Method for forming edging angle steel connecting oil tank vault and wall plate and special-purpose equipment

A technology of special equipment and edge angle steel, which is applied in the field of forming and special equipment for the edge angle steel connected between the vault of the oil tank and the wall plate, can solve the problems of irregular shape, poor quality, and long time consumption of the edge angle steel, and achieve Improved working conditions, low noise and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

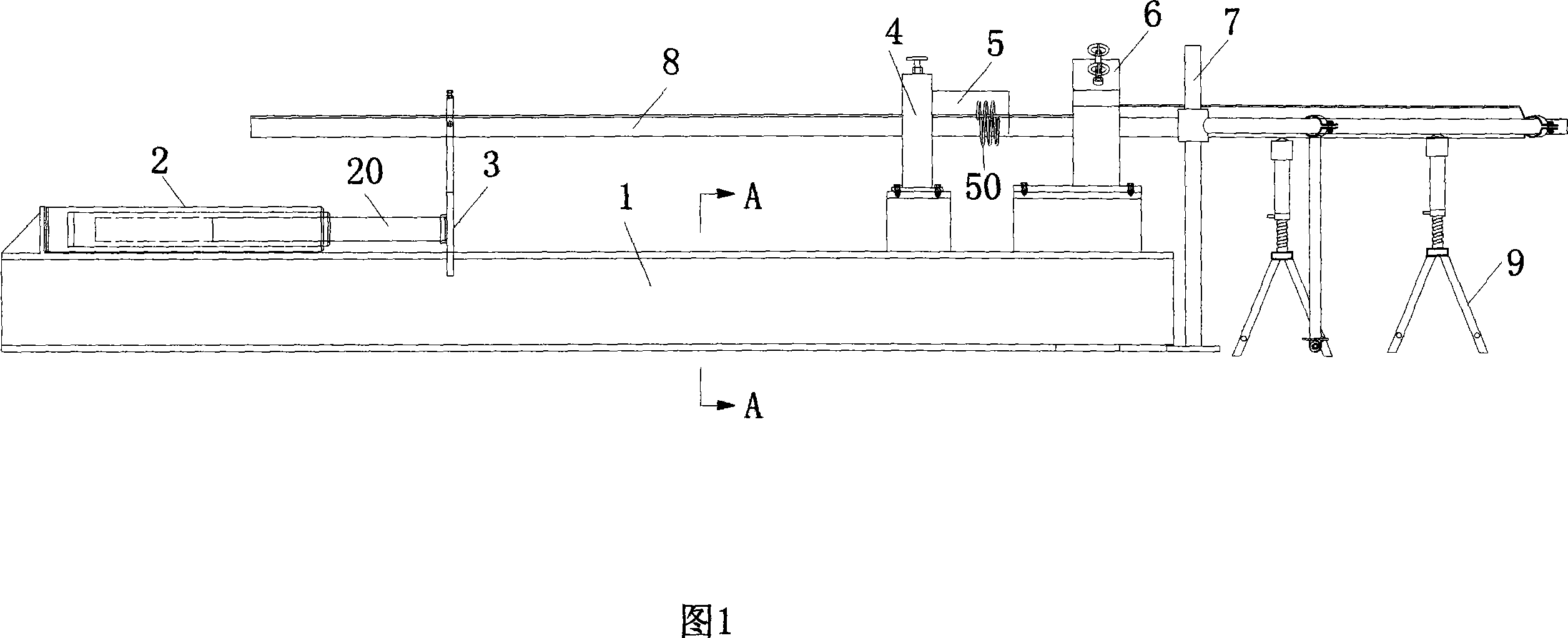

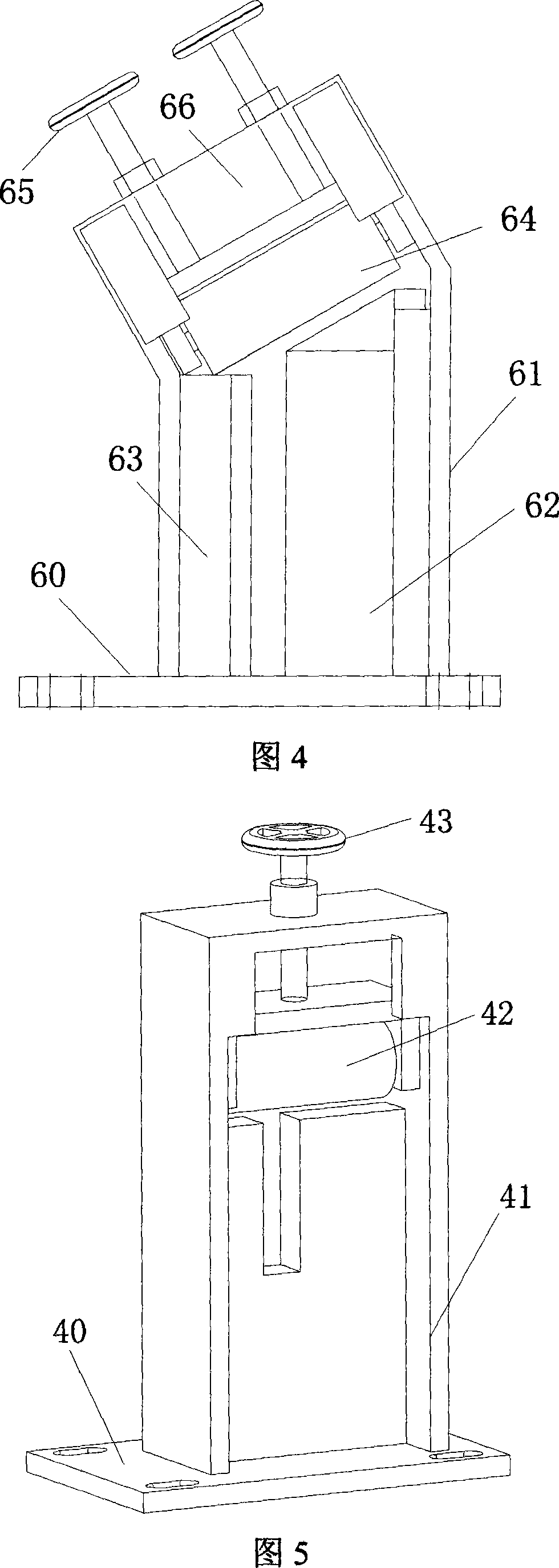

[0035] As shown in Figure 1, the special equipment for forming the edge-wrapped angle steel that connects the vault of the oil tank with the wall plate, on the workbench 1, the hydraulic cylinder 2 of the hydraulic station, the guide 3, the limiter 4, the height Frequency electric induction heating machine 5, angle former 6, also be provided with curvature former 7 on one side of workbench 1, the section view of workbench as shown in Figure 2.

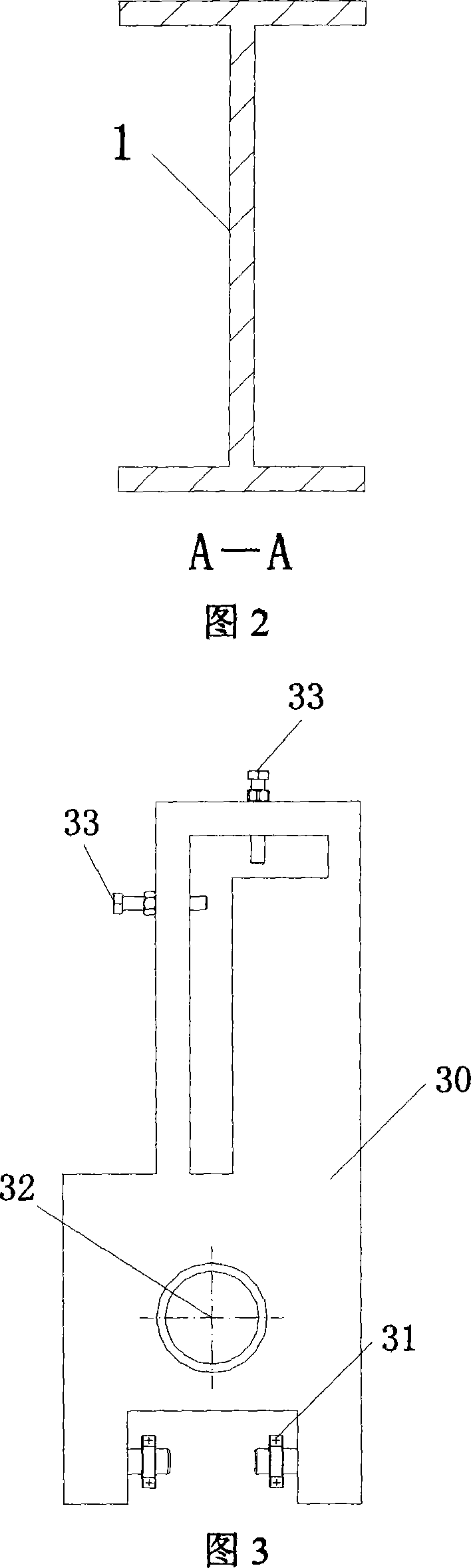

[0036] As shown in Figure 3, the piston rod 20 of the hydraulic cylinder 2 is fixedly connected with the cylindrical interface 32 on the bracket 30 of the guider 3, and the guider bracket 30 is equipped with a guide wheel 31, and the guide wheel 31 is limited to only work on the workbench. 1 for reciprocating movement; the wrapping angle steel 8 and the bracket 30 of the guide 3 are fixedly connected by two bolts 33.

[0037] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com