Tooth alignment clamp for ultra-long rack and positioning machining method for tooth alignment thereof

A processing method and rack technology, which are applied in metal processing equipment, gear tooth manufacturing devices, gear teeth, etc., can solve the problem that the ultra-long rack cannot be directly processed, the processing of the ultra-long rack is difficult, and the pitch accuracy is not easy to guarantee, etc. problems, to achieve the effect of reducing processing and manufacturing costs, saving processing time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and specific embodiments.

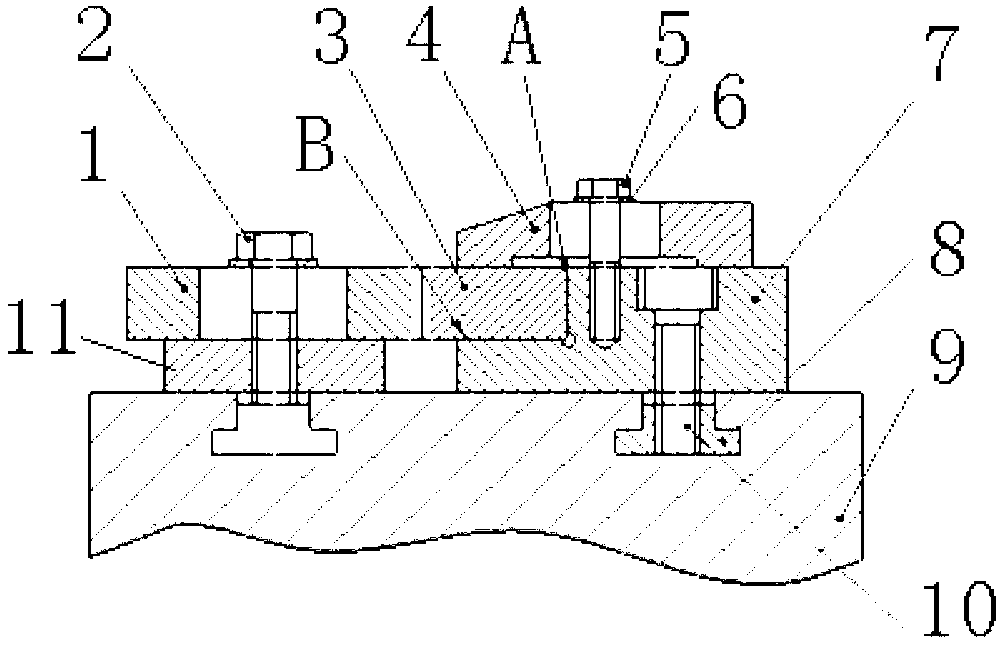

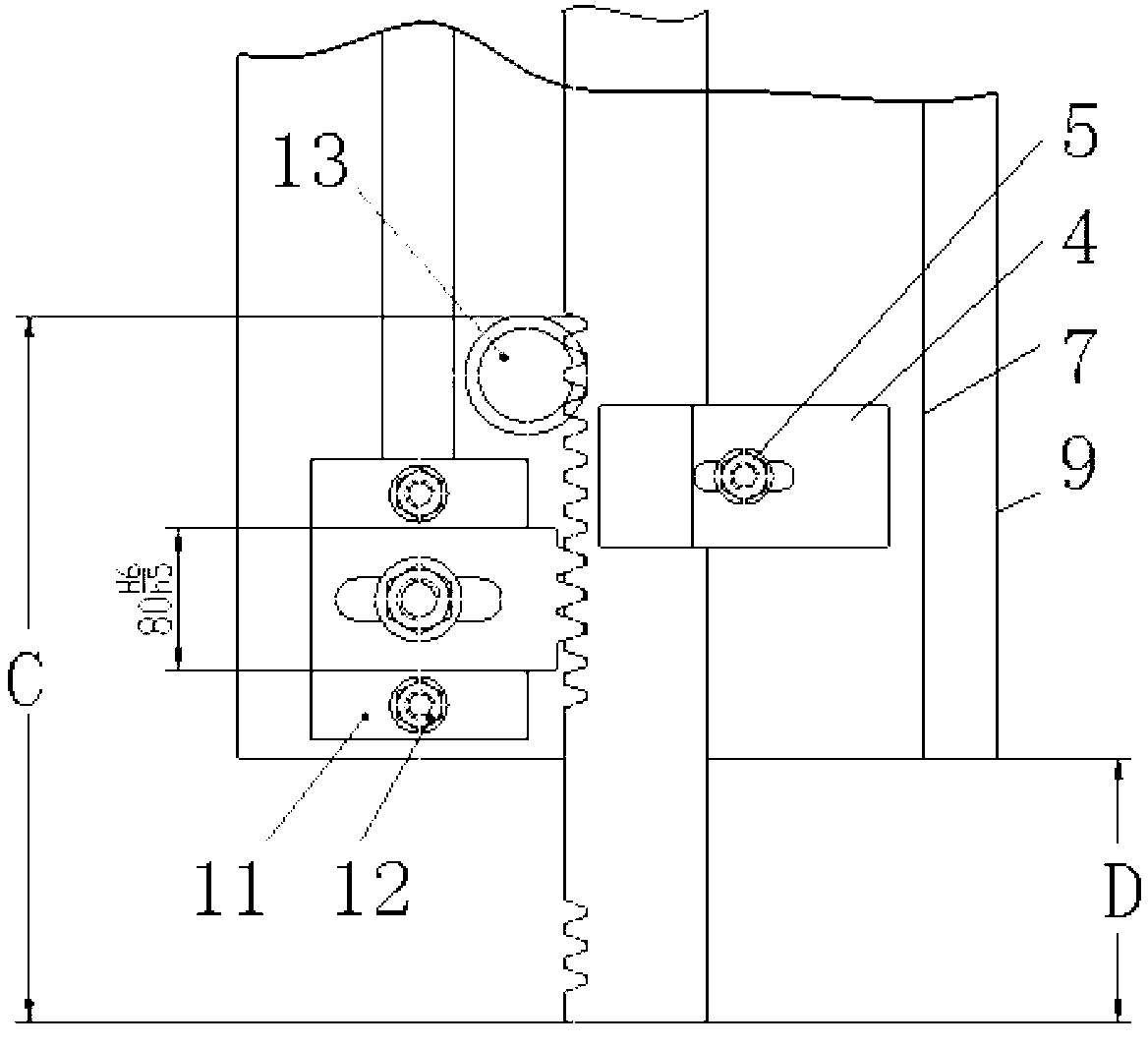

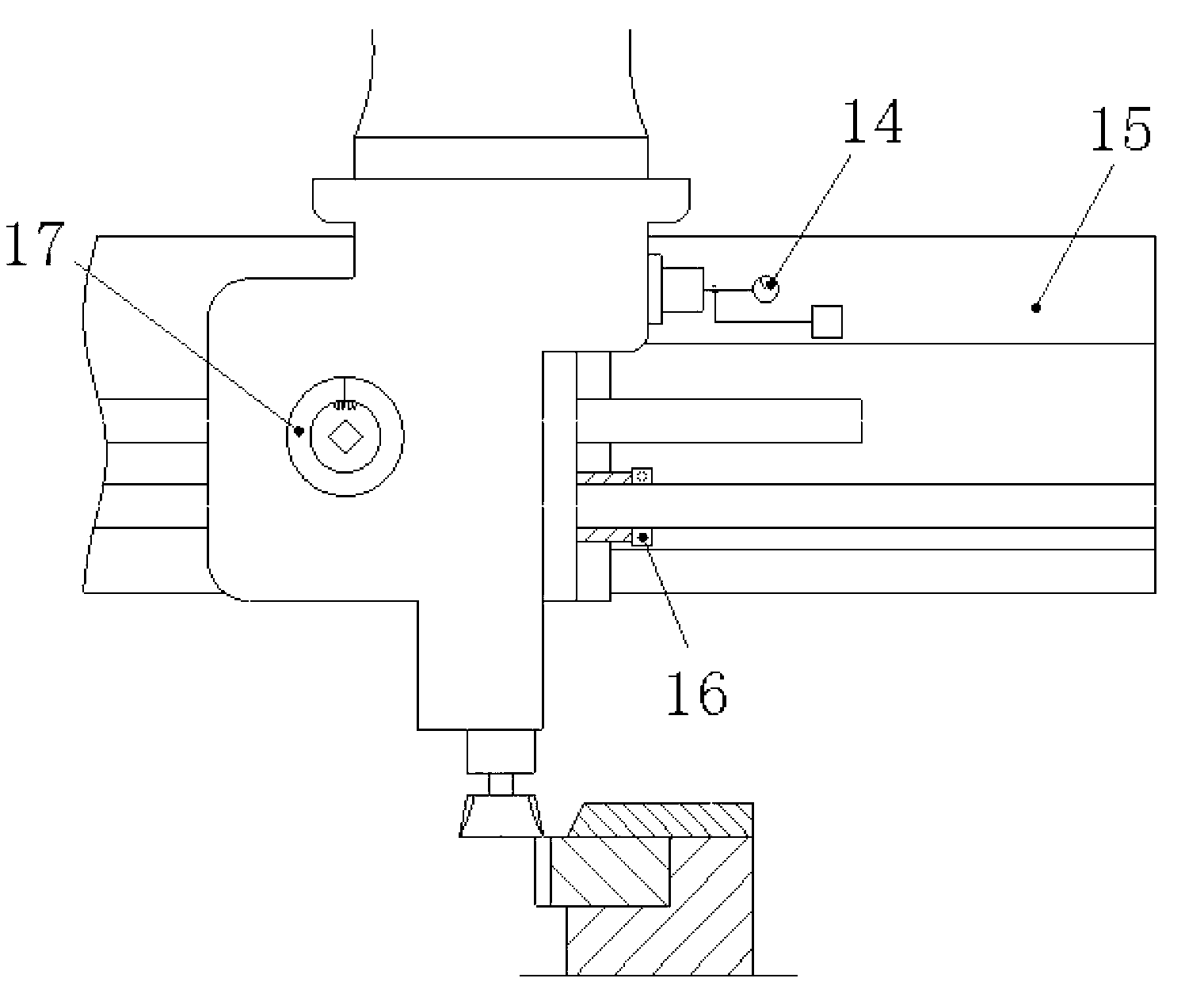

[0022] Reference figure 1 , figure 2 , Is a schematic diagram of the structure of the ultra-long rack-to-tooth fixture of the present invention (when the teeth are in the working state), including two parallel inverted T-slots longitudinally arranged on the table surface of the rack machine table 9, each inverted T An inverted T-shaped fixed block 8 is provided in the groove, and a positioning seat 11 and a clamping body 7 are respectively arranged on the upper edges of the two inverted T-shaped grooves; the positioning seat 11 is provided with a counter tooth block 1, the positioning seat 11 and the counter The tooth block 1 is fixedly connected by the hexagon socket screw 12. In addition, the tooth block 1, the positioning seat 11, and the corresponding lower inverted T-shaped fixed block 8 are connected together by the clamping bolt 2; the clamping body 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com