circumstance that a contact point on a driving gear moves from a tooth top to a tooth root and a contact point on a driven gear moves from a tooth root to a tooth top can occur, that is a reversal order meshing phenomenon. The invention, by using an angular velocity error model and an angular acceleration error model of a reversal order process, provides an analytic model of the meshing impact led by the gear reversal order meshing phenomenon. A relation function between geometric parameters of the gear and the base pitch error is constructed by doing study on the reversal order meshing phenomenon and analyzing a transmission error curve, an angular velocity error curve and an angular acceleration error curve, so that a batter explanation is provided for the meshing impact to the gear pair.

Owner:BEIJING UNIV OF TECH

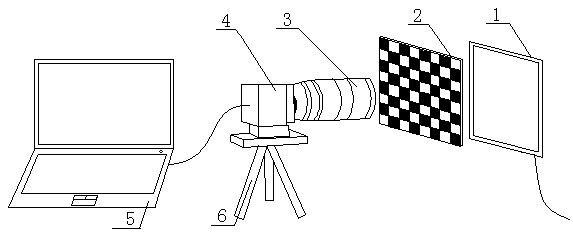

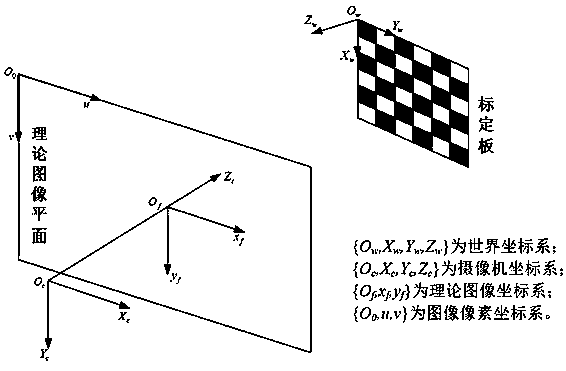

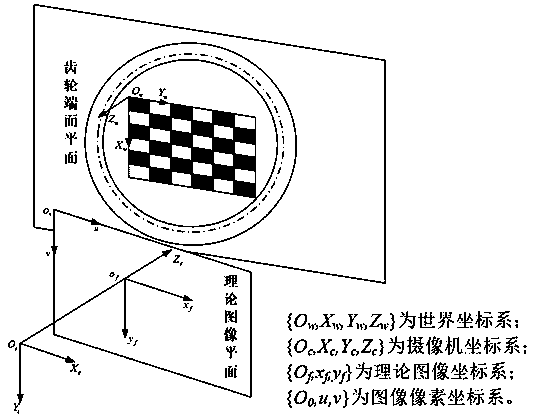

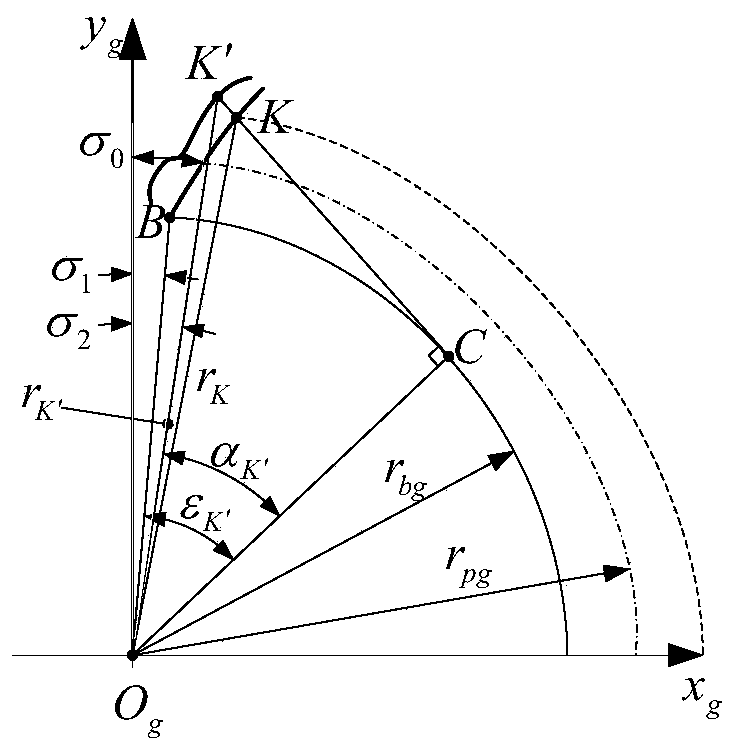

Measuring method for cumulative error of involute cylindrical gear tooth pitch based on machine vision

The invention relates to a measuring method for a cumulative error of an involute cylindrical gear tooth pitch based on machine vision, which belongs to the technical field of machine vision measurement. The measuring method for the accumulated error of the involute cylindrical gear tooth pitch based on the machine vision comprises the following steps: firstly, writing a parameter equation of a tooth profile involute by setting a world coordinate system and an imaginary coordinate system; secondly, obtaining a calculation equation of the parameter coordinate of a corresponding point on the tooth profile perpendicular to the detection point by using the relationship between the detection point and the parameter equation of the tooth profile involute in the imaginary coordinate system, thentransforming the calculation equation to the world coordinate system and accordingly establishing a geometric fitting model of the tooth profile involute equation on an X-Y plane of the world coordinate system; and finally, obtaining the cumulative pitch error of an involute cylindrical gear by using the radius of a gear base circle and a starting angle of the tooth profile involute obtained by fitting the involute equation of the tooth profile. According to the invention, by adopting a machine vision measurement technology, and adopting a method of geometrically fitting the involute equationof the tooth profile, the non-contact measurement of the cumulative error of the tooth pitch of the involute cylindrical gear is realized. The measurement process is simplified, and the measurement precision is improved.

Owner:JILIN UNIV

Work positioning method, and positioning device

A method for positioning a work, which is adapted for a knock hole of a small diameter and which can absorb a pitch error between a main positioning hole and an auxiliary positioning hole of the work is disclosed. An insert shaft of a main positioning device is inserted into the main positioning hole. An auxiliary positioning device includes a base lower block having a parallel slide holding surface, a sliding flange having a sliding surface, and an insert shaft disposed above the sliding flange. The sliding flange of the auxiliary positioning device is guided and moved by the slide holding surface, and is inserted, while absorbing the pitch error, into the auxiliary positioning hole, thereby to position the work.

Owner:TOYOTA JIDOSHA KK +1

Granite step gauge measuring device

InactiveCN1850443AReasonable designSimple structureMeasurement/indication equipmentsMechanical measuring arrangementsMeasurement devicePitch error

A granite step-pitch gage measuring device is composed of the granite step-pitch gage and the displacement sensor. Because of the accuracy of the granite step-pitch gage and the sensor, it can be used in the workshop to measure the error of the machine axis to a series discrete point. So it can reach the evaluation of the machine accuracy and the compensation of the pitch error. The invention can resist the wearing, acid, alkali, rust and cost little, especially it has the high measurement accuracy.

Owner:GUANGDONG OCEAN UNIVERSITY

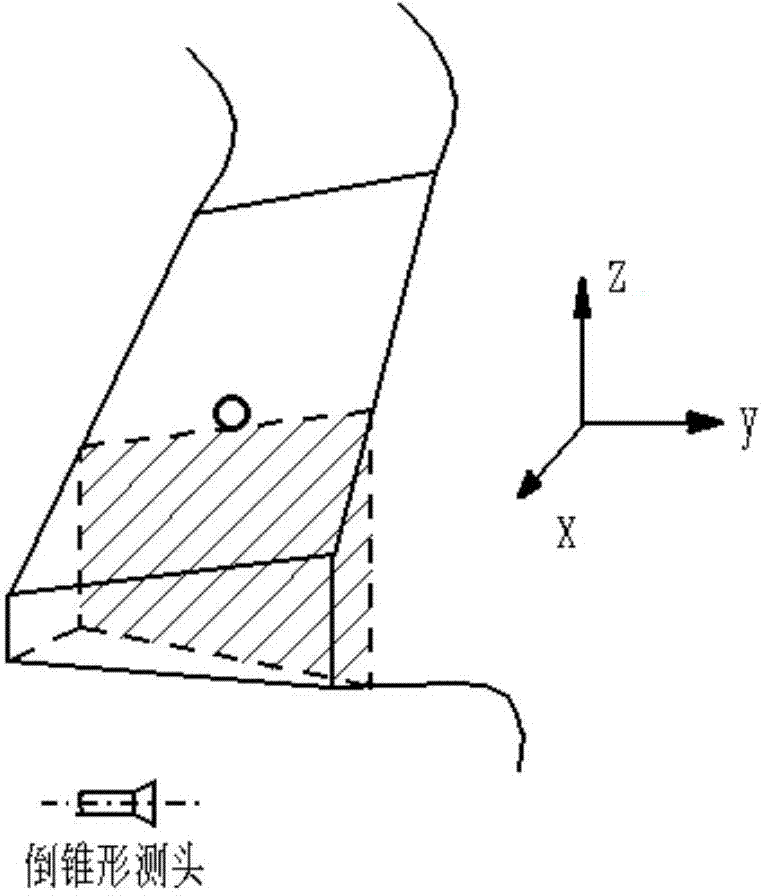

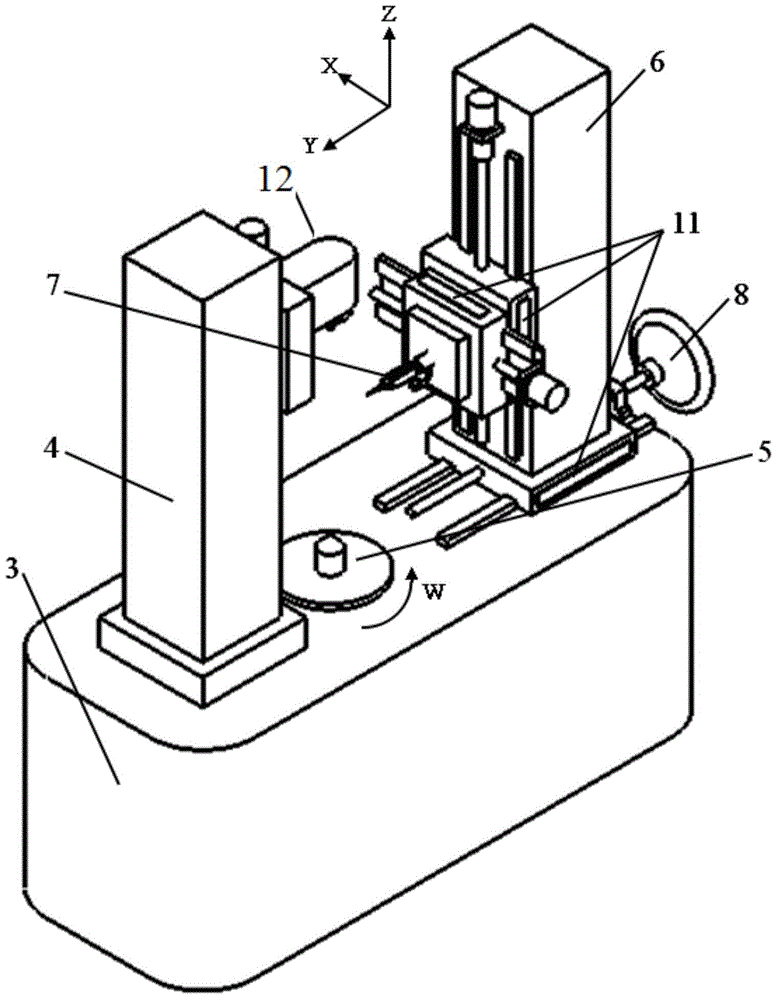

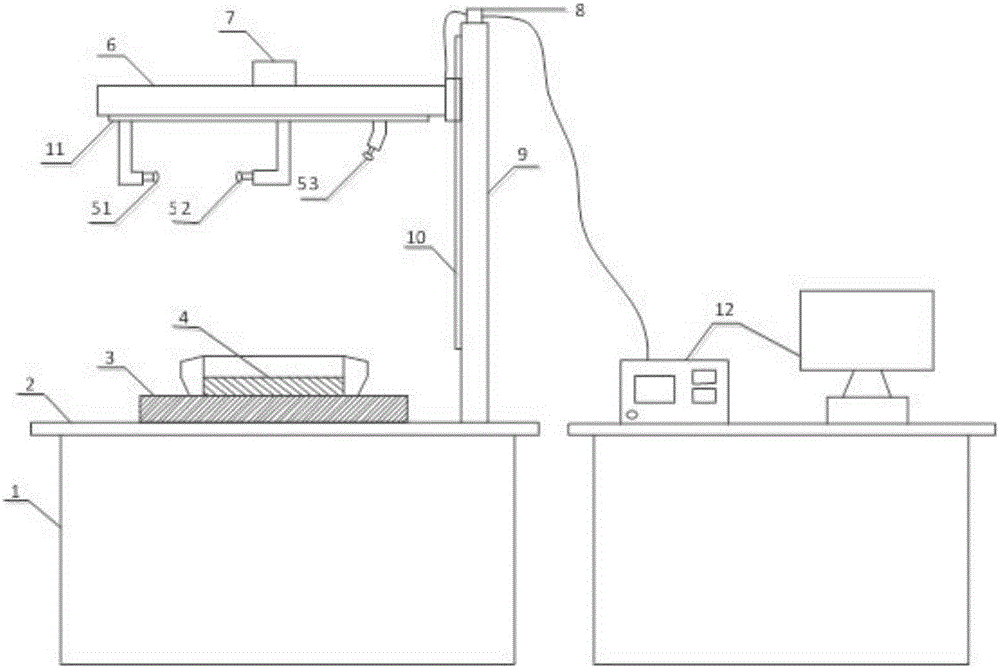

Laser detection system for key parameters of spiral bevel gear and detection method of laser detection system

ActiveCN106813584AReduce mistakesImprove detection efficiencyUsing optical meansData displayData acquisition

The invention relates to a laser detection system for key parameters of a spiral bevel gear and a detection method of the laser detection system. Detected key parameters comprise root circle radius, tip circle radius and pitch error. The detection system comprises a box body, a rotating mechanism, a workbench, a revolving platform, a centring device, a first laser triangular displacement sensor, a second laser triangular displacement sensor, a third laser triangular displacement sensor, a beam, a servo motor mounted on a vertical column, the vertical column, a Z-axis guide rail, an X-axis guide rail, a data collection and communication system and a data processing and display system. The detection method comprises the following steps that the rotating mechanism drives a gear to be detected to rotate; the data collection and communication system collects laser displacement signals in real time and transmits the collected laser displacement signals to the data processing system and data display system. The laser detection system takes the laser triangular displacement sensors as main detection components, and adopts a non-contact laser measurement method, so that the detection accuracy and speed are greatly improved.

Owner:秦皇岛市和平无损检测有限公司

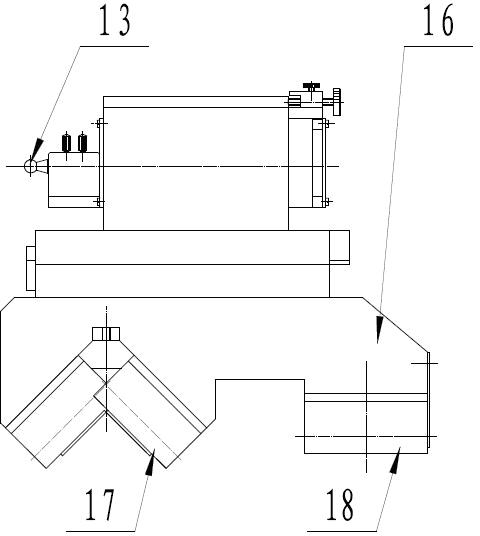

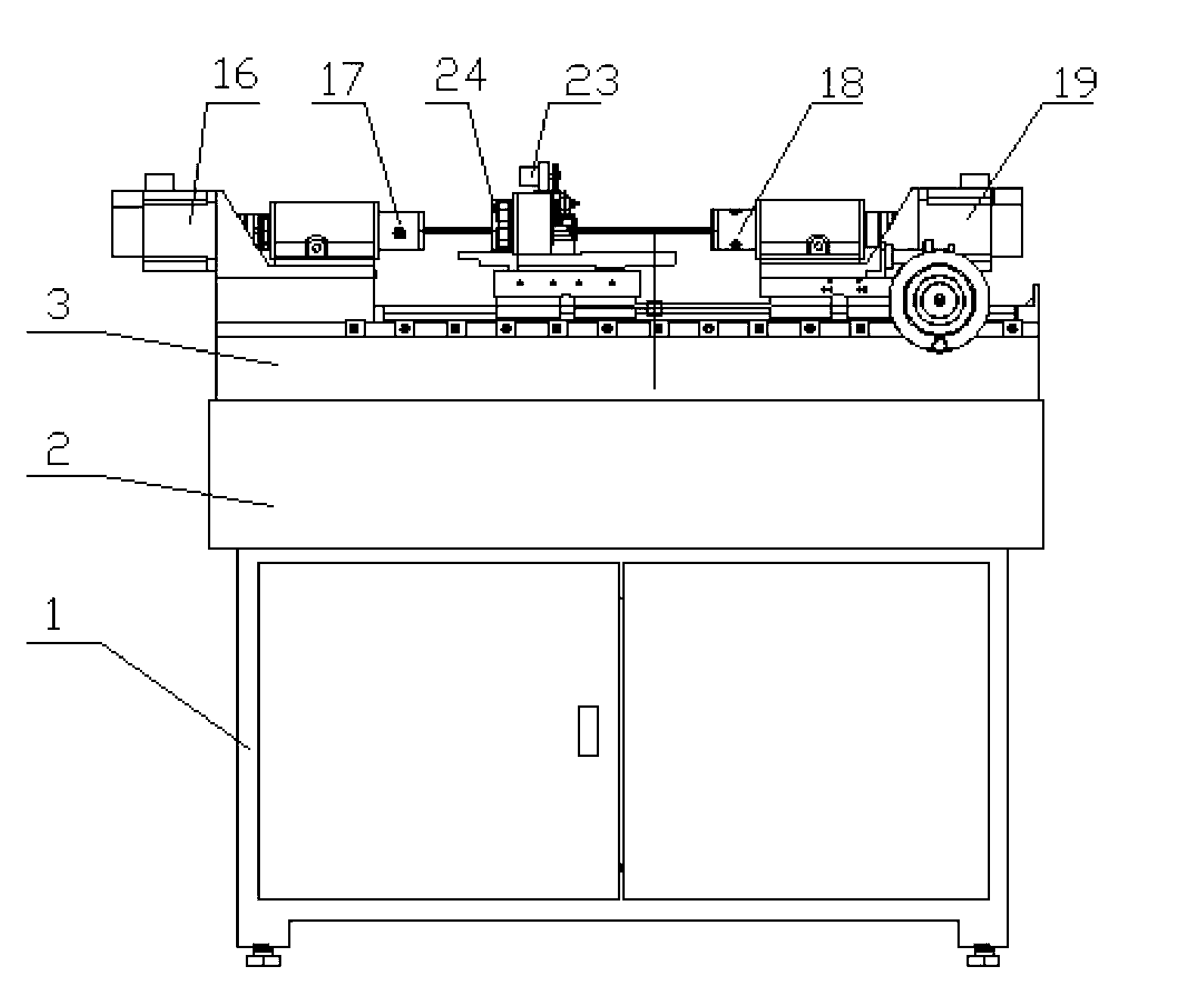

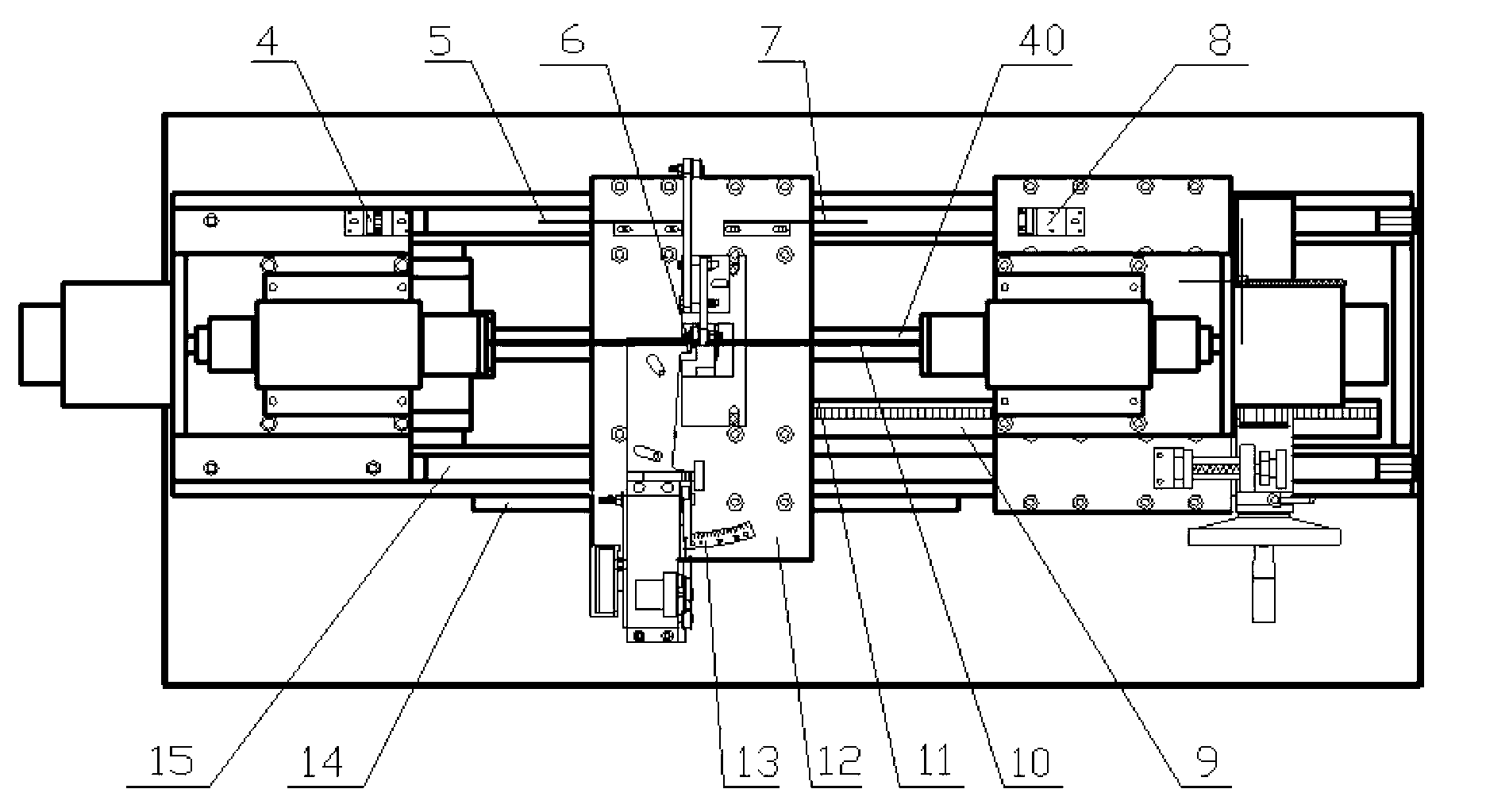

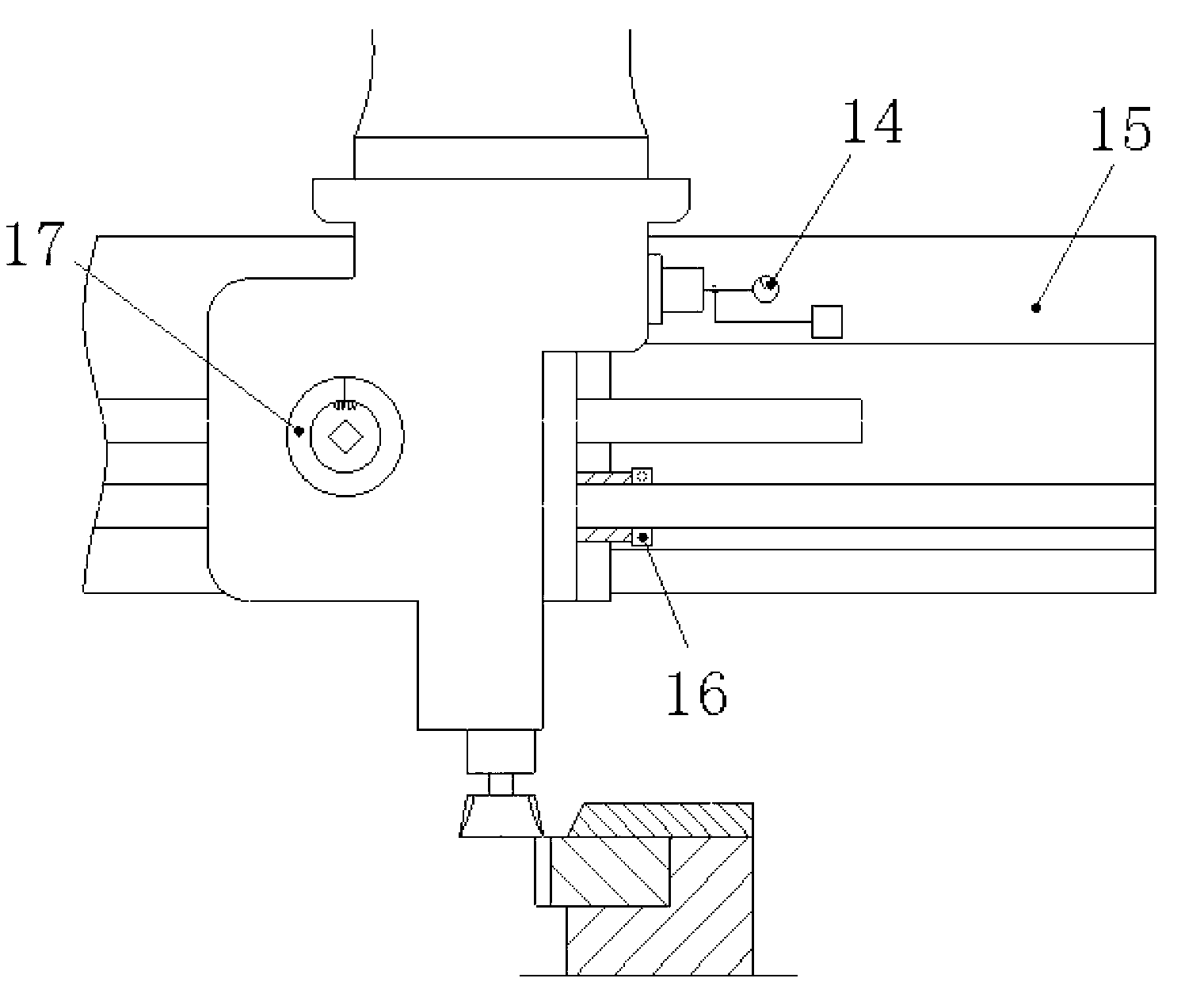

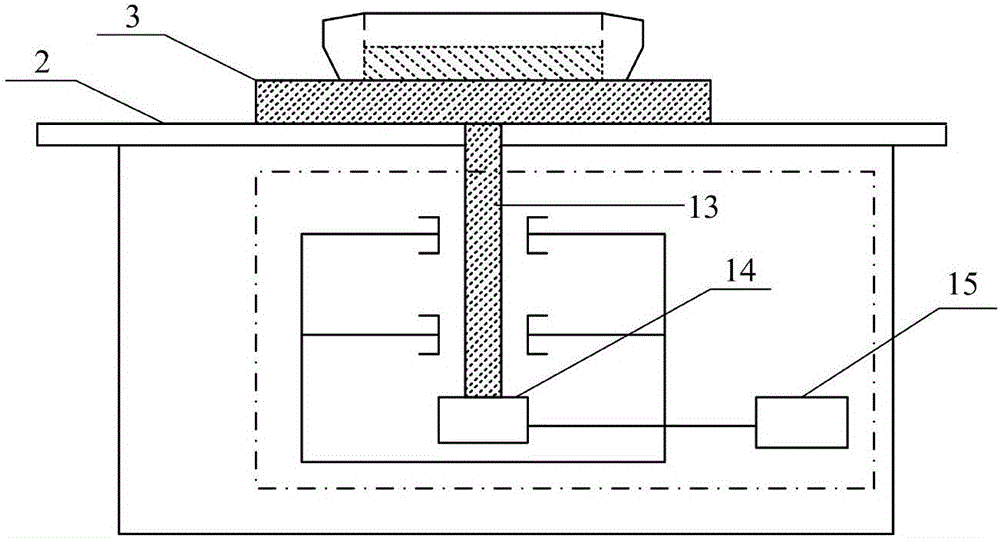

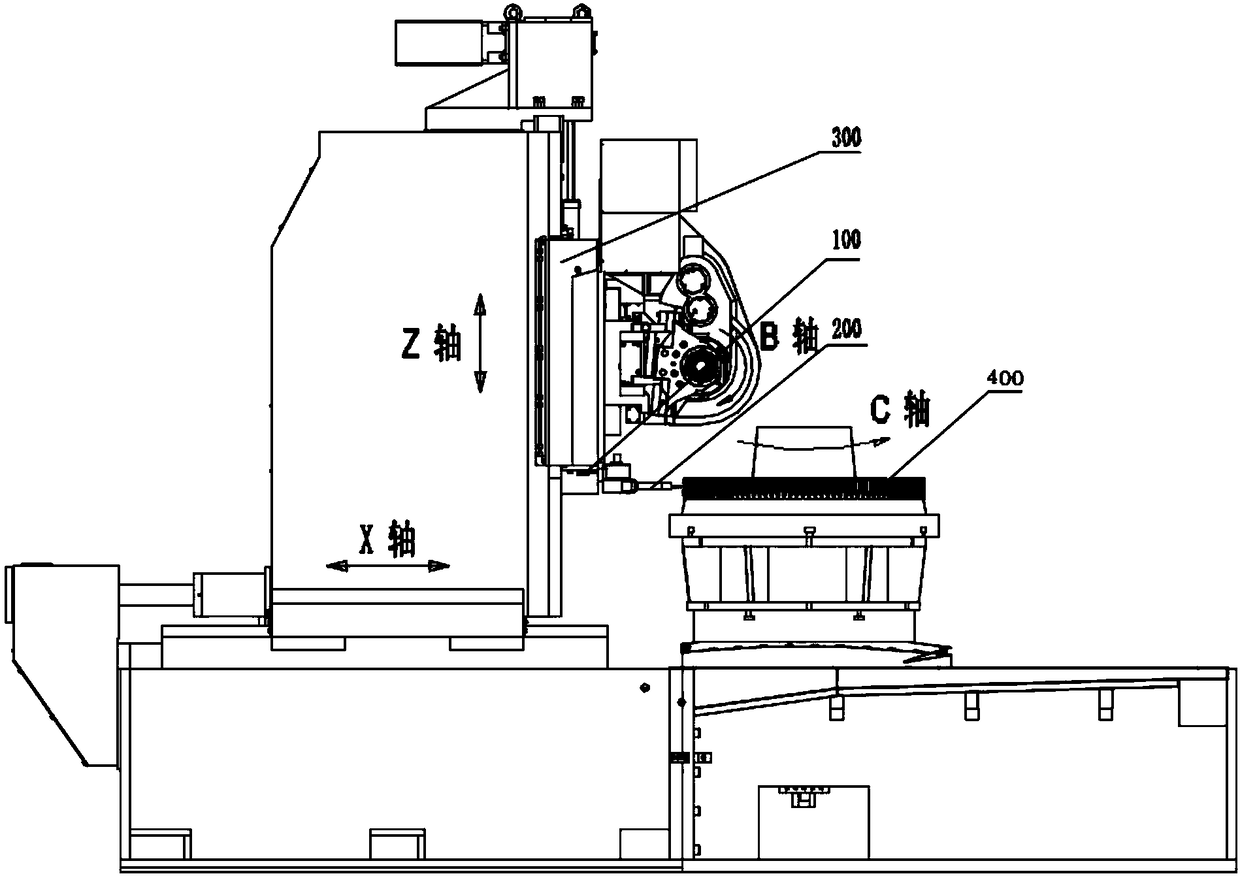

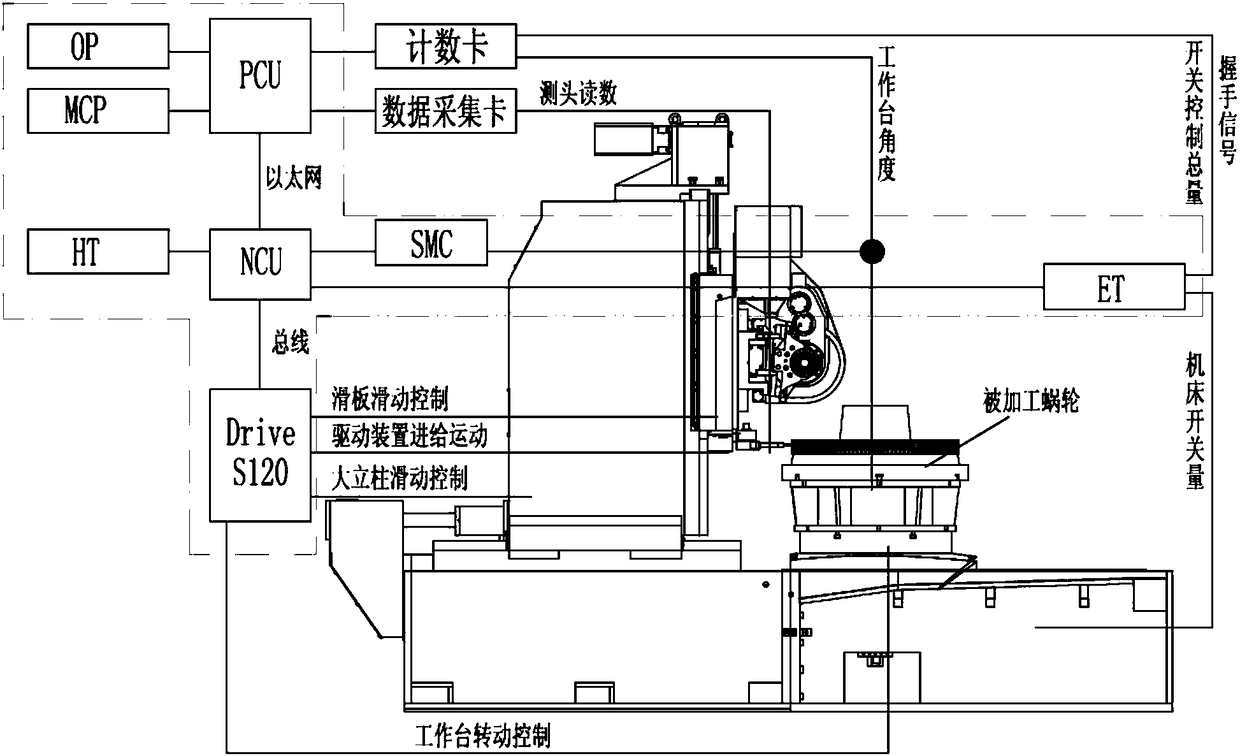

High-precision worm gear machining machine tool with online detection mechanism and measurement control system of high-precision worm gear machining machine tool

PendingCN108080749AHigh repeat positioning accuracyWorm wheelsGear-cutting machinesMeasurement deviceControl system

The invention belongs to the field of online detection and discloses a high-precision worm gear machining machine tool with an online detection mechanism and a measurement control system of the high-precision worm gear machining machine tool. The high-precision worm gear machining machine tool comprises a large vertical column and a workbench, and a slide plate is arranged on the large vertical column arranged on a machine tool body. The online detection mechanism is formed by a driving device and a measurement device, the driving device comprises a slide seat, a fixed seat and a travel switch, the slide seat is arranged on a mounting seat which is fixed to the bottom of the slide plate, the measurement device is mounted on the slide seat, and a piston is arranged on the fixed seat. The slide seat is further provided with a storage cavity, a switch starter, a rear oil port and a front oil port, the storage cavity matched with the piston, the switch starter matches with the travel switch, and the rear oil port and the front oil port are communicated, on two sides of the piston, with the storage cavity. The high-precision worm gear machining machine tool has advantages that by the driving device, the measurement device is clamped on the slide plate, small-stroke feeding of the measurement device is realized so as to realize detection of pitch errors and pitch accumulative overallerrors of worm gears machined by the machine tool, repeat positioning precision of the measurement device is improved, and accordingly measurement precision is improved.

Owner:CHONGQING MACHINE TOOL GROUP

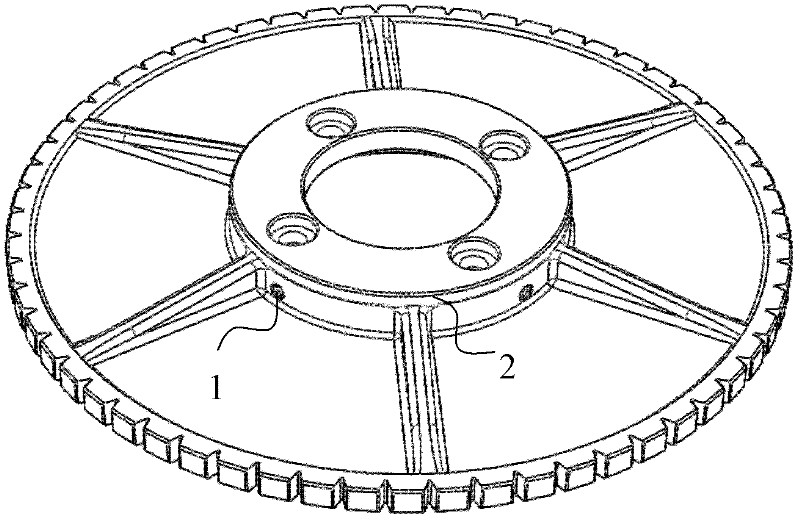

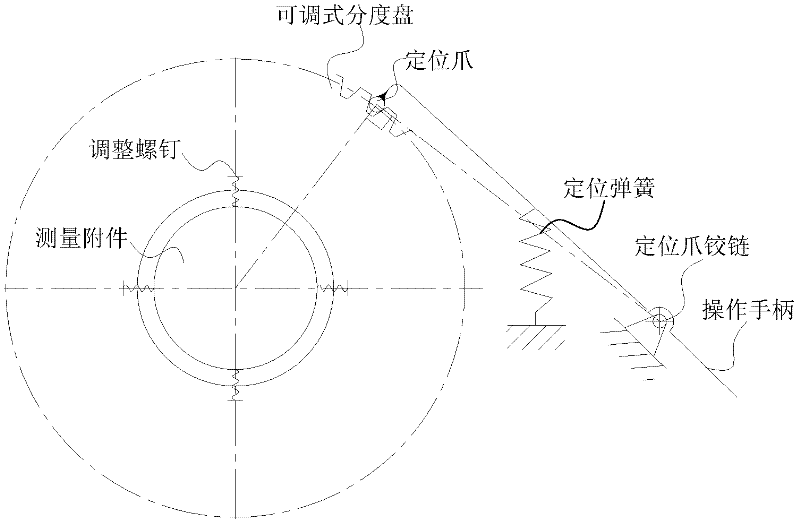

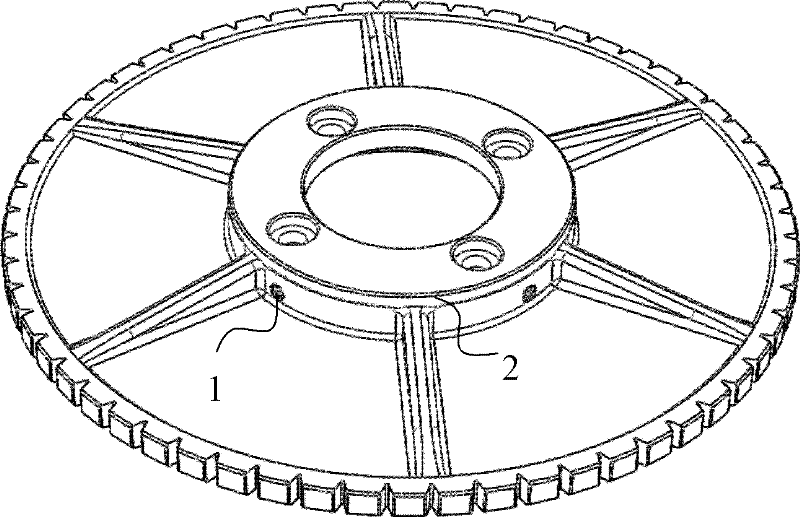

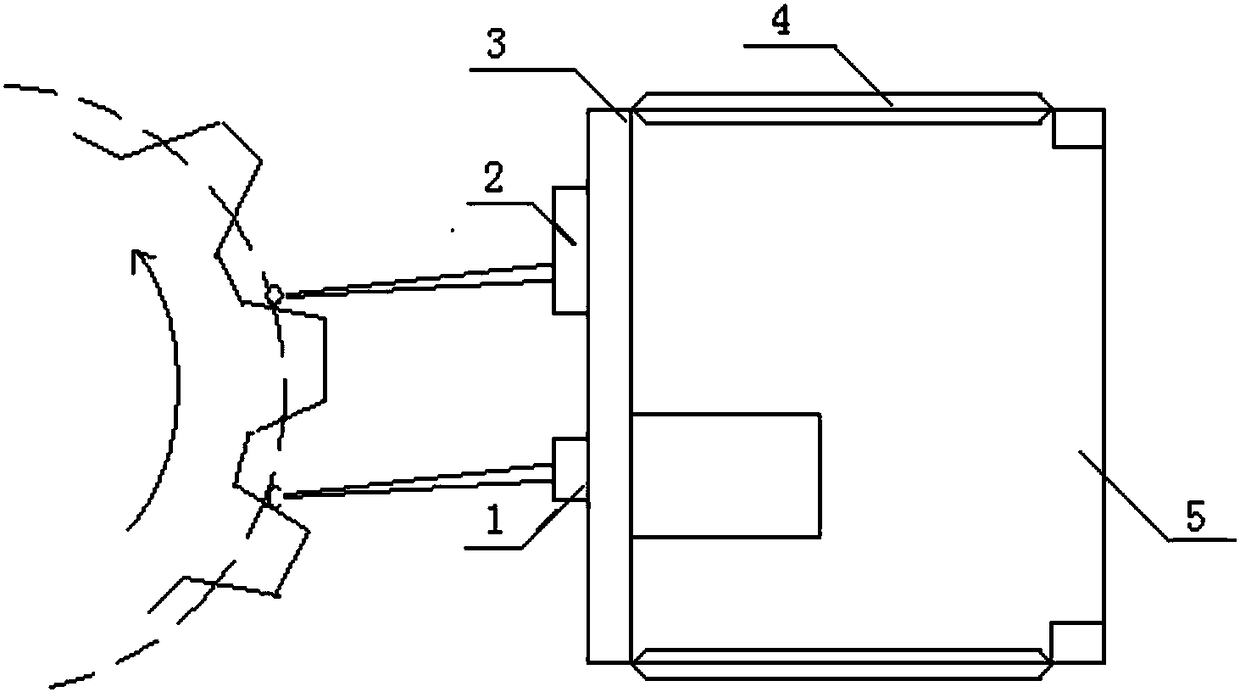

Radially adjustable indexing disc and adjusting method for same

InactiveCN102500839AThe accumulative total deviation of the tooth pitch is improvedEasy to adjustGear-cutting machinesGear teethRadial positionHarmonic

The invention discloses a radially adjustable indexing disc and an adjusting method for the same. The radially adjustable indexing disc is characterized in that: a radial reference datum and four uniformly distributed screw holes are arranged on a mounting hub of the radially adjustable indexing disc, roundness of the radial reference datum is not greater than 1 micron, and a radial gap (around 1mm) is arranged between a mounting aperture and an axial diameter of the indexing disc. The adjusting method comprises the following steps of: measuring an indexing error curve of the indexing disc by using an indexing error measuring device of the indexing disc, and adjusting the radial position of the indexing disc, wherein the adjustment amount is the magnitude of a primary harmonic component in total cumulative pitch error of a processed gear or total accumulative indexing error of the indexing disc; adjusting an azimuth angle to lag behind the maximum value (90 degrees) of the primary harmonic component; and using an end-face screw to fix the indexing disc on a shaft of the indexing disc after the radial position of the indexing disc is adjusted in place. In the invention, the radial position of the adjustable indexing disc is adjusted to compensate the primary harmonic component in the total cumulative pitch error of the grinded gear and improve the total cumulative pitch error of the same; and the adjusting method disclosed by the invention has the advantages of convenience for adjustment and obvious error compensating effect.

Owner:DALIAN UNIV OF TECH

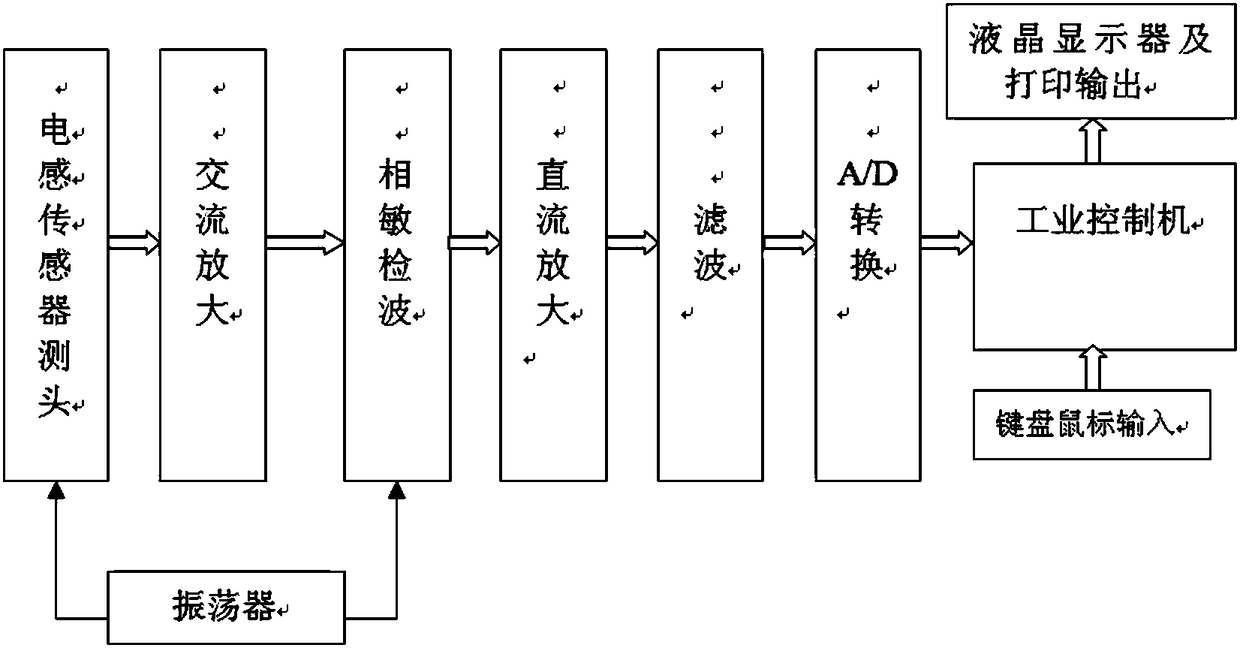

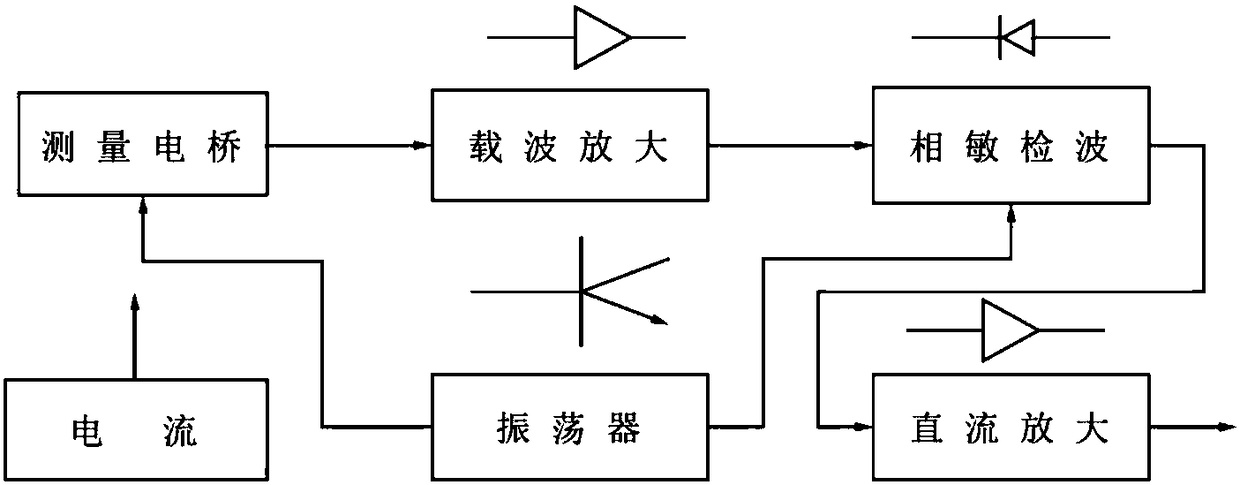

Upper tooth pitch measuring instrument for large gear hobbing machine

The invention belongs to the technical field of gear detection and relates to an upper tooth pitch measuring instrument for a large gear hobbing machine. By adoption of an upper relative measurement method, relative measurement of tooth pitch errors of straight gears, bevel gears and worm gears machined on a gear machine tool is carried out. The measurement method is free of any indexing standards, tooth pitches of tested gears are subjected to one-by-one own tooth pitch comparison according to the circumference closed principle, and an industrial controller is used as a data processing systemfor calculating single tooth pitch deviation, N tooth pitch cumulative deviations and total tooth pitch cumulative deviation. The upper tooth pitch measuring instrument has advantages that online detection of the single tooth pitch deviation, the tooth pitch cumulative deviation and the total tooth pitch cumulative deviation of the tested gears can be realized, machining conditions are adjusted according to deviation values, and time of workpiece moving, lifting and recalibration in testing can be saved.

Owner:CHONGQING MACHINE TOOL GROUP

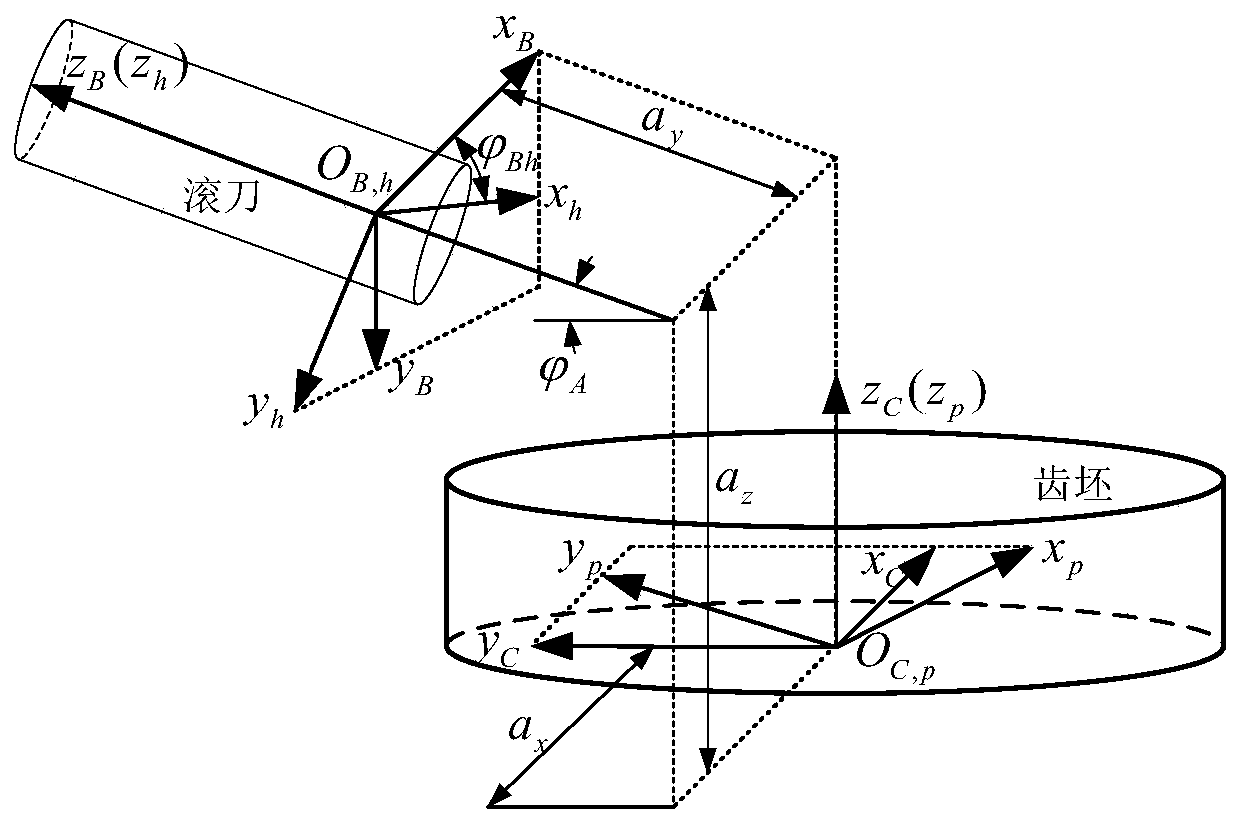

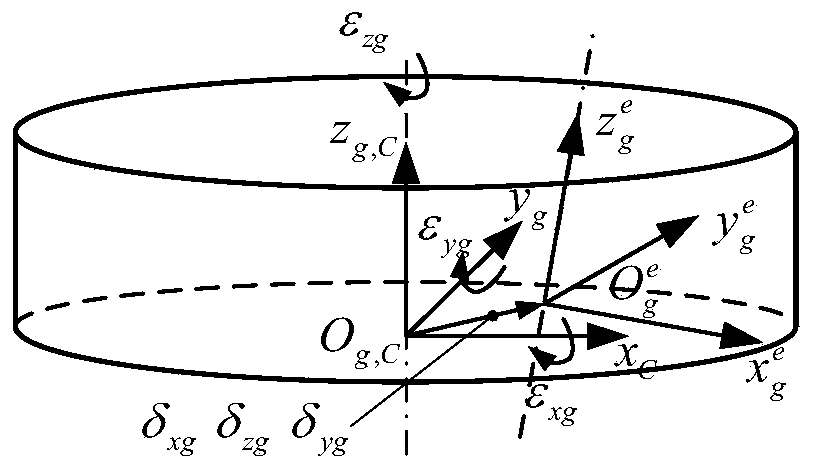

Gear hobbing tooth surface error compensation method and system based on equivalent transmission chain error calculation

ActiveCN110568816AImprove machining accuracyProgramme controlComputer controlHobbingMethod selection

The invention discloses a gear hobbing tooth surface error compensation method based on equivalent transmission chain error calculation, which comprises the following steps: establishing a gear hobbing machining error prediction model; predicting the tooth profile and pitch errors of a machined gear according to the transmission chain error and the work piece gear installation error; calculating amapping relationship among the transmission chain error, the installation error and the tooth surface error; and finally, making compensation for the tooth surface error through equivalent transmission chain error compensation based on a tooth surface error compensation value calculated according to the equivalent transmission chain error. According to the method, a workbench is selected as a main control object of error compensation, and the transmission chain error is offset by adjusting and controlling the position of the workbench. An accurate mapping relationship between the transmissionchain error and the tooth surface error is deduced, then, the equivalent transmission chain error compensation value is calculated according to a measured tooth surface error value, and finally, thetooth surface error is reduced through a transmission chain error compensation method based on position control of a workbench or a hob shaft. Therefore, the precision of gear hobbing machine is improved.

Owner:CHONGQING UNIV

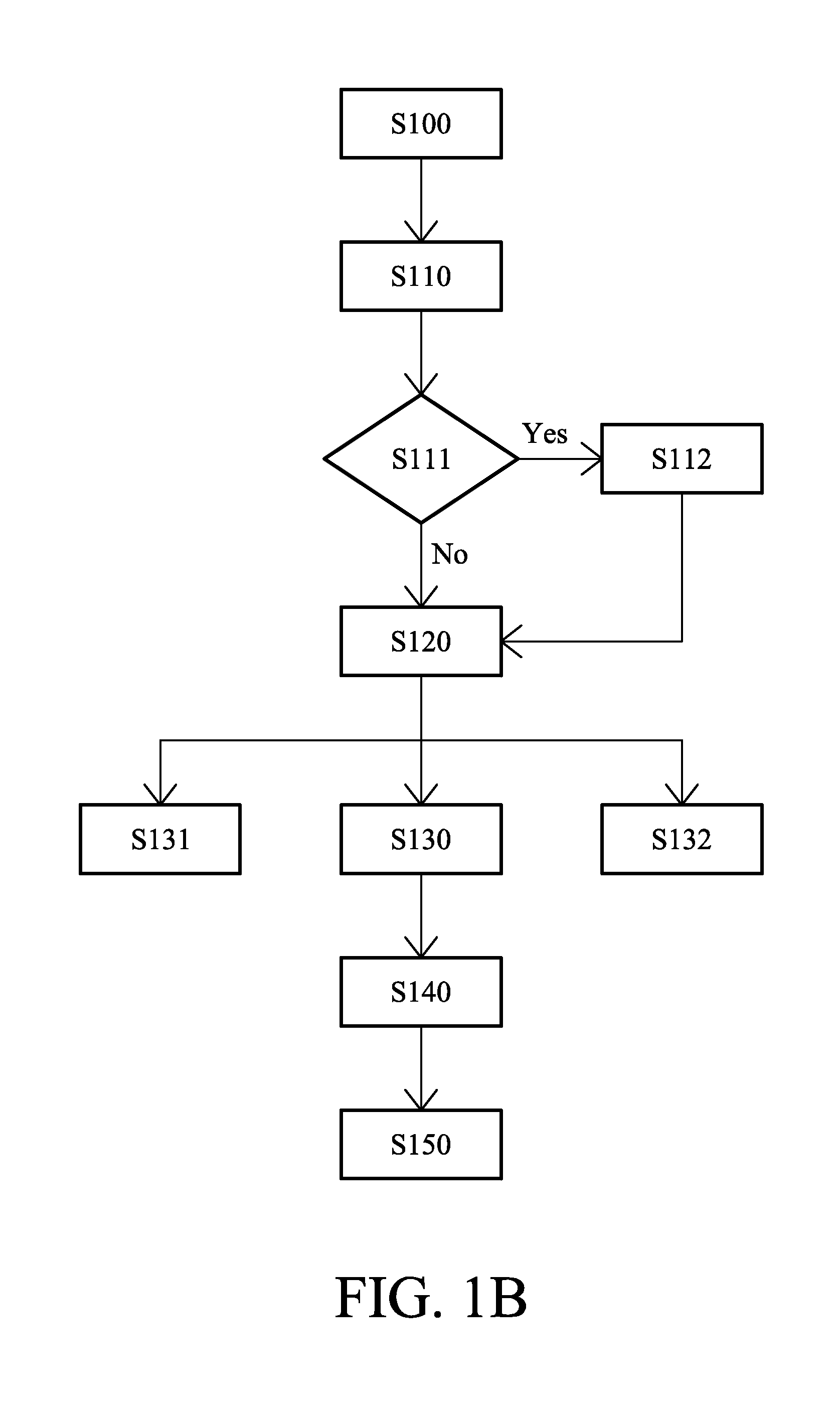

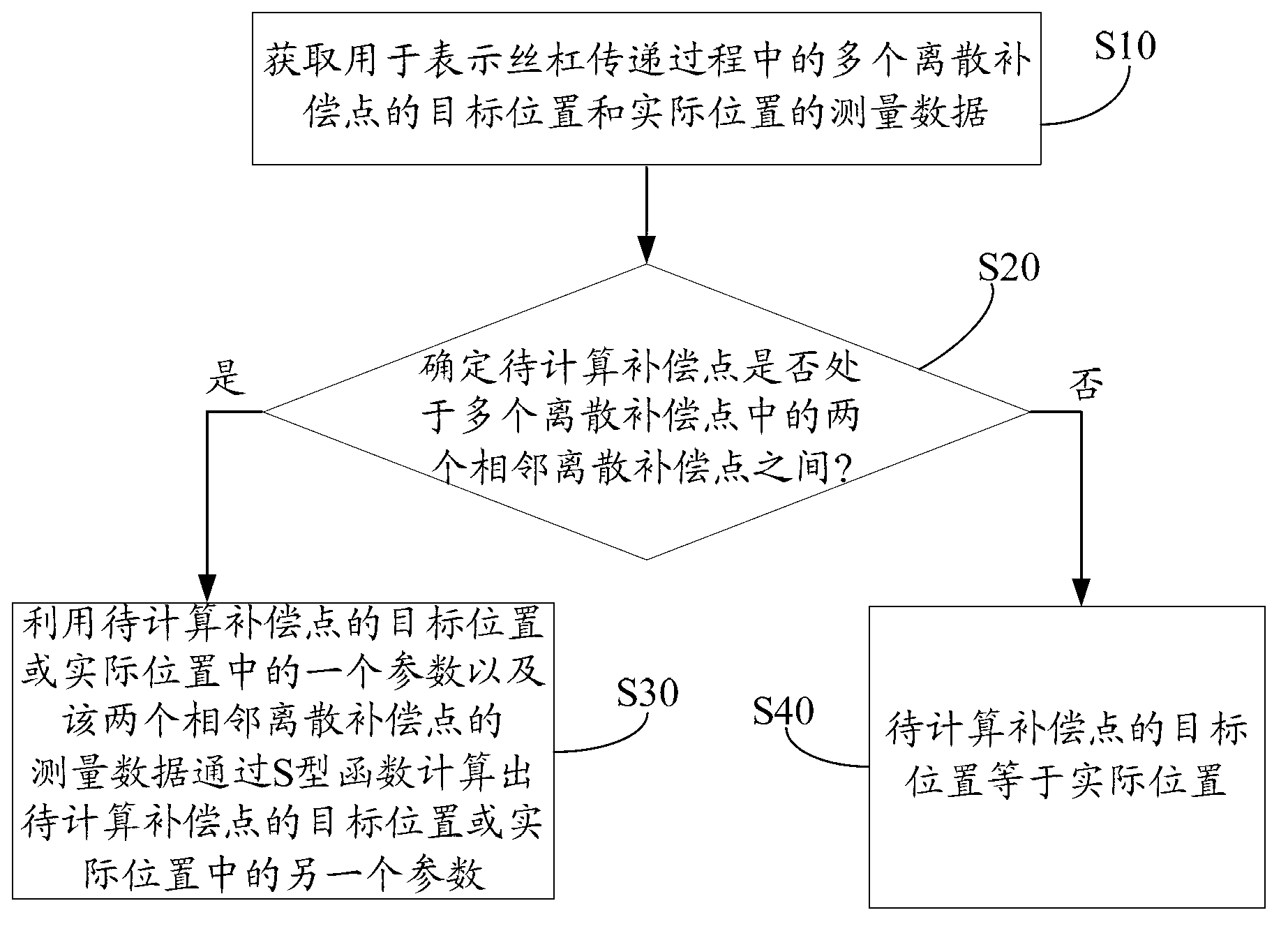

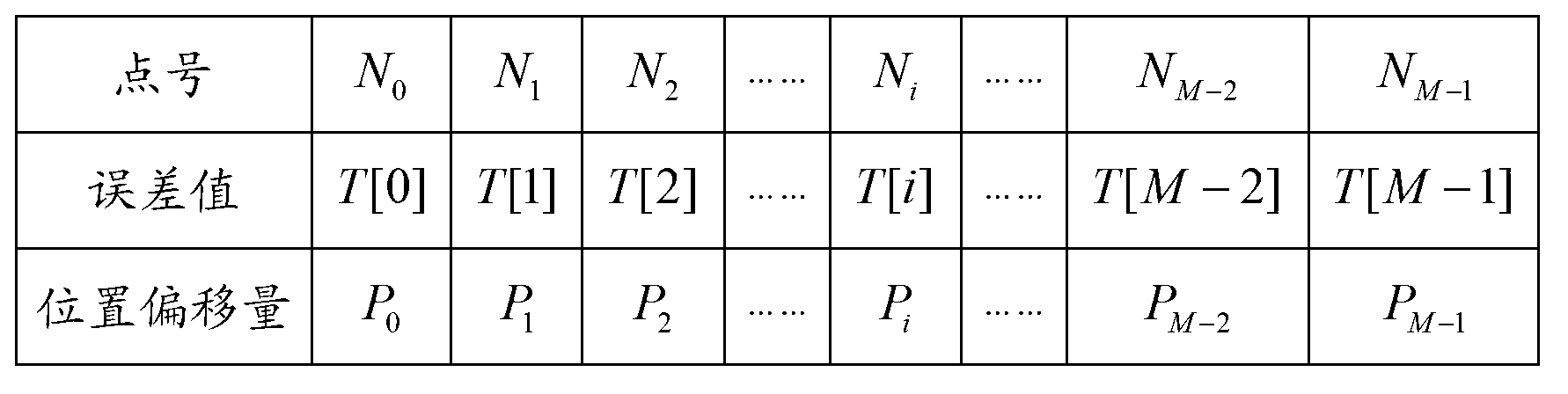

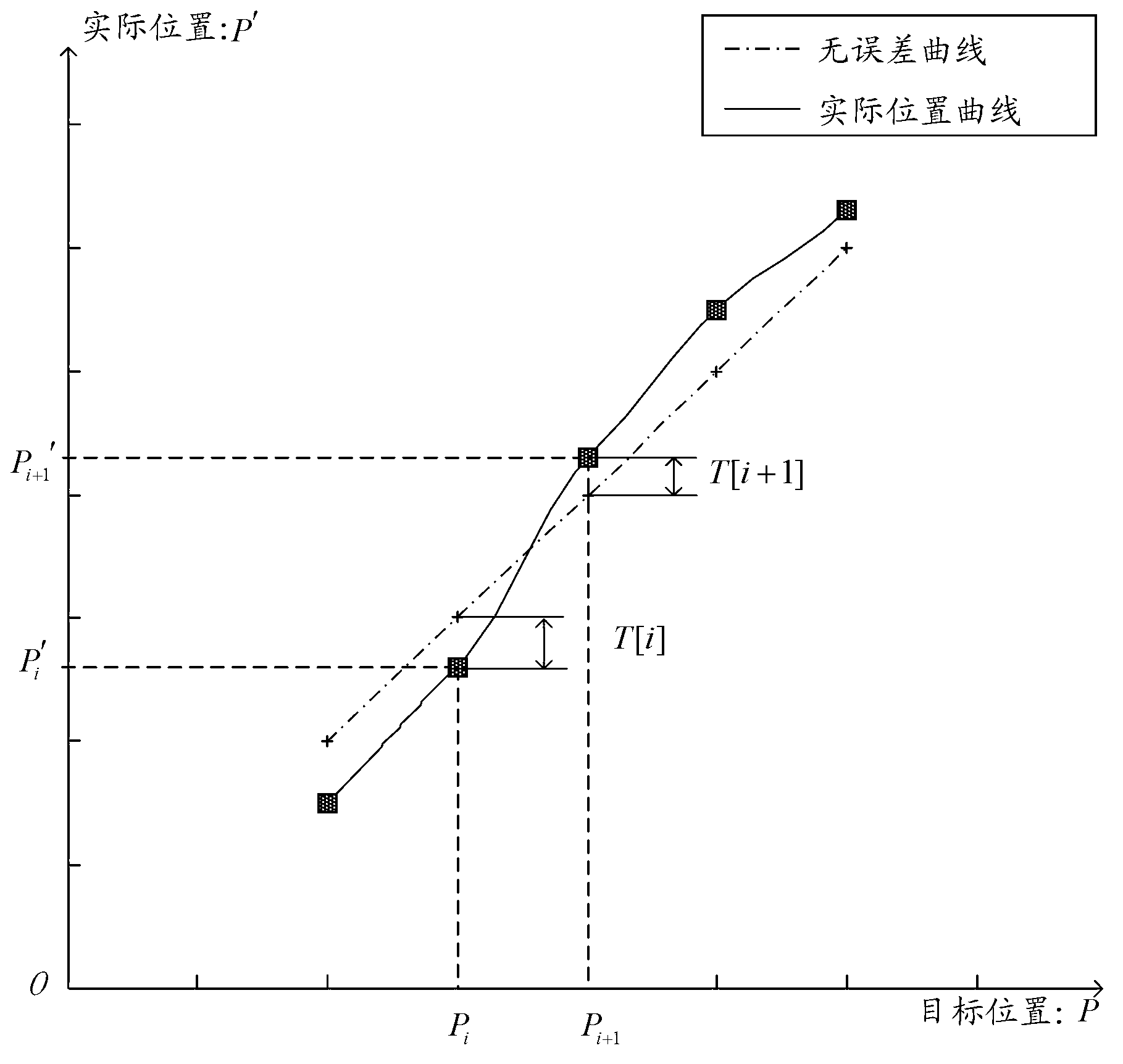

Screw pitch error compensating method

The invention discloses a screw pitch error compensating method. The method comprises the following steps that measurement data used for showing the target position and the practical position of a plurality of discrete compensation points in the lead screw transferring process is obtained; whether compensation points to be calculated are positioned between two adjacent discrete compensation points in the discrete compensation points or not is determined; and when the compensation points to be calculated are positioned between two adjacent discrete compensation points, the other parameter in the target position or the practical position of the compensation points to be calculated is calculated through a S type function according to the measurement data of the two adjacent discrete compensation points and one parameter in the target position or the practical position of the compensation points to be calculated. Through adopting the mode, the screw pitch error can be compensated in a mode of conforming to the practical condition, so better compensation effects are obtained.

Owner:SHENZHEN A&E INTELLIGENT EQUIP

Apparatus and method for machining bevel gears in a pitching method with complete pitch error compensation

ActiveCN101421067AGraduated AccurateGrinding feed controlAbrasive surface conditioning devicesBevel gearMaster data

The invention relates to apparatuses for machining bevel gears in a pitching method and method for machining the pitch of gears, wherein the production-related pitch error is compensated. The apparatus (20) comprises an interface (11, 12) and can be connected to a measurement system (10) by means of this interface (11, 12), wherein the interface is designed such that the apparatus (20) can take correction values or correction factors from the measurement system (10) in a form in order to be able to adapt master data or neutral data which was originally present in a memory (51) of the apparatus (20) on the basis of these correction values or correction factors before production of one or more bevel gears (31) is initiated on the apparatus (20).

Owner:COLIN KIENBERGER GMBH

Hob mounting structure

InactiveCN103042439AEliminate fit gapsEliminate weekly pitch cumulative errorMilling cuttersMechanical engineeringPitch error

The invention discloses a hob mounting structure which comprises a hob and a conical mandrel. A hob inner hole is arranged on the conical mandrel. The conical mandrel is fixed by the hob through nuts. Positioning wafers are further arranged between the hob and the nuts. The hob inner hole of the conical mandrel is positioned, so that a fit clearance butane the hob inner hole and the conical mandrel is eliminated. The conical mandrel is highly tapered and prevents the hob from being tilted during clamping. The hob is axially positioned through the positioning wafers at two ends of the conical mandrel. Therefore, accumulative pitch errors of a chip pocket caused by the clearance are basically eliminated. Cutter sharpening precision of a front tool surface of the hob is increased, cutter sharpening quality is guaranteed, and accordingly tooth profile errors in gears are decreased. Machined products are stable in stability, with the precision meeting the design requirement.

Owner:归杏花

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com