Laser detection system for key parameters of spiral bevel gear and detection method of laser detection system

A key parameter, laser detection technology, applied in the field of optical detection, can solve the problem of unable to achieve rapid and accurate detection of key parameters of spiral bevel gears, and achieve the effect of improving efficiency, rapid and accurate detection, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

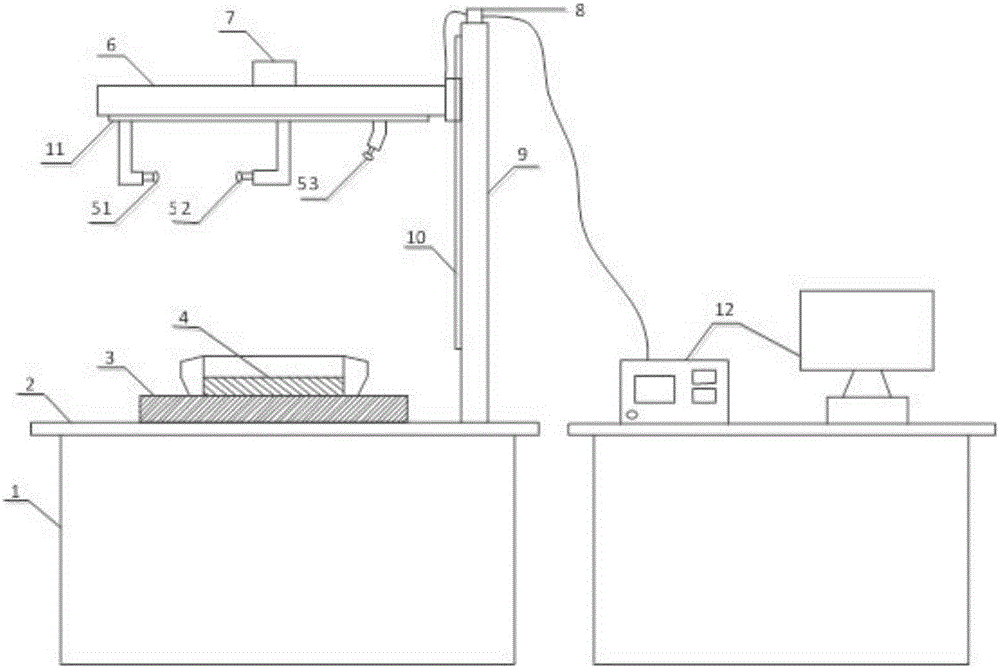

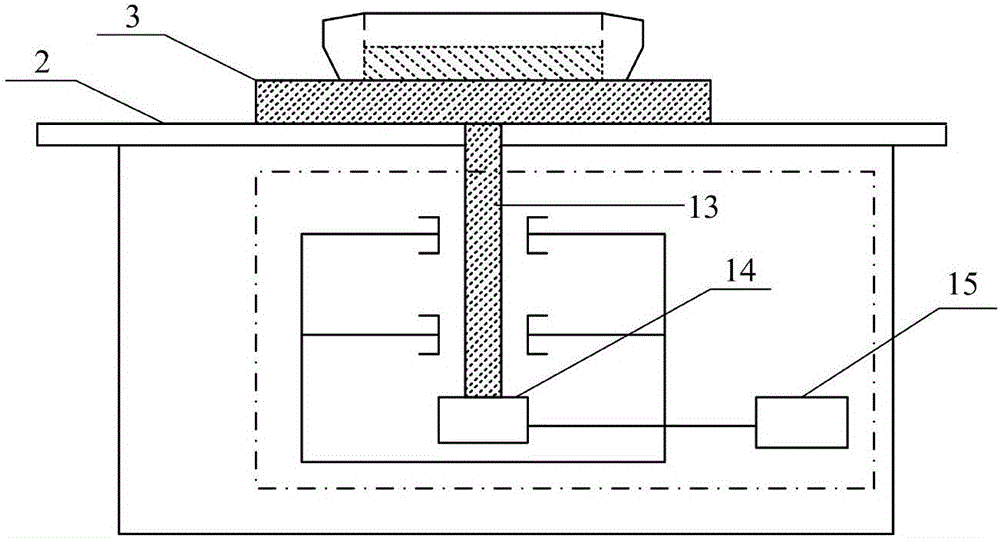

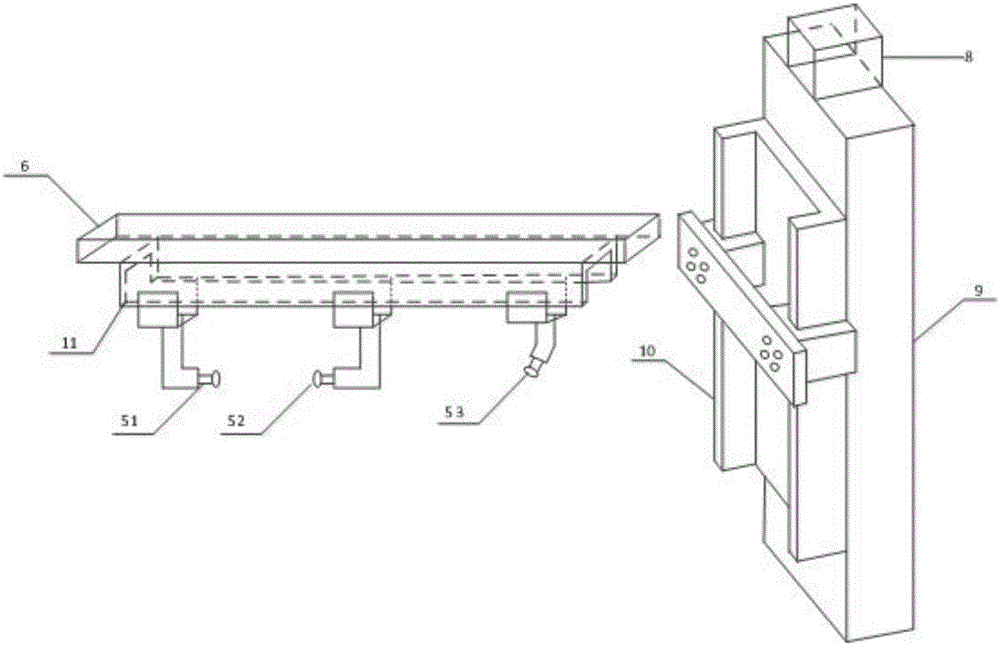

[0029] Such as figure 1 As shown, the spiral bevel gear key parameter detection system of the present invention will be composed of a box body 1, a workbench 2, a rotating mechanism, a rotary platform 3, a centering device 4, a first laser triangular displacement sensor 5 (1), a second laser Triangular displacement sensor 5(2) and third laser triangular displacement sensor 5(3), beam 6, data acquisition and communication system 7, servo motor 8, column 9, Z-axis guide rail 10, X-axis guide rail 11, data processing and display System 12 etc. are formed. The workbench is fixedly installed on the box body, and the rotary platform and the column are arranged on the worktable; the column is perpendicular to the rotary platform, and the servo motor is installed on the column. The rotary platform is connected with the rotary mechanism through the rotating shaft, and rotates under the drive of the rotary mechanism; the centering device is provided on the rotary platform; the rotary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com