Full-yarn automatic stop device of long spinning machine

A self-stop device and long-running technology, which is applied in textiles and papermaking, can solve problems such as bobbins rolling to the ground, and achieve the effects of guaranteed yarn quality, convenient operation, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

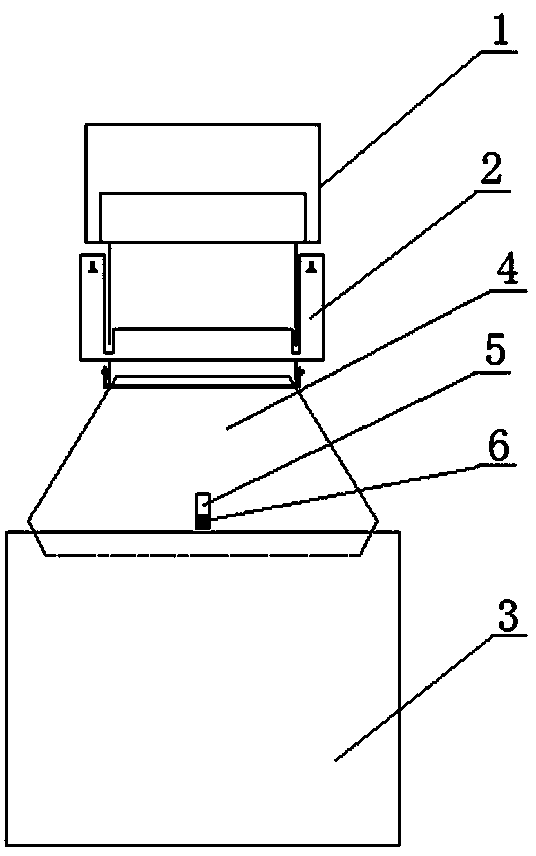

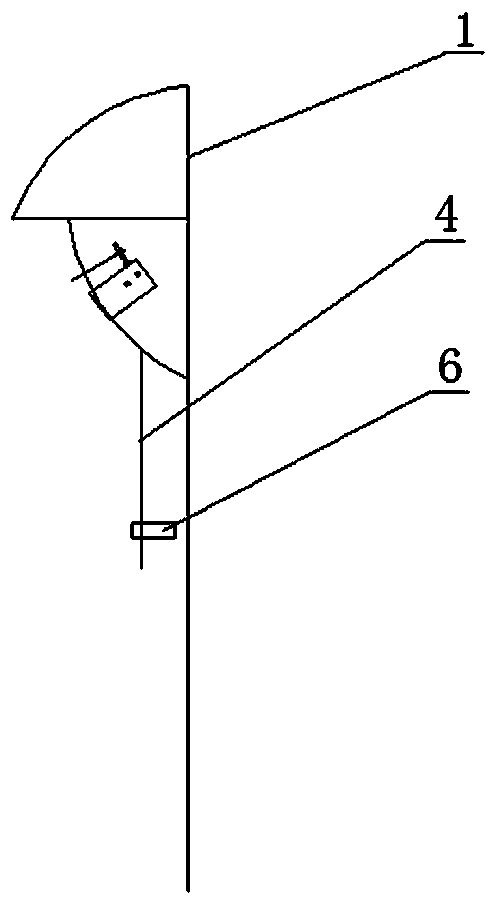

[0009] combine figure 1 , figure 2 It can be seen that the full-spun automatic stop device of a long spinning machine of the present invention is fixedly installed on the outer walls of the casing 1 at the exit of the conveyor belt with an angle downwardly inclined upper baffle 2 to slow down the fall of the bobbin from the conveyor belt. The speed of the yarn basket 3 can also be adjusted to fall into the angle. The top of the yarn basket 3 is provided with a lower baffle plate 4, and the lower baffle plate 4 is fixedly installed on the inner walls of the two side casings 1 below the conveyor belt outlet. The bottom of the lower baffle 4 is provided with a mounting hole 5, the photoelectric sensor switch 6 is fixed on the wall of the lower baffle 4 next to the mounting hole 5 and the front part of the photoelectric sensor switch 6 passes outside the mounting hole 5, and the photoelectric sensor switch 6 is located in the yarn basket 3 At a height of 45mm on the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com