Patents

Literature

60 results about "Electric sense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

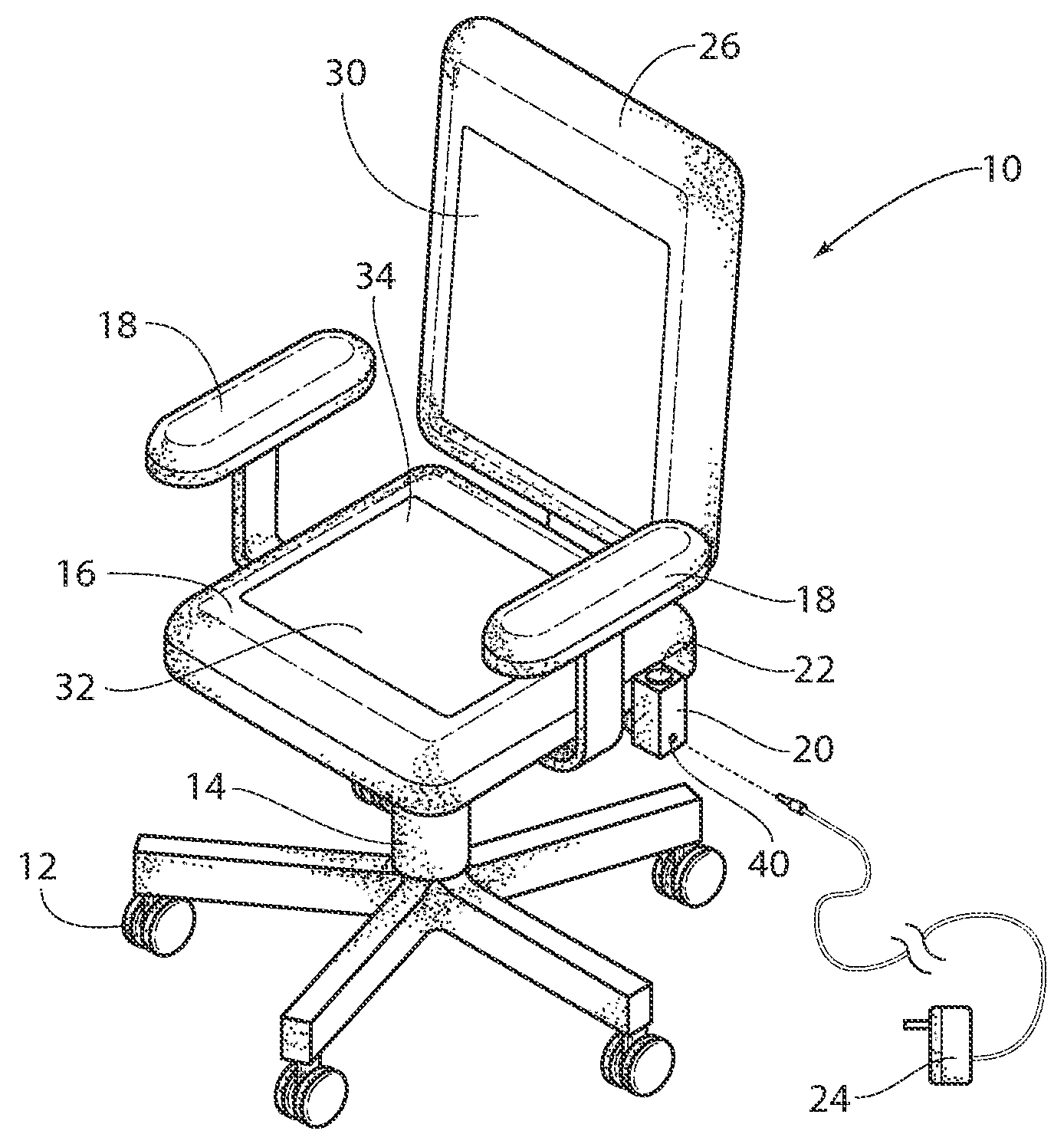

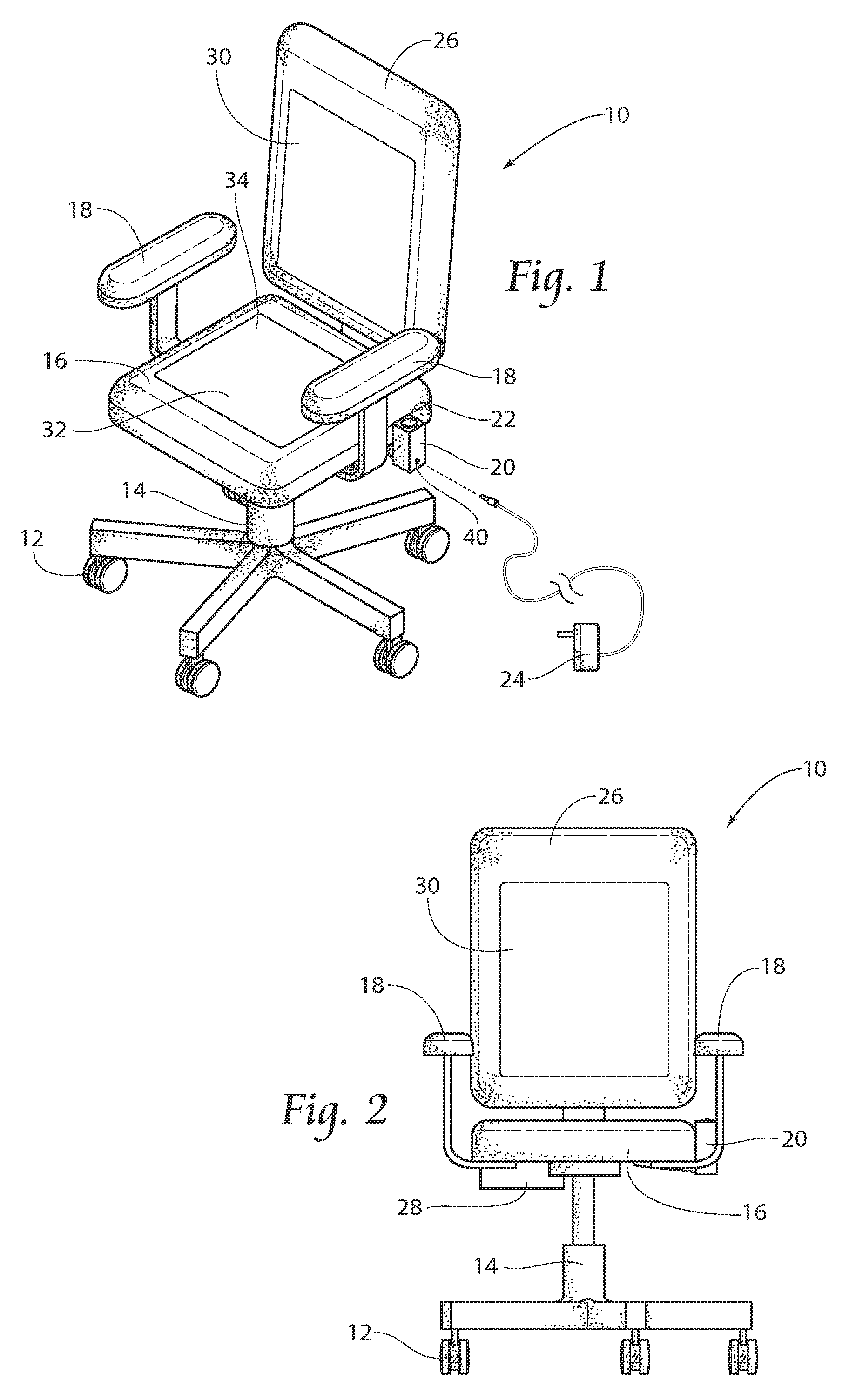

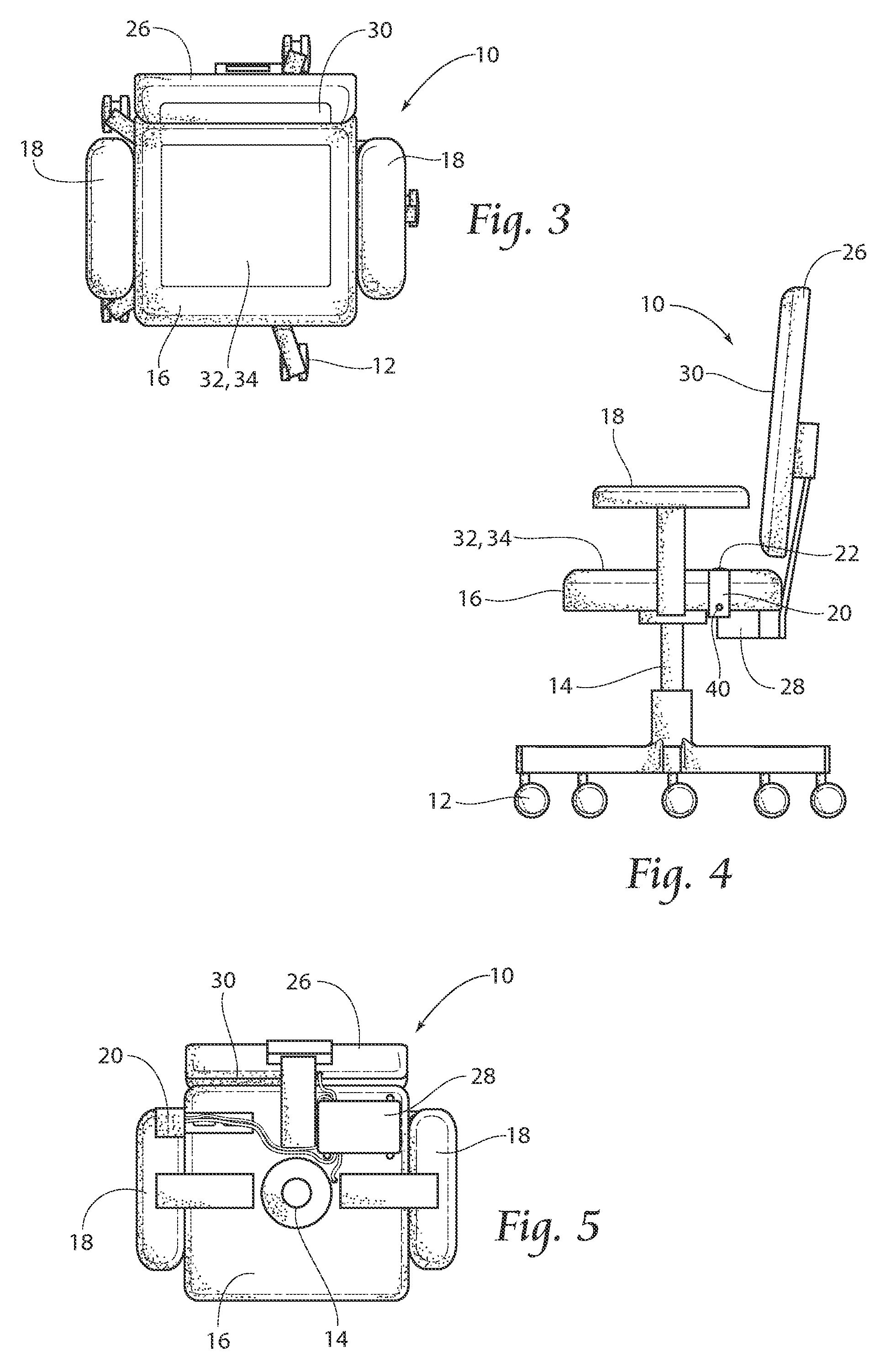

Heated and/or cooled home and office furnishings

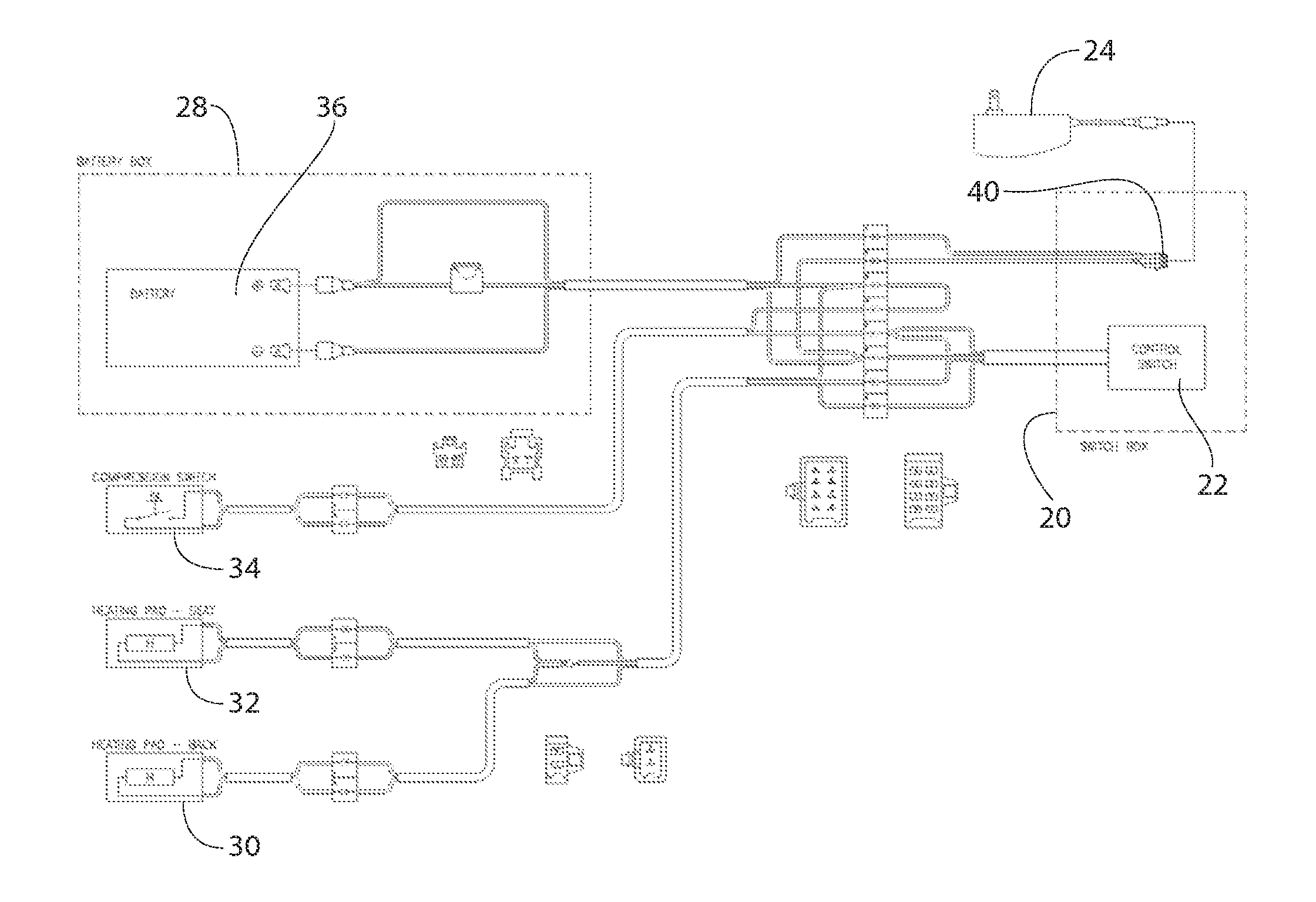

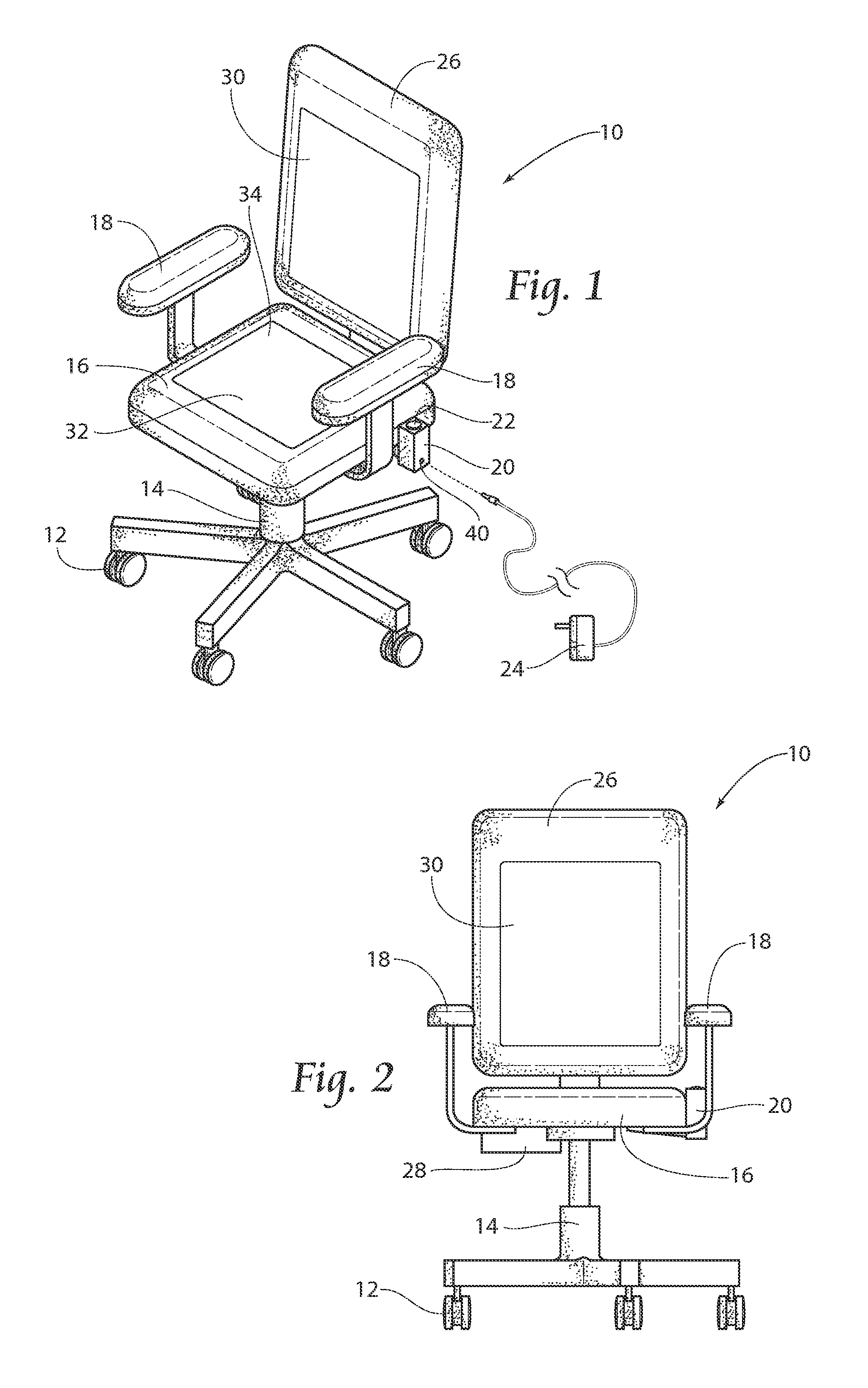

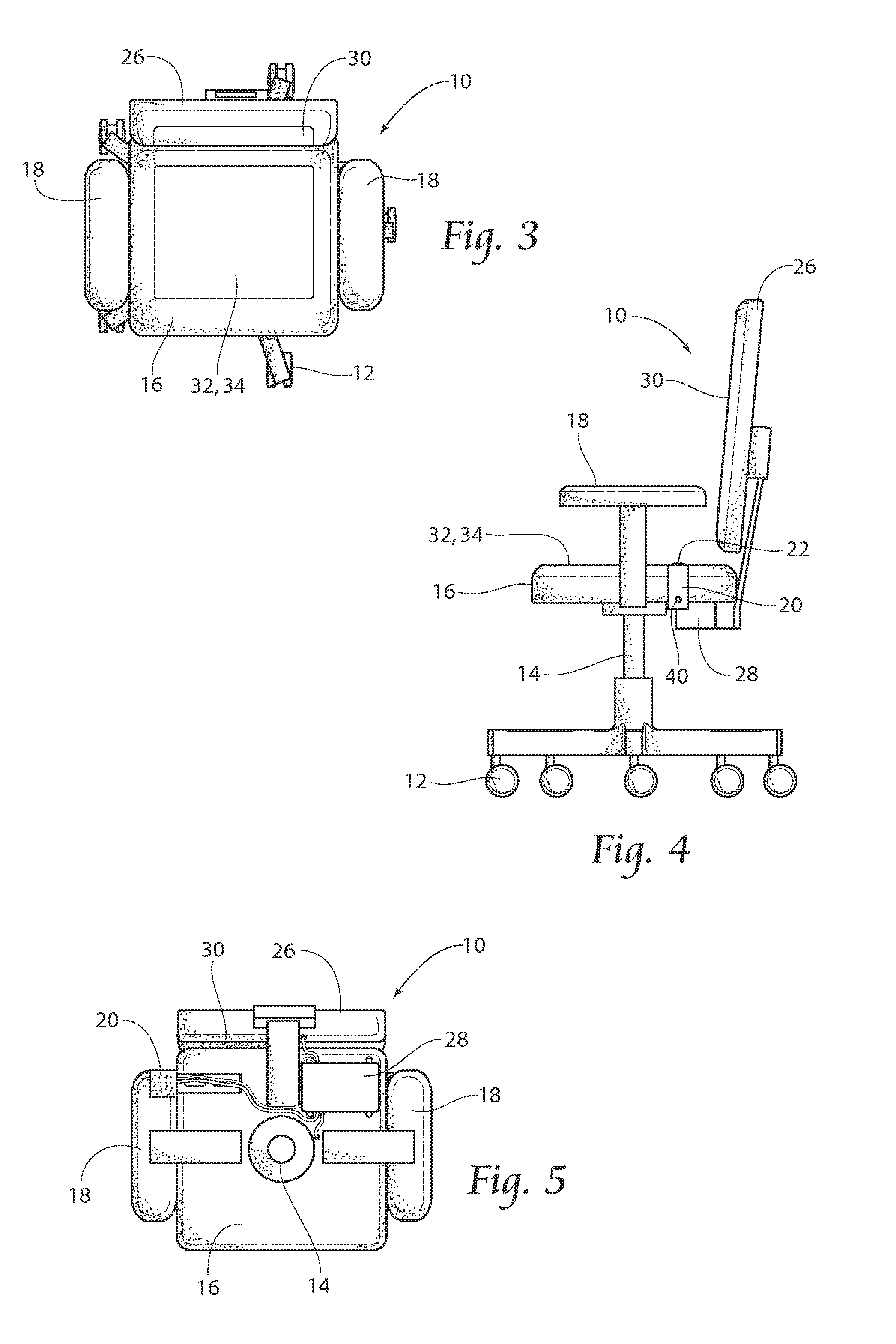

A heated and cooled seating unit is disclosed with an apparatus to determine if the chair is in use, such as a pressure sensor, or an electric sensing apparatus. This apparatus controls the heating apparatus and powers the heat off, to conserve power, in the event that a person or object is not seated in the chair.

Owner:RADIAN

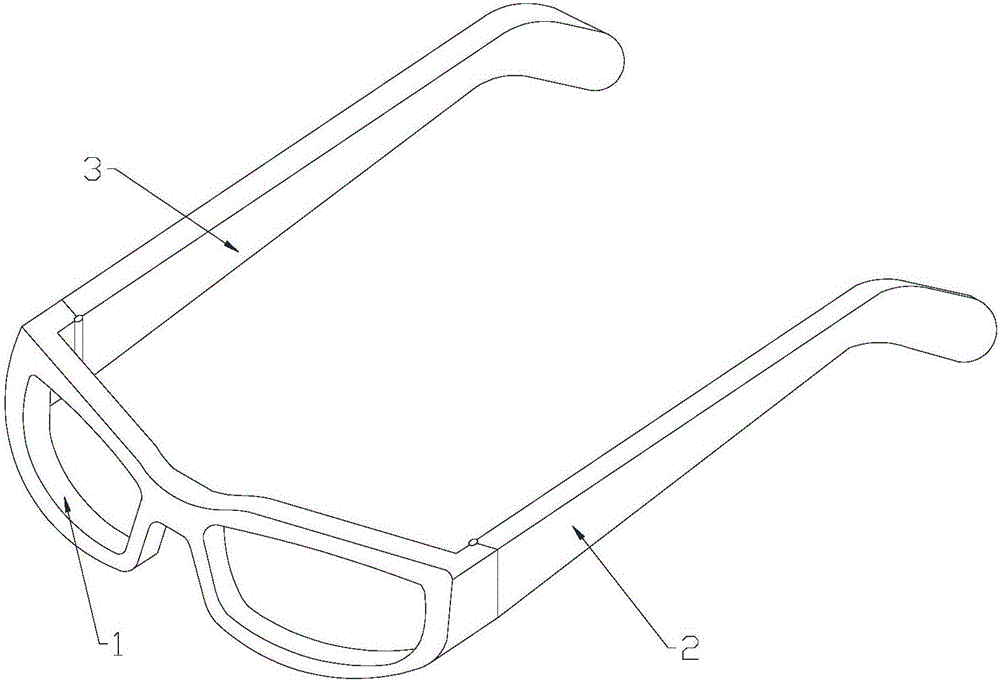

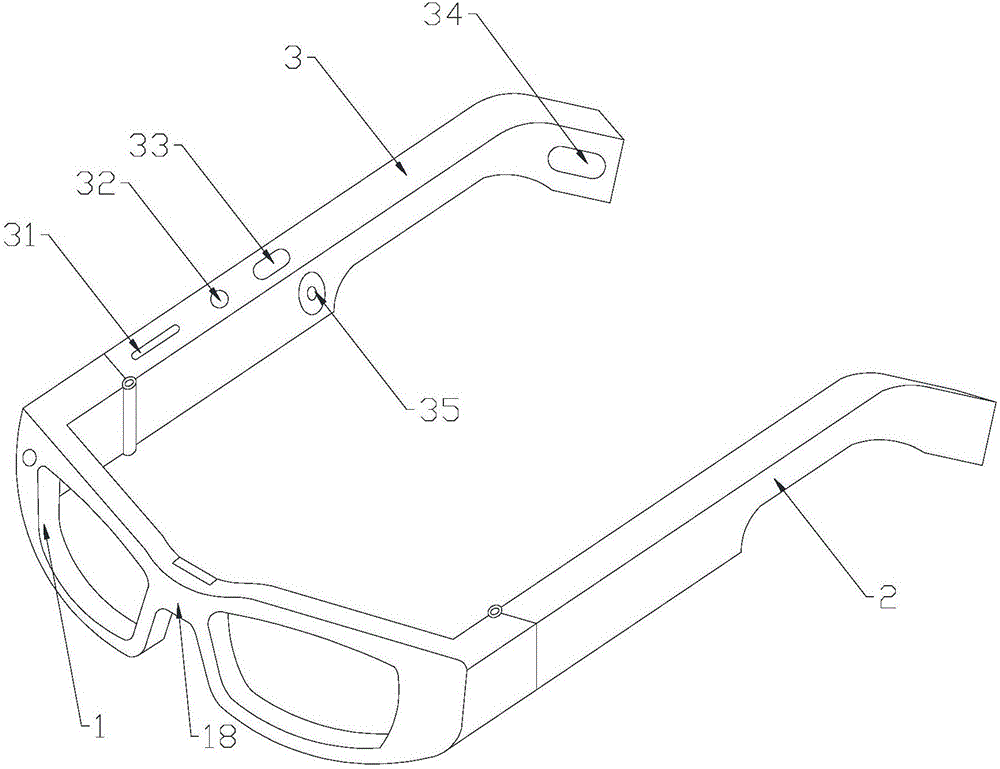

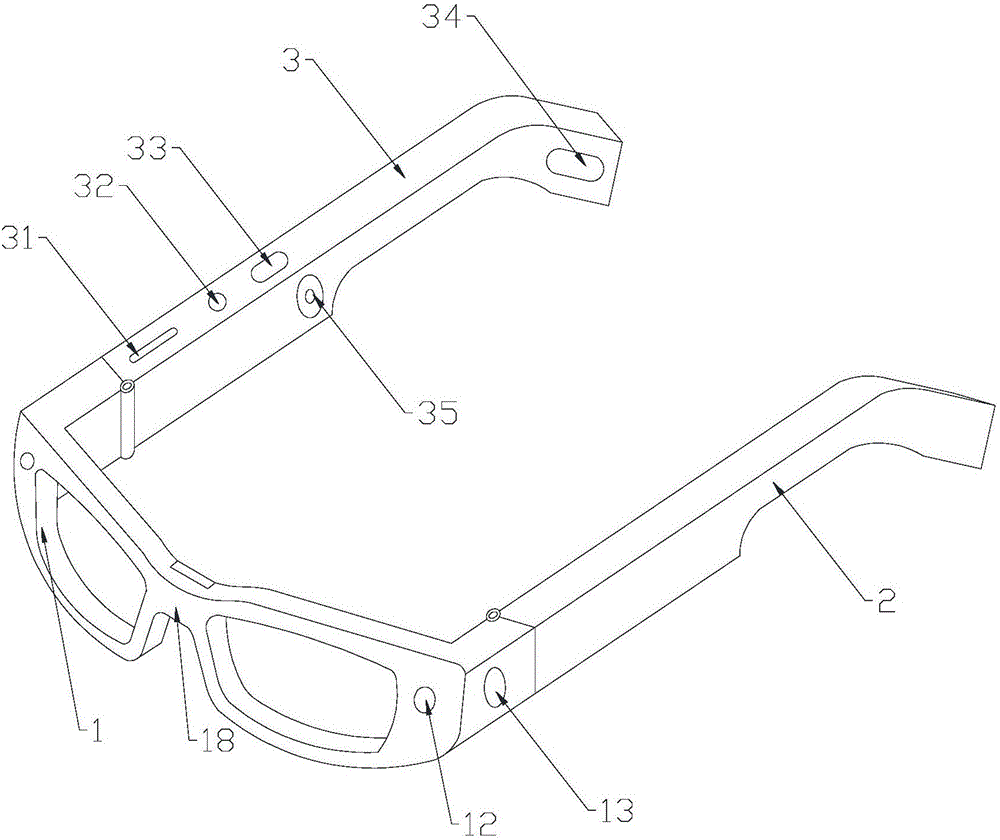

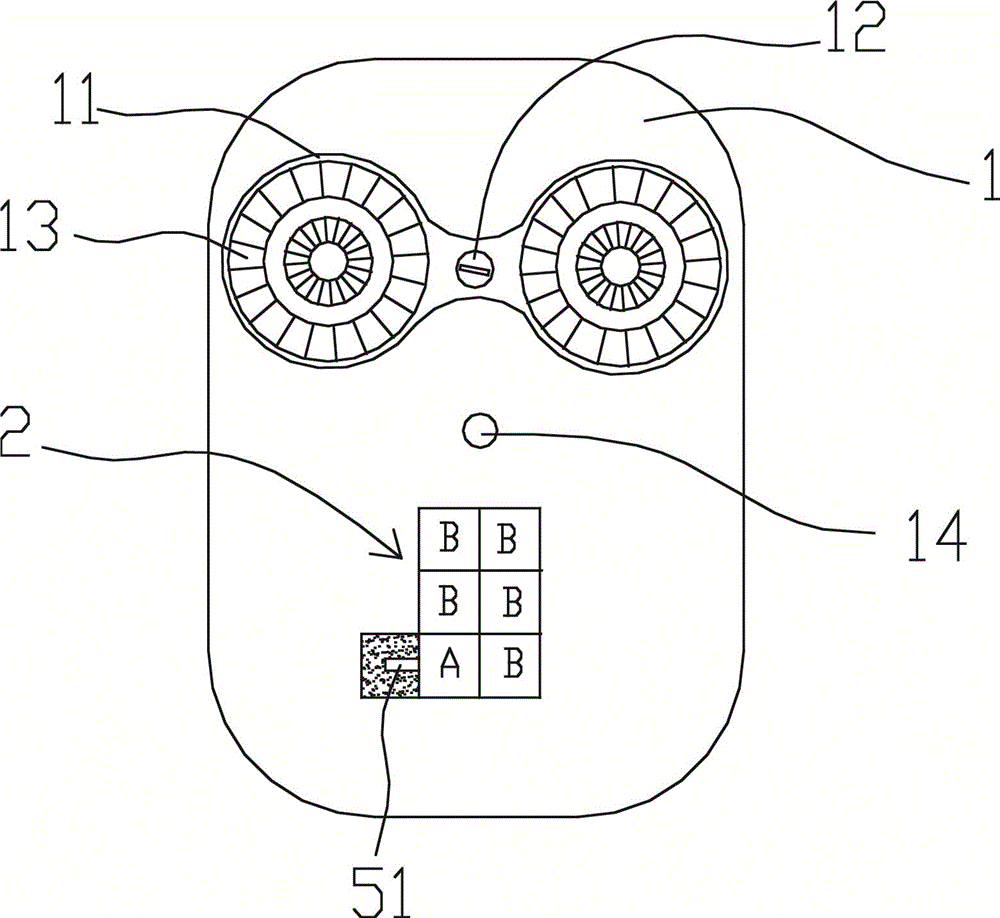

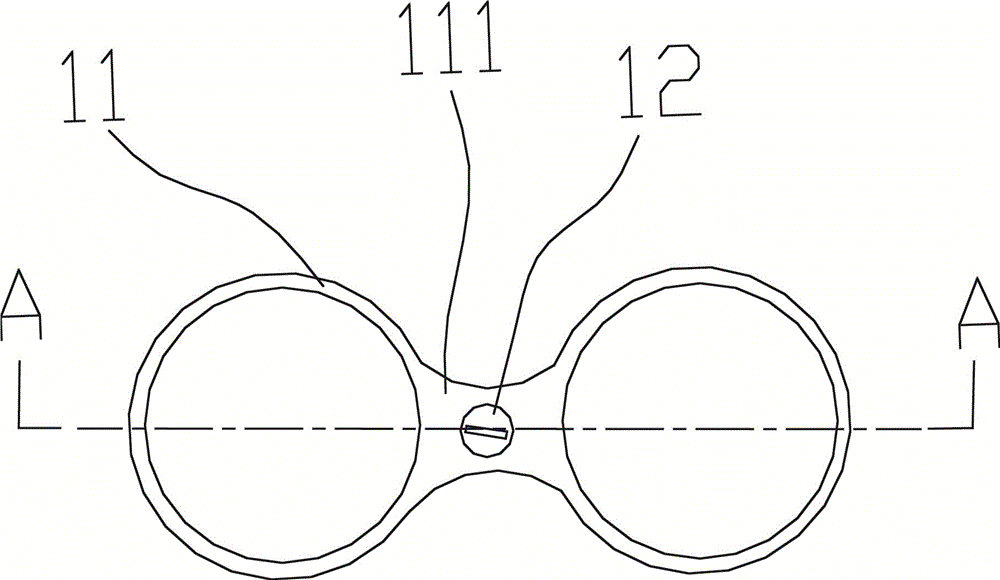

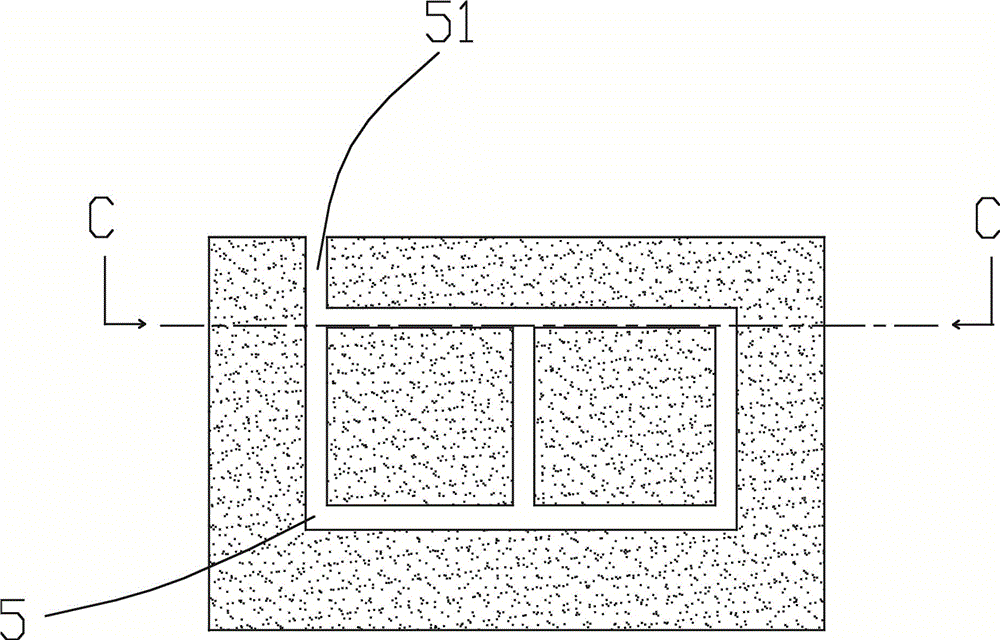

Motion monitoring intelligent glasses based on eye electric sensing control

InactiveCN106291984AExtend battery lifeSolve problems that cannot be widely promotedNon-optical adjunctsMicrocontrollerGyroscope

The invention relates to a pair of motion monitoring intelligent glasses based on eye electric sensing control. The pair of glasses comprises a glasses frame, a first glasses leg and a second glasses leg, wherein the first glasses leg and the second glasses leg are connected with the glasses frame. The glasses frame, the first glasses leg and the second glasses leg are each of a hollow structure. A detecting device is arranged on a nose beam of the glasses frame of the hollow structure and comprises a first electrode, a second electrode, a U-shaped buckling plate and a light distance sensor. The light distance sensor is electrically connected with a microcontroller. A data transmission interface and a power module are arranged in an inner cavity of the first glasses leg. The microcontroller, an acceleration sensor, a gyroscope and a heart rate sensor are arranged in an inner cavity of the second glasses leg. The motion monitoring intelligent glasses are reasonable in structure, have the advantages of being simple in structure, convenient to use, popular in shape, long in runtime, balanced in weight, free of pressure, high in intelligent degree and the like, and effectively solve the problem that existing intelligent glasses can not be popularized on a large range.

Owner:广州初曲科技有限公司

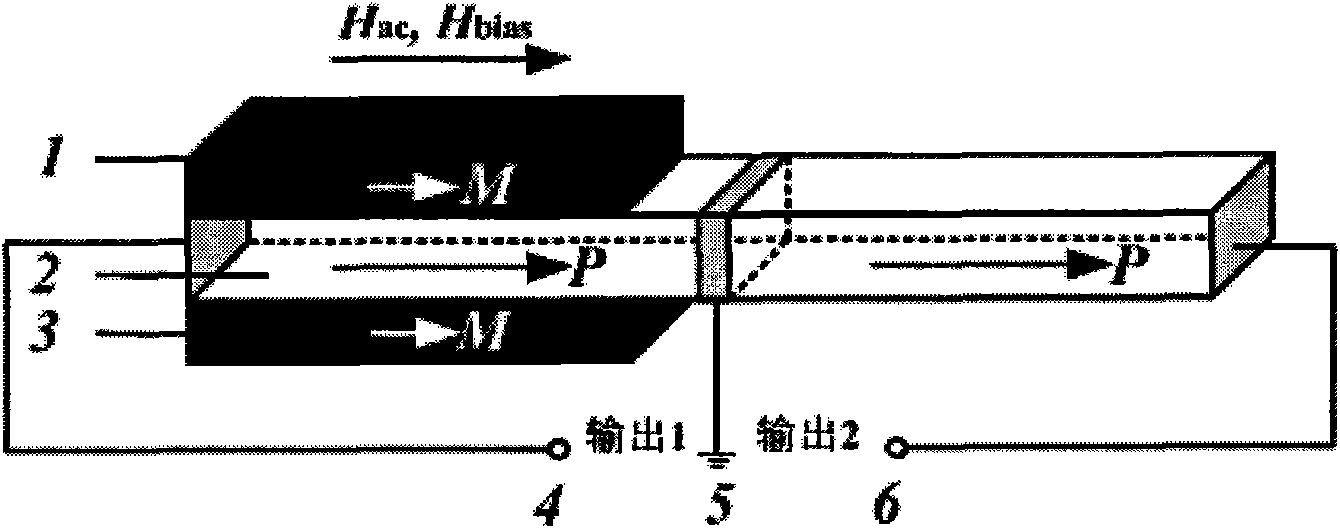

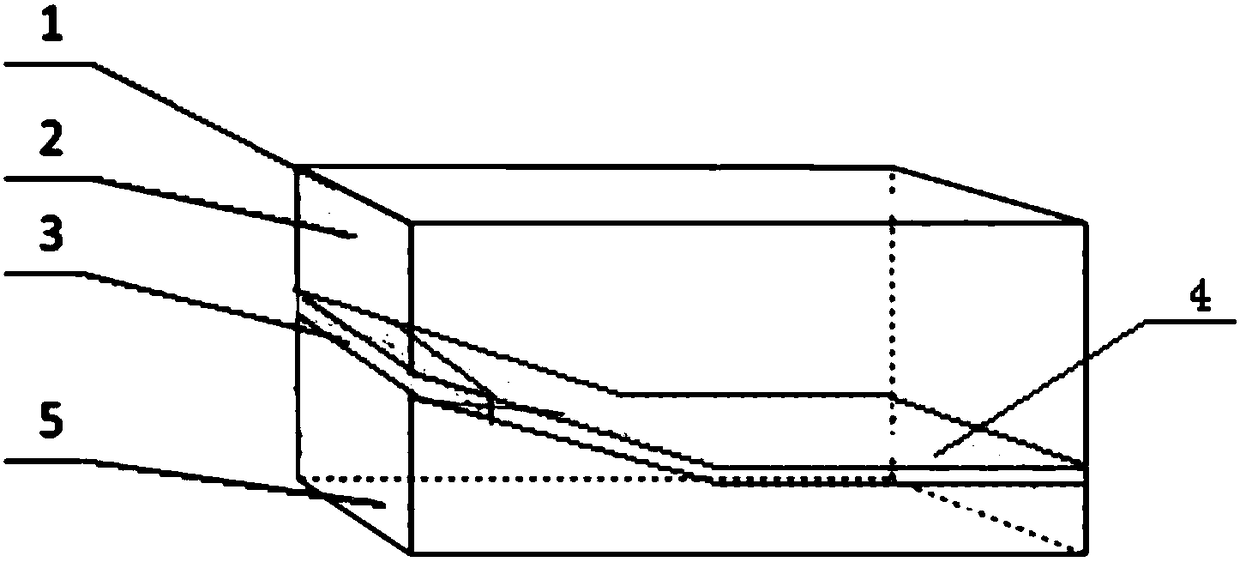

Magnetic-electric sensing transducer

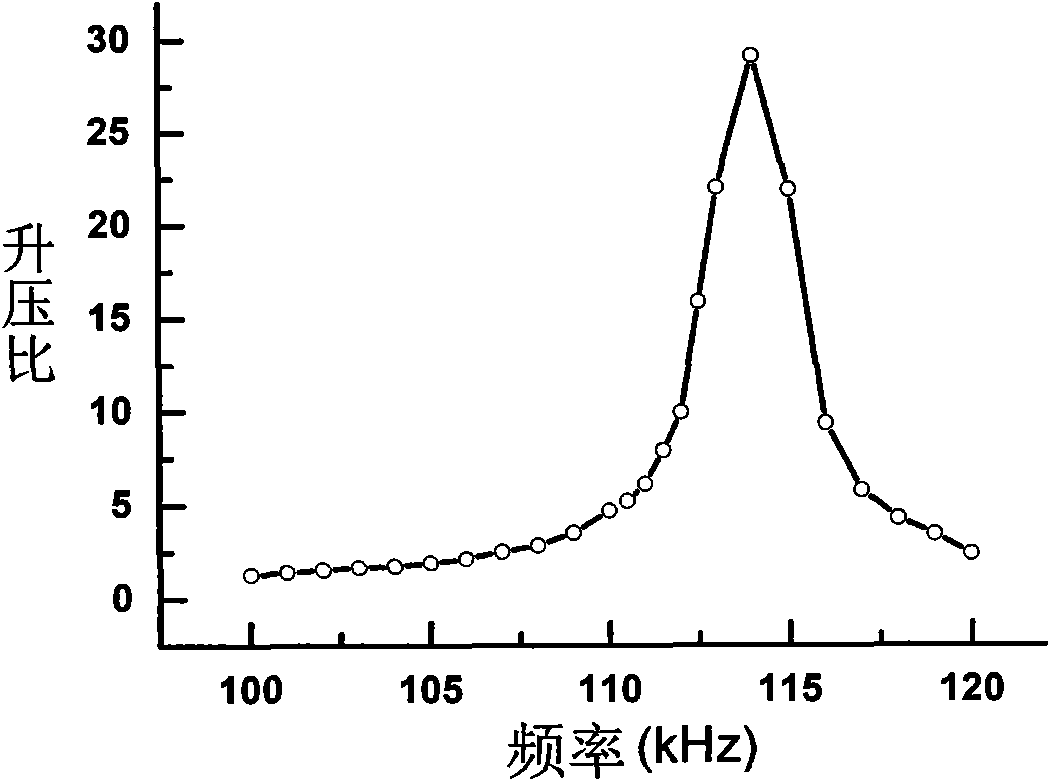

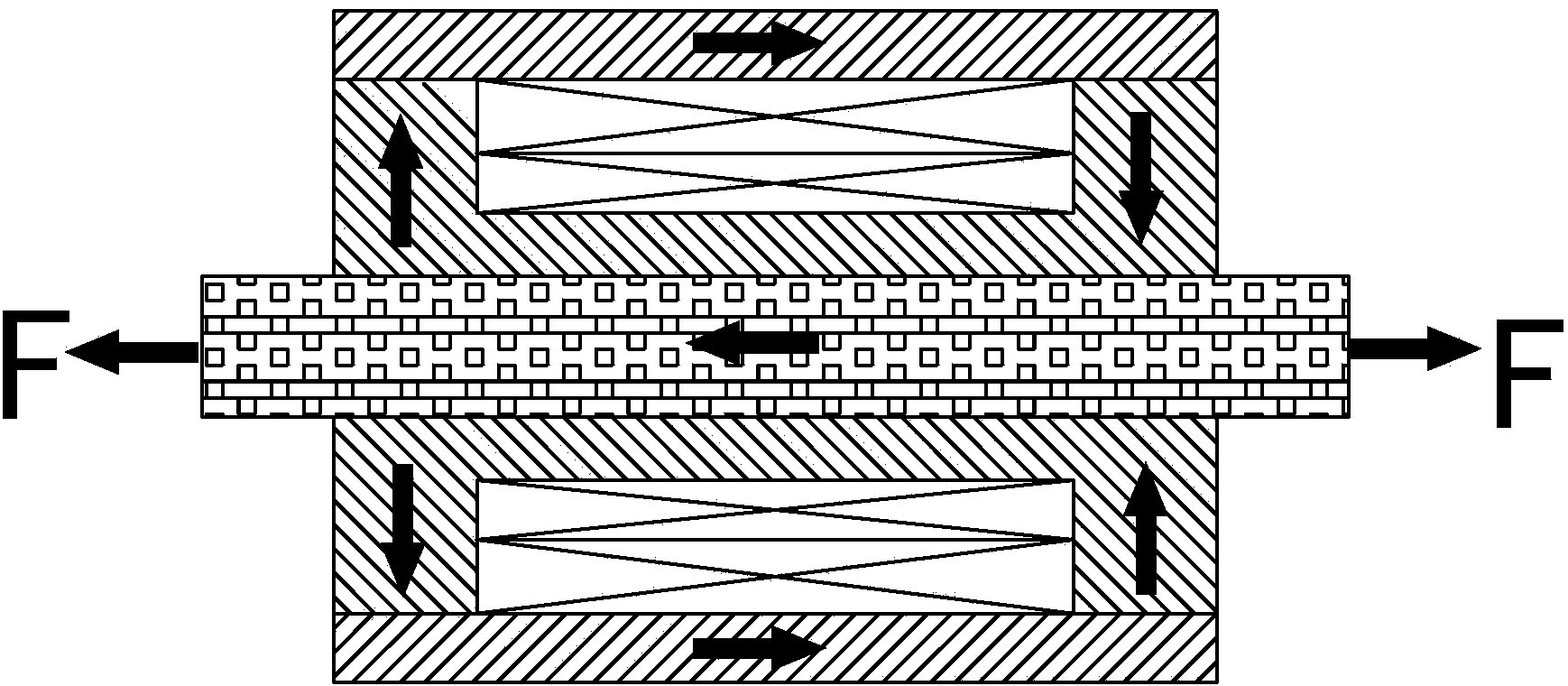

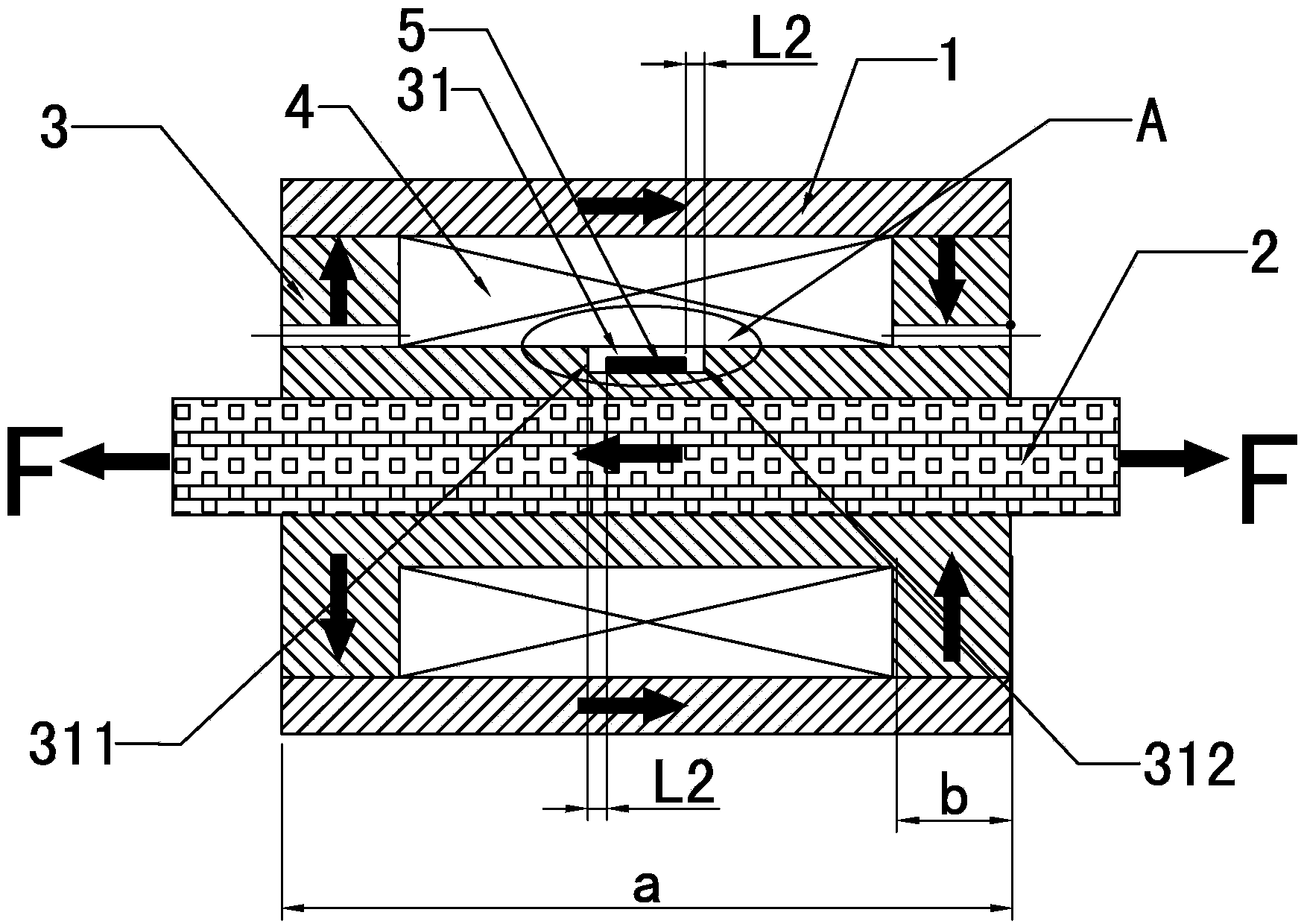

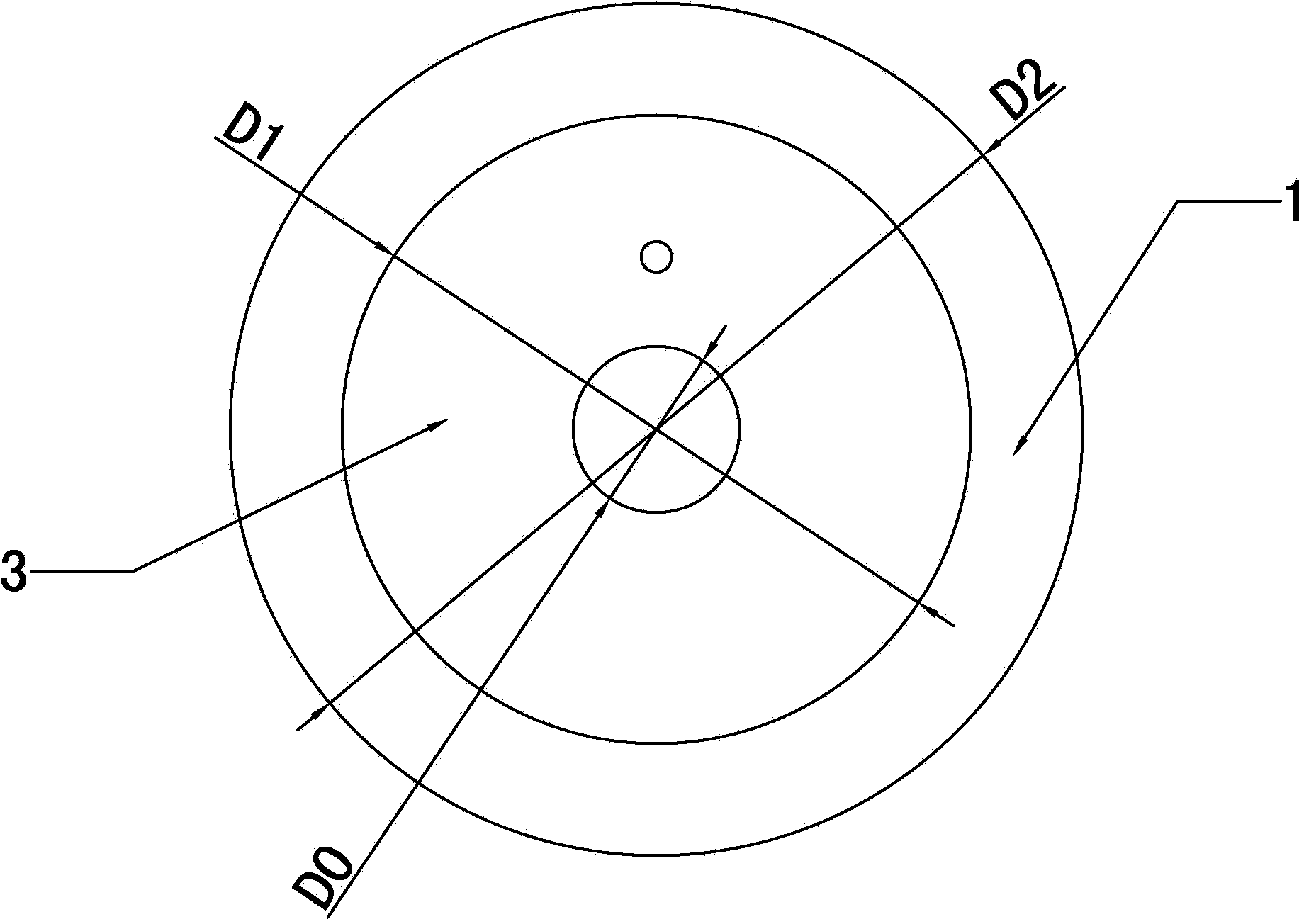

InactiveCN101882919AFlat Frequency ResponseHigh voltage outputPolycrystalline material growthImpedence networksElectric senseElectricity

The invention belongs to piezoelectric devices, and discloses a high-performance magnetic-electric sensing transducer. Along with the progress of science and technology, the demands of people for detection sensitivity are becoming increasingly higher. However, due to the limitation of material properties, the demand for further improving the magnetic-electric coefficient and increasing the detection sensitivity is still a key issue which needs a solution but can not be solved easily. The magnetic-electric sensing transducer comprises a magnetostrictive material (1), a piezoelectric material (2) and a magnetostrictive material (3), the three material layers are bonded through insulating adhesives, the optimal thickness ratio of the three material layers is 1: (0.6-1): 1, and the piezoelectric material is a leadmagnesio niobate-lead titanate single-crystal material. The utility model has the advantage of multi-end output, simple structure, convenient manufacture, no need for any power supply and fast response. The input end has stable frequency response under the low frequency and is applicable to sensors, and the output end has high-voltage output in the resonant state and is suitable for high-performance transducers.

Owner:SHANGHAI NORMAL UNIVERSITY

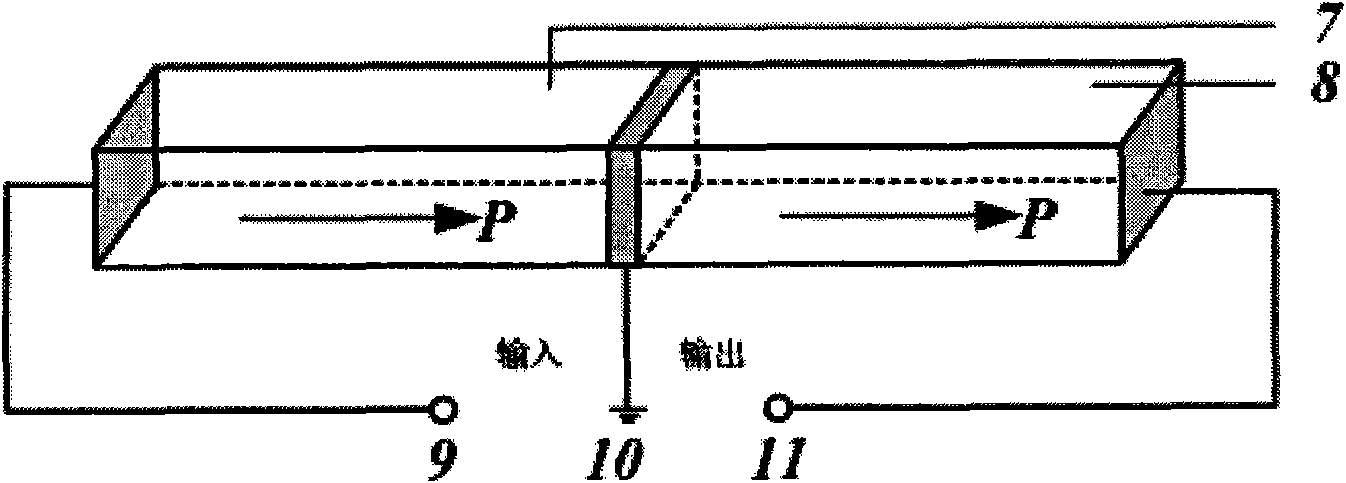

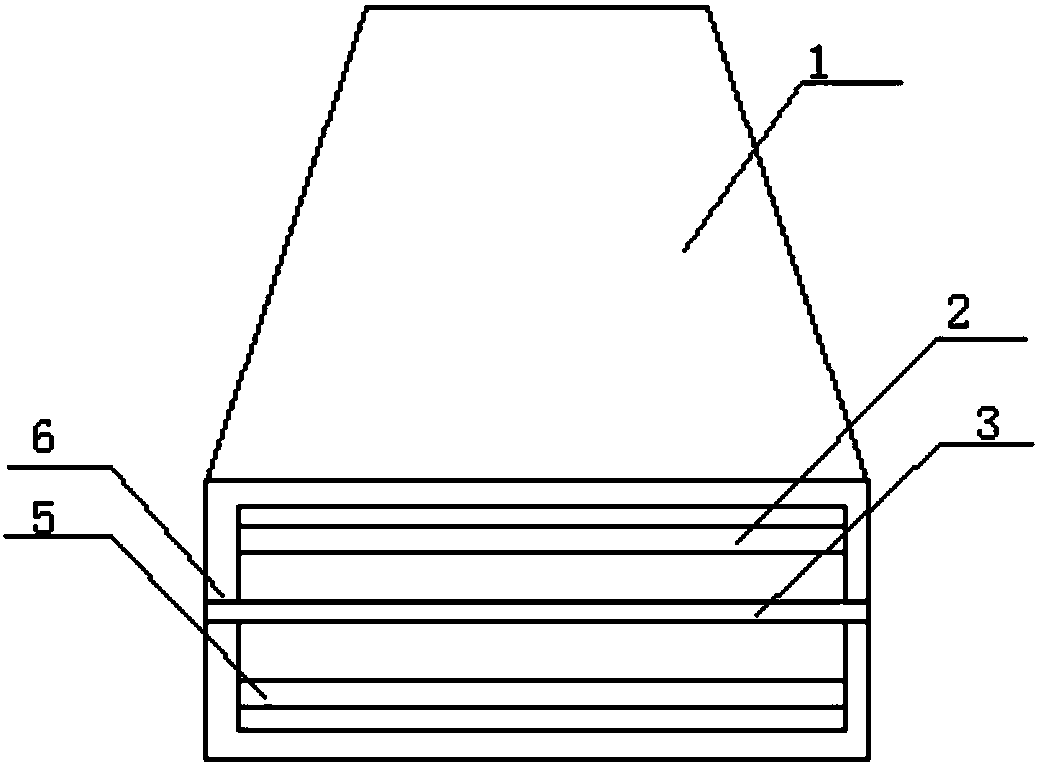

Cable force detecting method and cable force sensor using same

ActiveCN104006909ASimple manufacturing processImprove signal-to-noise ratioApparatus for force/torque/work measurementElectric senseSignal-to-noise ratio (imaging)

The invention discloses a cable force detecting method and a cable force sensor using the same. A linear relationship between induction voltage and steel cable force is decided, the induction voltage is generated by a magnetic-electric sensing unit in the cable force sensor along with the change of the magnetic field, and the magnetic-electric sensing unit with magnetostriction performance is utilized to replace a detecting coil of a magnetic flux senor as a detecting unit to detect the induction voltage of the cable force sensor in axial deformation of a steel cable. The cable force detecting method has the advantages of reducing magnetic flux leakage of the detecting unit and magnetic flux leakage between the detecting unit and an excitation coil and improving the measurement accuracy of the sensor. In addition, the magnetic-electric sensing unit with the magnetostriction performance can directly respond the induction voltage through change of the internal magnetic field of a coil framework, and a method of responding the induction voltage through the change of the magnetic flux and then transmitting the induction voltage through the detecting unit to obtain response voltage is avoided. Thus, the response time is short, and the testing speed is high. Furthermore, the cable force sensor is simple in manufacturing procedure, and the signal to noise ratio of the sensor is improved.

Owner:NINGBO UNIV +1

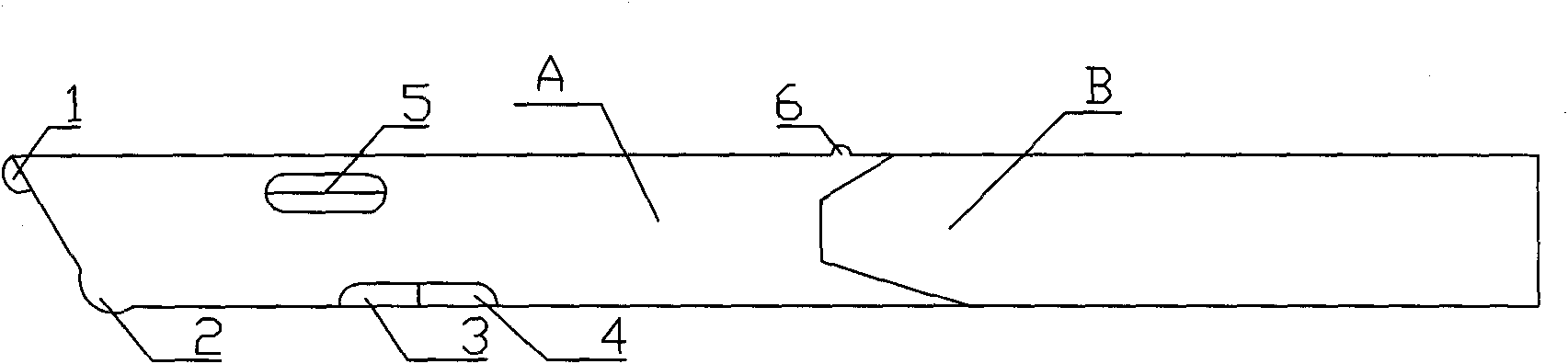

Multifunctional electronic writing pen

InactiveCN101833386ASensing changes in pen holding movementsImprove writing fluencyWriting implementsInput/output processes for data processingElectric senseControl system

The invention discloses a multifunctional electronic writing pen. The integral appearance of the pen is similar to that of a common writing pen, and a pen body is divided into a front section and a rear section which are movably connected; a nib position is provided with a photo-electric sensing system, a function control system is arranged on the front pen body, and the tail end of the pen body is provided with a connecting system which is communicated with a computer in a wired or wireless way; a plug / socket element is arranged on a connecting opening of the front pen body and the rear pen body, and circuits on the front pen body and the rear pen body are communicated or separated by the element; and a common ink pen core is arranged in the pen body. After a character handwriting recognition system is additionally installed on the writing pen, the operation and the use are similar to holding a common pen by a hand, the control and the operation on the computer can be finished just in a writing way without special drive on any computer, and the pen is suitable for all people; and the built-in common ink pen core can be used at random.

Owner:王东 +1

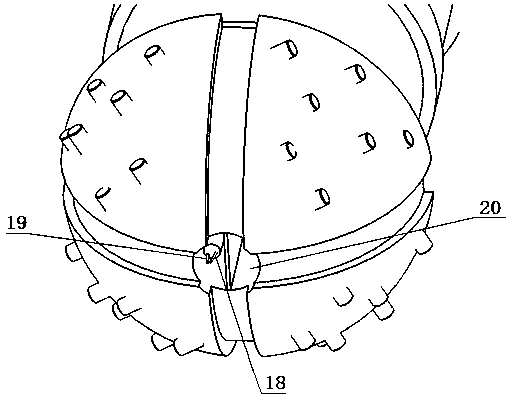

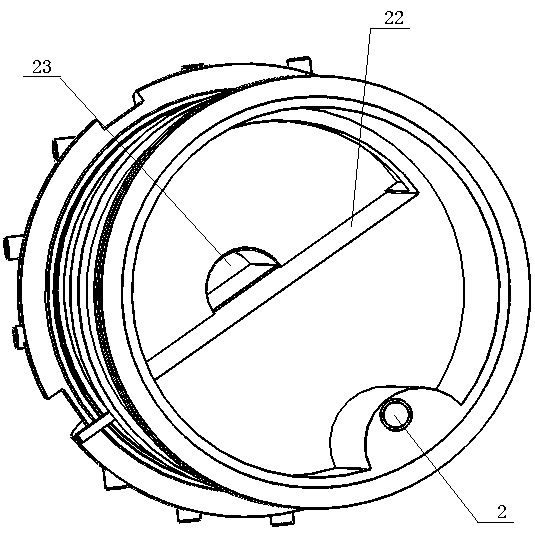

Plasma channel and mechanical drilling tool combined device and well drilling method thereof

InactiveCN108661554AReduce wearReduce energy consumptionDrill bitsDrilling rodsPressure sensePlasma channel

The invention relates to a plasma channel and mechanical drilling tool combined device and a well drilling method thereof. An inner cavity of a double-inner-chamber connecting rod of the device basedon combination of the plasma channel and the mechanical drilling tool is partitioned into a closed electric chamber and a well drilling fluid channel. An electric sensing device is mounted in the electric chamber. The upper end of the double-inner-chamber connecting rod is sequentially connected with a drilling rod and a rotating disc. An electric cable channel is formed in the inner wall of the drilling rod. An electric cable penetrates through the electric cable channel to be connected with a direct-current power supply in the electric chamber. The lower end of the double-inner-chamber connecting rod is sequentially connected with a pressure telescopic rod and a drill bit. A pressure sensing device is mounted on the pressure telescopic rod and connected with the electric sensing device.A partition plate is arranged in a central water hole of the drill bit. A partition-type water hole is formed in one side of the partition plate. A grounding electrode and a high-voltage electrode aremounted on the other side of the partition plate and exposed. The lower end of an electrode connecting device in the electric chamber is in the drill bit and is connected with the grounding electrodeand the high-voltage electrode. According to the plasma channel and mechanical drilling tool combined device and the well drilling method thereof, simultaneous working of the drill bit, the high-voltage electrode and the grounding electrode is achieved.

Owner:NORTHEAST GASOLINEEUM UNIV

Friction electric sensing coupled mine shaft harmful gas passive detection apparatus

InactiveCN108548847AAvoid layingSave energyMaterial analysis by electric/magnetic meansFriction generatorsGeneration processElectric sense

The invention relates to the field of gas sensing, particularly to a friction electric sensing coupled mine shaft harmful gas passive detection apparatus, which comprises a sensing component and a displaying component, wherein the sensing component comprises a shell, a negative friction layer and a positive friction layer, and the displaying component comprises a rectification bridge, a voltage dividing resistor and six LEDs. According to the present invention, the self-powered mine shaft harmful gas sensor is constructed by using the electric-conduction polymer material as the friction and sensing material, such that the gas sensing is achieved at the room temperature, the power supply for the sensor by the power source, the electric cable and the like is not required, and the power supply problem of the sensor is solved; and the friction power generation process and the gas sensing process are combined in the same process, such that the two processes of the conversion of the wind energy into the electric energy and the sensing are achieved in one step.

Owner:蔡青青 +2

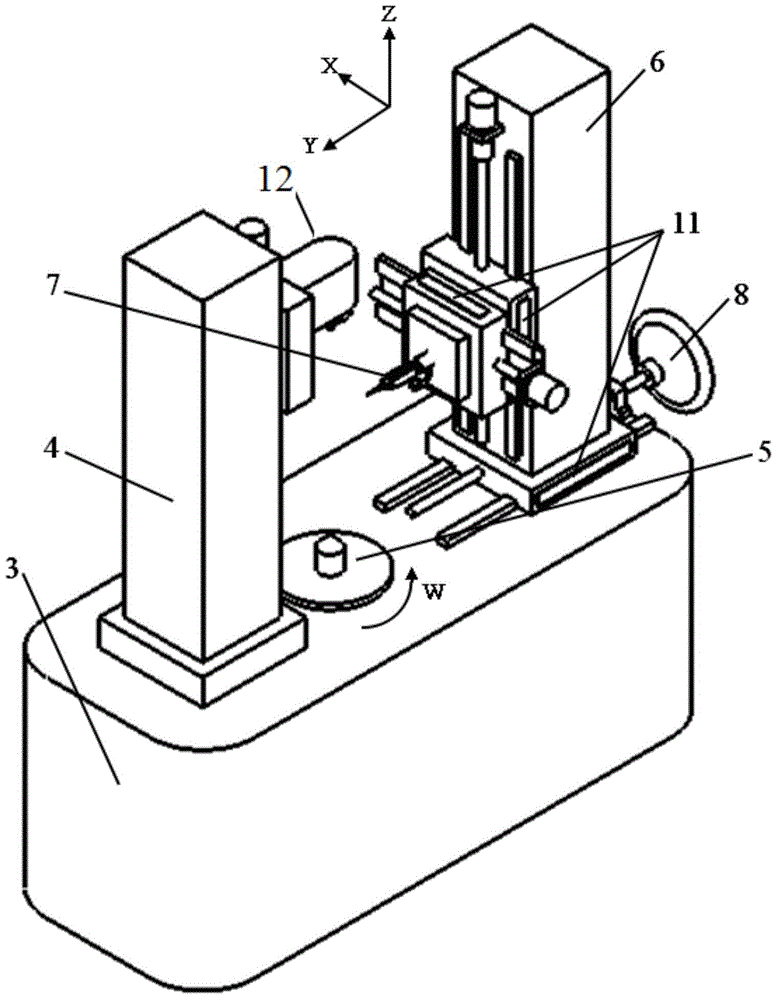

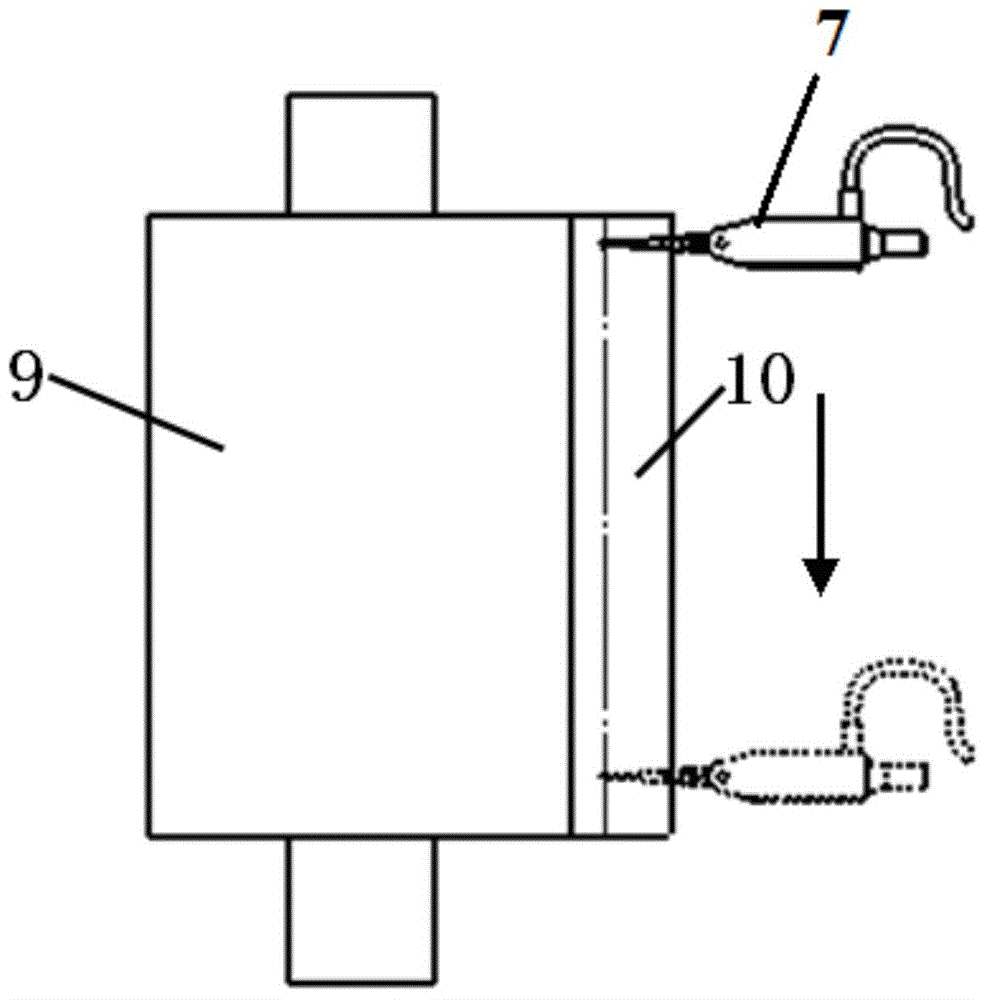

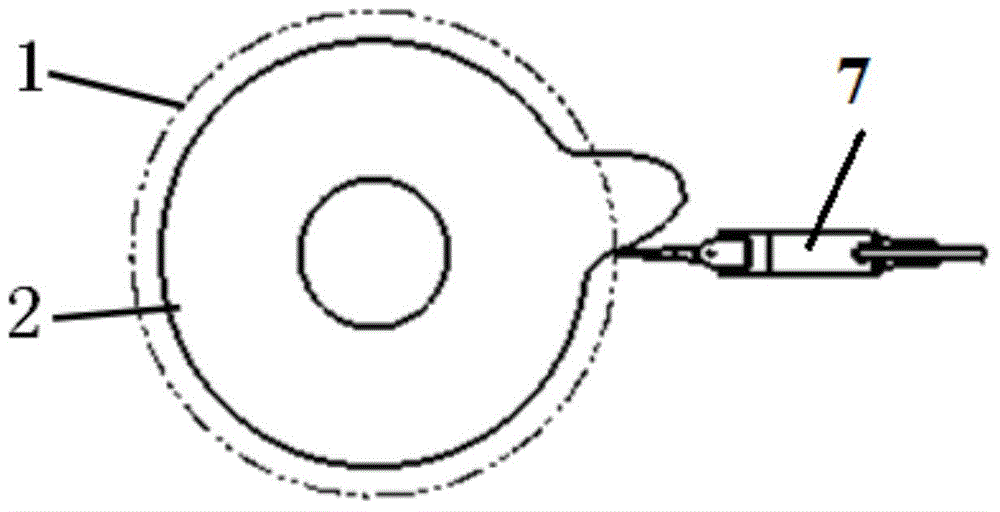

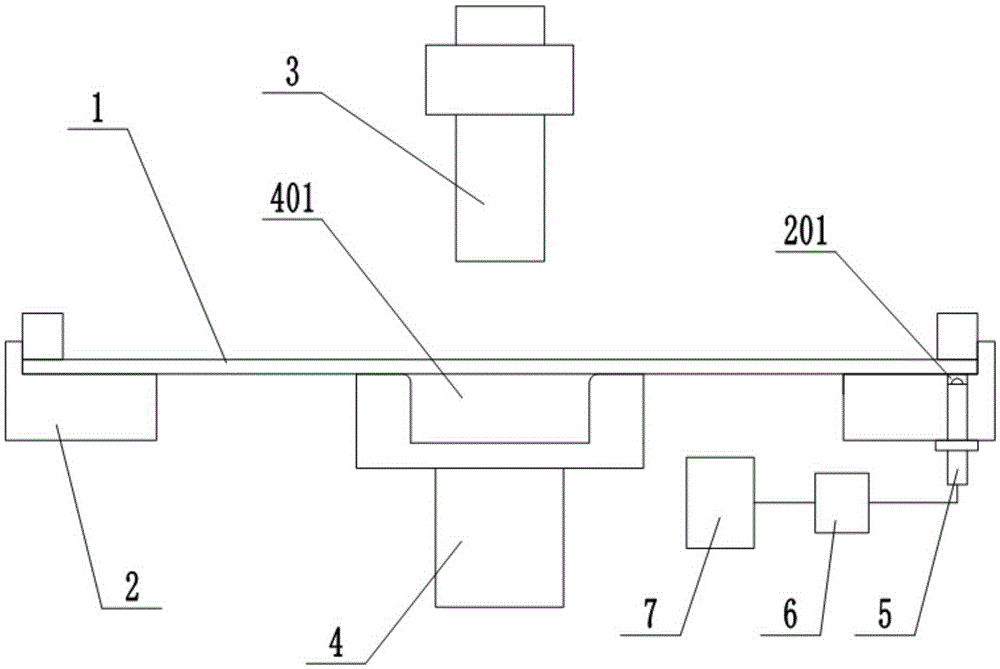

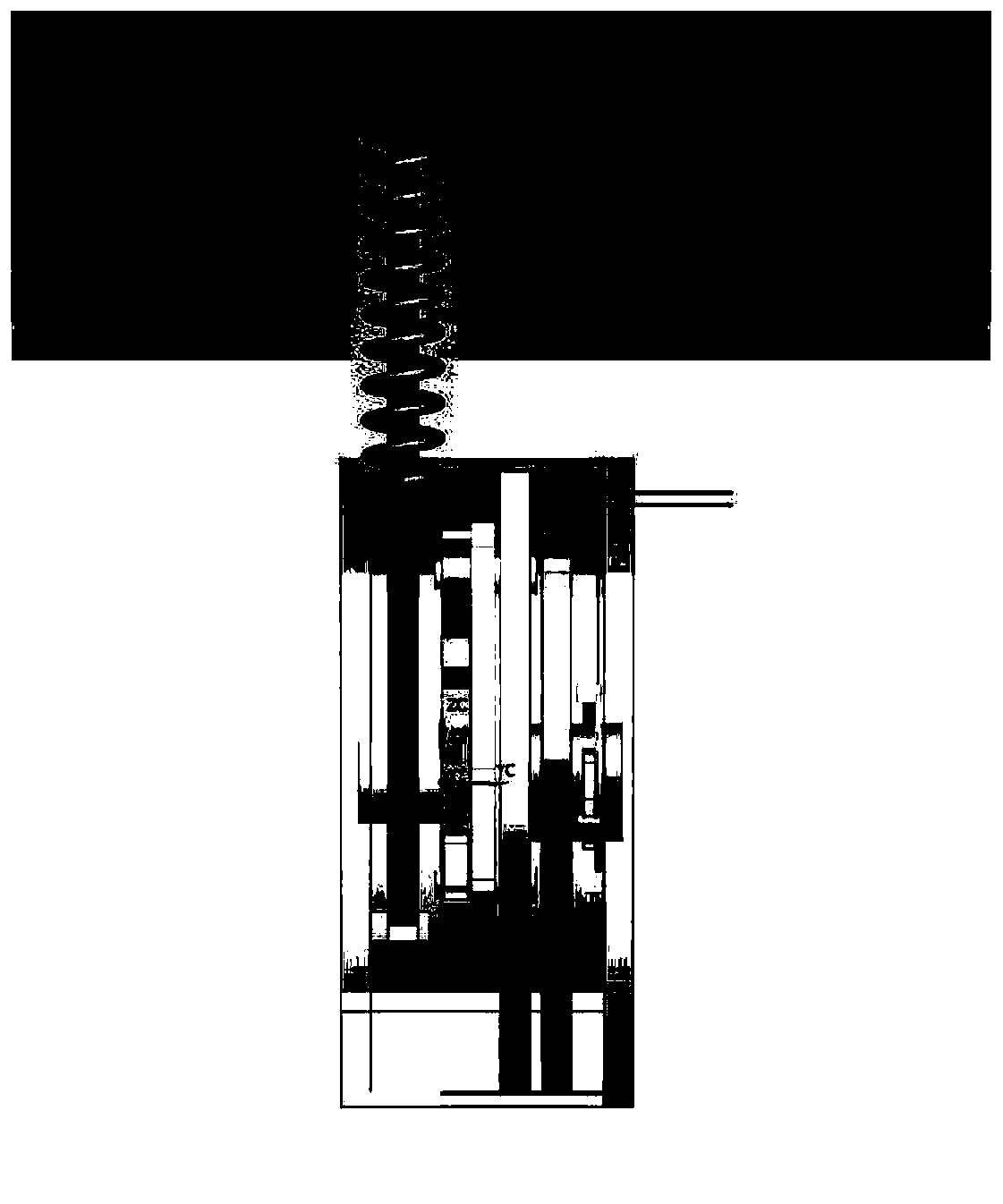

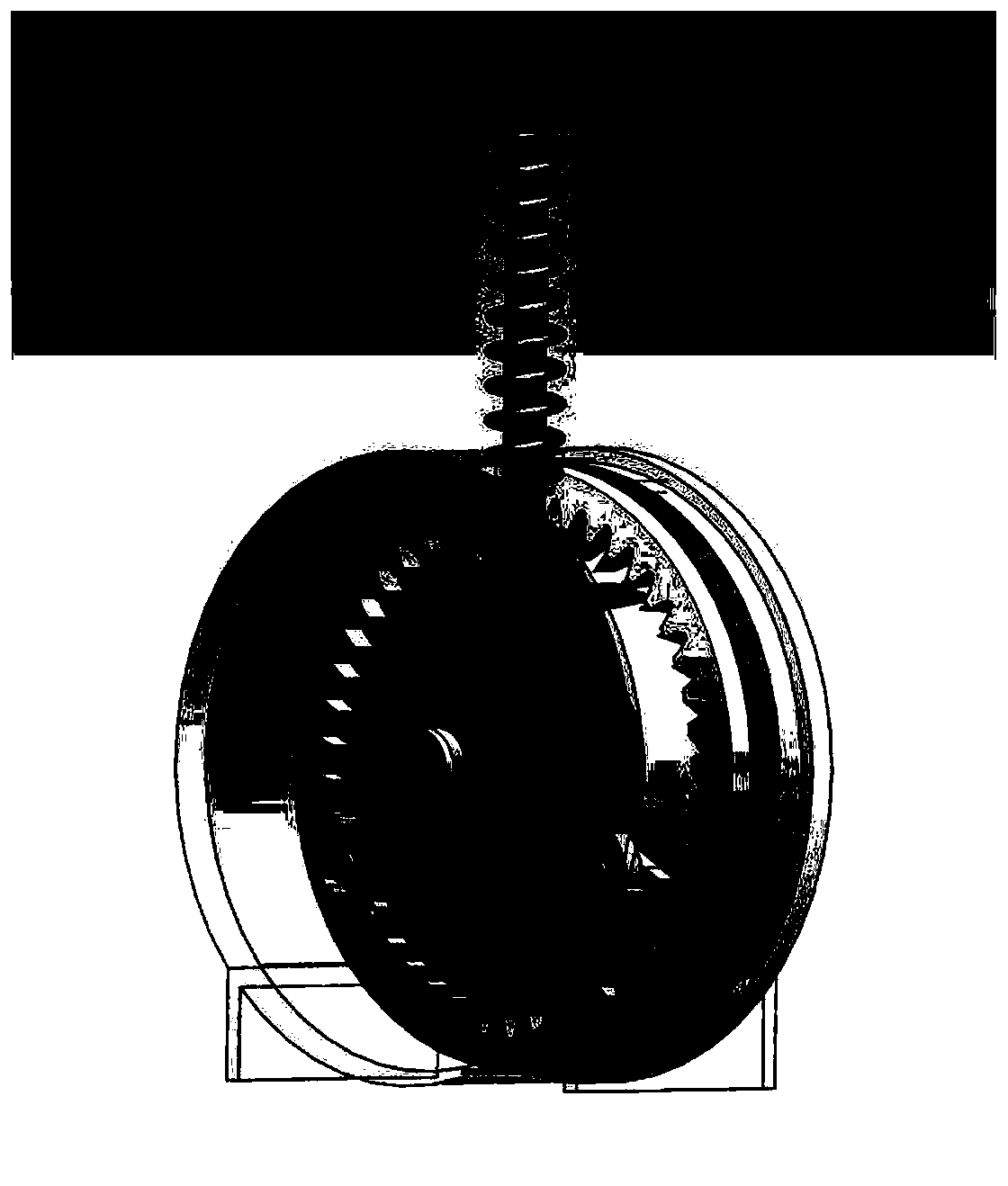

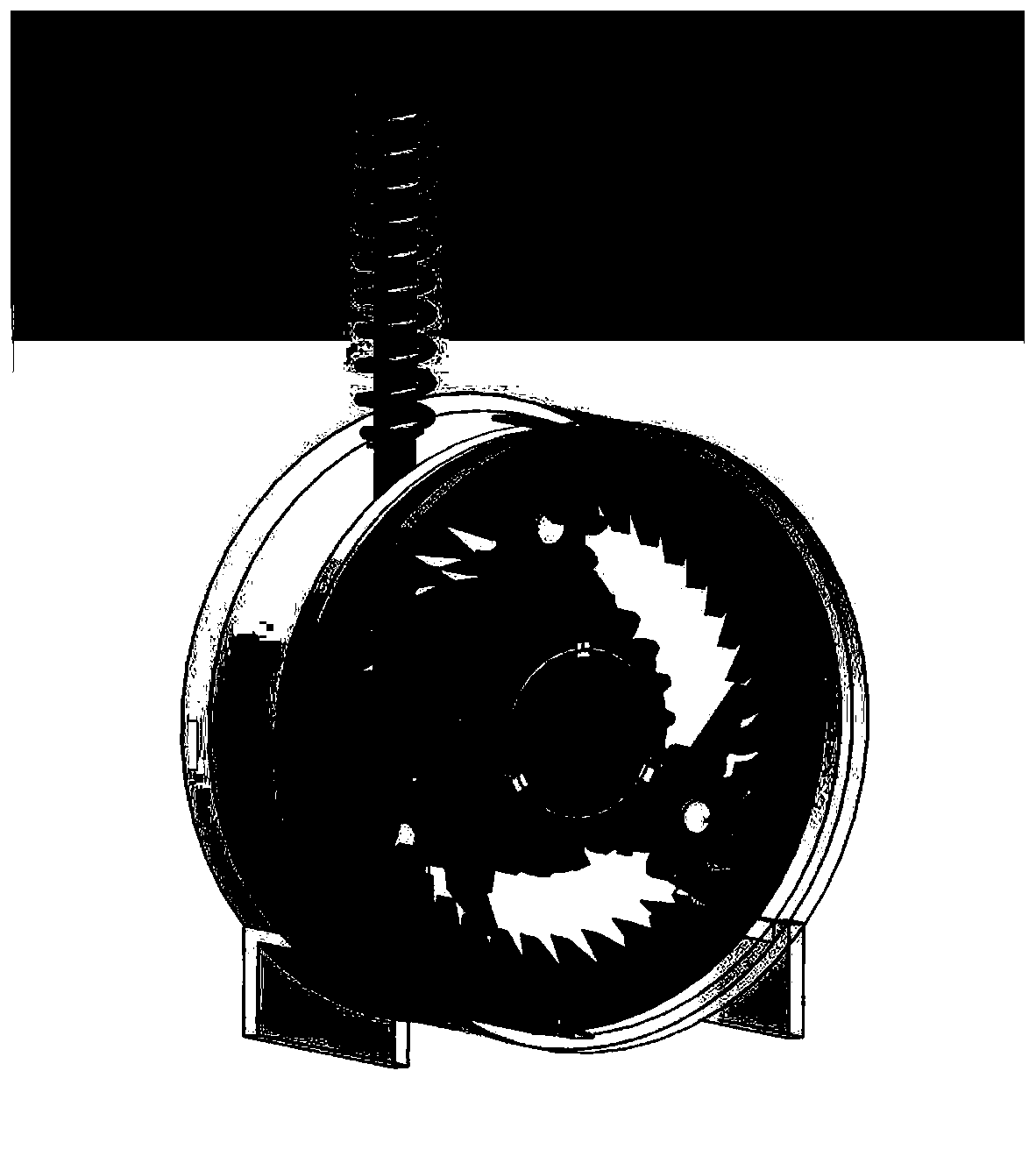

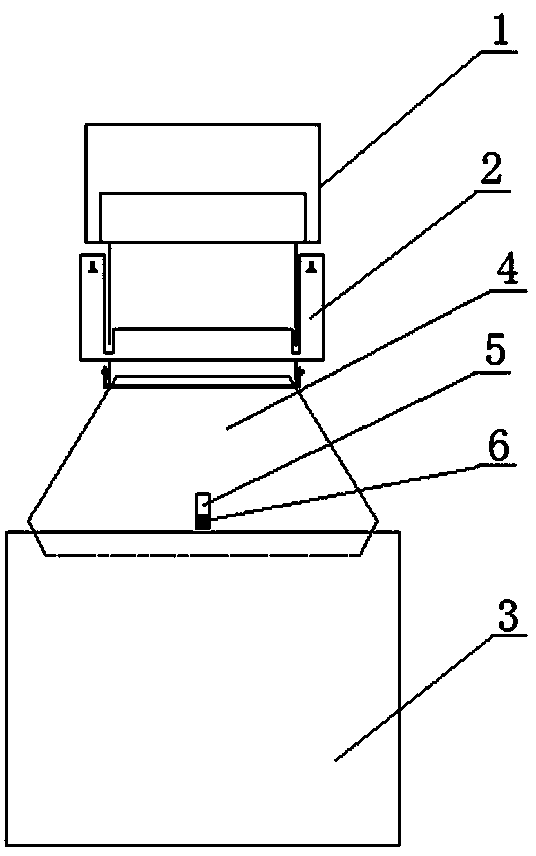

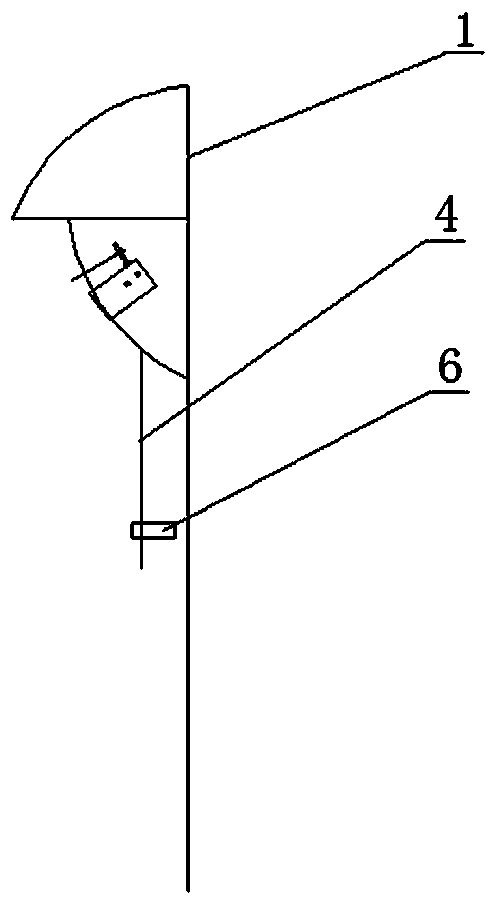

Three-axis linkage-based complicated part accurate measurement central path planning realizing method and device

ActiveCN104154849ARealize stepless adjustmentEasy to detectUsing electrical meansUsing optical meansCircular discElectric sense

The invention provides a three-axis linkage-based complicated part accurate measurement central path planning realizing method and a device. the device comprises a base, a workpiece vertical column, and a measurement vertical column, wherein the measurement vertical column is provided with an electric sensing head capable of moving vertically and horizontally. Horizontal movement of the measurement vertical column is used for contotrlling the distance between the measuring head and the center of a spindle rotating shaft system, stepless adjustment of a basic circle can be realized, a series of basic circle discs do not need to assist measurement of a gear, the detection process is simplified, and detection errors due to wear of the basic circle discs can be solved. Through controlling vertical movement, horizontal movement of the measuring head and linkage of the spindle rotating shaft system, control of the measuring trajectory of the measuring head can be realized respectively, and helix, tooth profile and pitch error of the gear with any base circle radius value within the measuring range can be fully automatically measured. In addition, path planning of an eccentric gear can be realized, and full-automatic measurement on helix, tooth profile and pitch error of the eccentric gear can be realized.

Owner:西安秦川思源测量仪器有限公司

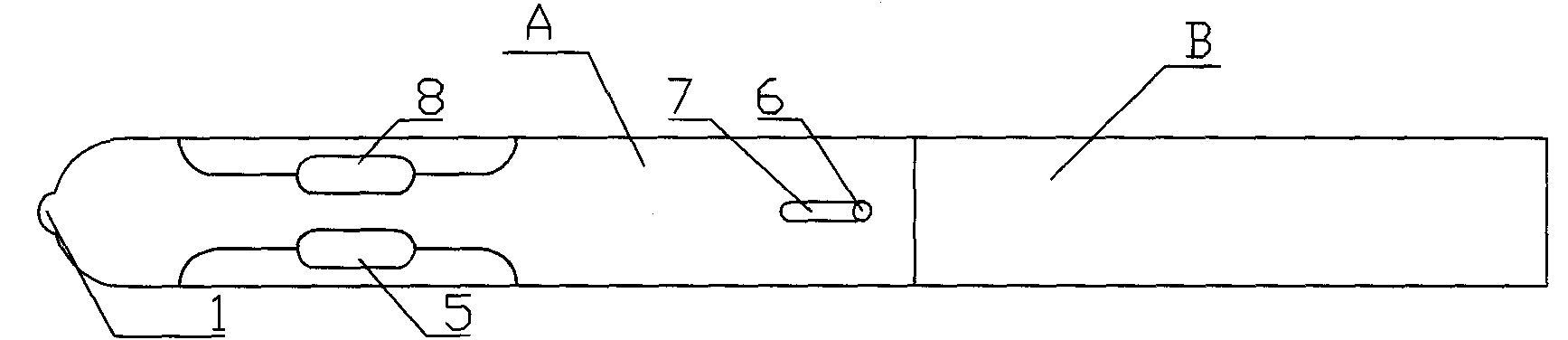

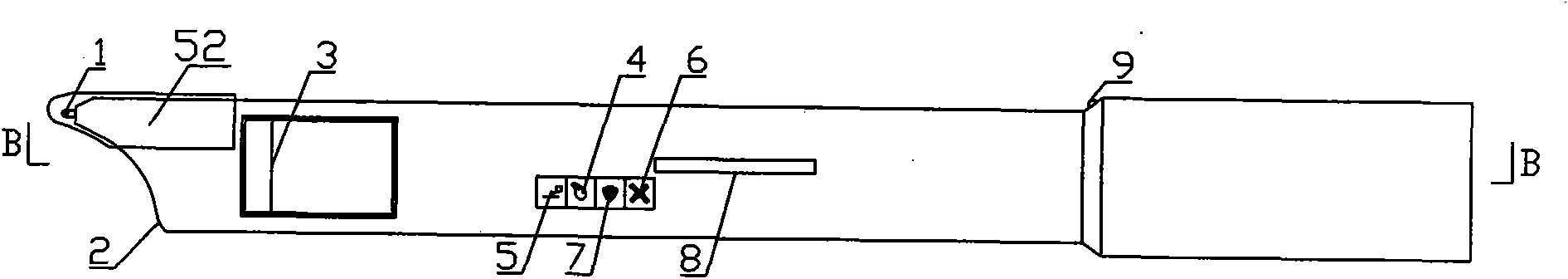

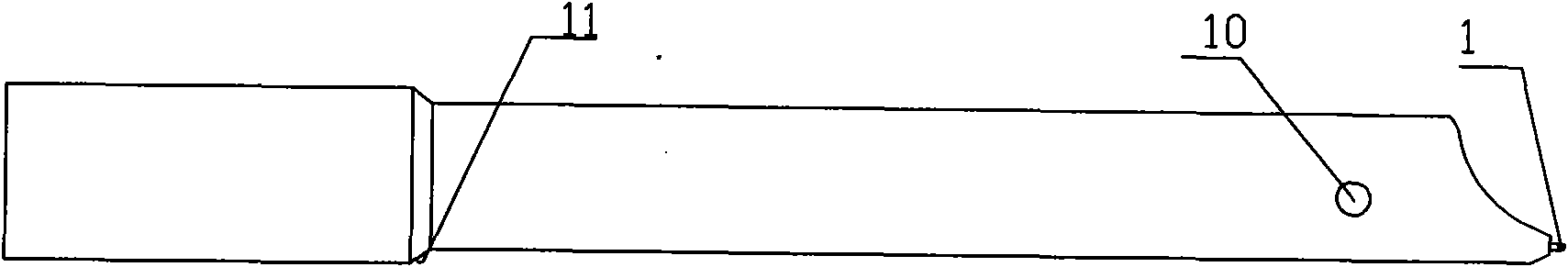

Multi-functional electronic pen

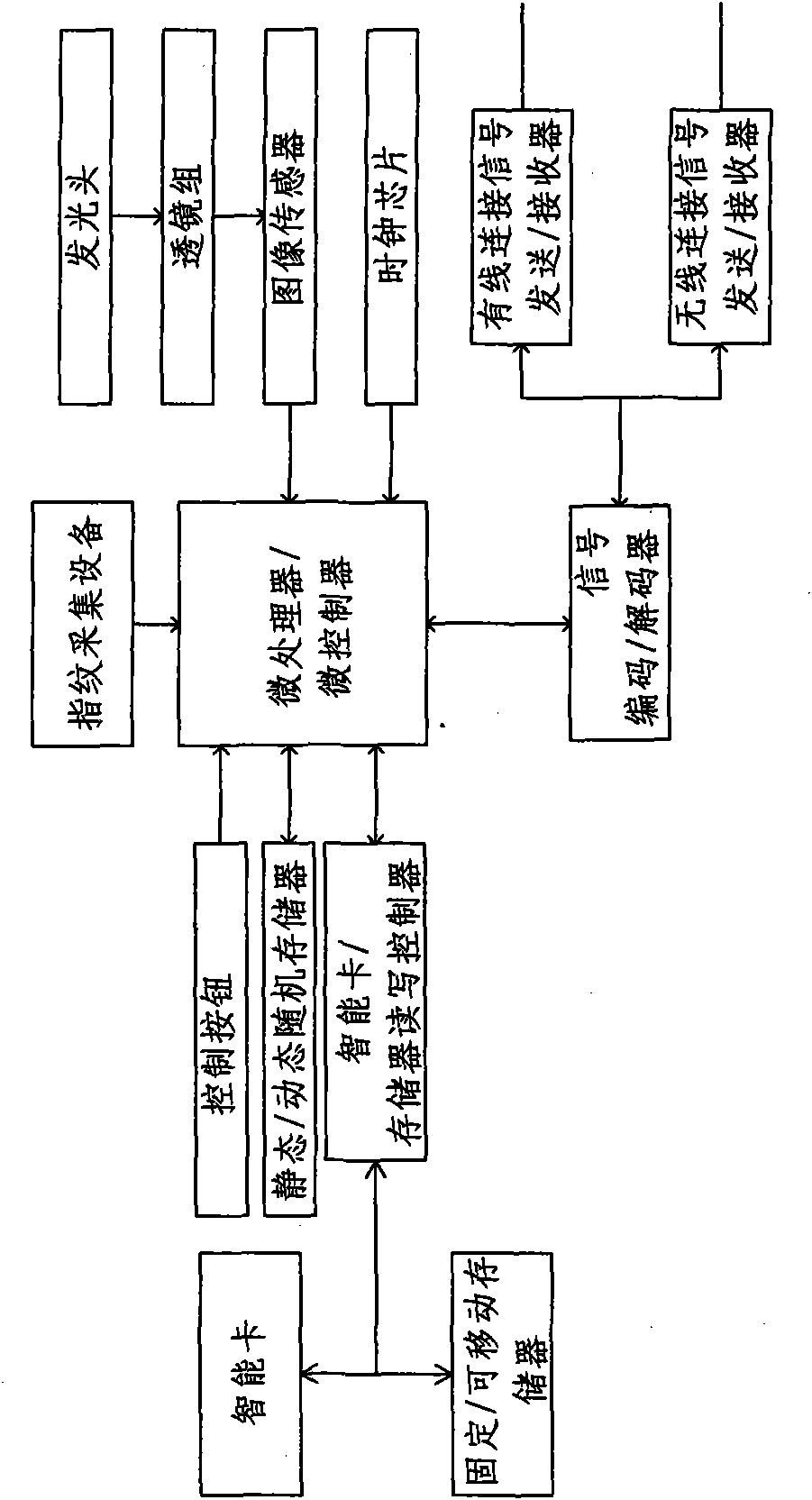

InactiveCN101976126ATraceableAchieving non-combinabilityWriting implementsInput/output processes for data processingMicrocontrollerElectronic book

The invention discloses a multi-functional electronic pen. The overall shape of the multi-functional electronic pen is similar to an ordinary writing pen, and a pen body is internally provided with an ordinary writing refill. The multi-functional electronic pen is characterized in that: an electronic pen point is provided with a photo-electric sensing system; the front section of the pen body is provided with a function control system and a clock chip; the middle section of the pen body is provided with a fingerprint acquisition and processing system, an intelligent card / storage card read-write system and an interface thereof; the tail end of the pen body is provided with a socket and a signal lamp which are connected with a computer wired connection and wireless connection system and an identity identification interface on an external device; and all the systems and the clock chip are connected with an internal microprocessor / microcontroller. The pen can write in an electronic way or in an ink way and can also write in the electronic way and in the ink way simultaneously. The invention can add identity identification and time identification to writing content in the process of writing, has tractability, can prevent others from tampering and reproducing and can also carry out identity identification, information acquisition and information interaction confirmation with the identity identification interface on the external device.

Owner:王东

Counting and stamping device for metal plates

InactiveCN105290185ANo need for post-manual inventoryImprove efficiencyMetal working apparatusElectric senseSignal processing

The invention relates to a counting and stamping device for metal plates. A sheet metal part is transversely arranged and installed on a stamping supporting seat; a stamping head is arranged above the sheet metal part, and a stamping die is installed below the sheet metal part; a stamping cavity is formed in the stamping die; a penetrating installation hole is formed in the stamping supporting seat; and a photo-electric sensing switch is installed in the installation hole and connected with a counter through a signal processor. According to the device, the photo-electric sensing switch is used for detecting the processed sheet metal part; a detected signal is sent to the counter for counting through the signal processor 6; manual counting is not required in the later period; and the efficiency is improved.

Owner:谭华

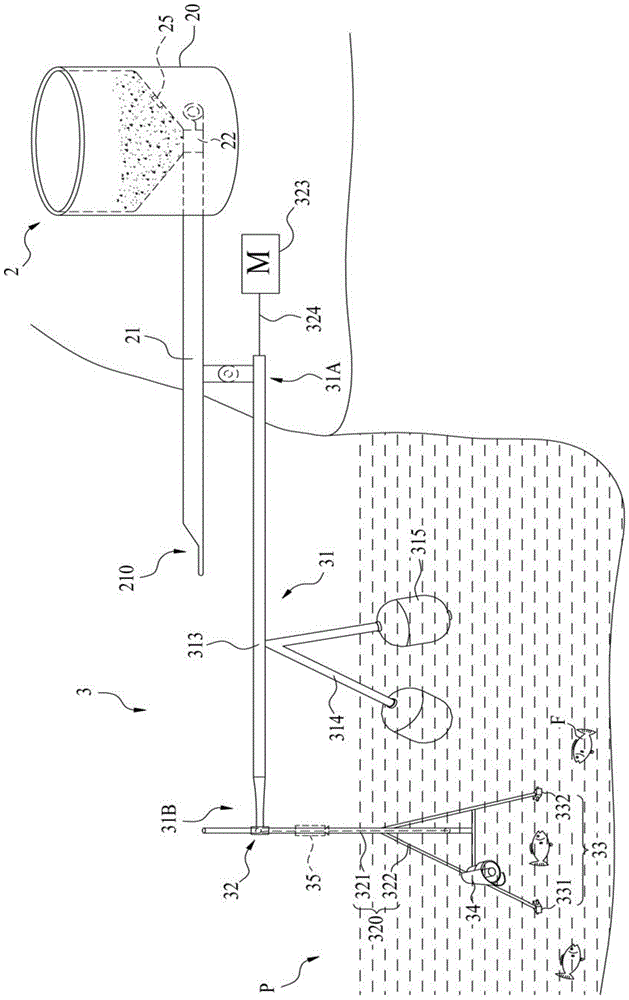

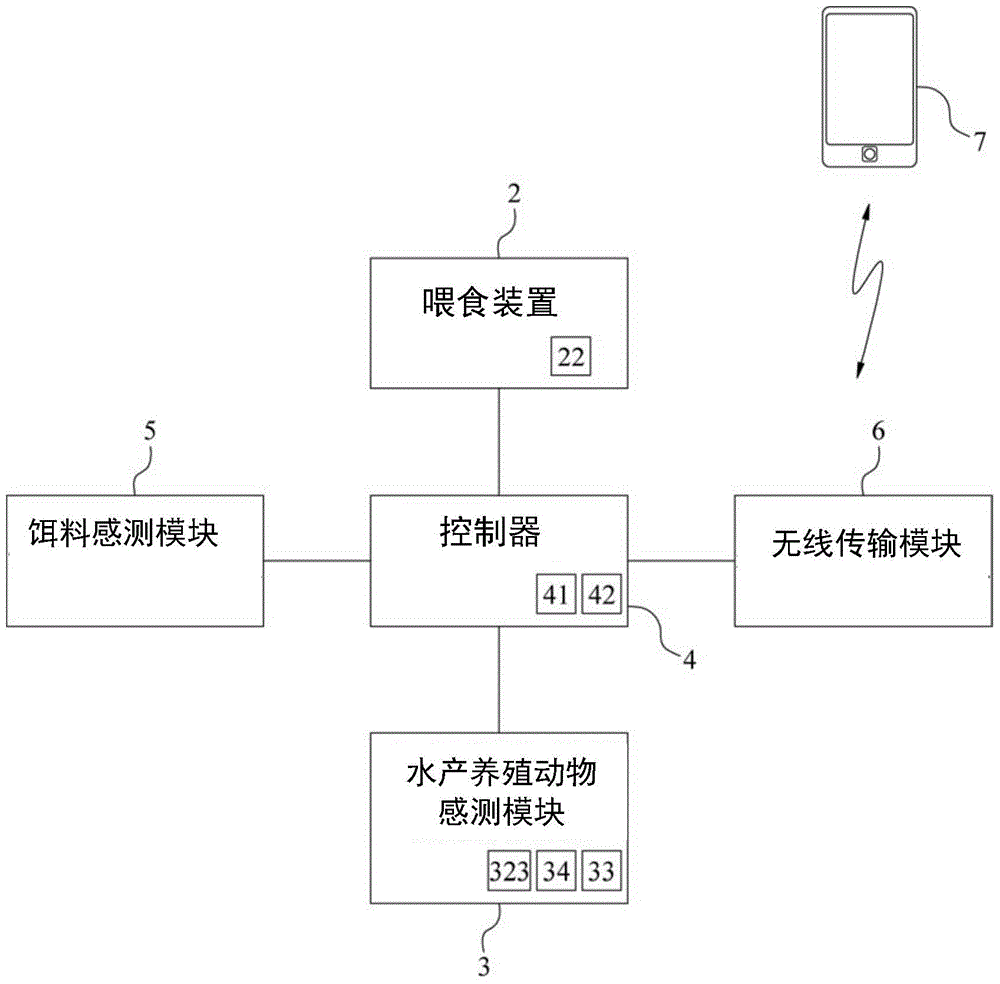

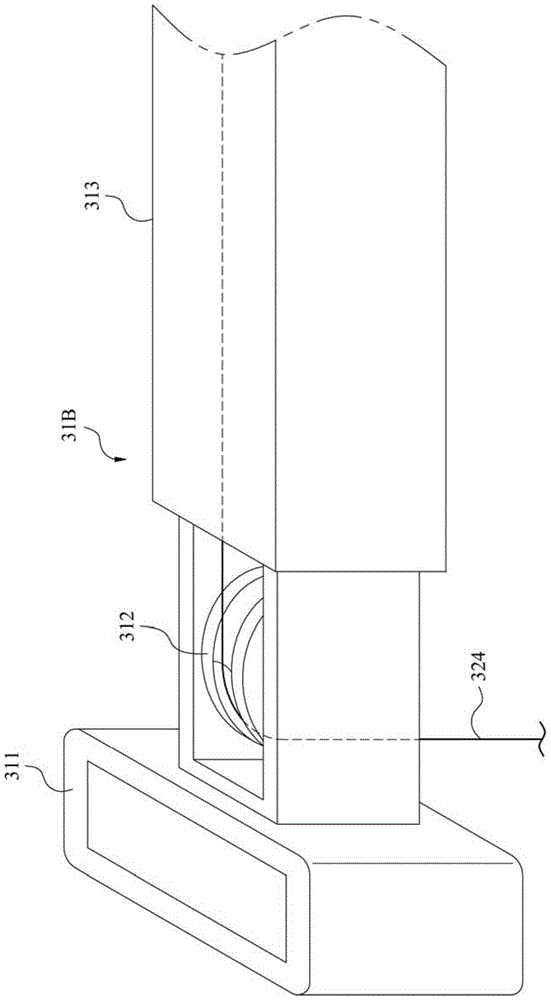

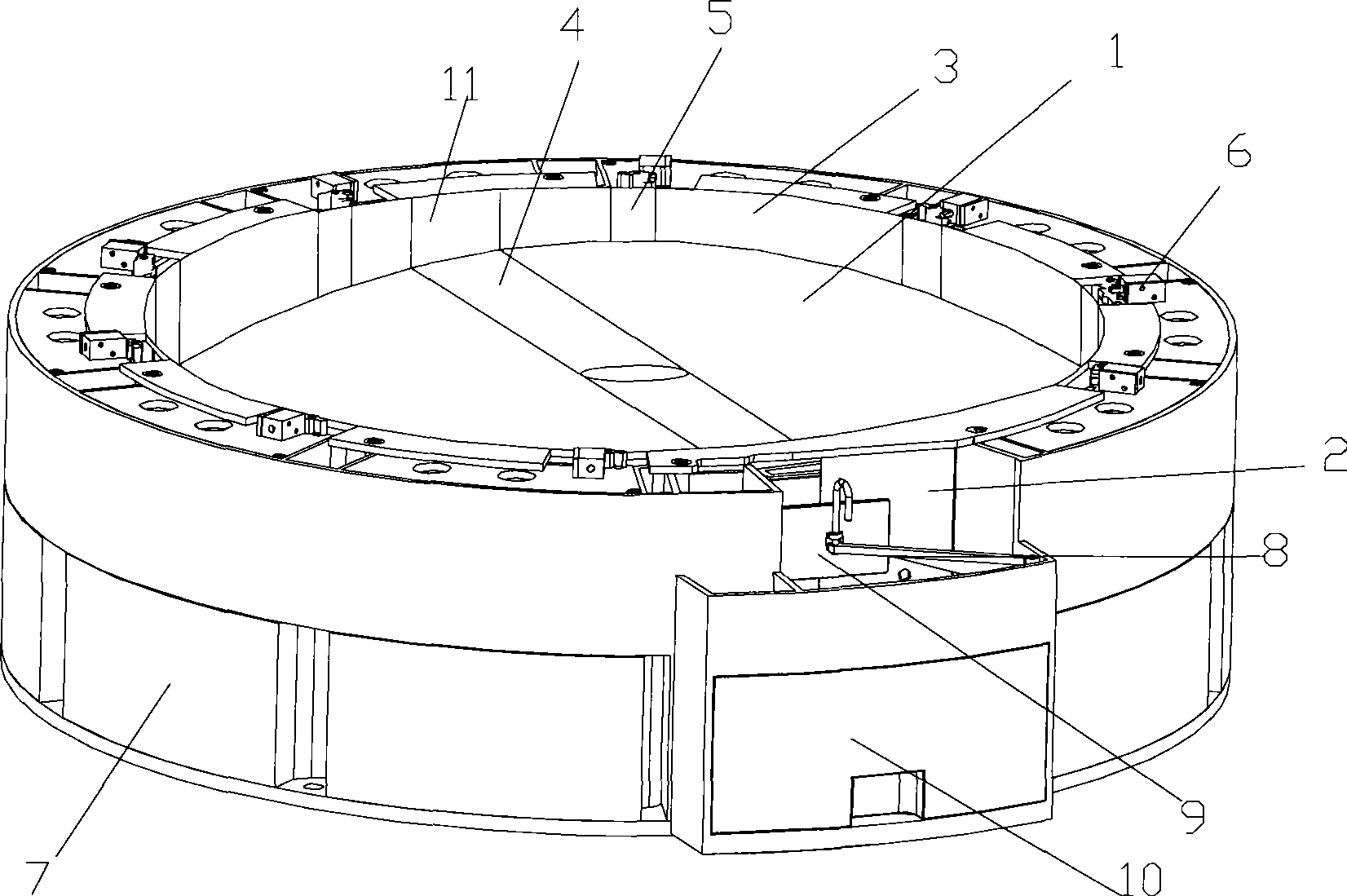

Feeding control apparatus for aquiculture of animals

ActiveCN106665447AReal-time observation of feeding situationControl flowClimate change adaptationPisciculture and aquariaElectric senseAquatic animal

The invention relates to a feeding control apparatus for aquiculture of animals, which mainly includes an aquiculture aminal sensing module and a controller. The aquiculture aminal sensing module includes a lifting mechanism and a photo-electric sensing module, wherein the lifting mechanism is arranged in a material feeding zone and the photo-electric sensing module is arranged on the lifting mechanism. During feeding, the controller controls the lifting mechanism to move to drive the photo-electric sensing module to be immersed into the material feeding zone underwater in a pool and controls the photo-electric sensing module to start sensing. When the photo-electric sensing module detects the animals, the controller controls a feeding device to deliver feed. The apparatus is suitable for the vast majority of aquatic animals and can control the feeding full-automatically, thus significantly avoiding insufficient or exceesed material feeding.

Owner:黄壹圣

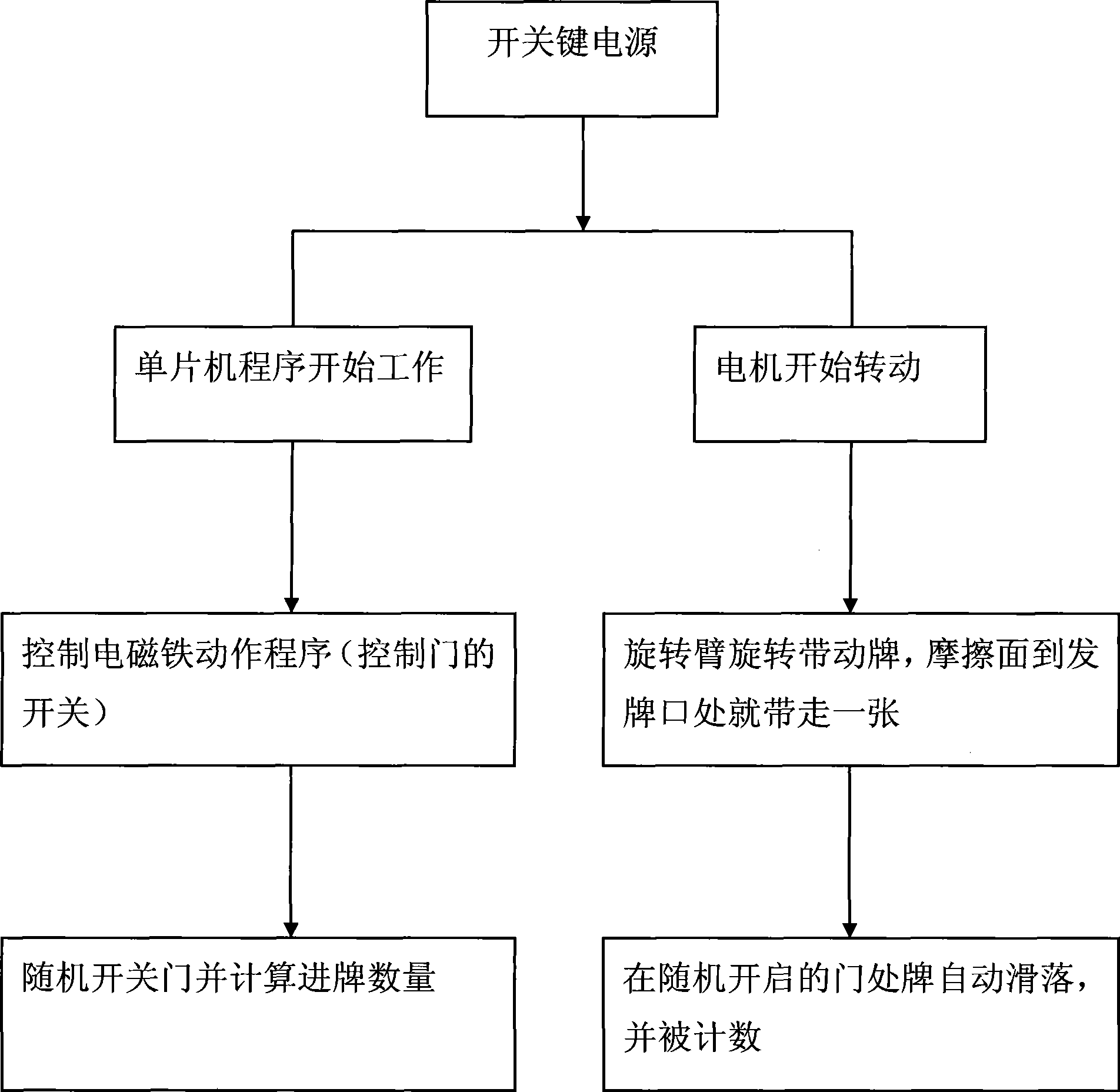

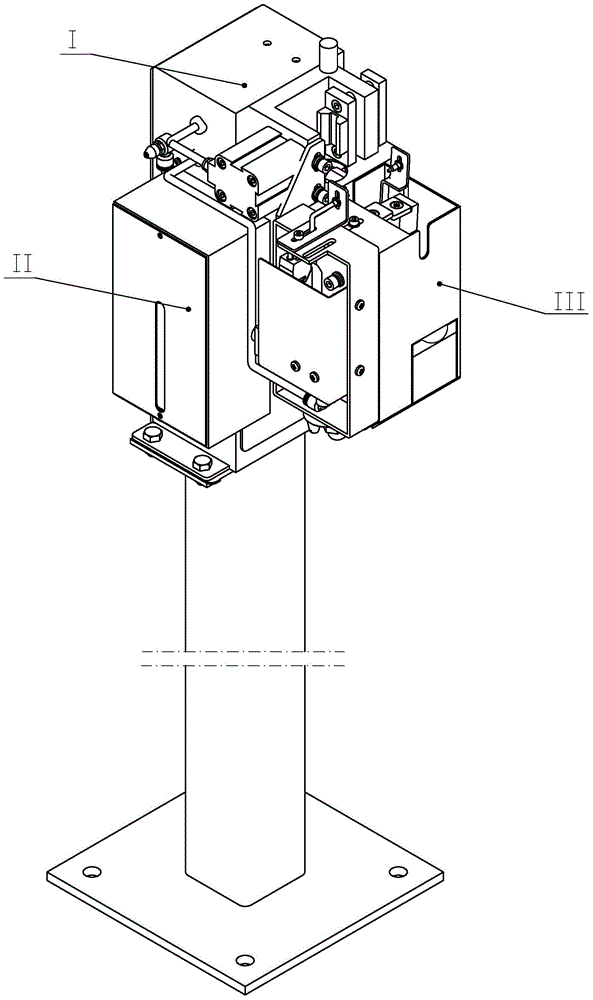

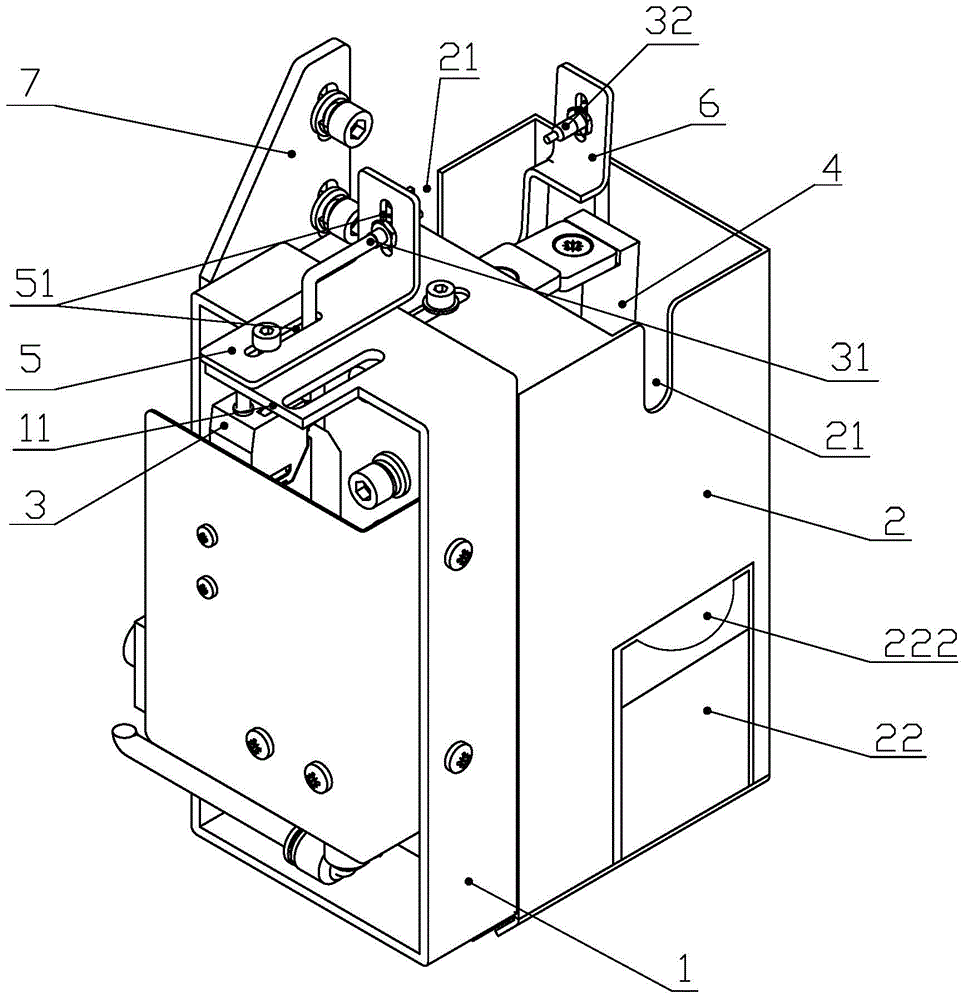

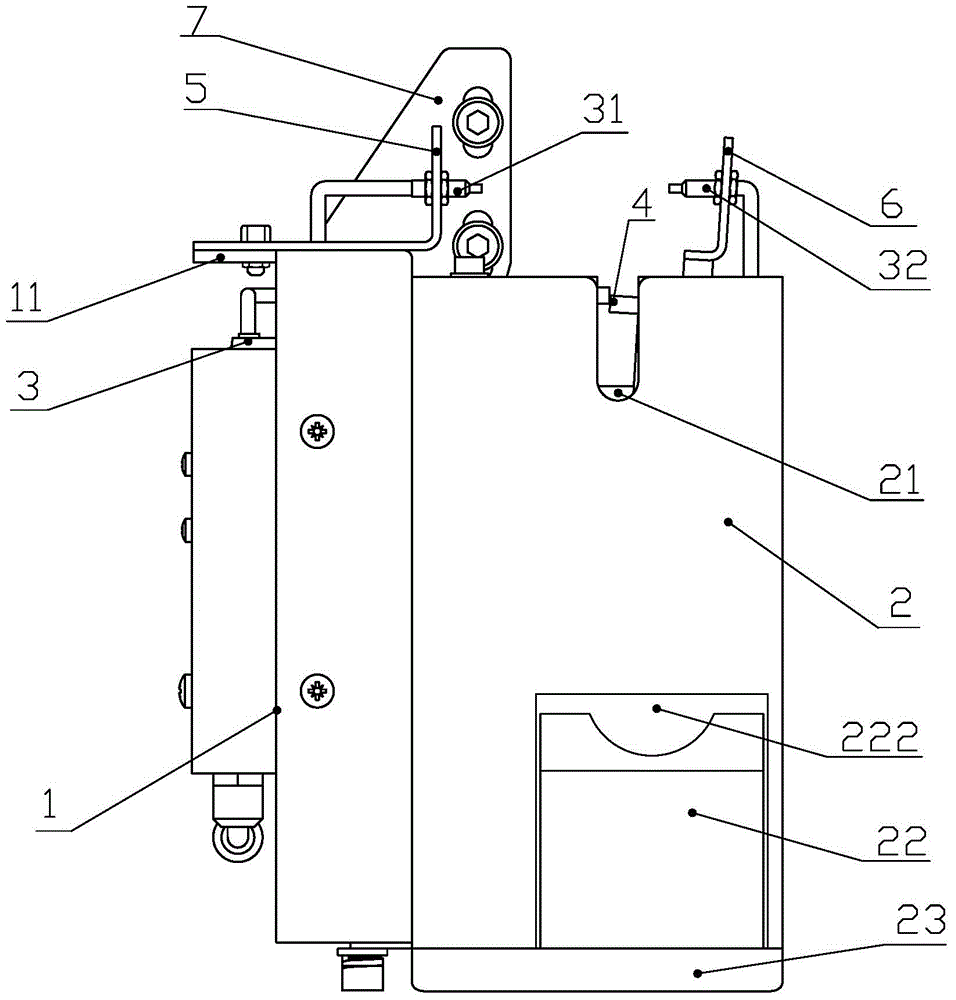

Automatic playing cards shuffling and dealing device

The invention discloses an automatic device for shuffling and distributing poker cards. The automatic device comprises a disk, and a card distribution box and a plurality of card collection boxes are evenly arranged on the wall of the disk; a rotating arm is arranged at the center of the disk, placed on a rolling bearing and connected with an electric motor, and the electric motor is connected with an electric power source by leads; the two ends of the rolling arm are provided with rubbing surfaces which are vertical to the rolling arms, the rubbing surfaces are covered with silica-gel sleeves and can be in frictional contact with the inner wall of the card collection box; a mouth is arranged on the inside wall of the card distribution box, a little door is arranged on the inside wall of each card collection box and connected with an electromagnet by a connecting rod, and a photo-electric sensing device connected with a display unit is arranged in the card collection box; the automatic device also comprises a singlechip connected with the electric power source and controlling the electromagnet to do the corresponding actions. The automatic device is characterized by simple structure, low cost, high degree of automatization and high efficiency of card distribution.

Owner:SHANGHAI LANGWEN INDAL

Welding gun cleaning device and welding wire cutting device

ActiveCN103949763AFlexible disassembly and installationIncrease flexibilityWeld torches cleaningElectric senseWire cutting

The invention provides a welding gun cleaning device and a welding wire cutting device. The welding wire cutting device comprises a rack, a wire cutting machine cover, a through beam type photo electric sensor, a wire cutting machine, a left support arm, a right support arm and a waste collecting box, wherein a concave arm which extends towards left is arranged on the upper end surface of the rack, a strip-shaped through groove is formed in the concave arm, the rack is connected with the wire cutting machine cover, the through beam type photo electric sensor main body and an electromagnetic valve of the wire cutting machine are fixed inside the rack, the left support arm is L-shaped, the strip-shaped through grooves are formed in both the left support arm and the right support arm, the left support arm is fixed on the upper end surface of the concave arm, a light emitter is fixed on the left support arm, the right support arm is fixed on the wire cutting machine cover, and a light receiver is fixed on the right support arm. The device can collect the cut waste, uses the photo electric sensing control way to control the cutting operation, and avoids the phenomenon of error alarm caused by that a welding robot collides; the device can be directly used for the welding robot which is few in output signal, the positions of the light emitter and the light receiver can be adjusted, and the device can be suitable for the arms of the welding robots in different appearance sizes.

Owner:TBI SHANDONG IND

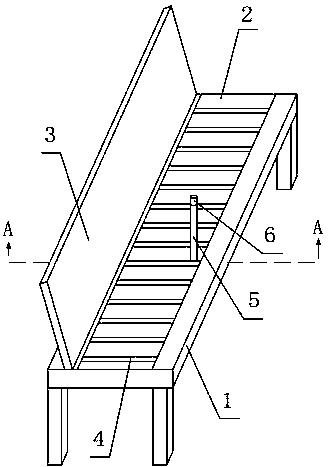

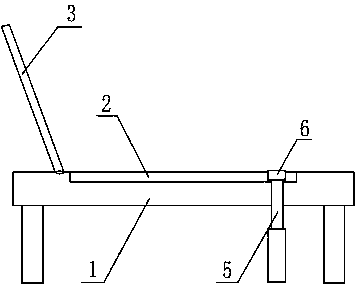

Conveying device for tire machining production line

InactiveCN107777309AReduce labor intensitySave human effortConveyorsConveyor partsElectric senseProduction line

The invention discloses a transmission device for a tire processing line, which comprises a frame and a roller conveyor belt arranged on the surface of the frame. There is a baffle on the side, and the baffle is inclined towards the outside of the frame; an electric push rod is arranged between any two adjacent rollers of the roller conveyor belt, and the electric push rod is located on the side of the roller conveyor belt away from the baffle , the top surface of the electric push rod is provided with an induction device, and the induction device is connected to a control module arranged on the frame, and the control module controls the electric push rod. The invention proposes a transmission device for the tire processing line to solve the problems of labor-intensive and inconvenient operation in the prior art when tires are laid flat and transported, and realizes automatically erecting the flat tires to the tilted state, so that the tires are tilted The purpose of conveying in the state.

Owner:史军

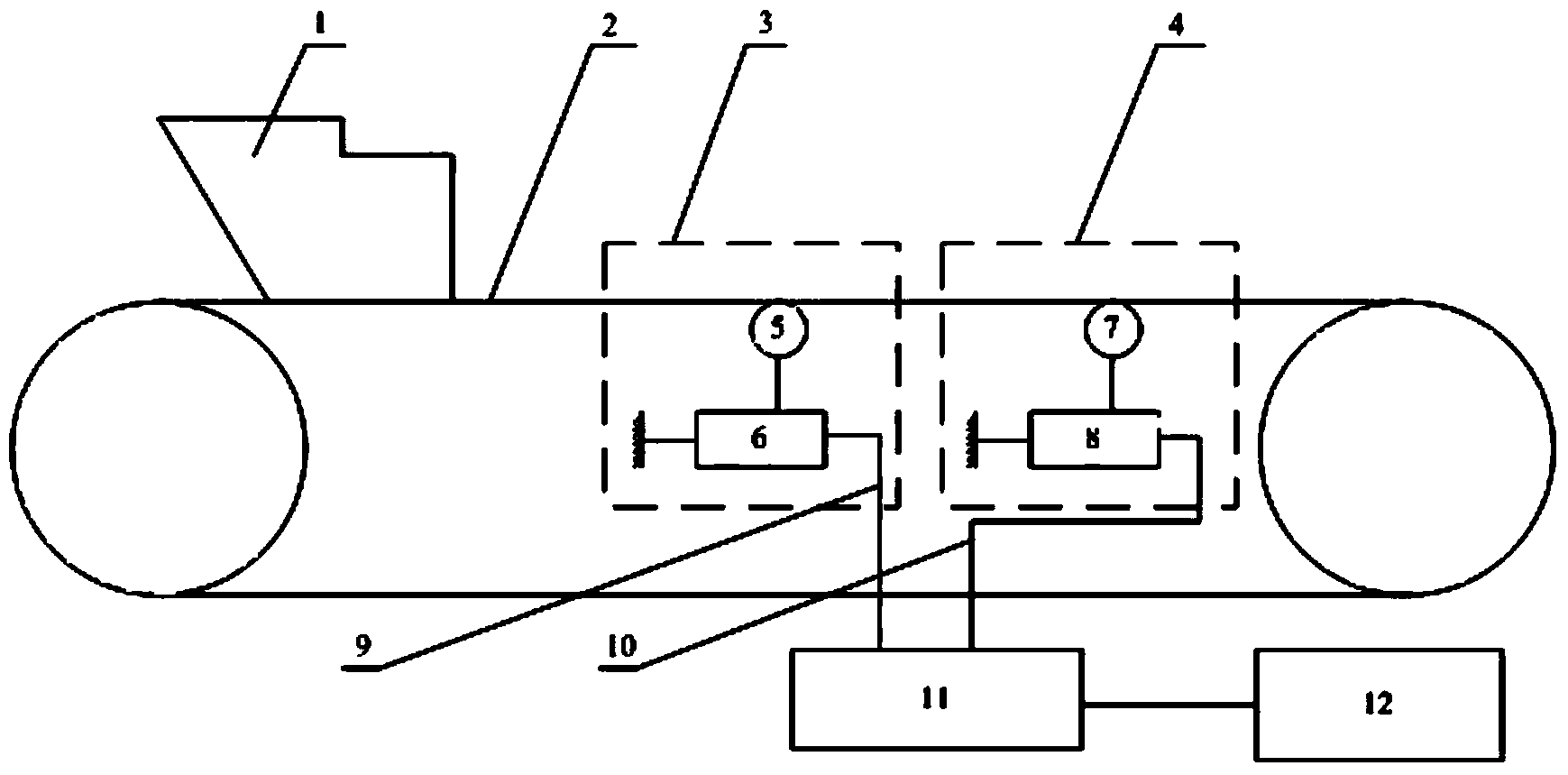

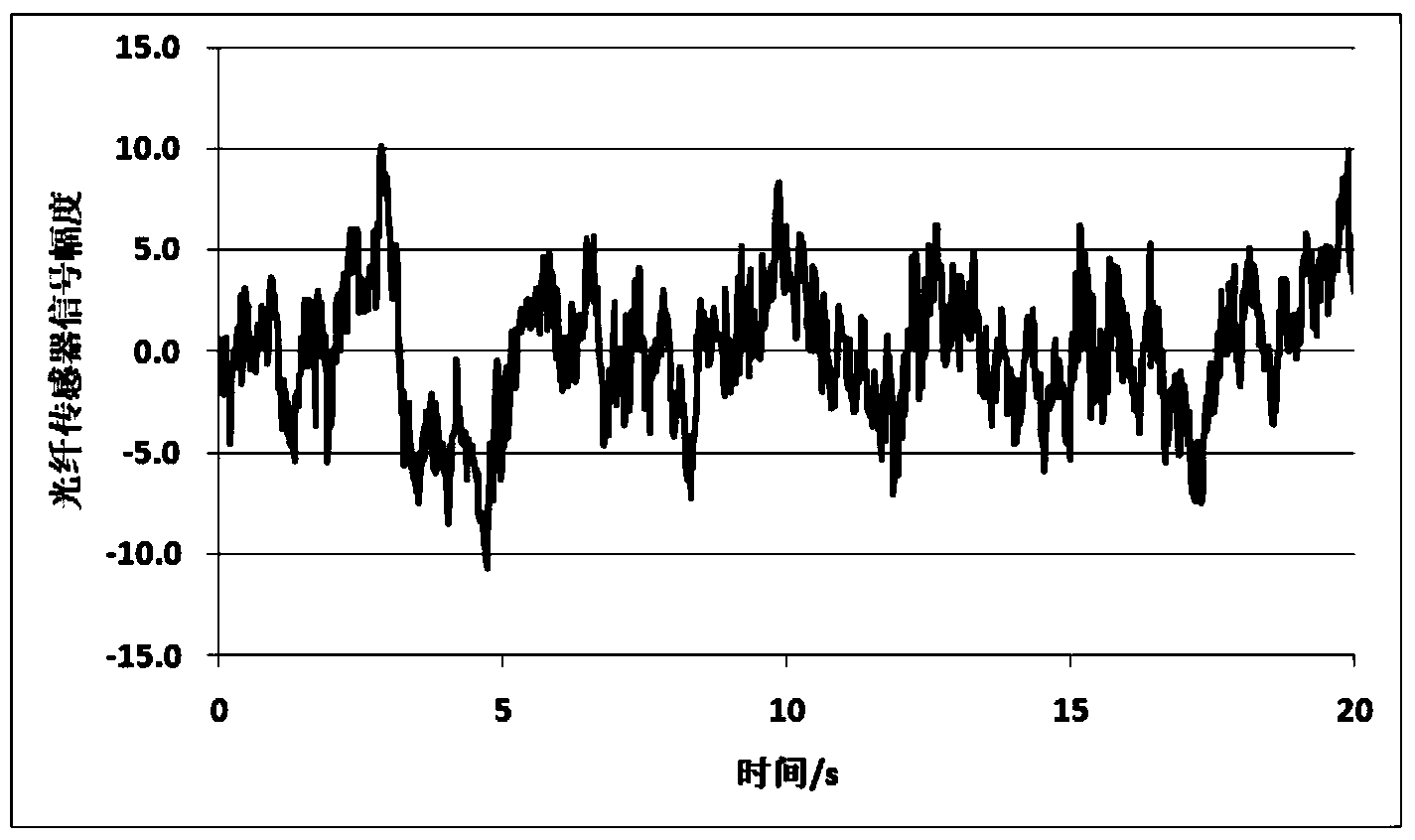

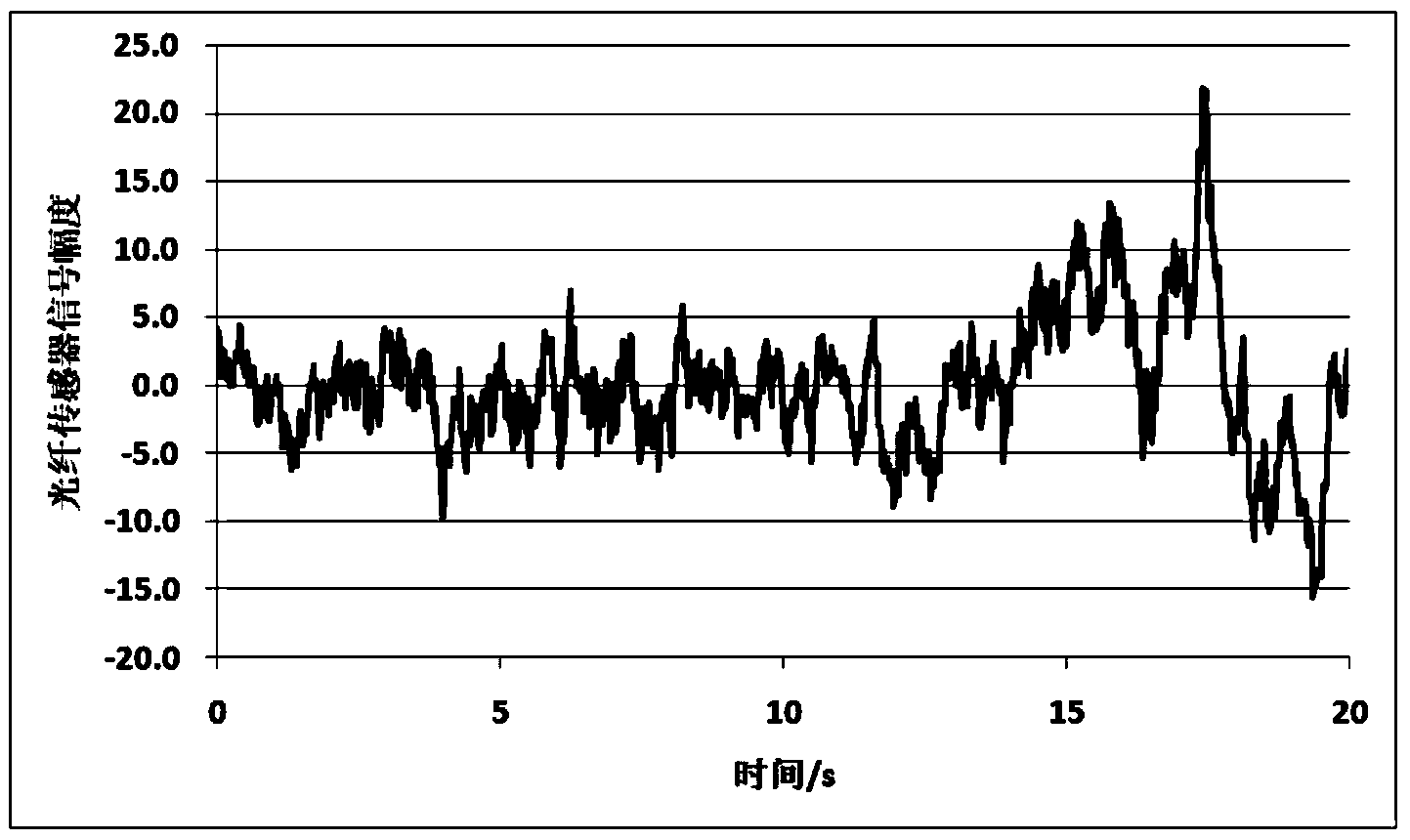

Optical fiber sensing type continuous automatic weighing system and method free of speed sensors

InactiveCN103925973ARealize all-fiberLow failure rateWeighing apparatus for continuous material flowFiberGrating

The invention provides an optical fiber sensing type continuous automatic weighing system free of speed sensors. The optical fiber sensing type continuous automatic weighing system free of the speed sensors comprises a first fiber bragg grating sensing weighing device, a second fiber bragg grating sensing weighing device, a fiber bragg grating demodulation instrument and a computer, wherein the first fiber bragg grating sensing weighing device and the second fiber bragg grating sensing weighing device respectively comprise a force transmission component used for transmitting the weight of materials on a material conveying belt, and a fiber bragg grating strain sensor used for converting the weight of the materials into an optical signal, the force transmission components are arranged at the front end and the rear end of the material conveying belt respectively, the output end of each fiber bragg grating strain sensor is connected with the fiber bragg grating demodulation instrument through a transmission optical path, and the two paths of optical signals are converted into digital signals through the fiber bragg grating demodulation instrument and are then transmitted to the computer. According to the optical fiber sensing type continuous automatic weighing system free of the speed sensors, all on-site detection elements are of the optical fiber type, electric sensing elements are eliminated completely, and thus the weighing system can be adapted to severe monitoring environments; due to the fact that a measurement unit is omitted, an error source is eliminated, and the fault rate of the weighing system is decreased.

Owner:WUHAN UNIV OF TECH

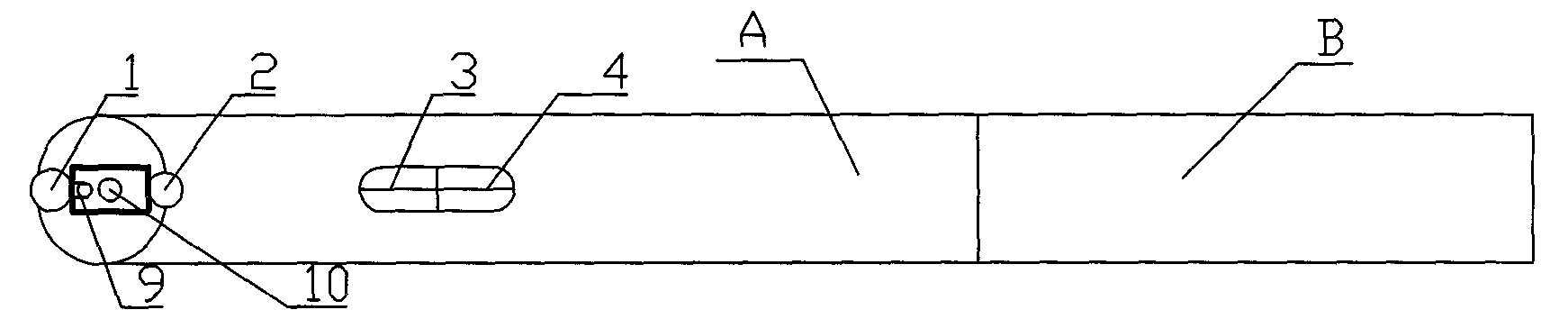

Automobile accelerator pedal anti-mistaken-pressing safety device and operation method thereof

ActiveCN110001397AReduce design costReduce use costPropulsion unit arrangementsElectric senseTraffic accident

The invention discloses an automobile accelerator pedal anti-mistaken-pressing safety device and an operation method thereof.The automobile accelerator pedal anti-mistaken-pressing safety device comprises a pedal stress transmitting device, a transmission device, a centrifugal locking device, a locking electric sensing braking device, a front shaft used for transmitting torquebetween the pedal stress transmitting device and the transmission device, and a rear shaft used for transmitting torque between the transmission device and the centrifugal locking device. According to the automobile accelerator pedal anti-mistaken-pressing safety device and the operation method thereof, the abnormal pedaling speed of the accelerator pedal can be detected, a centrifugal locking principle is used for locking the accelerator pedal,a braking system is engaged to generate braking force so as to avoid the occurrence of traffic accidents to the greatest extent; the automobile accelerator pedal anti-mistaken-pressing safety device completely adopts mechanical design, the cost is low, energy consumption is low, the accelerator pedal can be locked when mistakenpressing on the accelerator pedal is detected, and safety of driving is improved.

Owner:河南警察学院

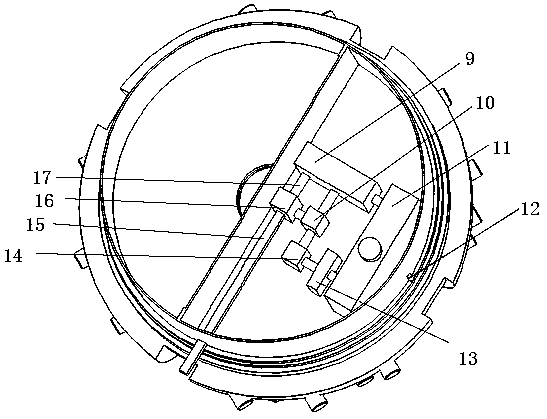

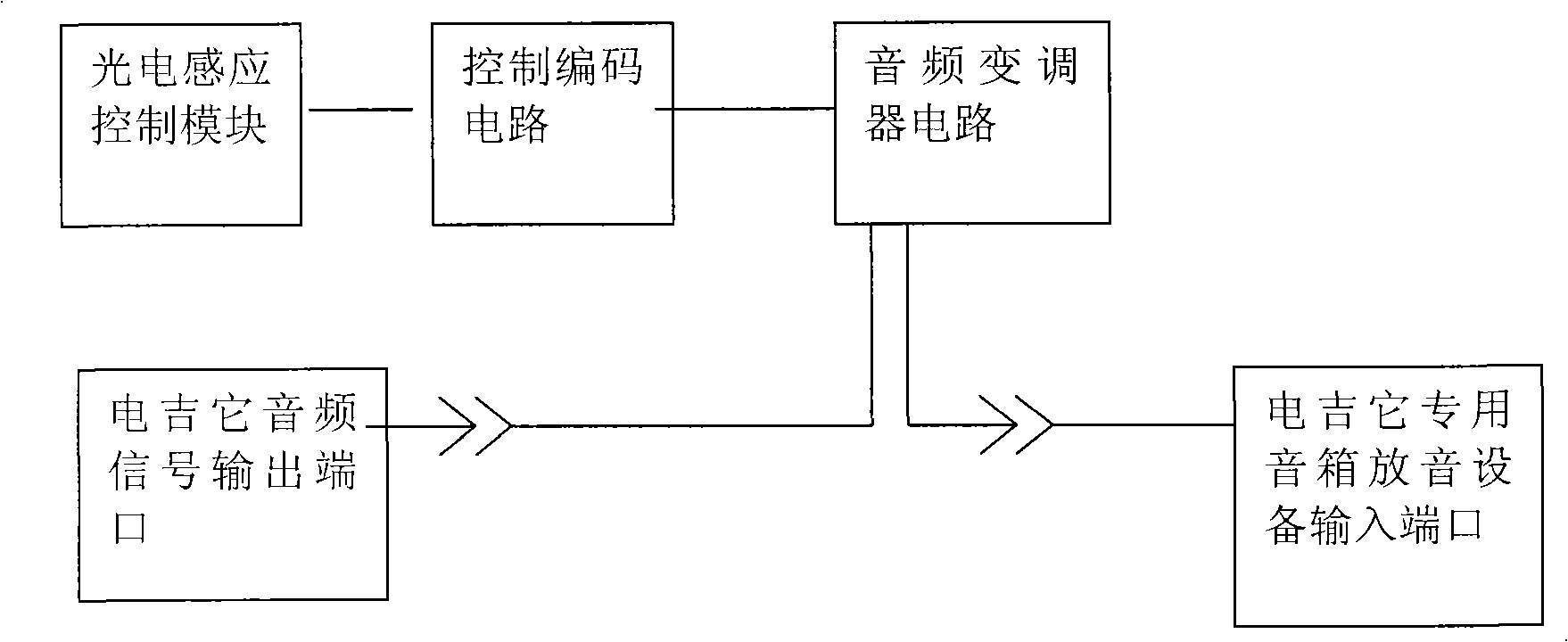

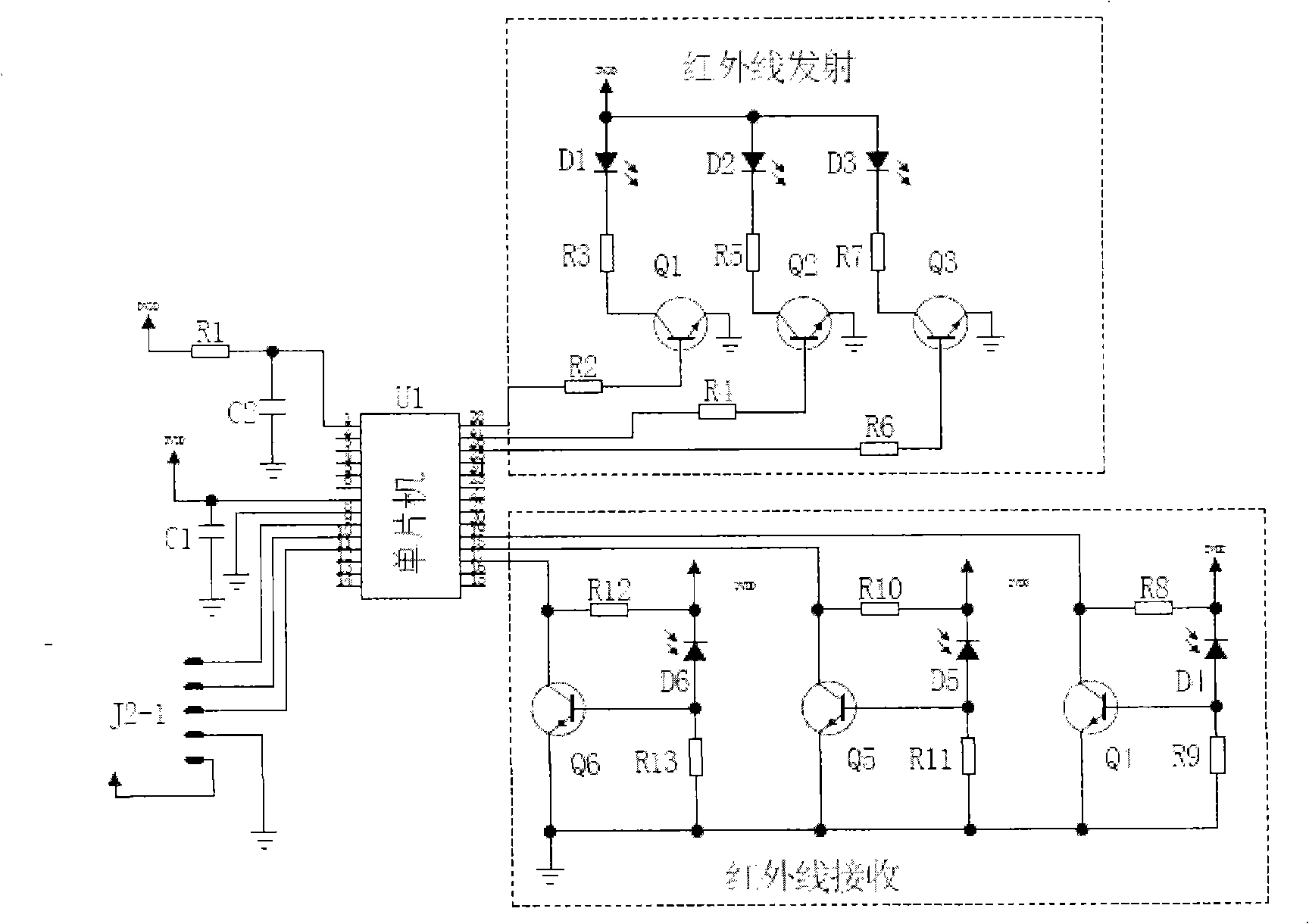

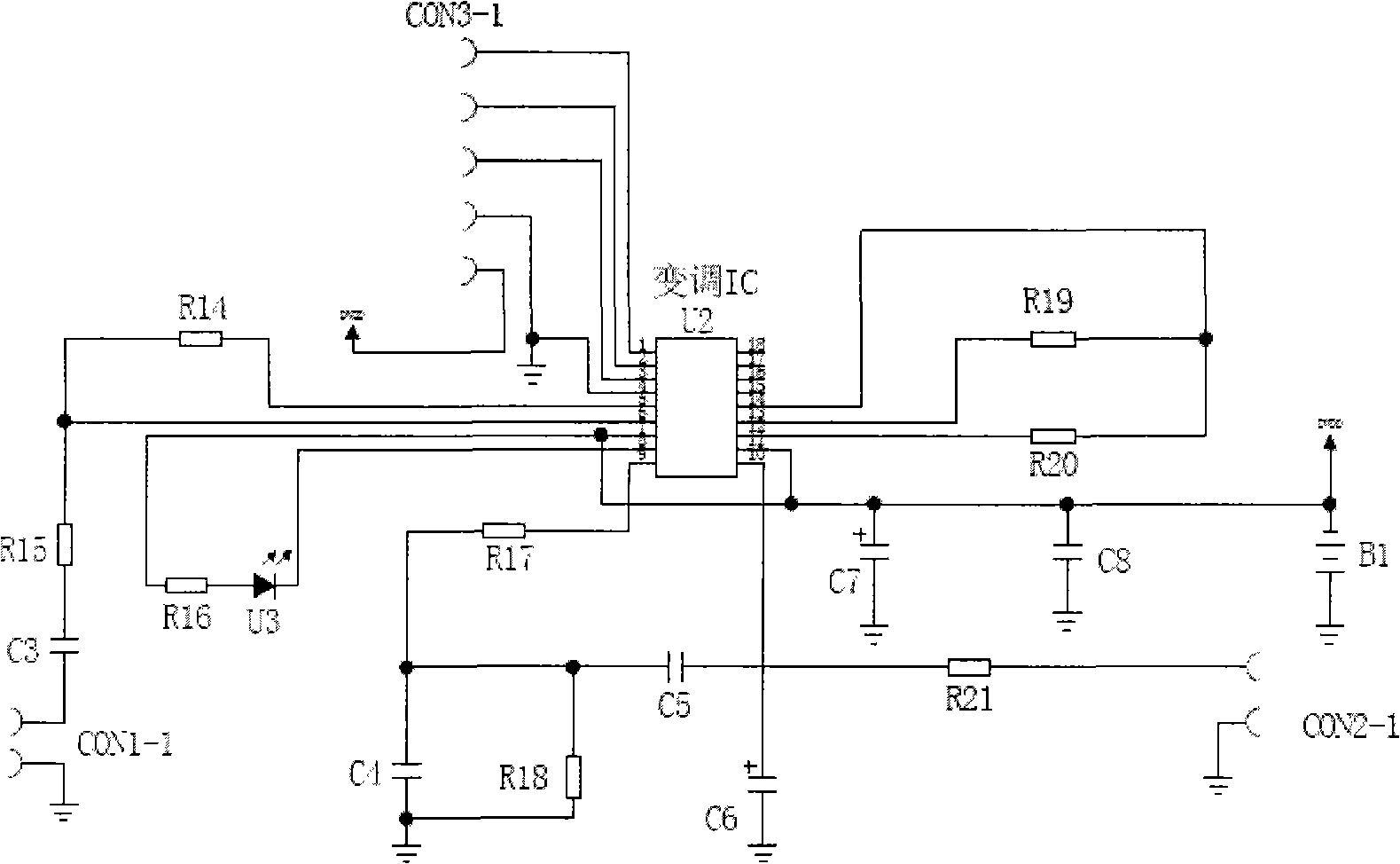

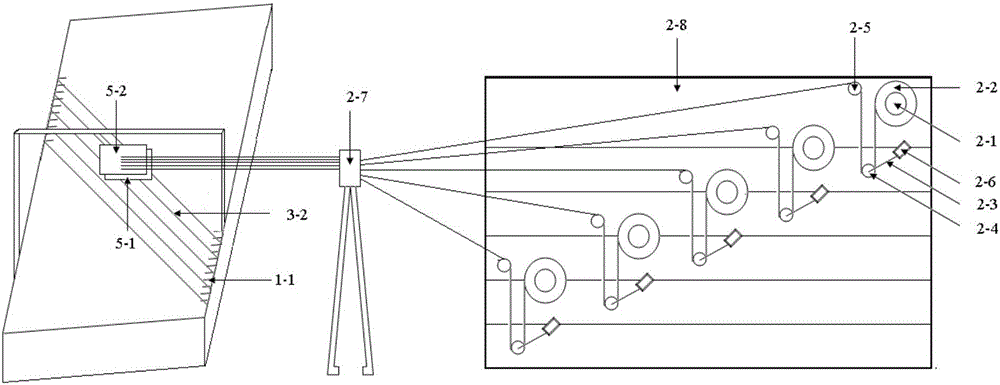

Photoelectric control transposer for electric guitar

InactiveCN101329863AControl and change the output toneImprove performanceElectrophonic musical instrumentsElectric senseElectric guitar

The invention relates to a photoelectric control electric guitar pitch shifter which comprises an AF (audio frequency) pitch shifter circuit and an AF pitch shifter control circuit. The pitch shifter is characterized in that: the AF pitch shifter control circuit comprises a control coding circuit and a photo-electric sensing control module connected with the control coding circuit. The photo-electric sensing control module comprises an infrared-emitting diode, an infrared-receiving diode in corresponding arrangement as well as a sensing block provided with a narrow and long sensing groove which is provided with the infrared-emitting diode and the infrared-receiving diode at two sides correspondingly. The pitch shifter of the invention has the beneficial effects that: 1. people who play the electric guitar can control and change the pitch of the electric guitar conveniently only by moving fingers on the sensing groove in the non-contact photo-electric sensing control module, thereby enhancing the playing effect of the electric guitar further; 2. the pitch shifter can be directly inserted in the output end of the electric guitar to fulfill the function of pitch shifting without changing the structure of the electric guitar; the operation is simple and the application is convenient.

Owner:武汉艾立卡电子有限公司

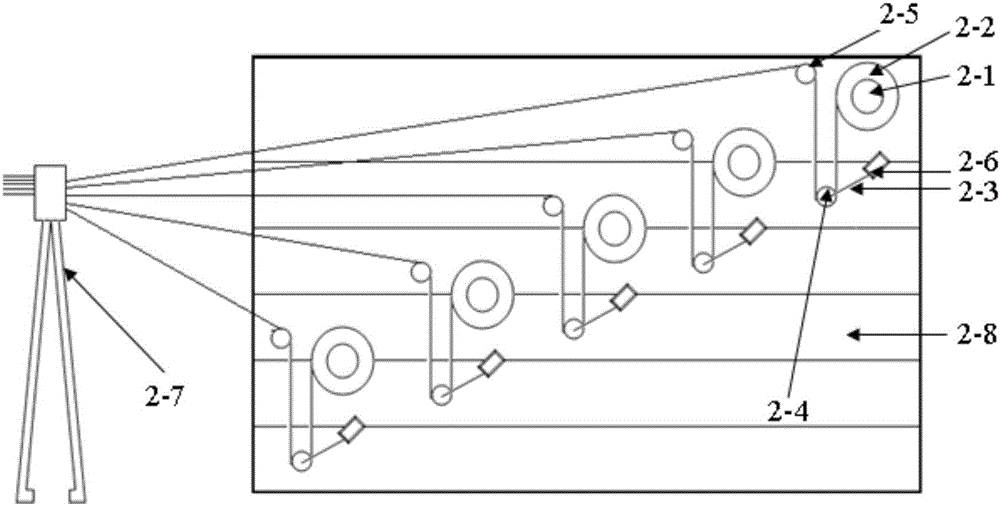

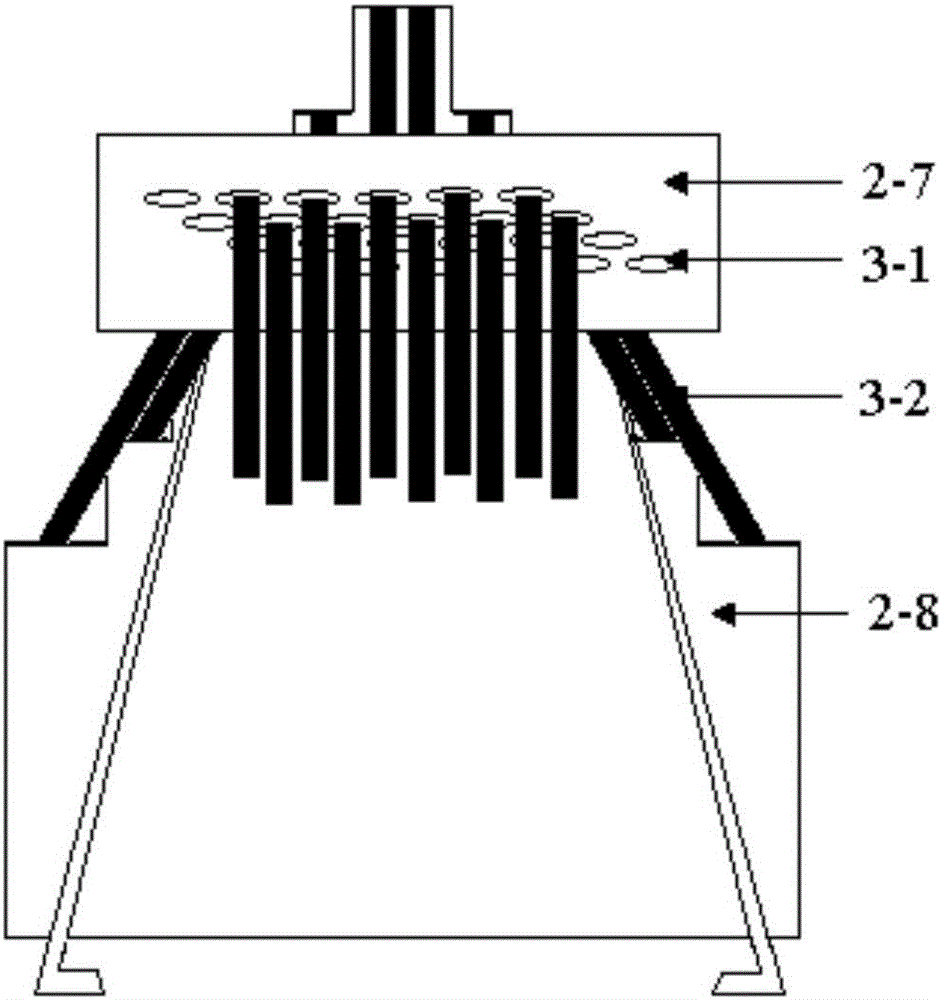

Flattened carbon yarn twistless laying-in system applicable to multiaxial warp knitting equipment

ActiveCN106757745AAvoid the phenomenon of friction and breakageWon't hurtWarp knittingDigital signal processingElectric sense

The invention relates to a flattened carbon yarn twistless laying-in system applicable to multiaxial warp knitting equipment, comprising a yarn reversal device and a weft laying-in device; the weft laying-in device is disposed at the front end of the yarn reversal device. Pneumatic-electric sensing combined grating and digital signal processing control are fitted to the movement of the flattened carbon yarn twistless laying-in apparatus sensing the whole multiaxial warp knitting equipment. The mutual sensing of a convex stepped creel in the yarn reversal device, the yarn reversal device and a tension device not only narrows the gaps among the flattened carbon yarns unwinded from the creel, and but also maintain uniform tension for carbon yarns; an angle rack and a controller in the weft laying-in device convey the flattened carbon yarns and also promote further uniform distribution of tows, keeping the uniform width of the flattened carbon yarns and keeping them twistless and free of abrasion and other defects, the flattened carbon yarns are maintained uniform in tension and low in gap rate, and therefore, the multiaxial warp knitting equipment can produce multiaxial fabric with less density and smaller thickness.

Owner:SHANGHAI CEDAR COMPOSITES TECHNOLOGY CO LTD +1

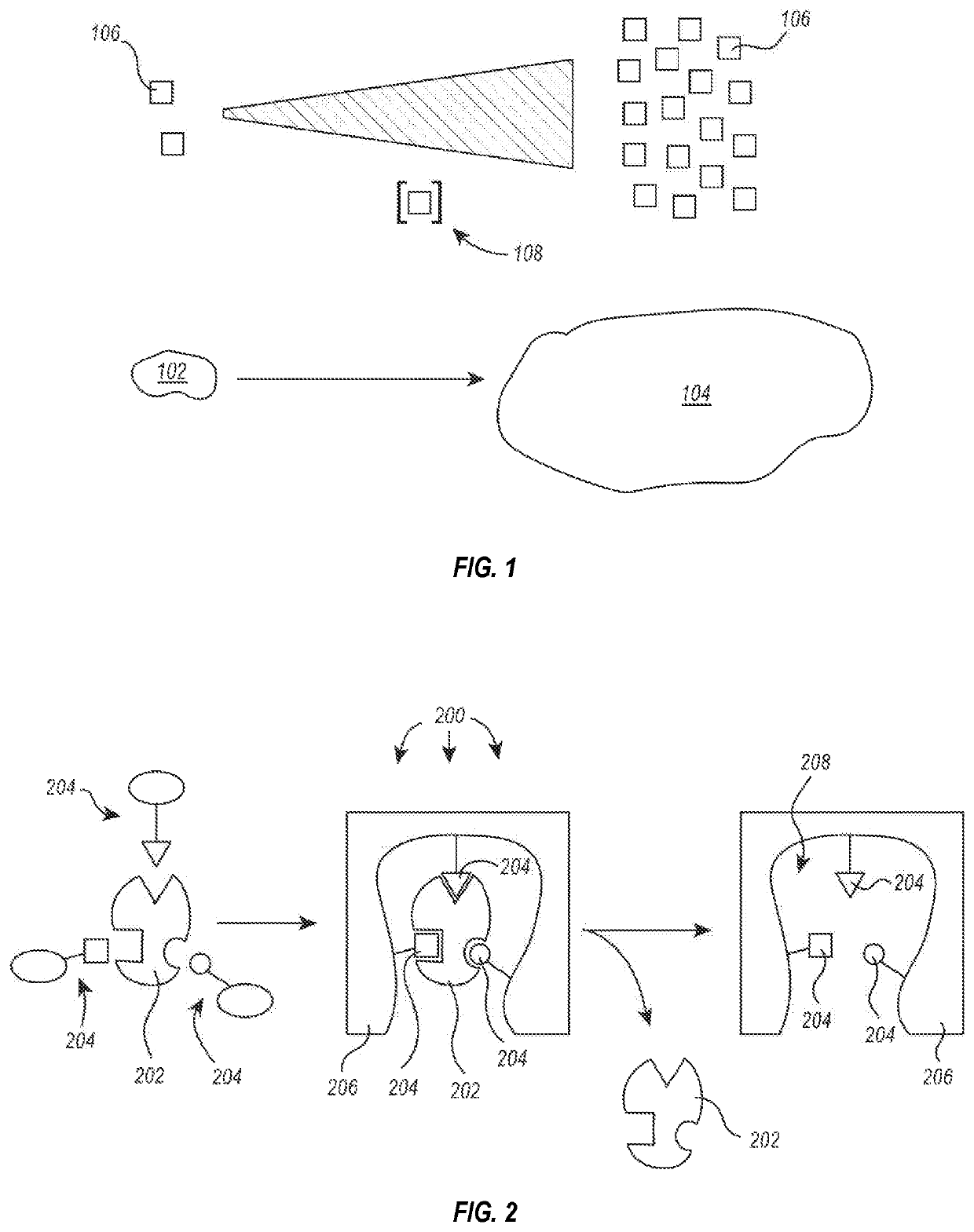

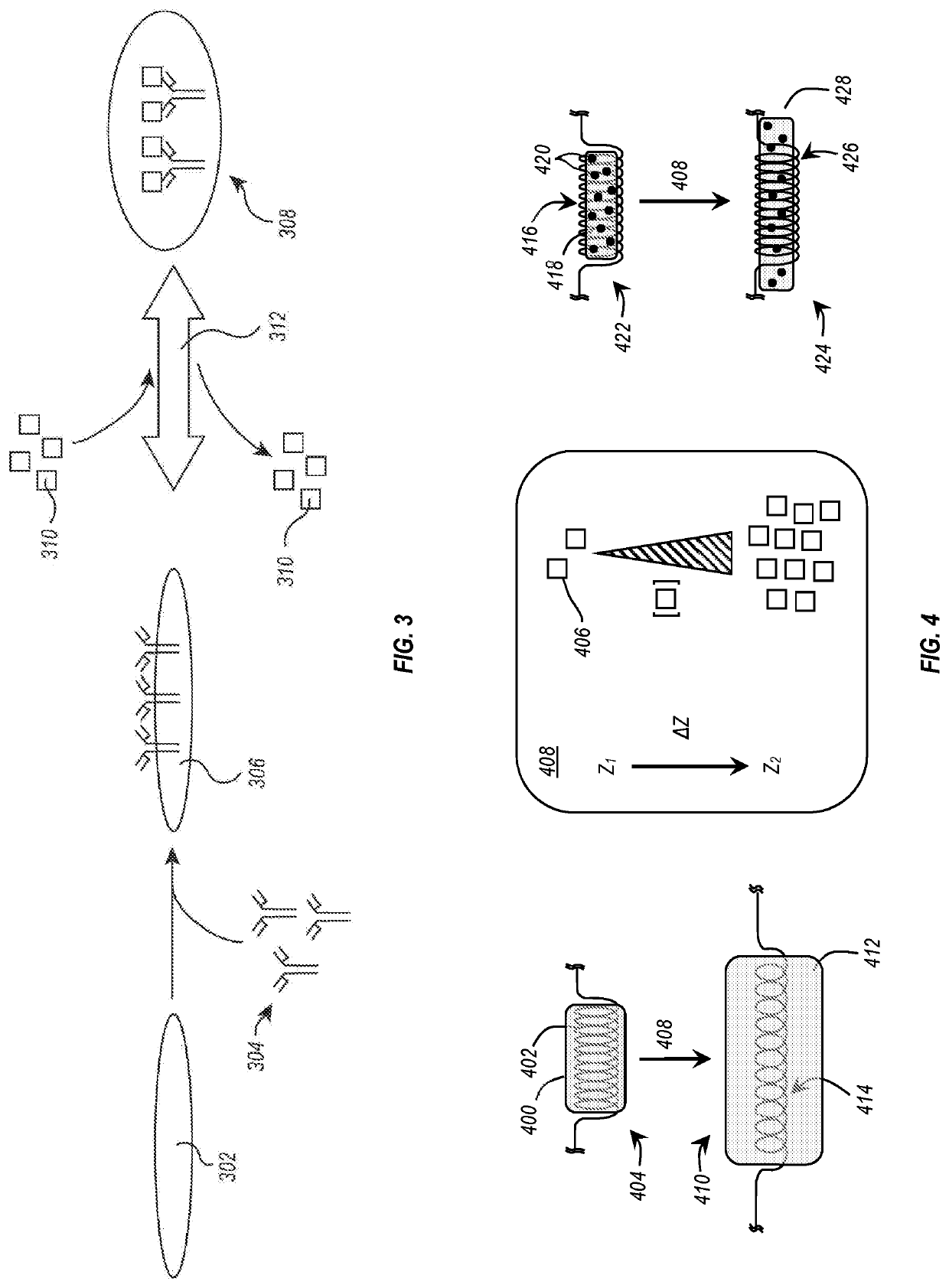

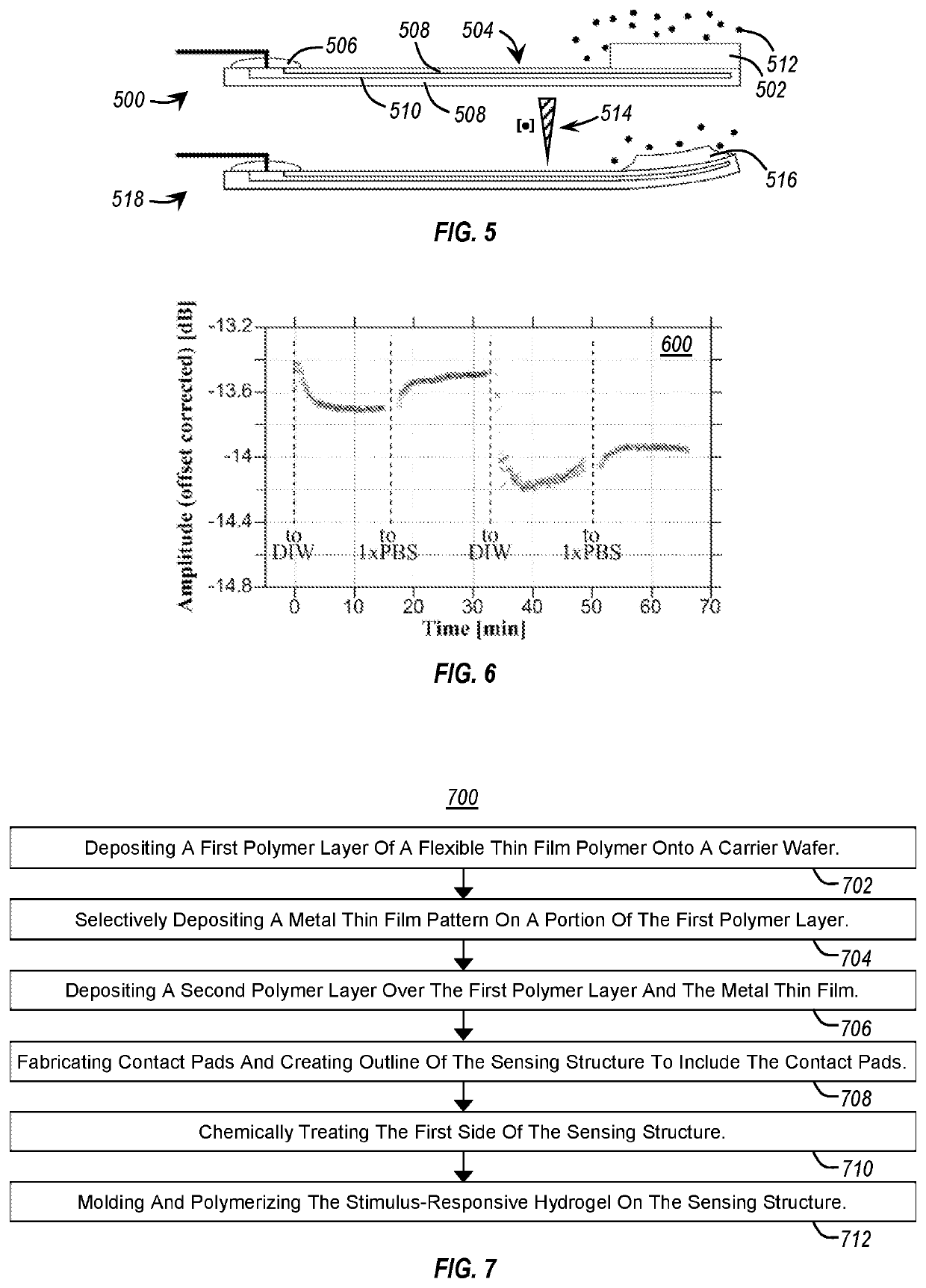

Systems, methods, and sensor devices for measuring changes in analyte-sensitive hydrogels

Systems, methods, and sensor devices for identifying one or more changes in a stimulus-responsive hydrogel include a sensor device having (i) a sensing structure and (ii) a stimulus-responsive hydrogel associated with a first side of the sensing structure. The sensing structure includes a flexible thin film polymer and an electric sensing element capable of electric impedance change, and the hydrogel is configured to dimensionally change in response to predefined stimuli such that a dimensional change of the hydrogel causes a change in an impedance property of the electric sensing element. Systems including such a sensor device can additionally include a meter in electrical communication with the sensor device to identify changes in the impedance properties of the structure and / or a catheter sheath configured for placement within an in vivo environment and is sized and shaped to receive the sensor device within a lumen thereof.

Owner:SOLZBACKER FLORIAN +8

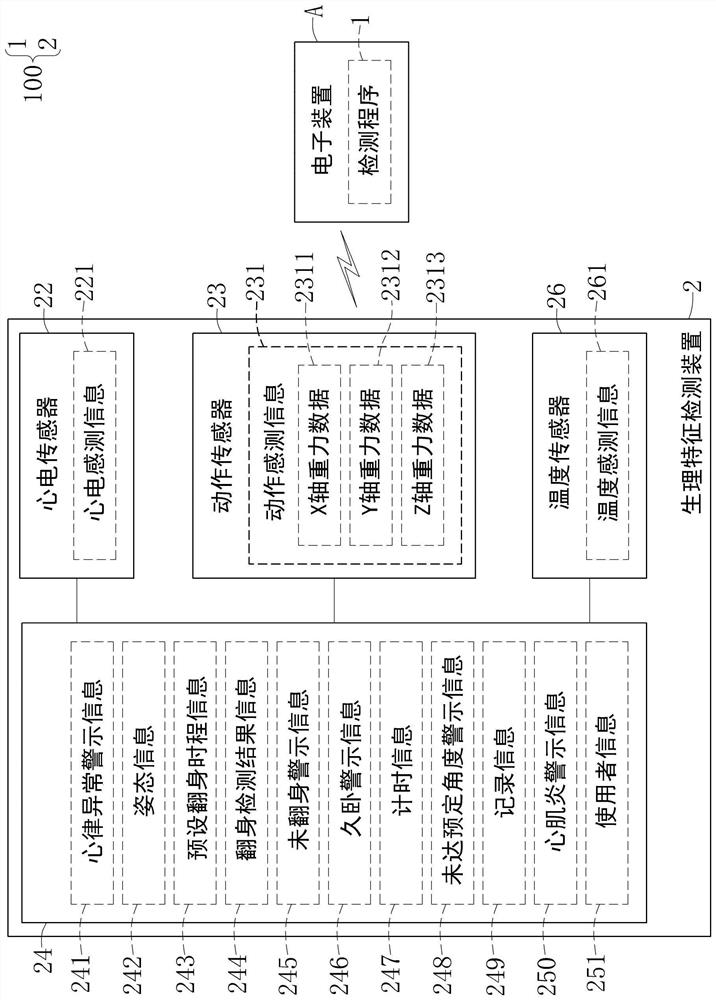

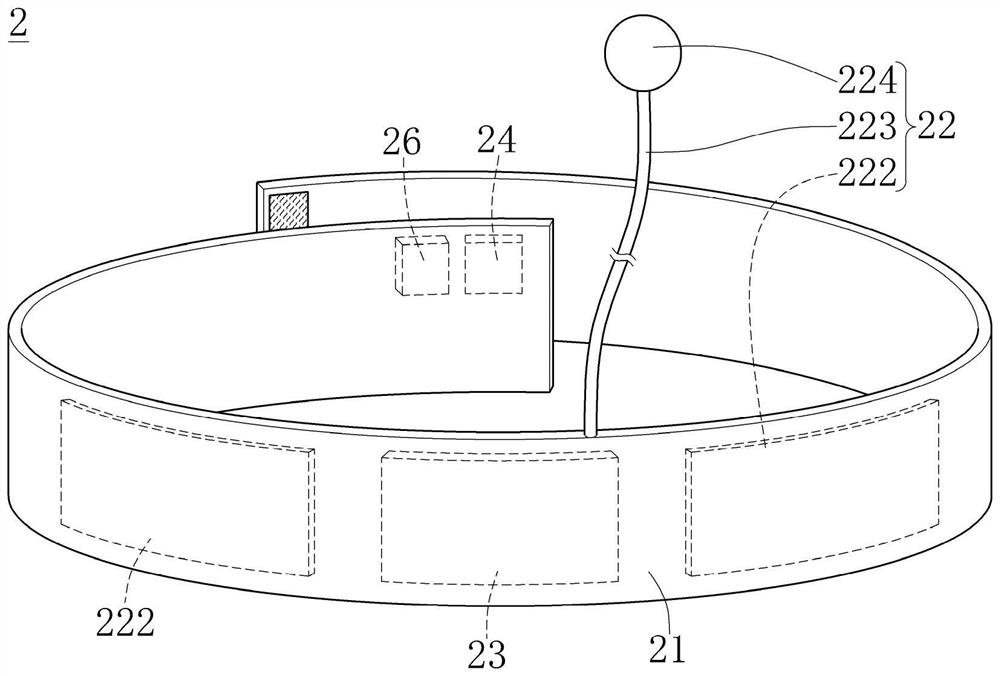

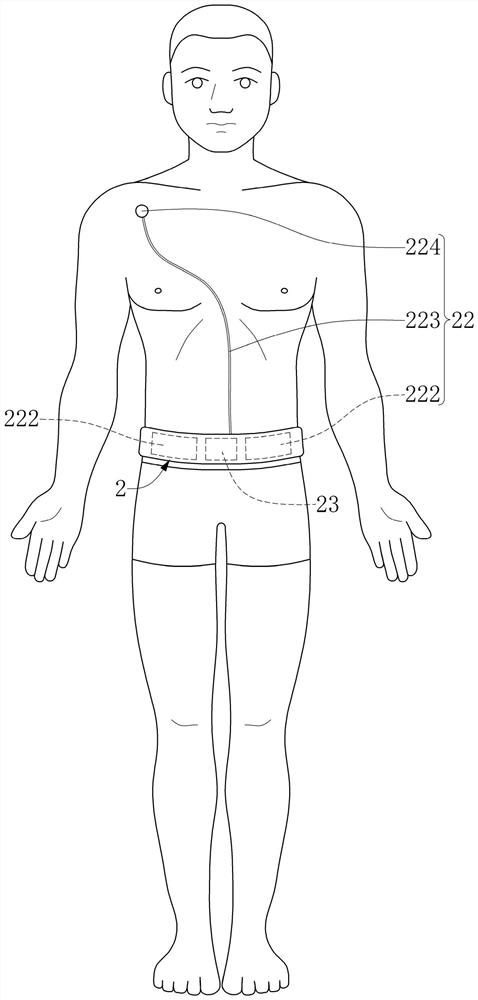

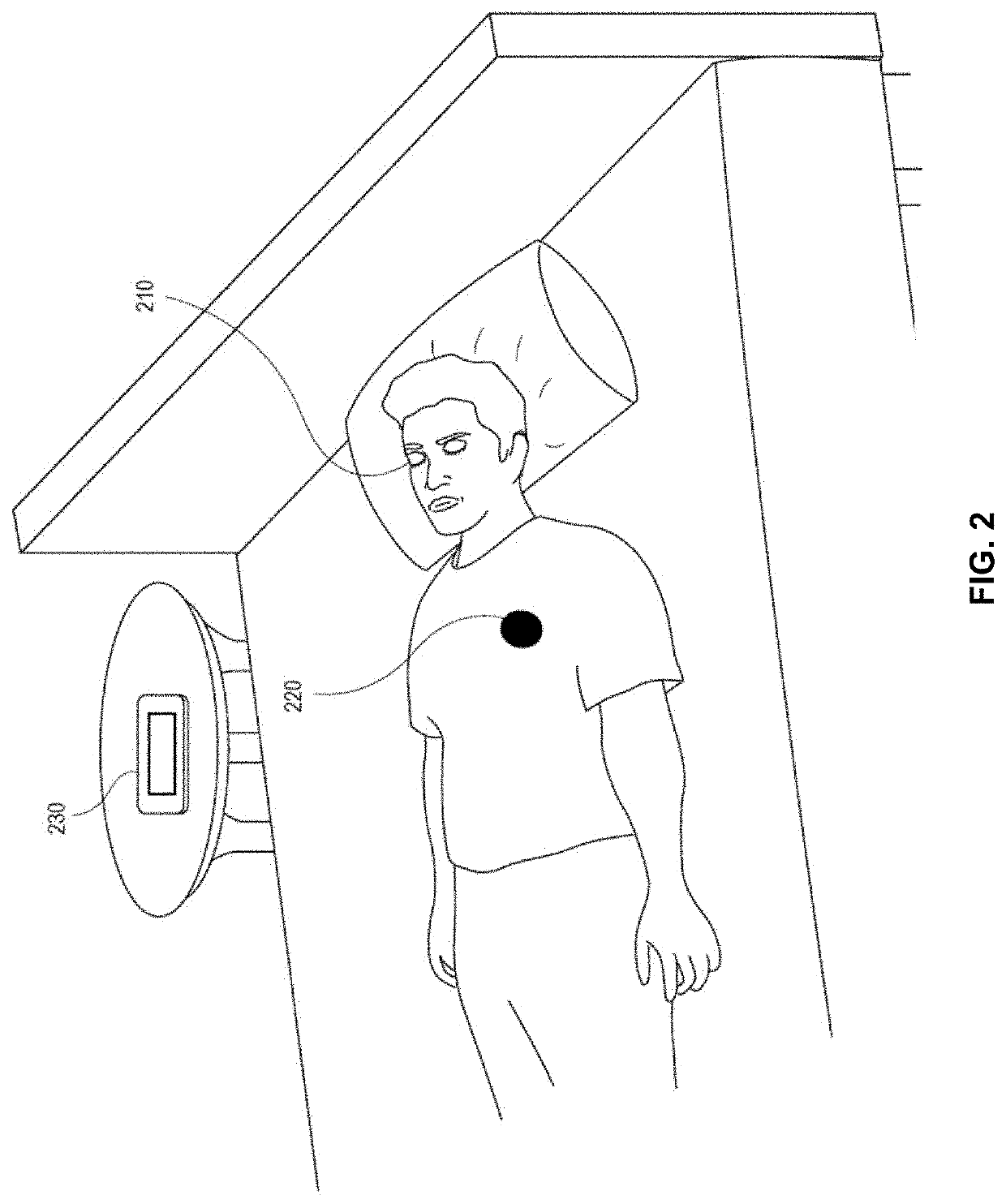

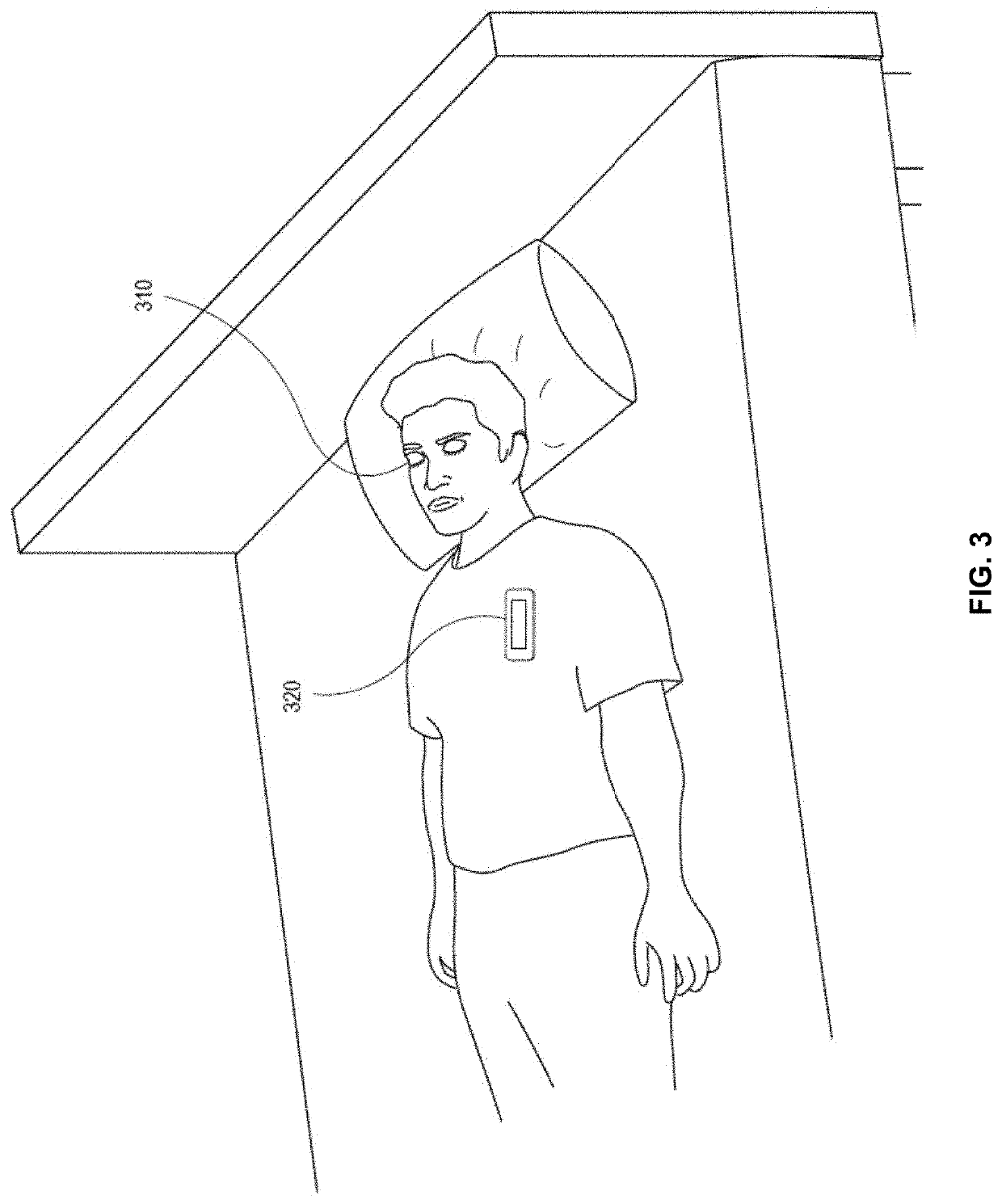

Physiological feature detection device, physiological feature detection system and nursing system

PendingCN114305443ANursing bedsDiagnostic recording/measuringElectric sensePhysical medicine and rehabilitation

The invention discloses a physiological feature detection device, a physiological feature detection system and a nursing system. The physiological feature detection device comprises a belt body, an electrocardio sensor, a motion sensor and a processing module. The belt body is used for being arranged on the body of a user. The electrocardio sensor is used for sensing the electrophysiological state of the heart of a user and generating electrocardio sensing information. The motion sensor is used for sensing the posture of a user and generating motion sensing information. The processing module can judge whether the posture of the user is changed or not according to the multiple pieces of action sensing information received in sequence, and when the processing module judges that the posture of the user is changed, the processing module judges whether the user has arrhythmia or not according to the electrocardio sensing information. And when the processing module judges that the user has the arrhythmia condition, heart rhythm abnormity warning information is sent out.

Owner:INVENTECSHANGHAI TECH +2

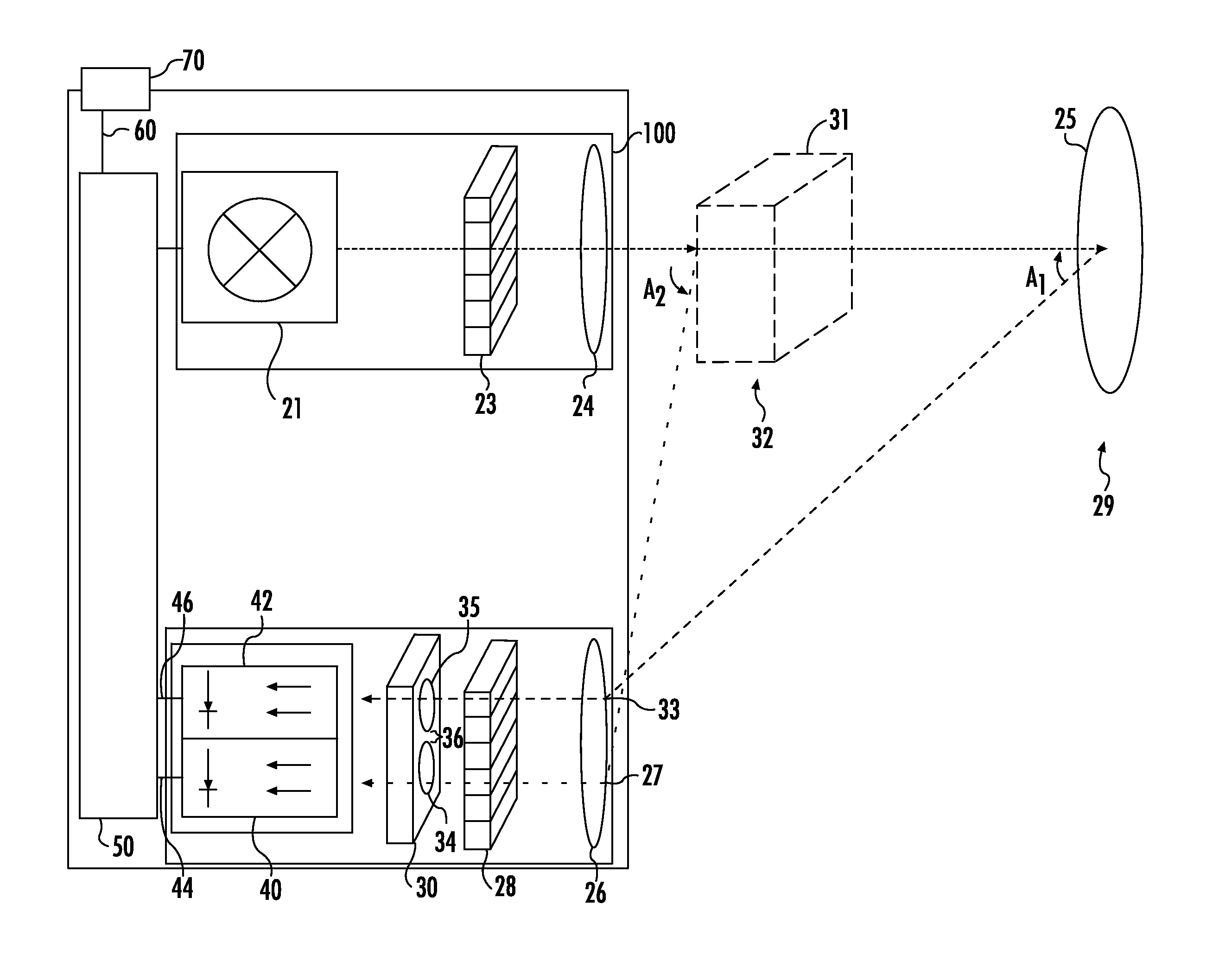

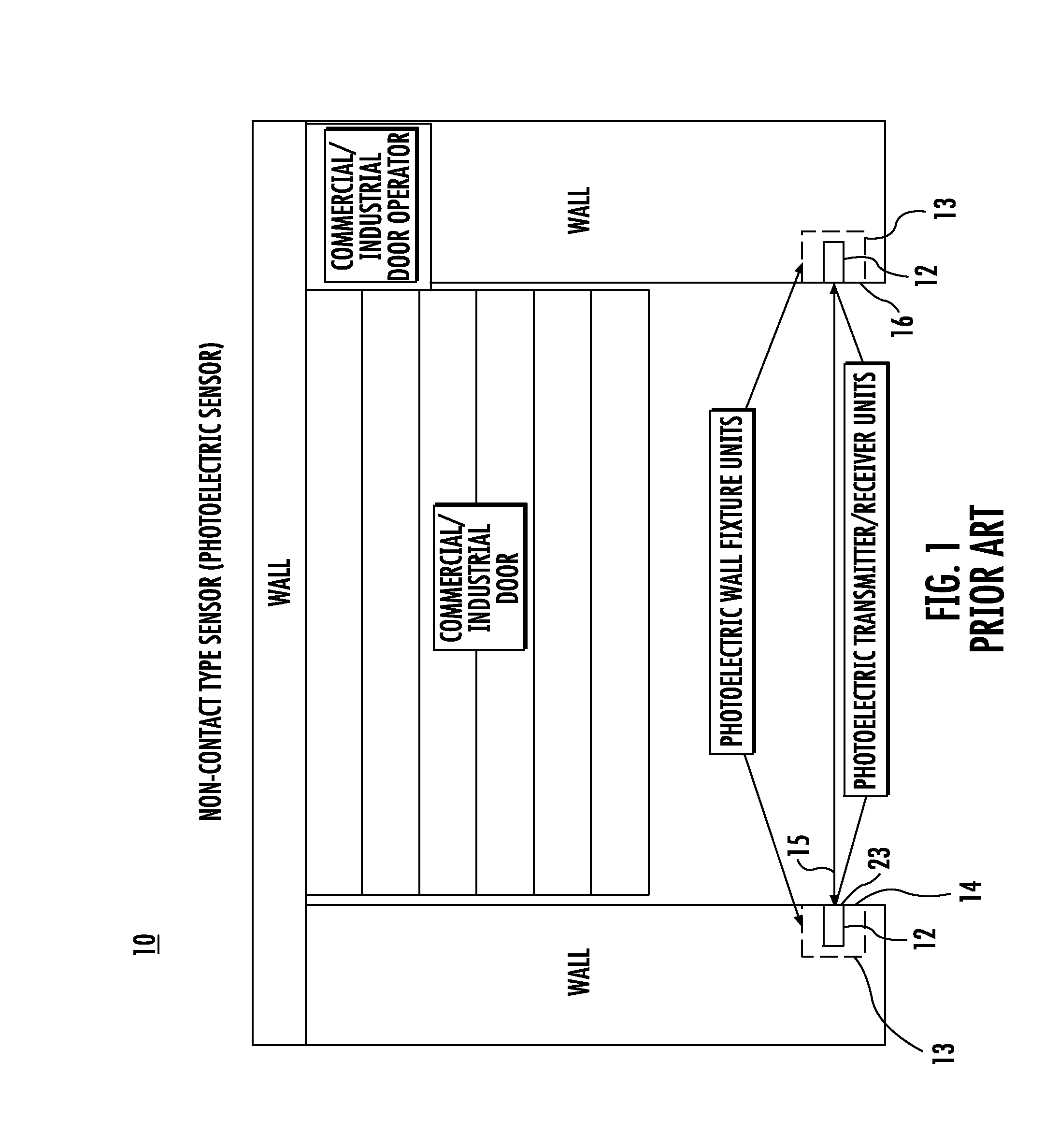

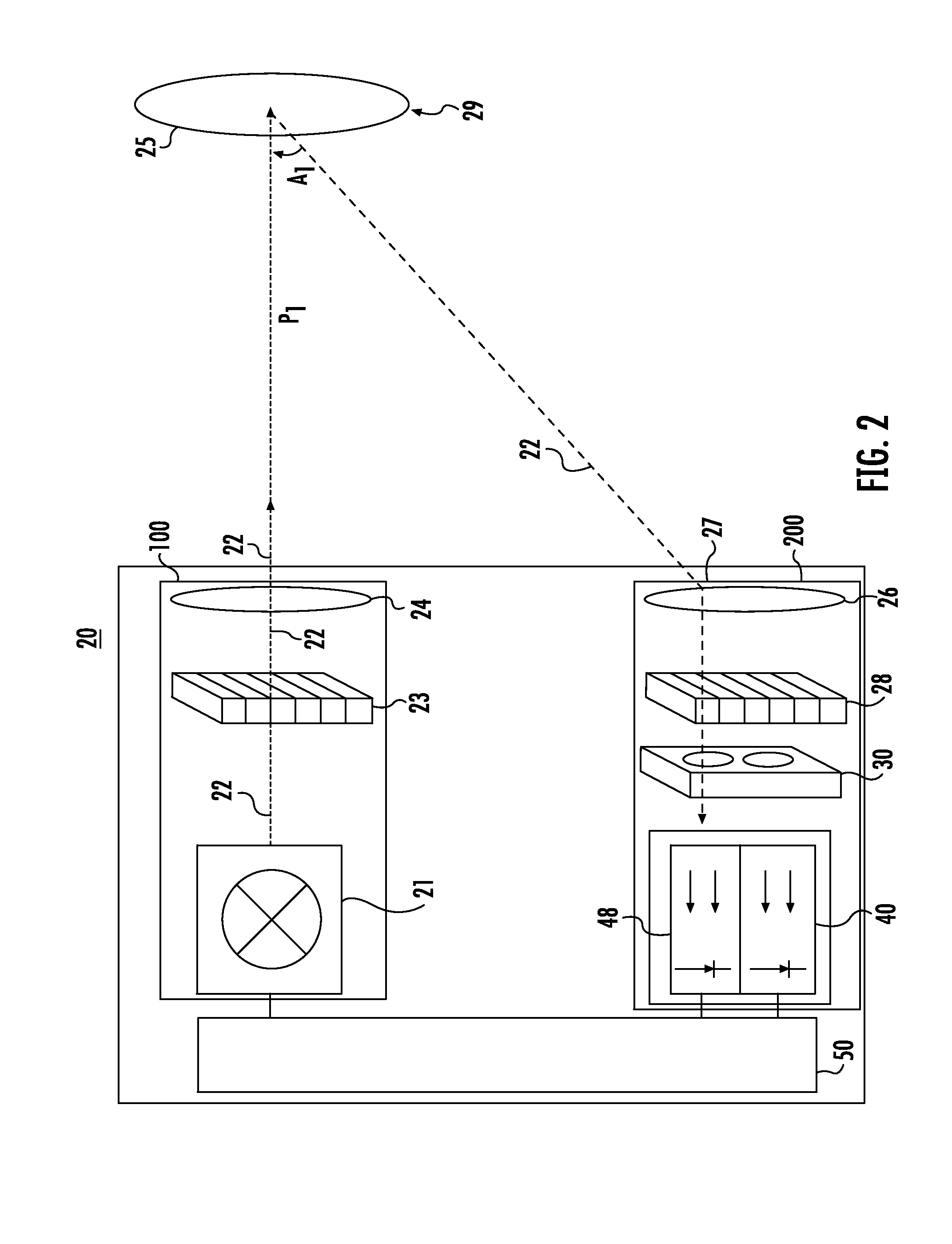

Method and system for sensing light reflective surfaces in a reflective photo-electric sensing system

InactiveUS20140217266A1Improve reliabilityOptical detectionMaterial analysis by optical meansElectric senseTransmitter

A reflective photo-electric sensing system includes a transmitter for the transmission of light and a reflector for reflecting the light. The reflector being positioned in a far field. A light channeling device receives reflected light from the far field or from a near field and channels the received reflected light to a near field receiver or a far field receiver dependent on an angle of the received reflected light. An electrical signal is generated at the near field receiver or the far field receiver. A controller evaluates the electrical signal of the near field receiver and the electrical signal of the far field receiver and generates an actuation signal dependent on the evaluation.

Owner:FRABA

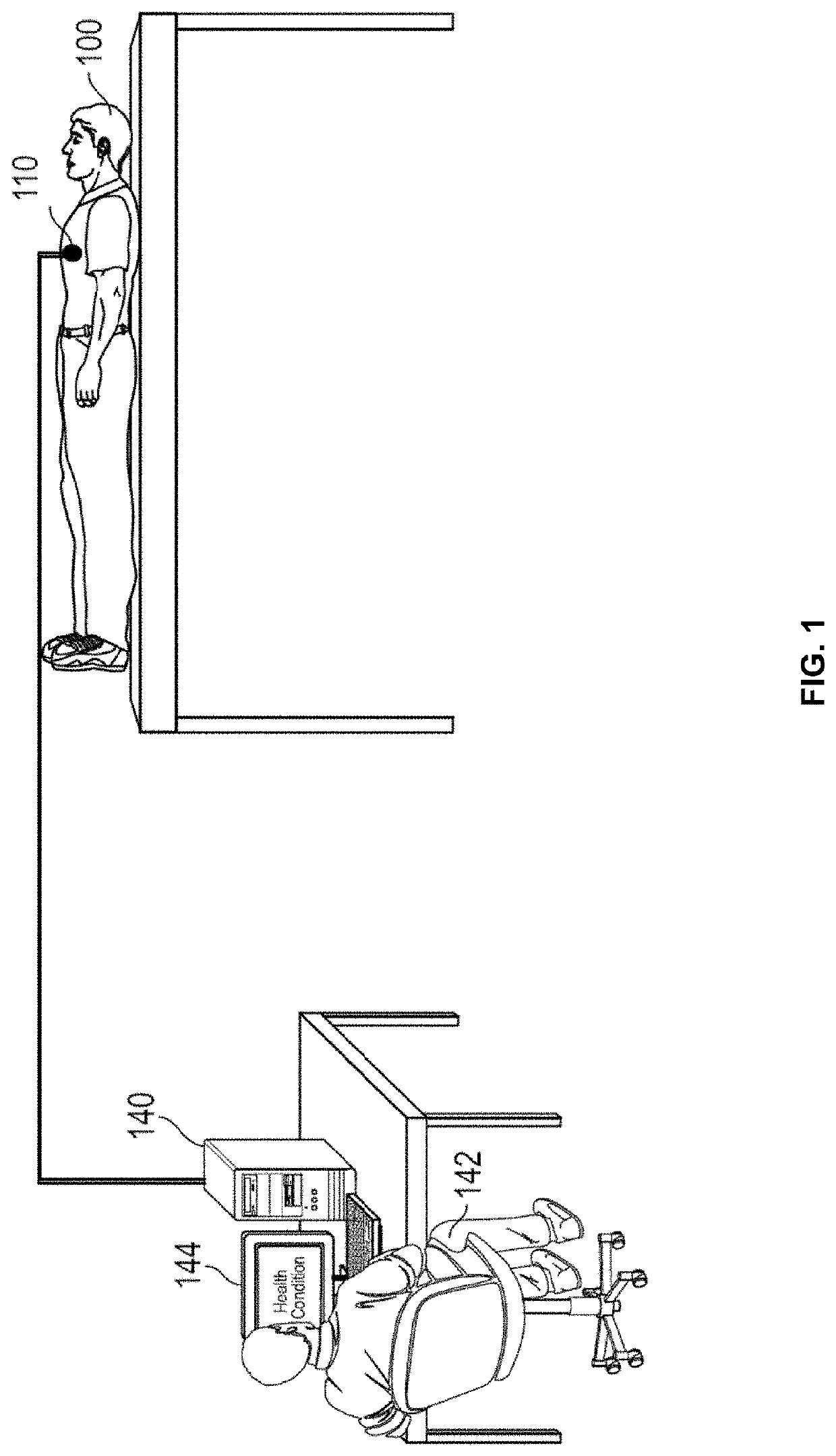

Wearable Inductive Damping Sensor

ActiveUS20200082926A1Physical therapies and activitiesInductance measurementsElectrical resistance and conductanceElectric sense

Techniques are described for a non-invasive detection of a health condition of an organ. In an example, the electrical conductivity of the organ reflects the organ's health of. An inductive damping sensor can be used to detect the organ's electrical conductivity and, thus, its health. The inductive damping sensor can be placed in proximity of the organ such as the organ is within the magnetic field generated based on a coil of the inductive damping sensor. The conductivity of the organ impacts the inductance and the resistance of the coil. Hence, the inductance and / or resistance of the coil can be measured, where the measurements can be associated with the health of the organ.

Owner:CALIFORNIA INST OF TECH

Heated and/or cooled home and office furnishings

A heated and cooled seating unit is disclosed with an apparatus to determine if the chair is in use, such as a pressure sensor, or an electric sensing apparatus. This apparatus controls the heating apparatus and powers the heat off, to conserve power, in the event that a person or object is not seated in the chair.

Owner:RADIAN

Remote heat-release electric sensing monitor

The invention discloses a remote heat-release electric sensing monitor which comprises an LED lamp, two Fresnel lenses and a trigger. The two Fresnel lenses form a certain angle, even a person walks towards the monitor, an infrared signal can be also sensed, keys on the trigger can be moved, and an alarm can be eliminated by correctly pressing down a corresponding key within specified time. The problem that a traditional heat-release electric sensing monitor is insensitive to the person forwards close to the monitor is effectively solved.

Owner:NINGBO COMEN ELECTRONICS TECH

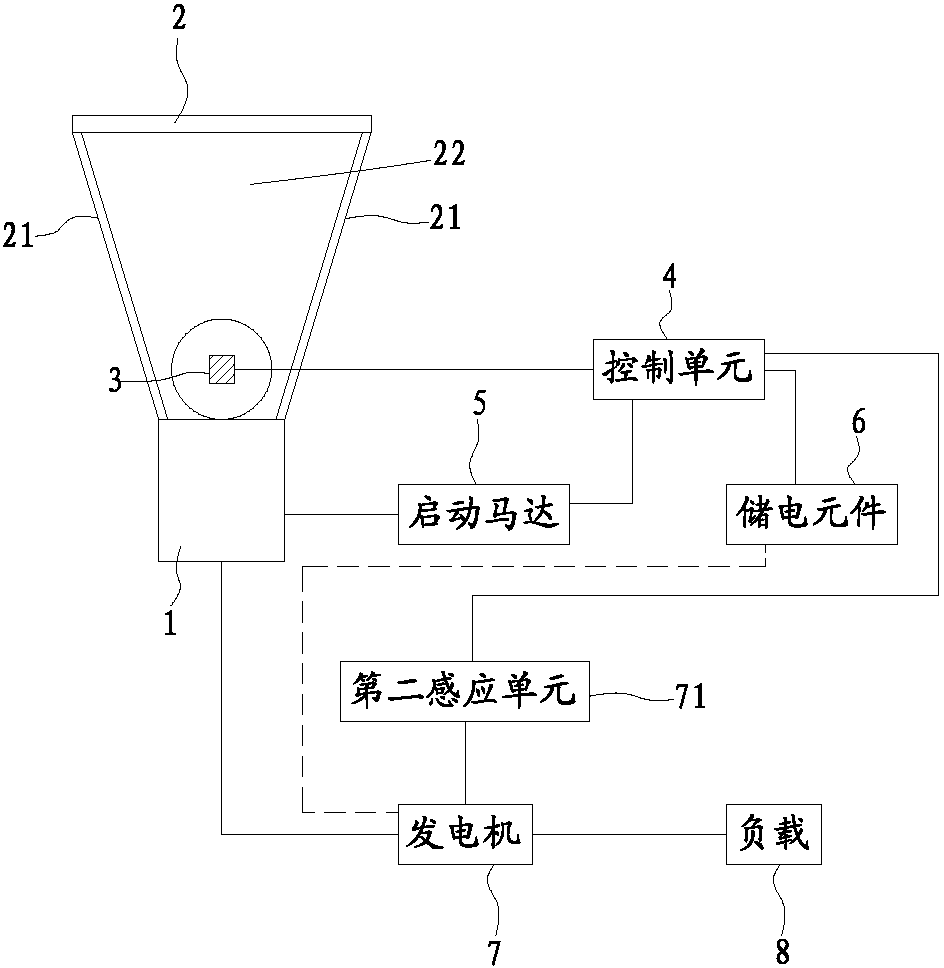

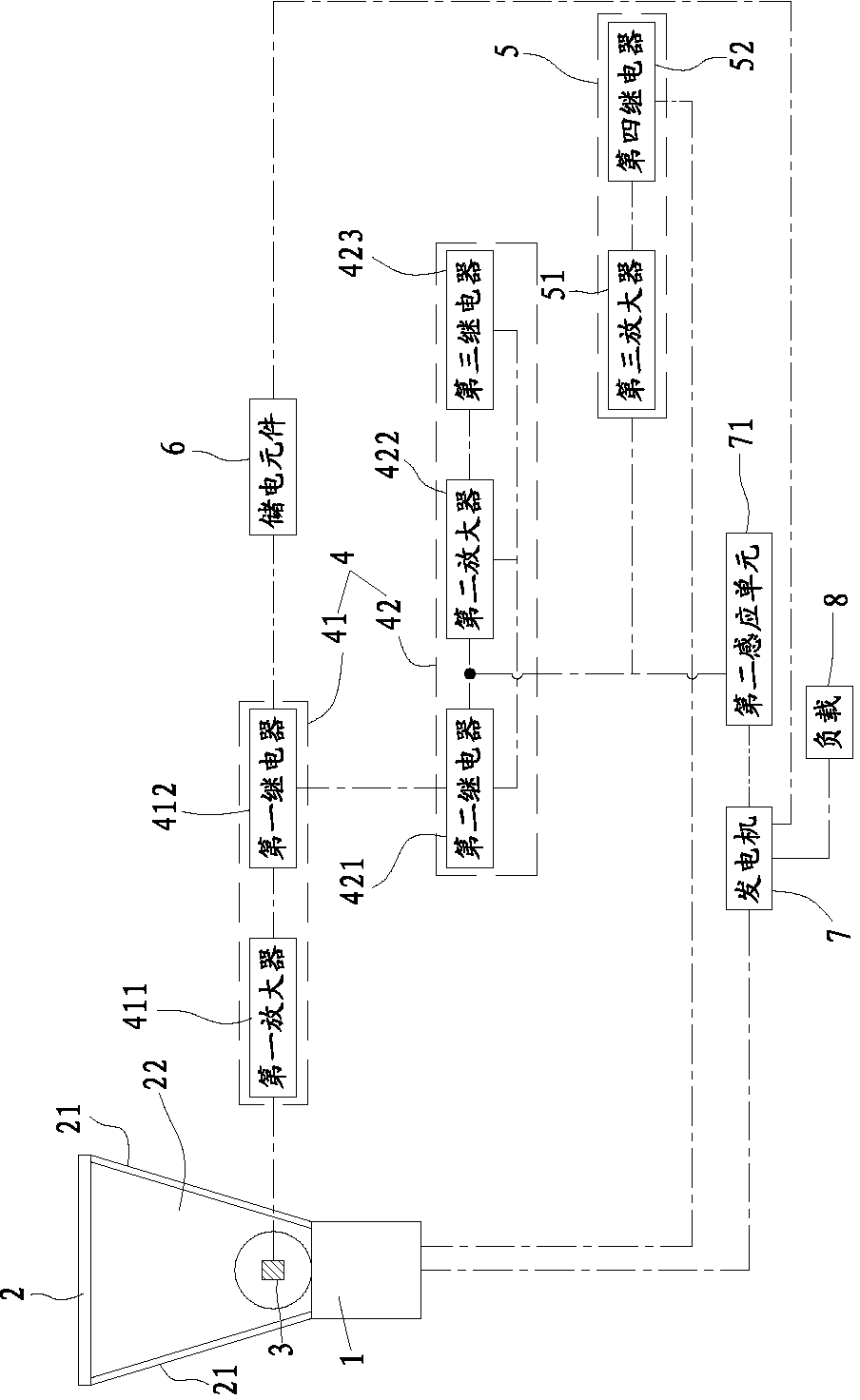

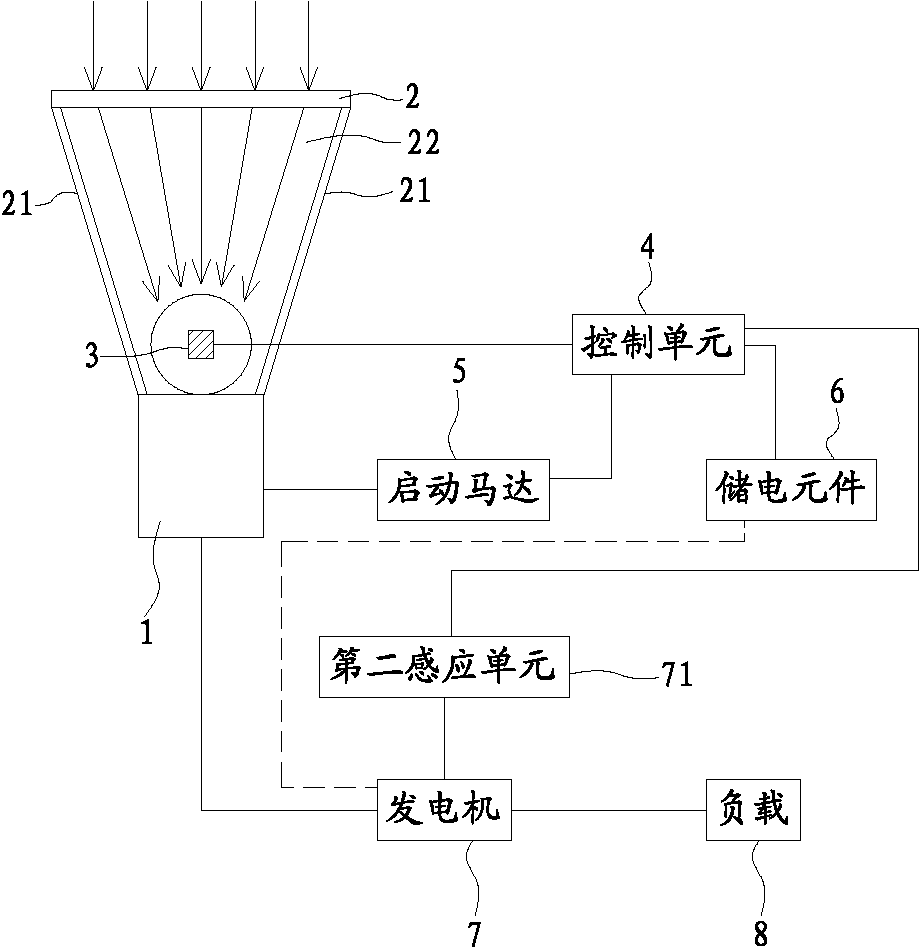

Intelligent Stirling engine start control device

ActiveCN103775242AAvoid undue downtimeGive full play to work efficiencyHot gas positive displacement engine plantsElectricityElectric sense

The invention discloses an intelligent Stirling engine start control device which comprises a concentration element, a Stirling engine, a temperature sensing unit, a control unit, a start motor, a power storage element, an electric generator and a second sensing unit. The concentration element is used for concentrating heat energy of sunlight on a concentration action zone. The Stirling engine is located in the concentration action zone. The temperature sensing unit is arranged in the concentration action zone and used for sensing the temperature of the concentration action zone and outputting a temperature sensing signal. The temperature sensing signal and an electric sensing signal are mainly received through the control unit, so that when the Stirling engine is under the state that the temperature sensing signal reaches a preset value but the electric sensing signal does not exist, a start signal is sent by the control unit, the Stirling engine is started by the start motor, and the control device automatically starting the Stirling engine can be obtained.

Owner:郑金祥

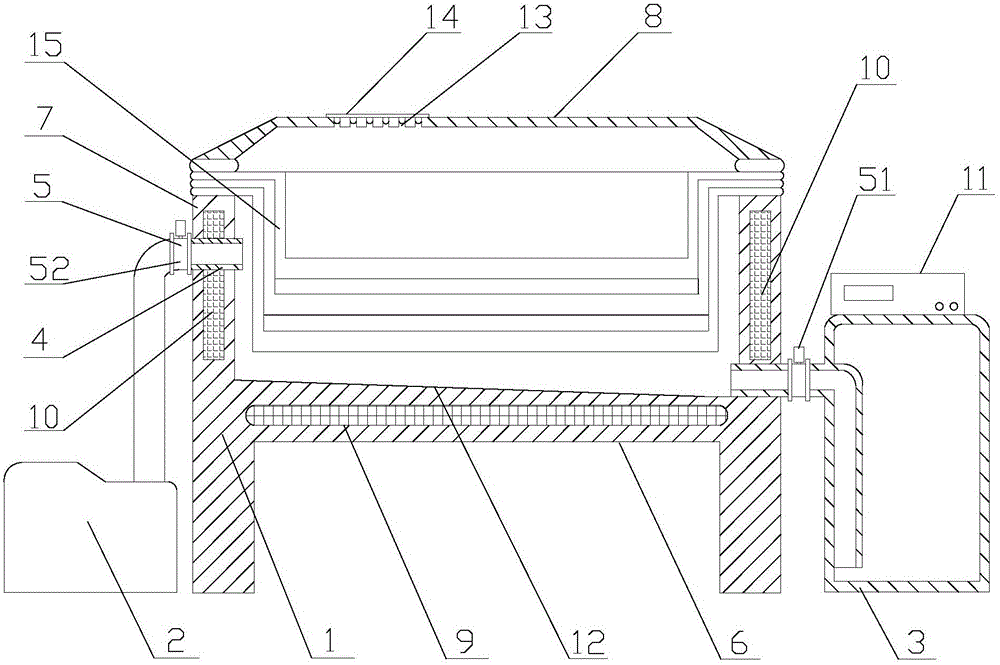

Integrated machine for lacquer-immersing and bakeout

InactiveCN105057172AReduce labor intensityAvoid pollutionLiquid surface applicatorsInductances/transformers/magnets manufactureElectric senseLacquer

The invention discloses an integrated machine for lacquer-immersing and bakeout. The integrated machine for the lacquer-immersing and the bakeout comprises a main body machine, a vacuum pump and a lacquer-storing barrel. The lacquer-storing barrel and the vacuum pump are connected with the main body machine through connecting pipes. The main body machine is composed of a base, side walls and a head cover. An exothermic disk is arranged in the base of the main body machine. The side walls are filled with thermal insulation materials. Electromagnetic valves are arranged on the connecting pipes. The main body machine and the vacuum pump are connected with a controller through wires. The controller is further connected with the electromagnetic valves. The integrated machine for the lacquer-immersing and the bakeout is convenient to use, free of pollution and capable of effectively improving the electrical inductance production efficiency.

Owner:ANHUI YILUMING PHOTOELECTRIC TECH CO LTD

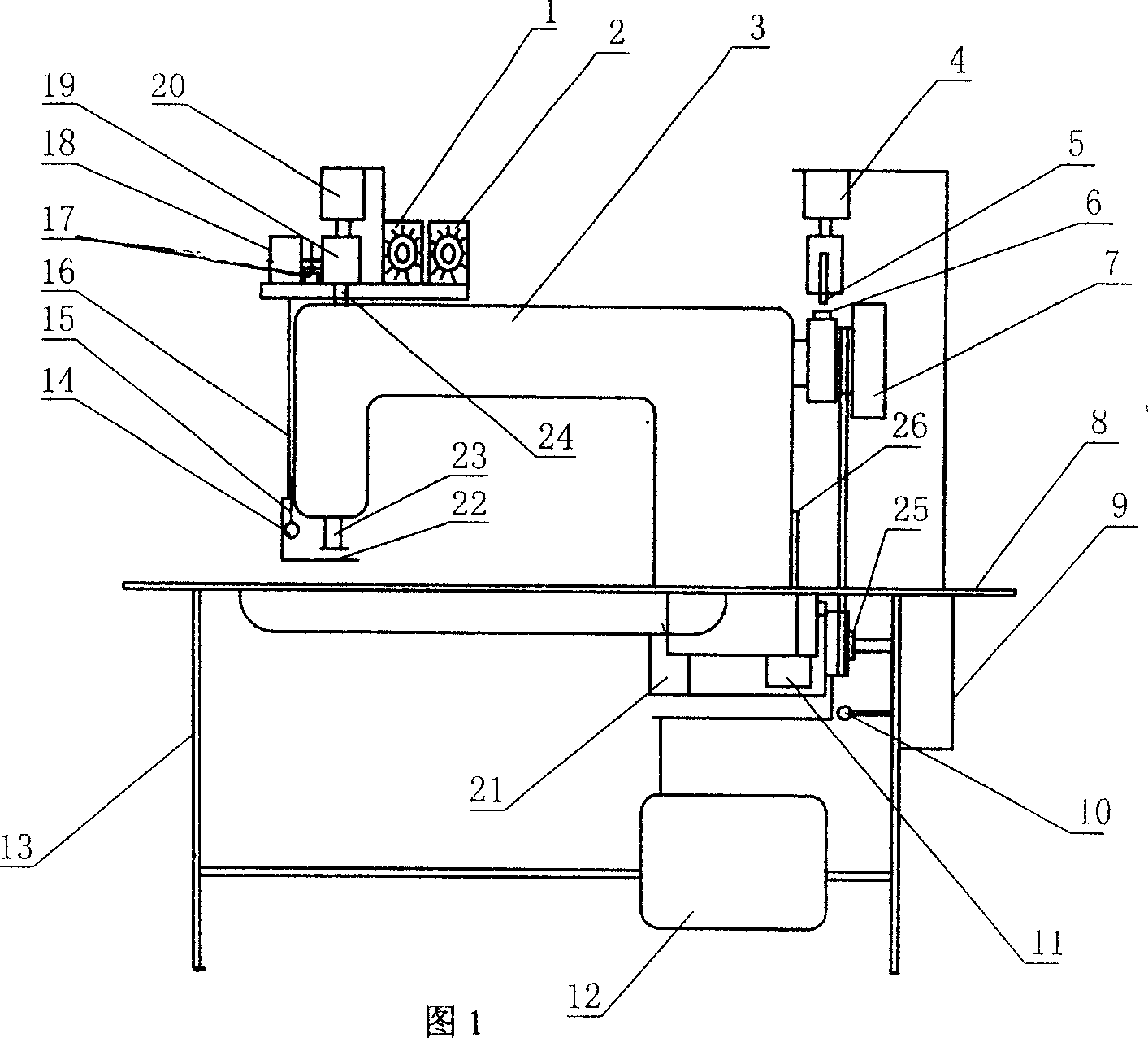

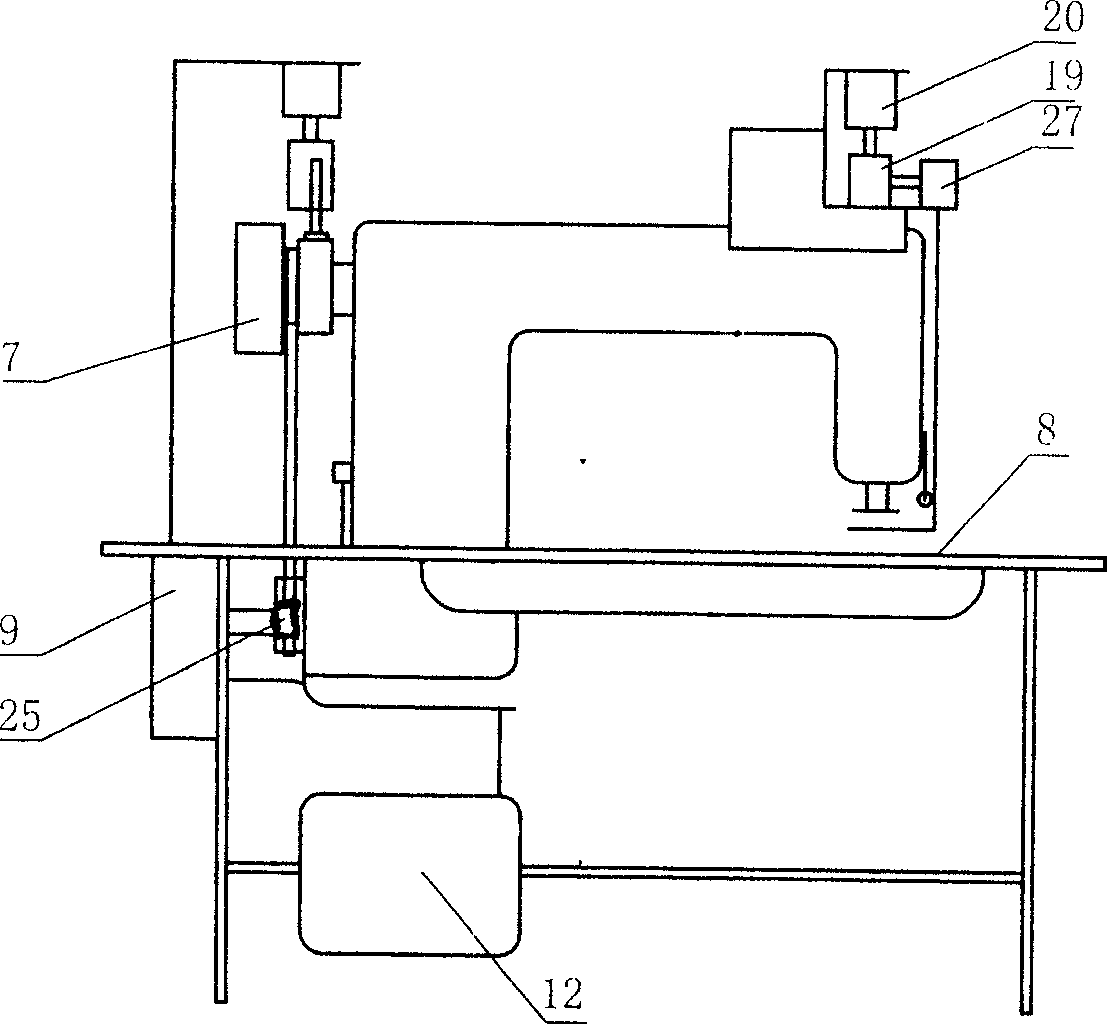

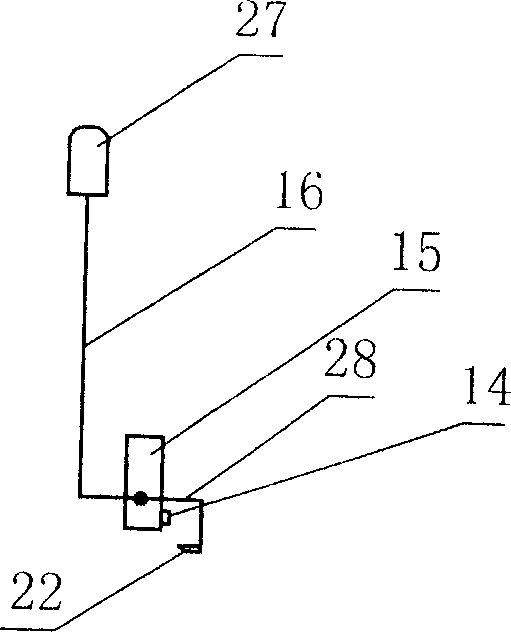

Five automatic industrial sewing machine

InactiveCN1861879AHigh degree of automatic actionEasy to operateProgramme-controlled sewing machinesElectric senseControl circuit

This invention discloses an automatic five industry sewing machine. It includes sewing machine head, platform, stand, electronic engine, clutch, pedal and controlled circuit. There is automatic wire broken electromagnetic valve assembly, high cut-off electromagnetic valve, feet up and down compound energy conservation electromagnetic valve and limit swift. There is index returning electromagnetic valve under the platform, and there is braking electromagnetic valve on the stand, the photo-electric sensing swift is on the high cut-off electromagnetic valve. The swift of photo-electric sensing directs toward the belt roller of the sewing machine head, there is starting index swift beside the upper side of the connecting link of pedal. This invention has the merits such as high automation, operating conveniently and good production efficiency.

Owner:林正扬

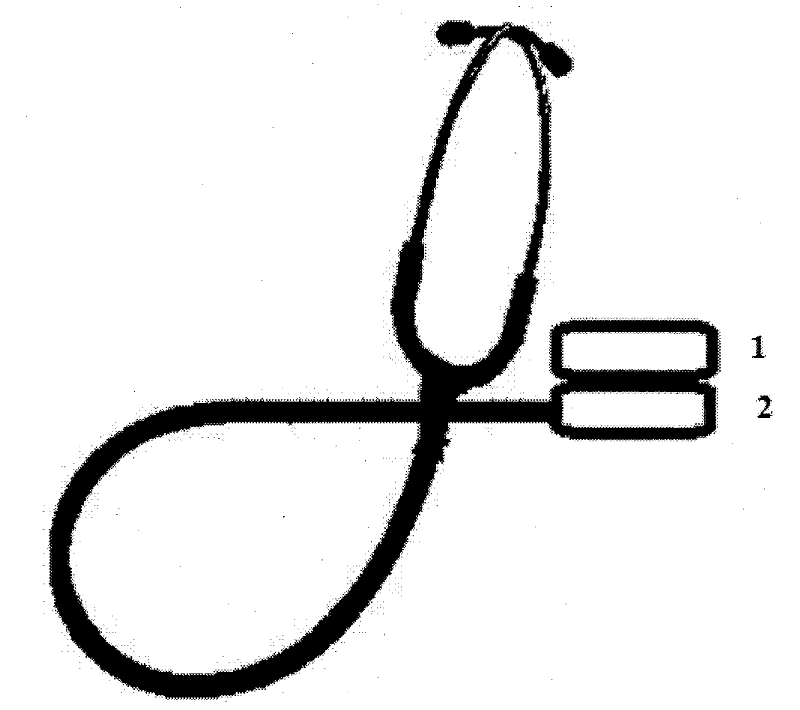

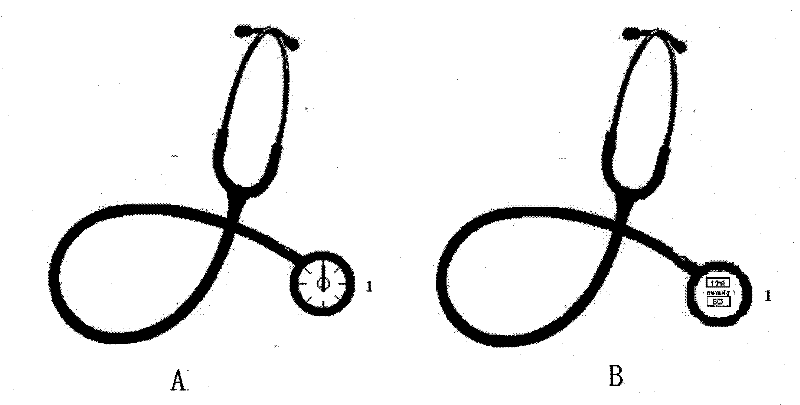

Blood-pressure measuring instrument and measuring method

The invention relates to a medical instrument for measuring the blood pressure and a blood-pressure measuring method. The blood-pressure measuring instrument consists of a pressure measuring part and an auscultation part, wherein the pressure measuring part adopts a pressure gauge, and an electric sensing element also can be adopted to convert the pressure value to a visible number. The pressure measuring part is vertically (or horizontally) overlapped with the auscultation part into a whole. A gold standard-Korotkoff-Sound auscultatory method for measuring the blood pressure is adopted by the instrument. When the blood-pressure measuring instrument is used for measuring the blood pressure, the blood-pressure measuring instrument is arranged on brachial artery of the human body to be leveled to the heart, pressure is applied by direct pressing (rather than by inflation of a sleeve band), so the instrument squeezes the brachial artery to completely stop the blood stream, then the pressure is slowly decreased until the auscultation part can hear the pulse sound, and the current measuring value of the pressure measuring part is the highest value (systolic pressure) of the blood pressure; and the pressure is continued to decrease slowly until the pulse sound completely disappeares, and the current measuring value of the measuring part is the lowest value (diastolic pressure) of the blood pressure. The instrument and the measuring method are free from the mercury pollution and are free from the assistance of the sleeve band, so the measuring instrument is convenient to carry, is simple and quick to operate and is accurate to measure the blood pressure.

Owner:牛锋

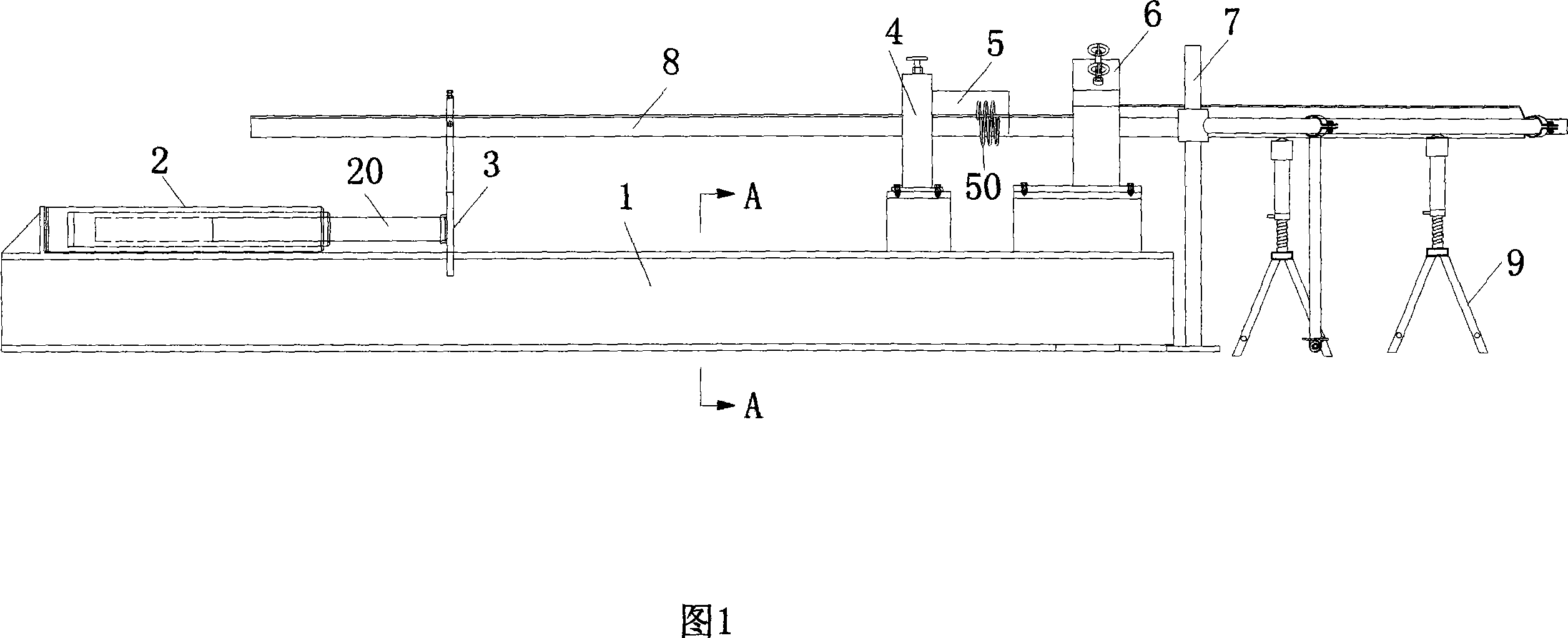

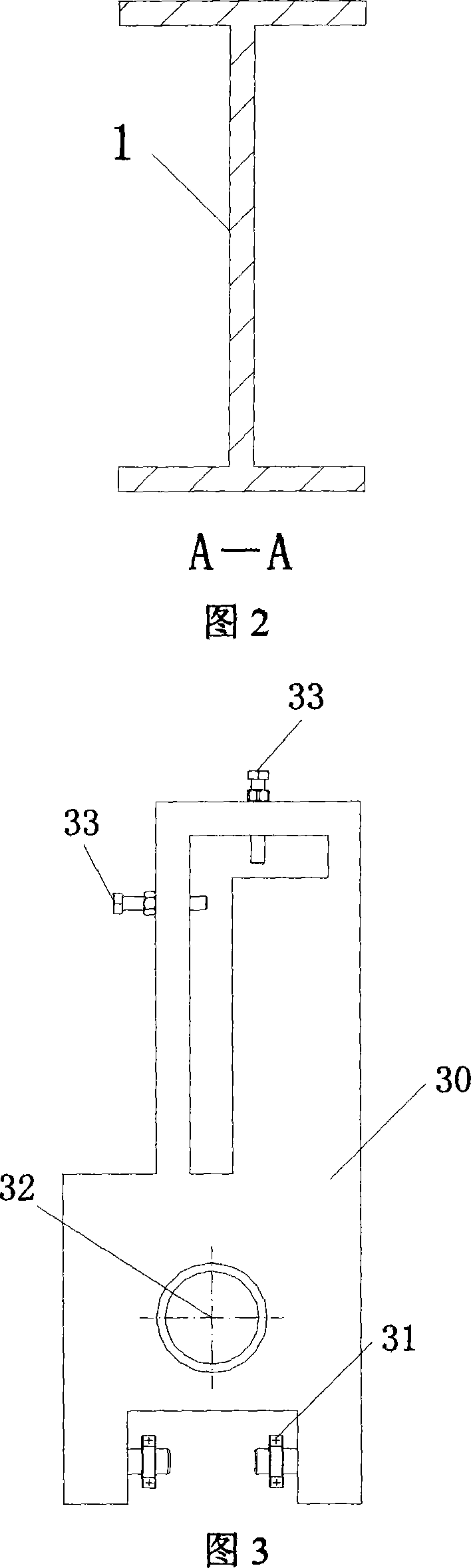

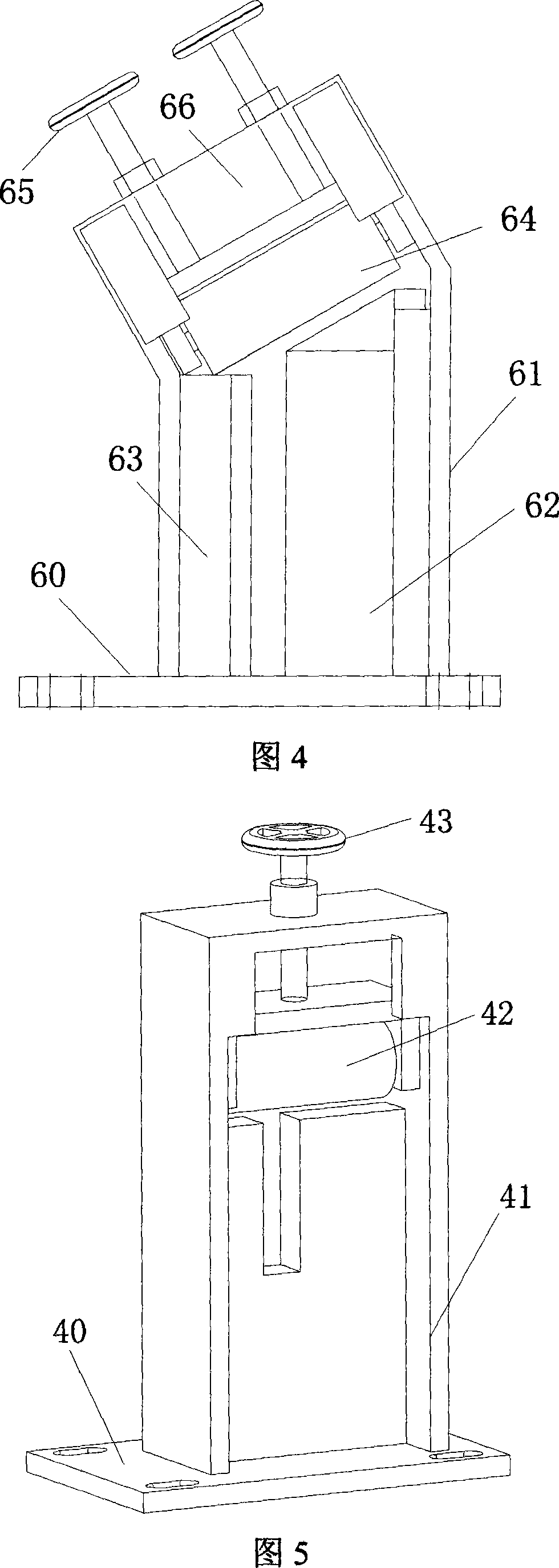

Method for forming edging angle steel connecting oil tank vault and wall plate and special-purpose equipment

The invention discloses a forming specialized device of an edge sealed angle steel which is jointed with an oil tank arc roof and a wall board. The forming specialized device comprises a pushing in unit, a high frequency electric sensing heater, an angle forming device, a curvature forming device and a working bench. The invention also discloses the forming method of the edge sealed angle steel which is jointed with the oil tank arc roof and the wall board. The angle forming device and the curvature forming device achieve to the sleeved processing forming operation from pressing to bend roasting with fine forming quality. The angle forming device and the curvature forming device are able to be flexibly combined and also to be extensively applied as well as meet various processing requirements and a processing goals. The method improves the working efficiency by many times and also has the advantages of simple operation, low noise and improved operation conditions.

Owner:TONGCHUANG KEXIN MATERIAL TECH CO LTD +1

Full-yarn automatic stop device of long spinning machine

InactiveCN103741299APrevent rolling off the groundRealize deliveryTextiles and paperYarnElectric sense

The invention discloses a full-yarn automatic stop device of a long spinning machine. A lower baffle plate is arranged above a yarn basket; a mounting hole is formed in the lower part of the lower baffle plate; a photo-electric sensing switch is fixed on the wall of the lower baffle plate and aside the mounting hole, and the front part of the photo-electric sensing switch penetrates the mounting hole; the back part of the photo-electric sensing switch is connected to a PLC (Programmable Logic Controller). When tube yarns are continuously accumulated in the yarn basket and reach to the height of the photo-electric sensing switch, the photo-electric sensing switch generates a signal, then the PLC is put through to send out the signal, a conveyor belt stops rotation, and an alarm signal light is turned on to remind workers that the yarn basket is full and remind the workers of replacing the yarn basket in time, so that the phenomenon that the tube yarns fall on the ground from the two sides of the yarn basket is eradicated completely and efficiently. The full-yarn automatic stop device of the long spinning machine can prevent the tube yarns from falling on the ground to form putty yarns when a yarn stacking worker does not itinerate in time, is not only convenient for the yarn stacking worker to operate, but also can realize normal conveying of the tube yarns, guarantees the quality of the yarns, is low in investment cost, convenient in processing, and wide in application range.

Owner:ANHUI HUAMAO TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com